Intelligent steel pipe drilling device

A technology of drilling device and steel pipe, applied in the direction of boring/drilling, drilling/drilling equipment, maintenance and safety accessories, etc., can solve the problems of troublesome drilling, high labor intensity, waste of manpower, etc. , the collection effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

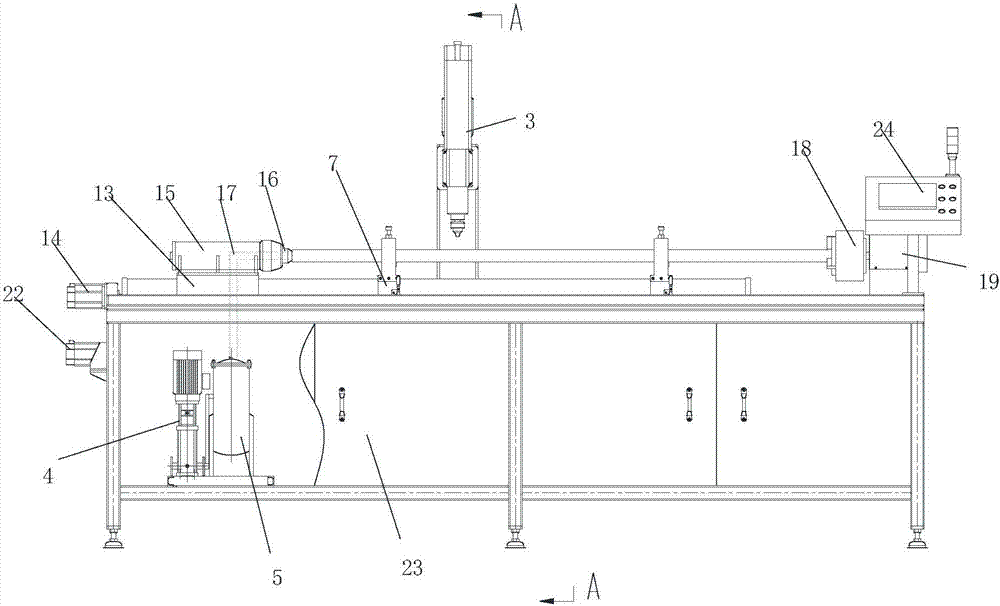

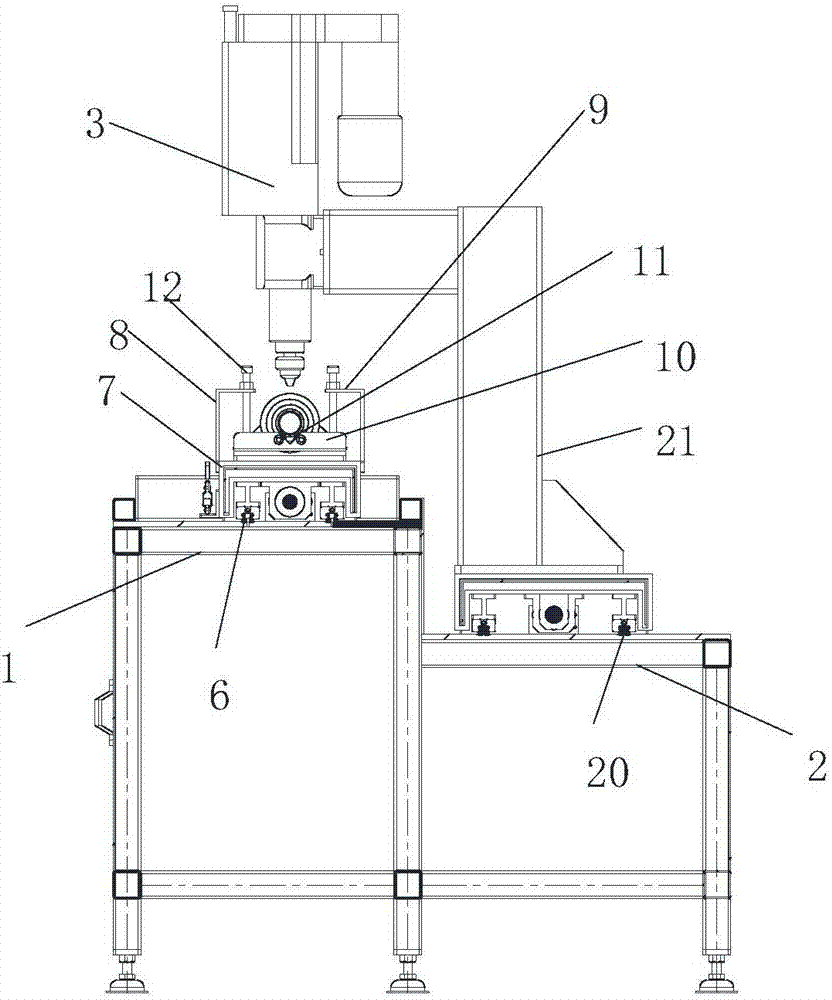

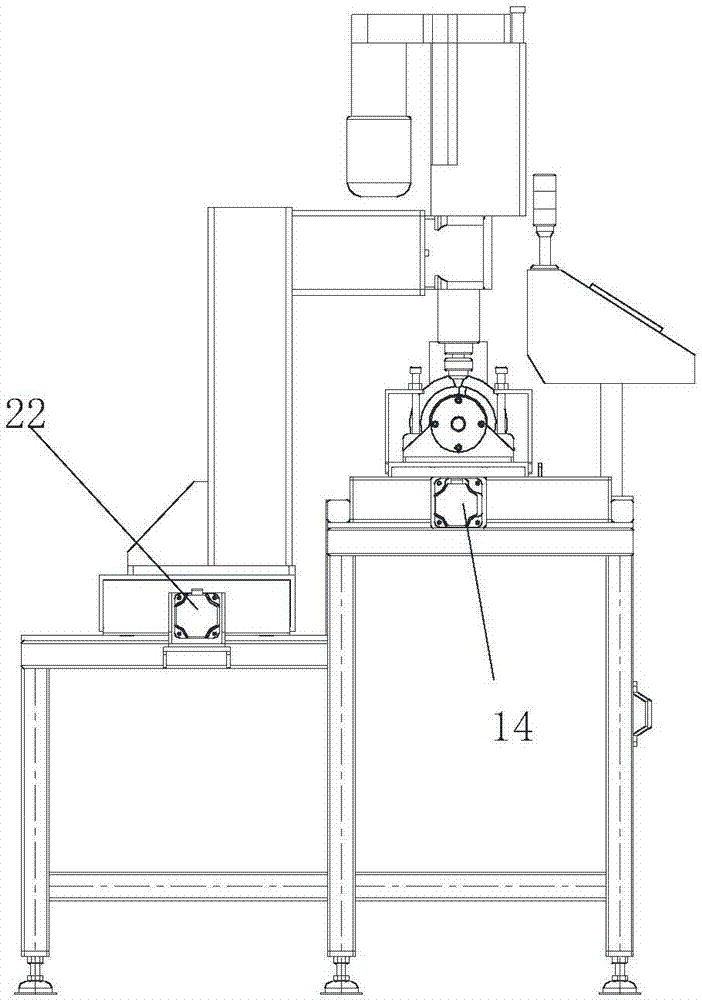

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred examples. Such as Figure 1 to Figure 3 As shown, an intelligent steel pipe drilling device includes a steel pipe fixed workbench 1, a drilling rig movable workbench 2, an automatic feed drilling machine 3, a negative pressure pump 4 and a negative pressure tank 5.

[0015] The first guide rail 6 is fixed on the steel pipe fixed workbench, and the steel pipe support mechanism is provided on the first guide rail. adjust.

[0016] The steel pipe support mechanism includes a sliding plate 7, a left clamping plate 8, a right clamping plate 9, a movable seat 10 and a supporting roller 11, the sliding plate is slidingly matched with the first guide rail, and the left clamping plate and the right clamping plate are respectively fixed on the The two sides of the sliding plate, the upper parts of the left splint and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com