Patents

Literature

67results about How to "Fast collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

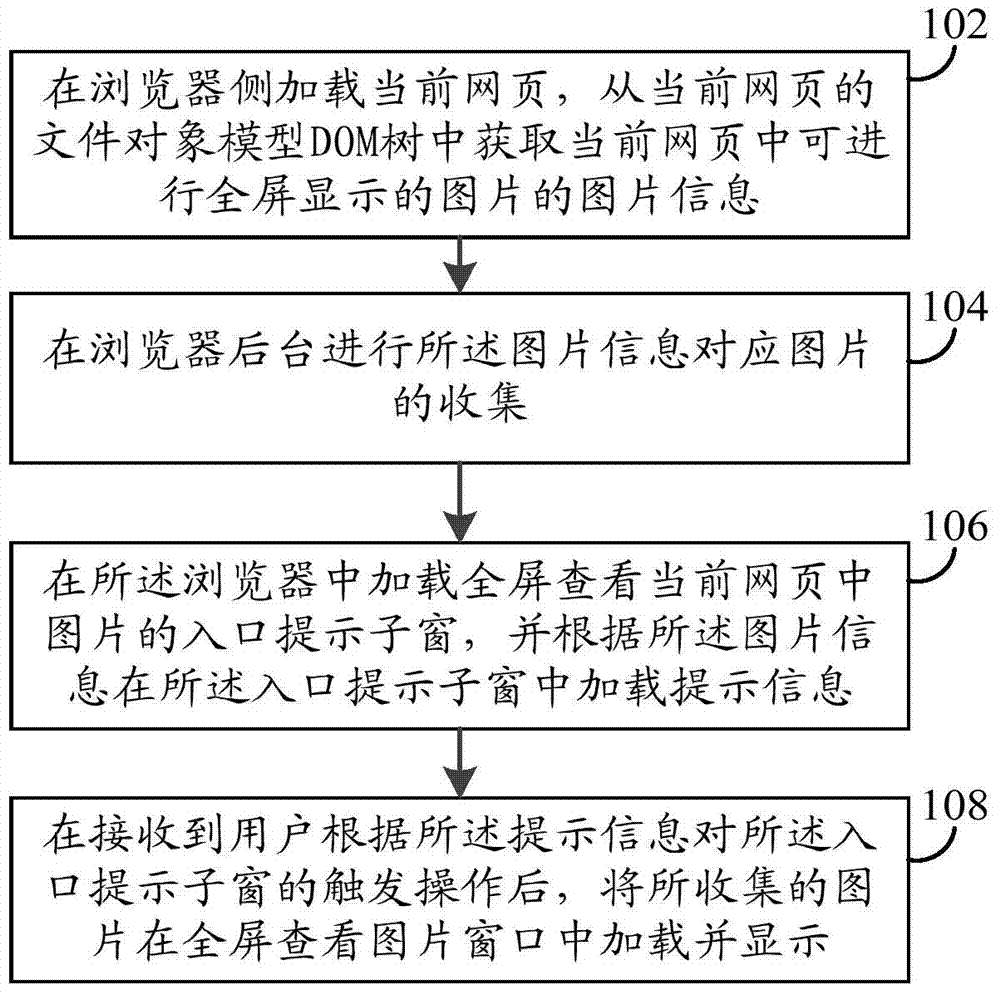

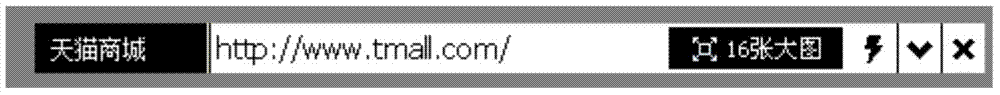

Method and device for displaying pictures in browser

InactiveCN103544272AImprove the display effectFast collectionSpecial data processing applicationsWeb data browsing optimisationComputer graphics (images)Document Object Model

The invention discloses a method and a device for displaying pictures in a browser. The method comprises the following steps of loading a current webpage on a browser side; acquiring information of pictures which can be displayed on a full screen in the current webpage from a document object model (DOM) tree of the current webpage; collecting pictures corresponding to the information of the pictures on a background of the browser; loading an entrance prompting child window for viewing the pictures in the current webpage in the browser; loading prompting information in the entrance prompting child window according to the information of the pictures; and loading and displaying the collected pictures in a full-screen picture viewing window after receiving triggering operation of a user on the entrance prompting child window according to the prompting information. By the method and the device for displaying the pictures in the browser, problems of poor picture displaying effect, low picture loading speed and low efficiency can be solved.

