Fly ash collecting device for hazardous waste incineration disposal

A technology for hazardous waste and collection devices, which is applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of different sizes of fine solid particles, pretreatment of fine solid particles, affecting the effect of fly ash collection, etc. The effect of better collection, easy subsequent use and processing, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

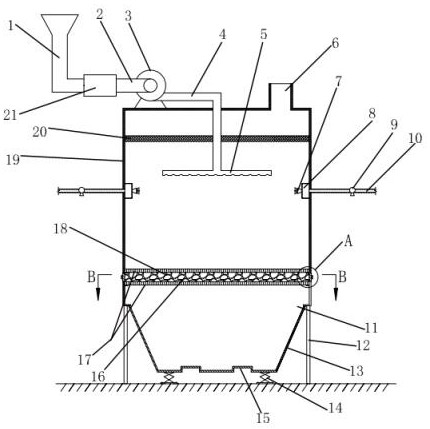

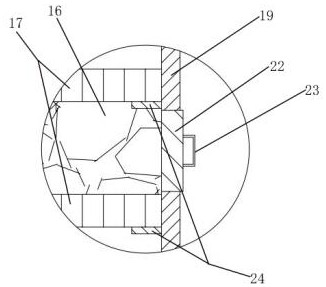

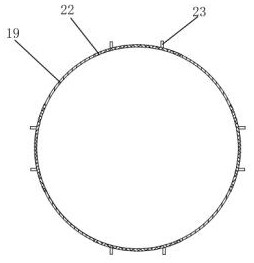

[0022] Such as Figure 1-Figure 3 As shown, the hazardous waste incineration disposal fly ash collection device includes a device housing 19 whose bottom end is fixed on the ground through support legs 12, and the upper surface of the device housing 19 is respectively provided with an air inlet and an exhaust port. The exhaust port is connected with an exhaust pipe 6 , and a fly ash outlet 11 is opened on the lower surface of the device housing 19 .

[0023] Wherein, a blower 3 is fixed above the device housing 19, and the inlet of the blower 3 is connected with a feeding pipe 2, and the inlet of the feeding pipe 2 is connected with the outlet of the turbine pulverizer 21, and the turbine pulverizer The feed inlet of machine 21 is connected with air inlet pipe 1, and the outlet of described blower 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com