Owner:BEIJING QIHOO TECH CO LTD +1

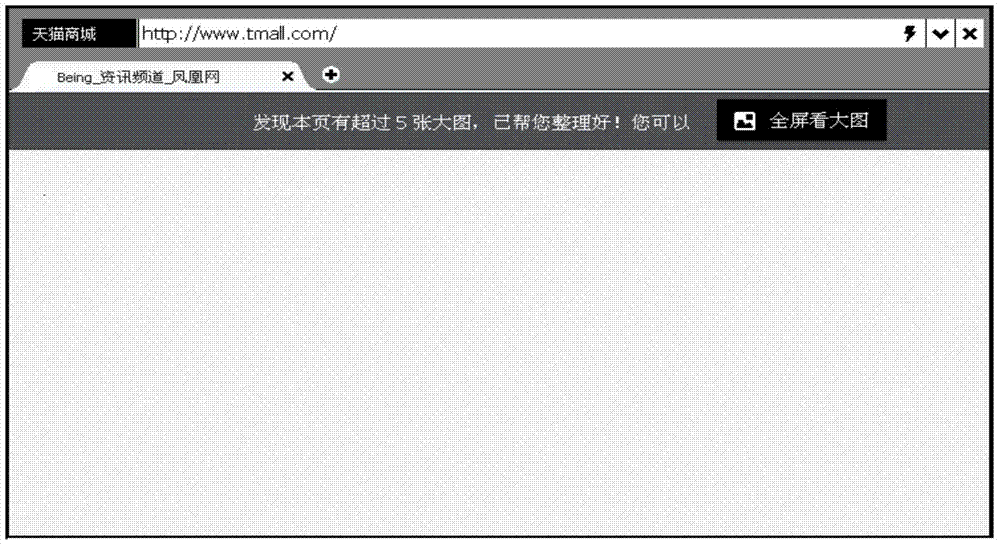

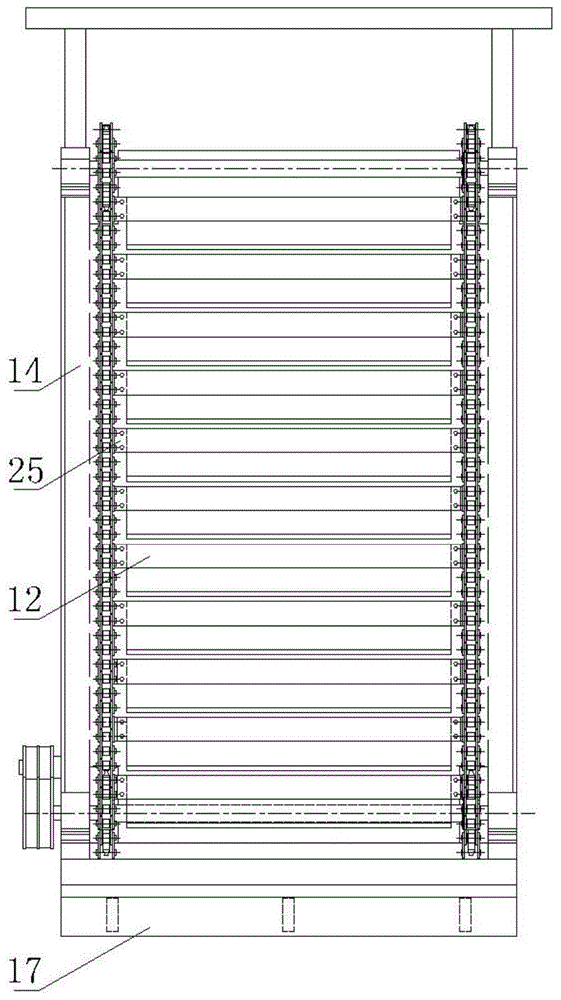

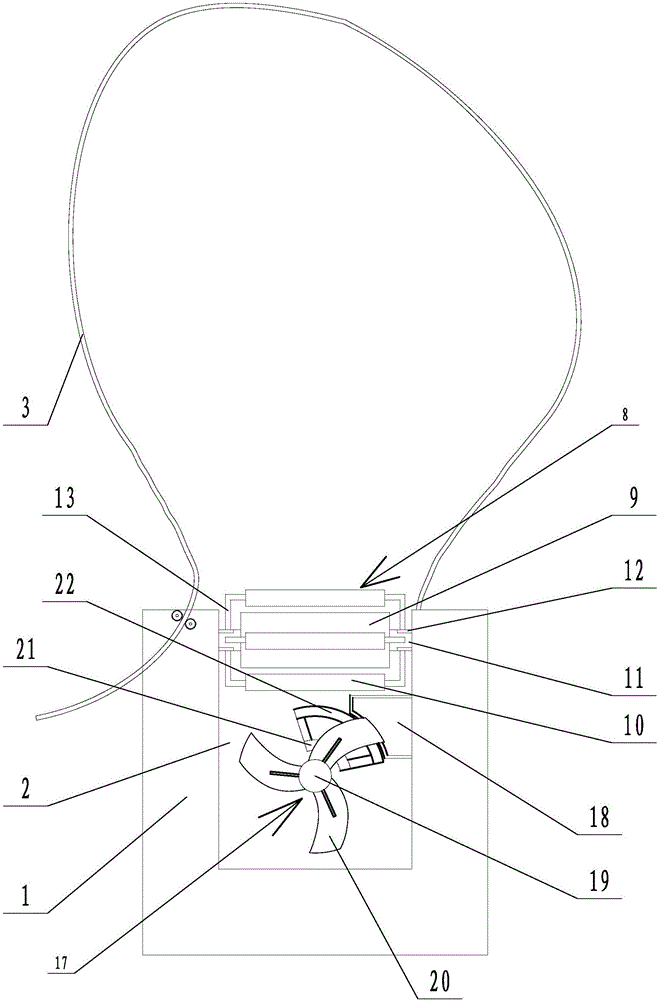

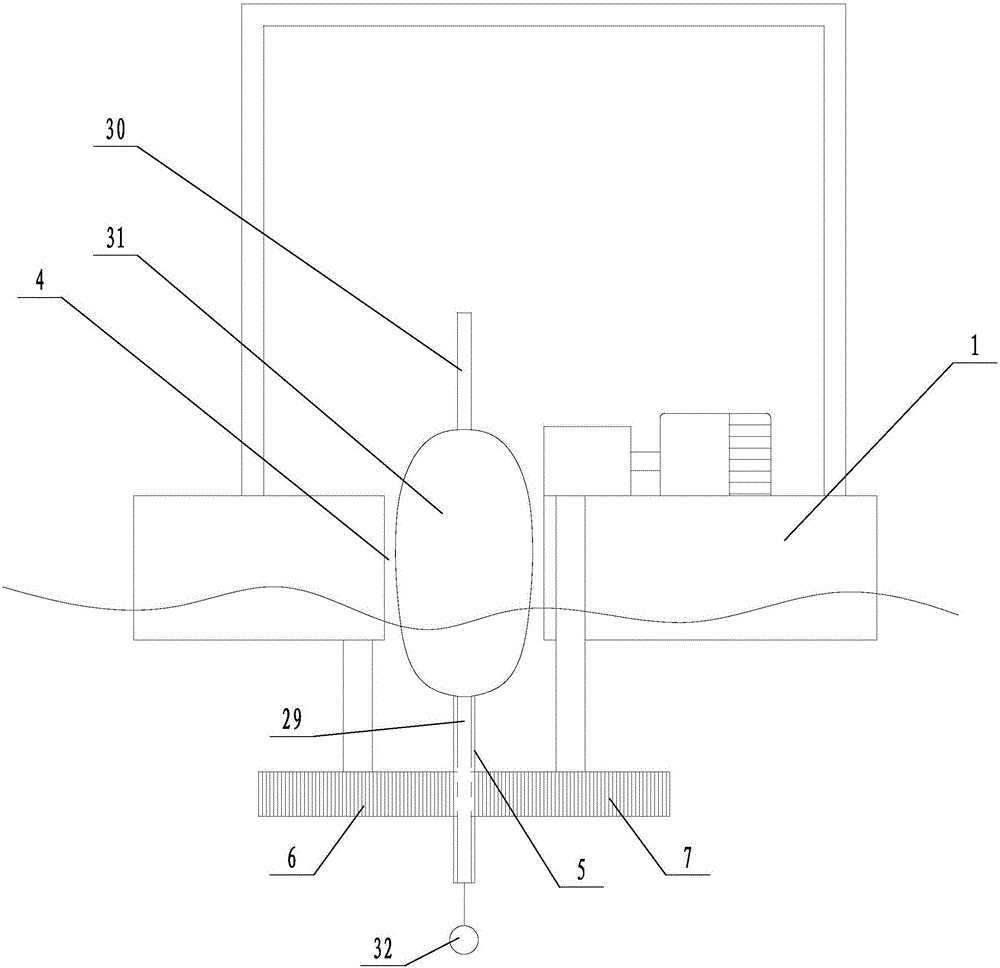

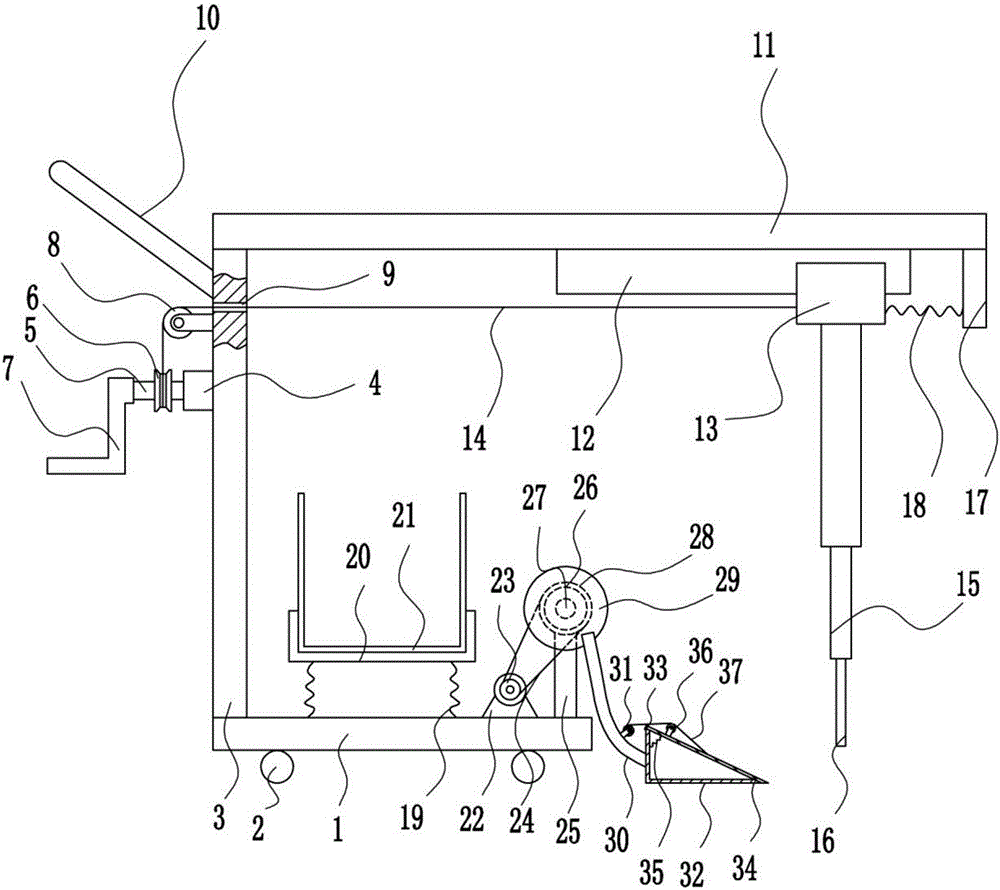

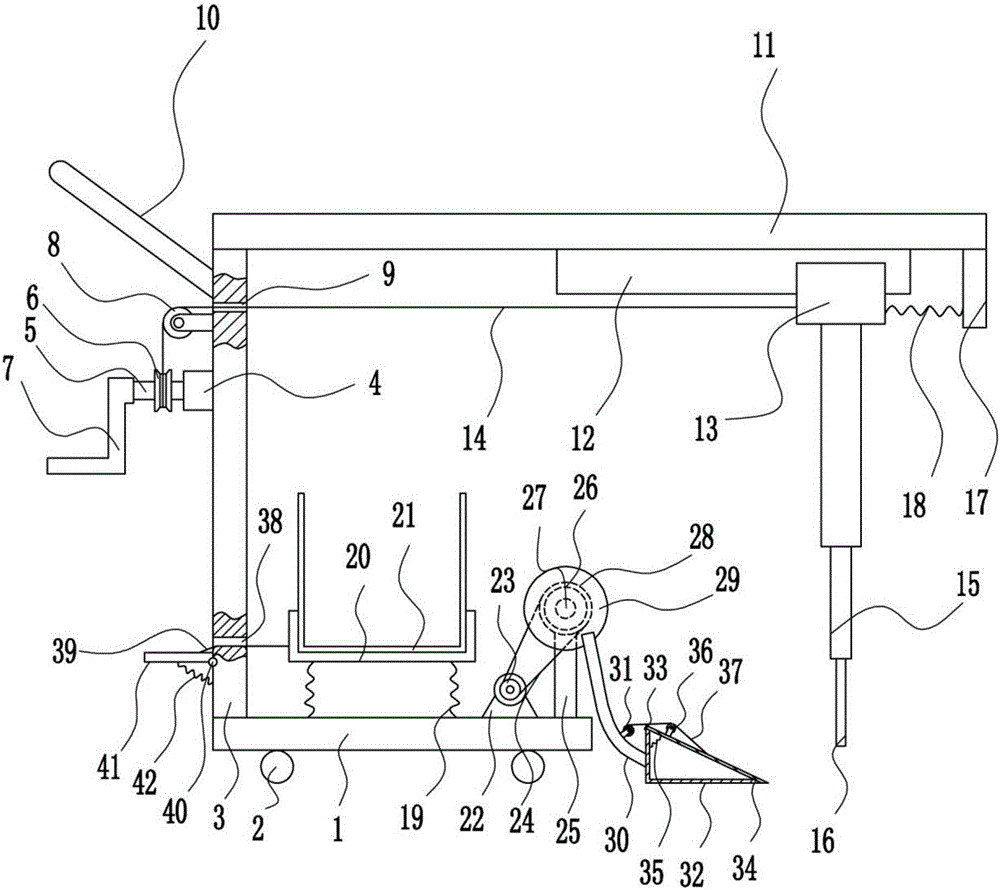

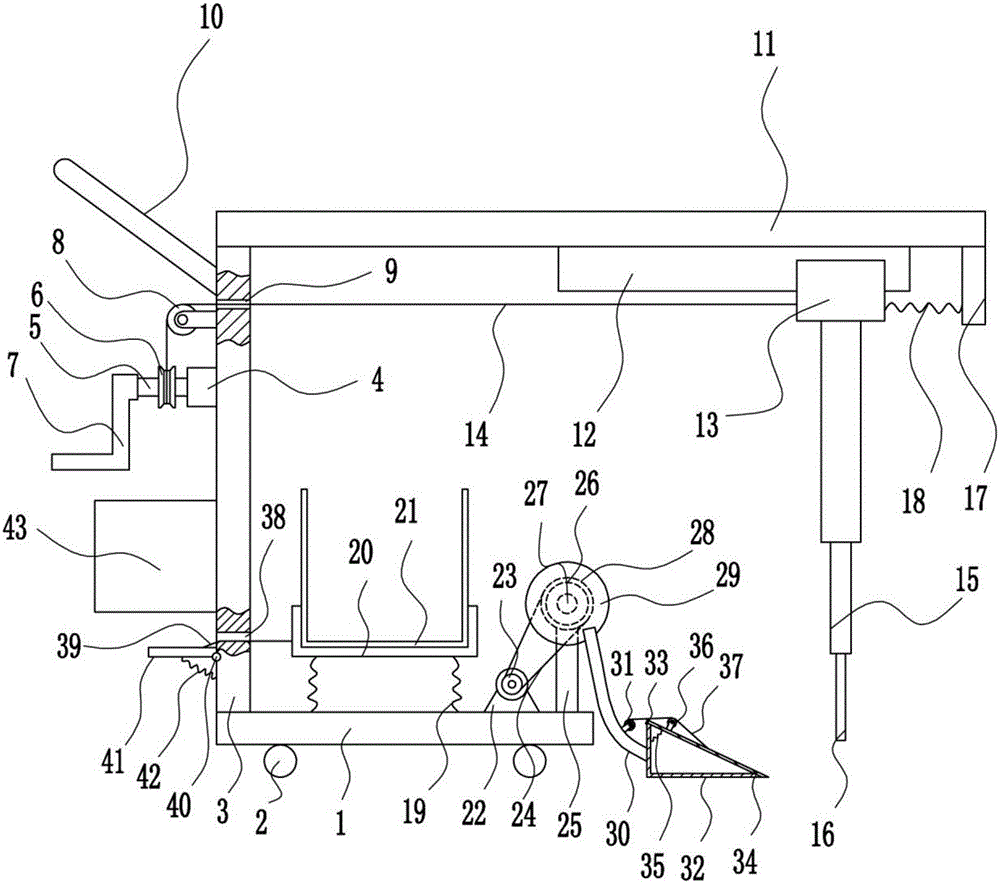

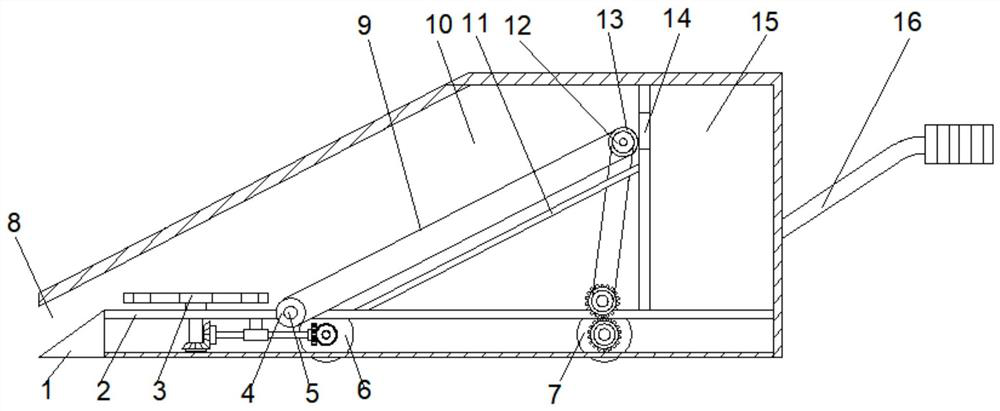

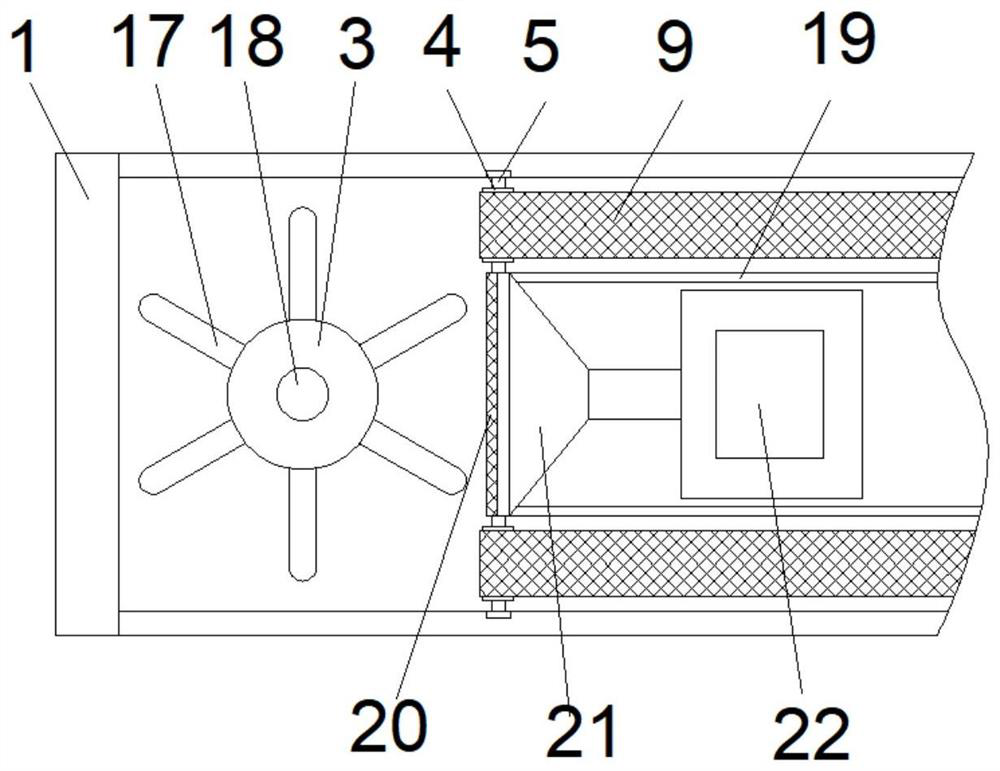

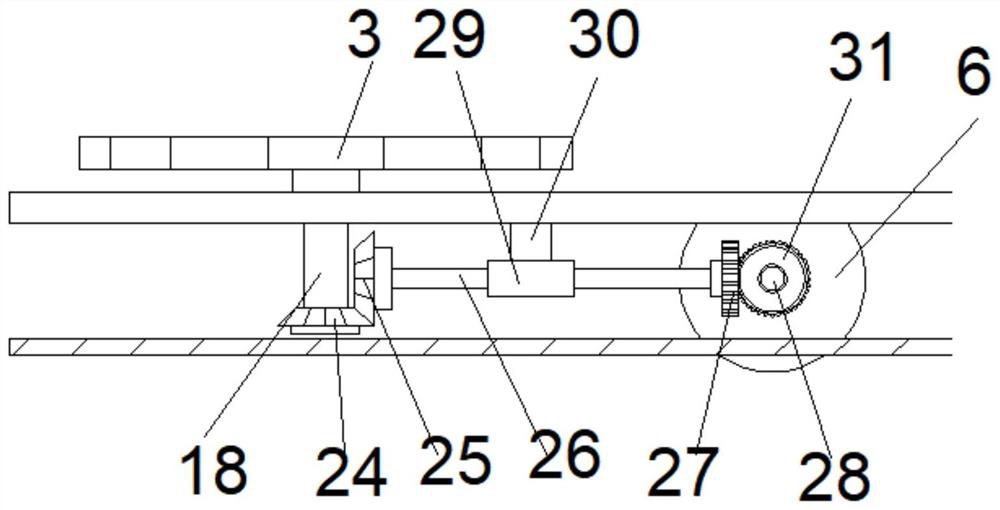

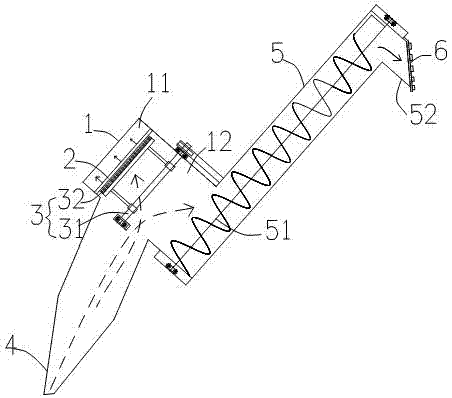

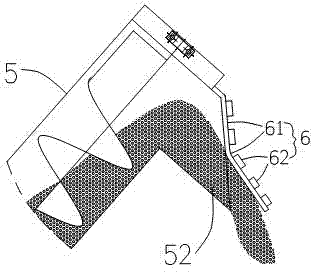

Small grain airing granule collector

ActiveCN104444415AAvoid getting wetShorten drying collection timeLoading/unloadingRight triangleDrive shaft

The invention discloses a small grain airing granule collector which comprises a rack. The rack is in a right triangle shape. A grain collection board slot is formed in the inclined face of the rack. The portions, inside the grain collection board slot, of the upper end and the lower end of the inclined plane of the rack are provided with a rotatable driven shaft and a rotatable driving shaft respectively. One end of the driving shaft is in transmission connection with a power source arranged inside the rack. A chain conveying mechanism is installed between the driving shaft and the driven shaft. Four walking wheels are arranged at the bottom of the rack. A collection hopper is arranged at the lower rear portion of the rack. An armrest frame is fixedly arranged at the upper rear end of the rack. The small grain airing granule collector has the advantages that aired grains can be rapidly collected to be put into a barn or bagged or the like, the collection speed is high, the thorough collection rate is high, the small grain airing granule collector is particularly suitable for rush collection of aired grains when it rains, the grain airing collecting time is greatly shortened, the grains are rapidly put into the barn, and the phenomenon that the grains are wetted by rainwater due to the low grain collection speed is avoided; the structure is compact, using is flexible and convenient, operation can be carried out by one person, and the manufacturing and maintenance costs are low.

Owner:卢志文

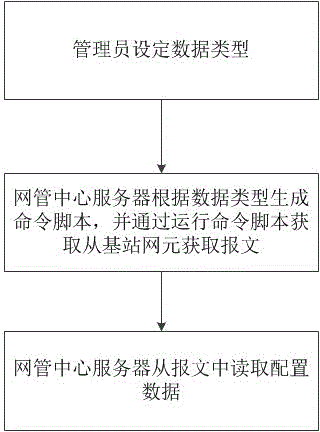

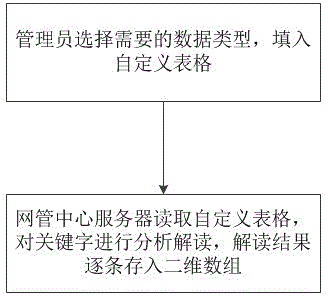

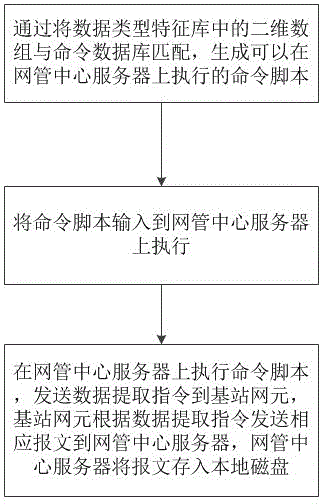

Method of obtaining network element configuration data of LTE (Long Term Evolution) network base station

The invention discloses a method of obtaining network element configuration data of an LTE (Long Term Evolution) network base station. The method comprises the following steps: S1, a data type is configured by an administrator; S2, a network management center server generates a command script according to the data type and obtains a message from a network element of the base station through operation of the command script; and S3, the network management center server reads the configuration data from the message. According to the scheme, the network element configuration data are extracted through a manner of the command script, so that the method has the advantages of quick collection speed and high efficiency, and the obtained data are complete and precise and can be directly shown to a user. The scheme is suitable for LTE network management.

Owner:ZHEJIANG SUNBELT NETWORK TECH CO LTD

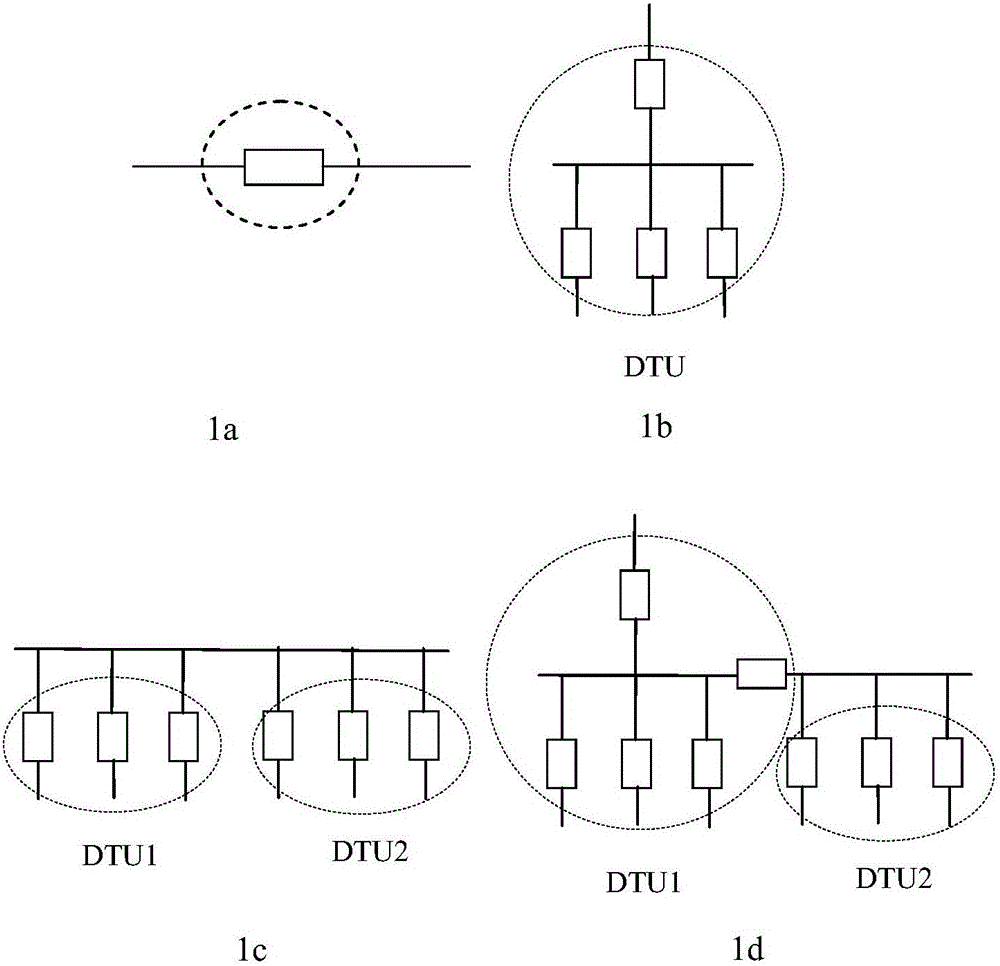

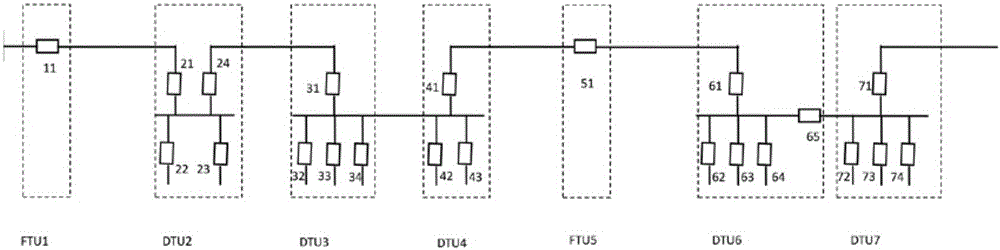

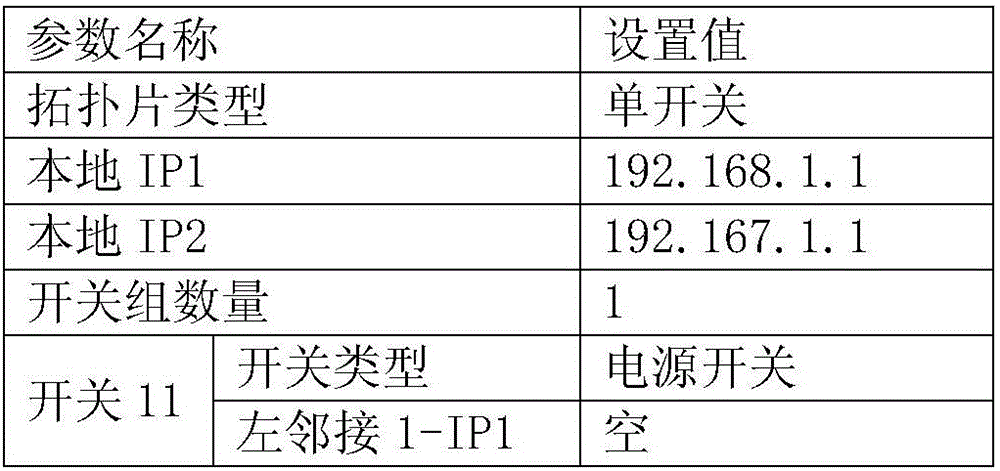

Switch adjacency relationship-based disperse configuration method of feeder topology

ActiveCN105977975AImprove maintenance efficiencyFast collectionContigency dealing ac circuit arrangementsNODALTopology information

The invention relates to the field of intelligent distributed feeder automation, in particular to a switch adjacency relationship-based disperse configuration method of a feeder topology. The method specifically comprises the steps as follows: dispersedly stored topology information employing a switch / switch group covered by each power distribution terminal as a basic unit is defined as topology piece information; the topology piece information is configured by a switch adjacency relationship represented by an adjacency IP mode; a line node, a bus node, a power supply node and a load node in a topological structure are automatically generated as implicit information through configuration information; and an intelligent distributed feeder automation system synthesizes required topology information of an overall or partial feeder by collecting the topology piece information which is dispersedly stored on each power distribution terminal through peer-to-peer communication. Building of the topological structure is achieved through information interaction between the power distribution terminals; the switch adjacency relationship-based disperse configuration method of the feeder topology has the advantages of high maintenance efficiency, a high collection speed and a small involved range; and a foundation is laid for automatic generation of a power supply recovery scheme of the intelligent distributed feeder automation system of a multi-contact power distribution network.

Owner:STATE GRID CORP OF CHINA +2

Marine spilt oil collecting device

ActiveCN106284258ACollect thoroughlyFast collectionWater cleaningGeneral water supply conservationPetroleum engineering

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Computer full-automatic sperm collecting, penis erection monitoring analysis system

The computer full-automatic sperm-collecting and penis erection monitoring analysis system includes sperm-taking device, controller instrument, display screen and printing machine, acoustic horn and electric pulse output electrode. Said sperm-taking device has a shell body with hole in which a sliding cover is set. Said sperm-taking device can adopt acoustic, optical, electric, magnetic and thermal multiple organoleptic all-bearing stimulation and adds the functions of gripping, circularly-pressing, vibration and magnetotherapy to simulate female vaginal environment in venered excitatory state.

Owner:叶文渊

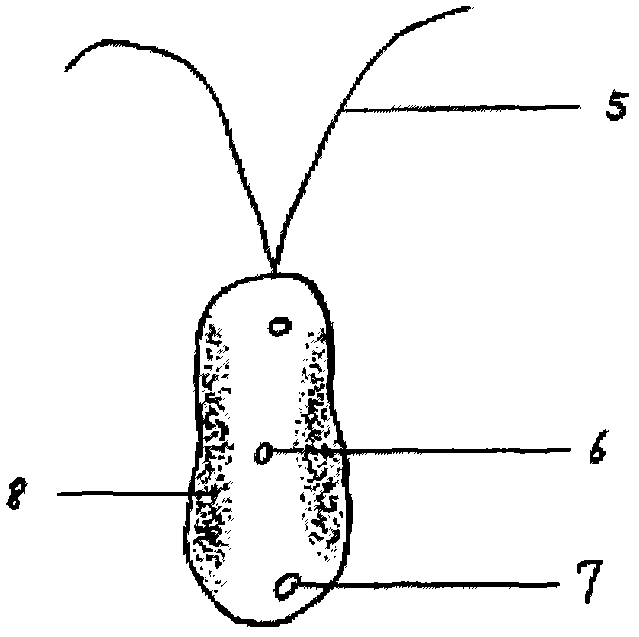

Series cultivation and rapid collection method for marine microalgae

InactiveCN104593262AAvoid light damageReduce wasteUnicellular algaeMicroorganism based processesSurface oceanPhotobioreactor

The invention discloses a series cultivation and rapid collection method for marine microalgae, belonging to the field of aquaculture cultivation and solving the deficiencies that marine microalgae is originally cultivated by adopting a photobioreactor or an open cement pond, which is large in capital construction investment, complicated in technology, high in technical requirement, easy to pollution, troublesome to operate and low in efficiency. The sequential cultivation and rapid collection method for marine microalgae has the technical characteristics that the two microalgaes are mixedly bred so as to achieve mutual advantages and mutual promotion and reduce the resource waste; introduced gas can be utilized for three times by adopting the sequential cultivation of conical flasks, so that the energy can be saved and cannot be easily contaminated; after a compound precipitator is added, the microalgae liquid is stored in a dark environment at the low temperature of 5 DEG C, the collection efficiency is high, the nutrition is not lost, the operation is simple and the practicability is strong.

Owner:LINYI UNIVERSITY

Crop airing support capable of increasing illumination

InactiveCN107560324AImprove drying effectFast collectionDrying solid materials with heatSeed preservation by dryingSelf lockingEngineering

The invention discloses a crop drying rack with increased illumination, which comprises a first drying plate, a second groove and a second drying plate. The bottom of the plate is provided with a universal self-locking wheel, one side of the support plate is provided with a fixing block, and one side of the fixing block is provided with a foot pedal, and one side of the foot pedal is connected with a connecting rod. In the present invention, one side of the foot pedal is provided with a connecting rod, the bottom of the connecting rod is provided with a spring, one side of the spring is provided with a fulcrum, and the connecting rod is connected with the supporting rod through the connecting shaft, and the top of the supporting rod is connected with a first Drying board, so press the foot pedal, the grains on the first drying board will be collected into the first groove from the gap between the first drying board and the support board, so it can automatically collect the grains for drying, collect The speed is faster and does not cause the scattering of grains.

Owner:CHENGDU ZHONGFU LIXIANG TECH

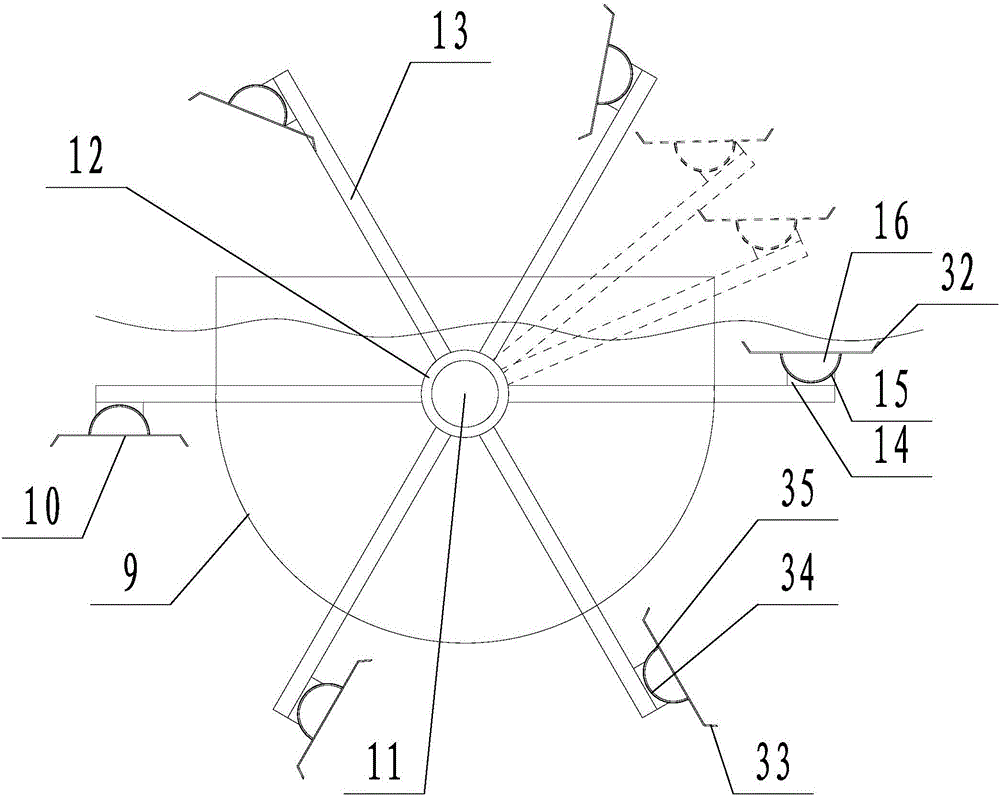

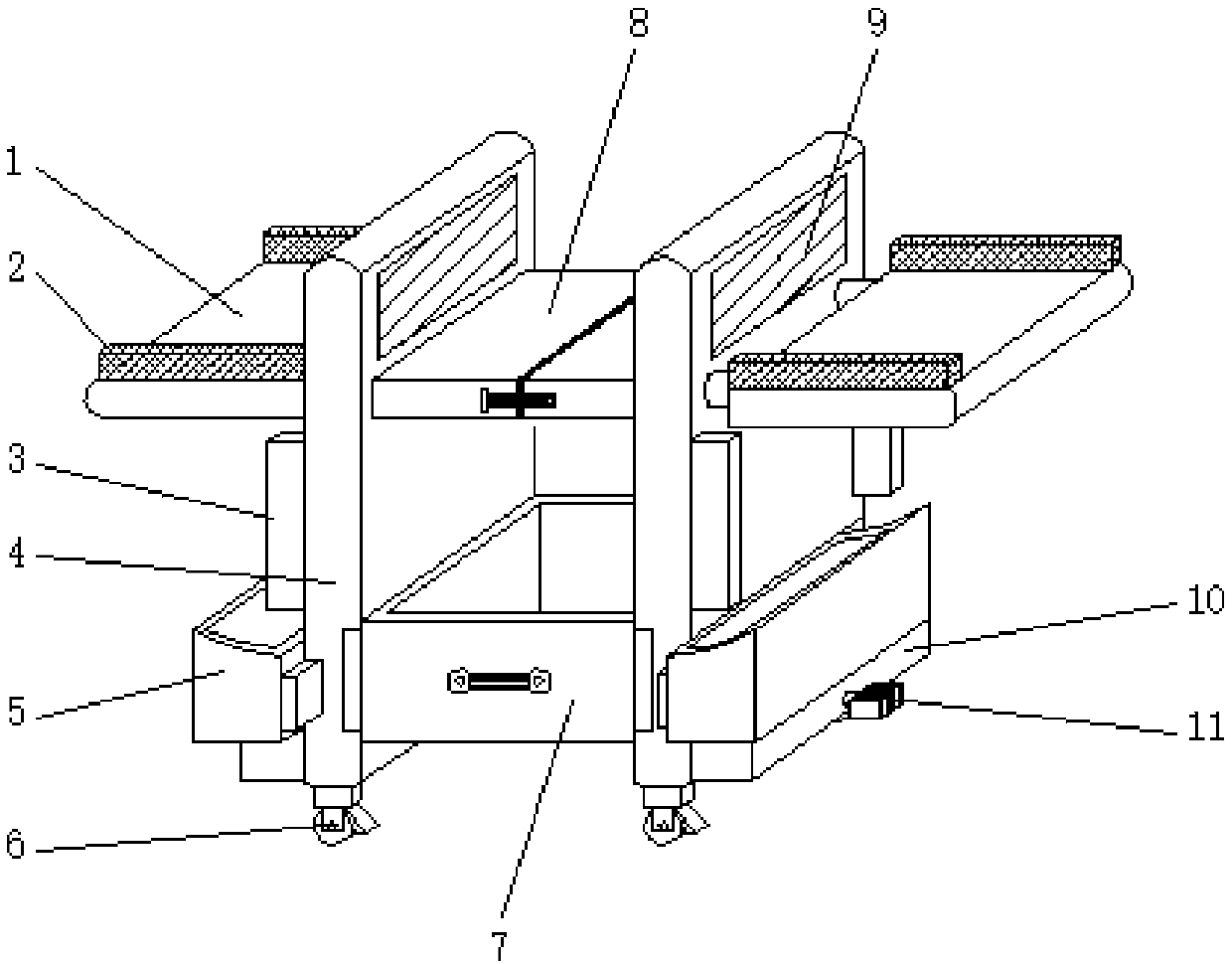

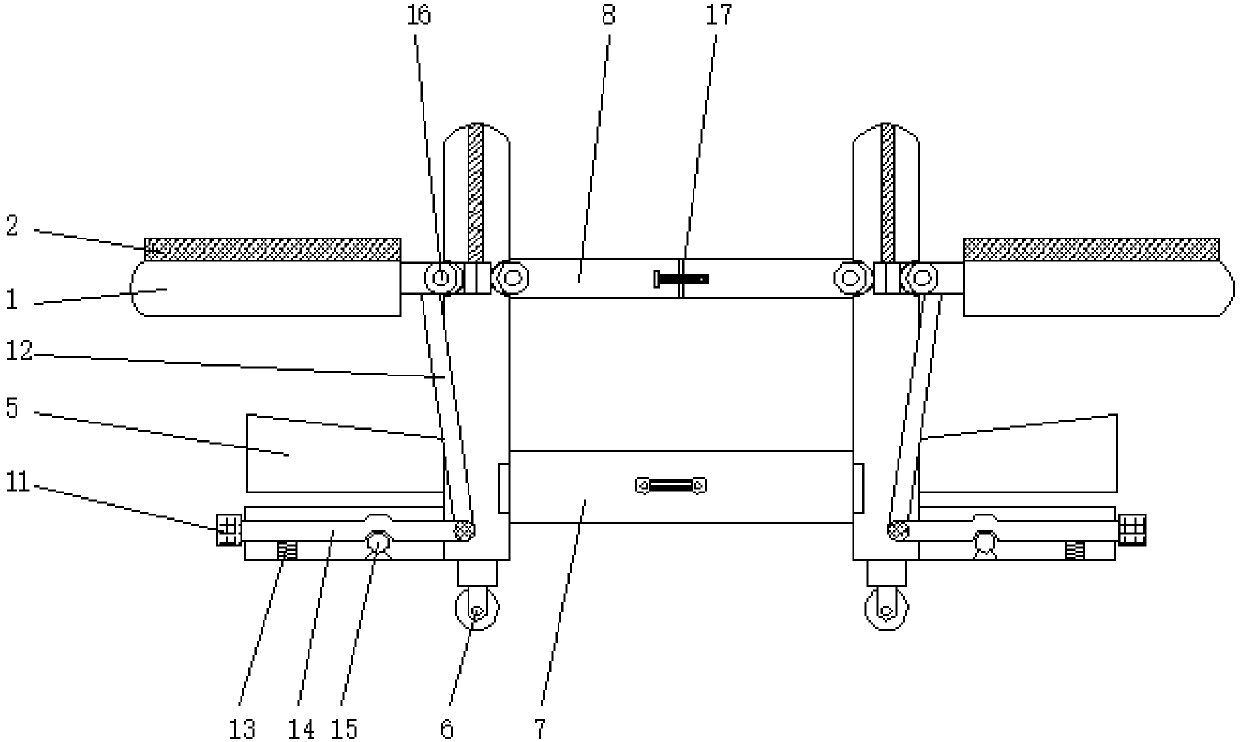

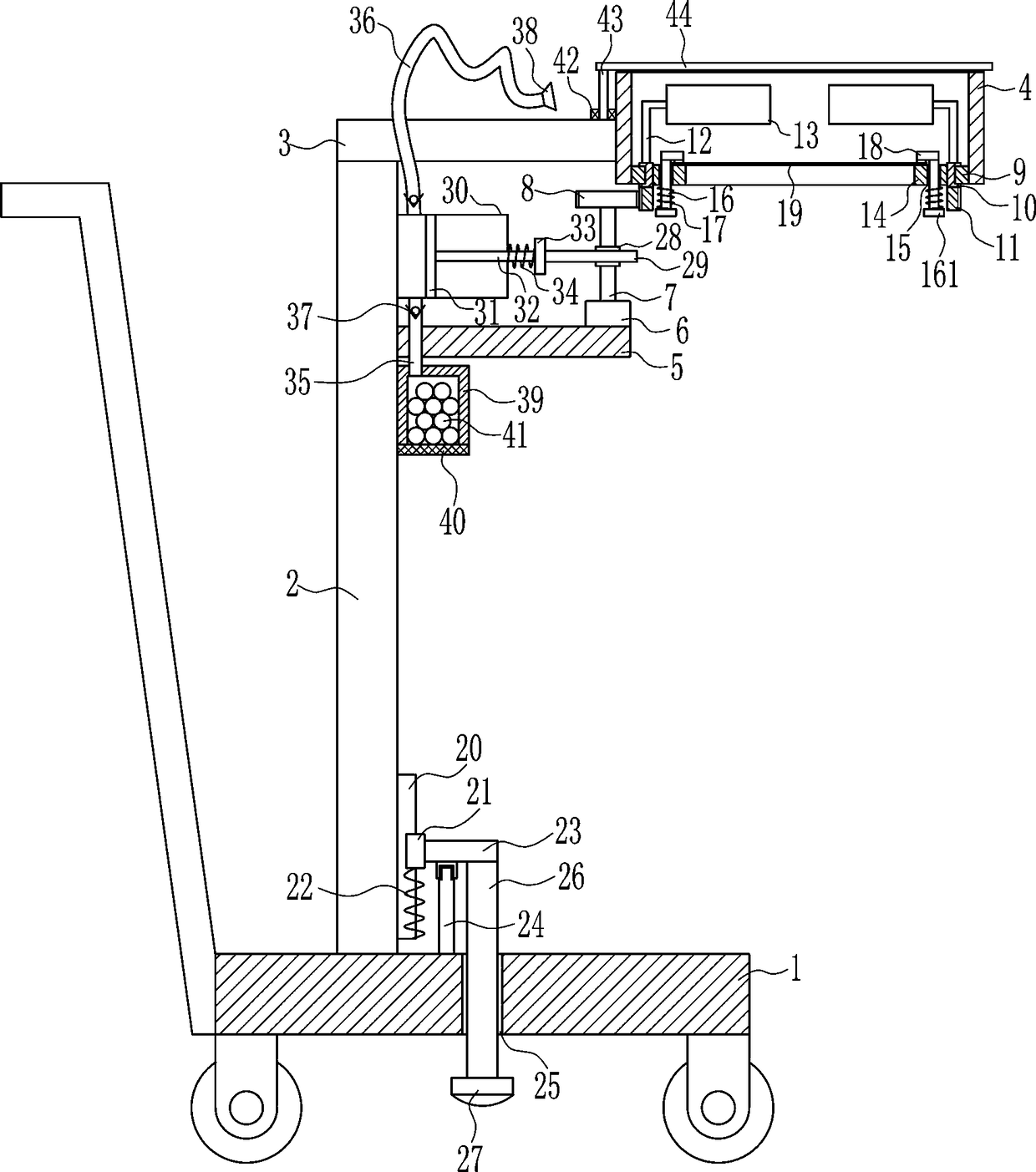

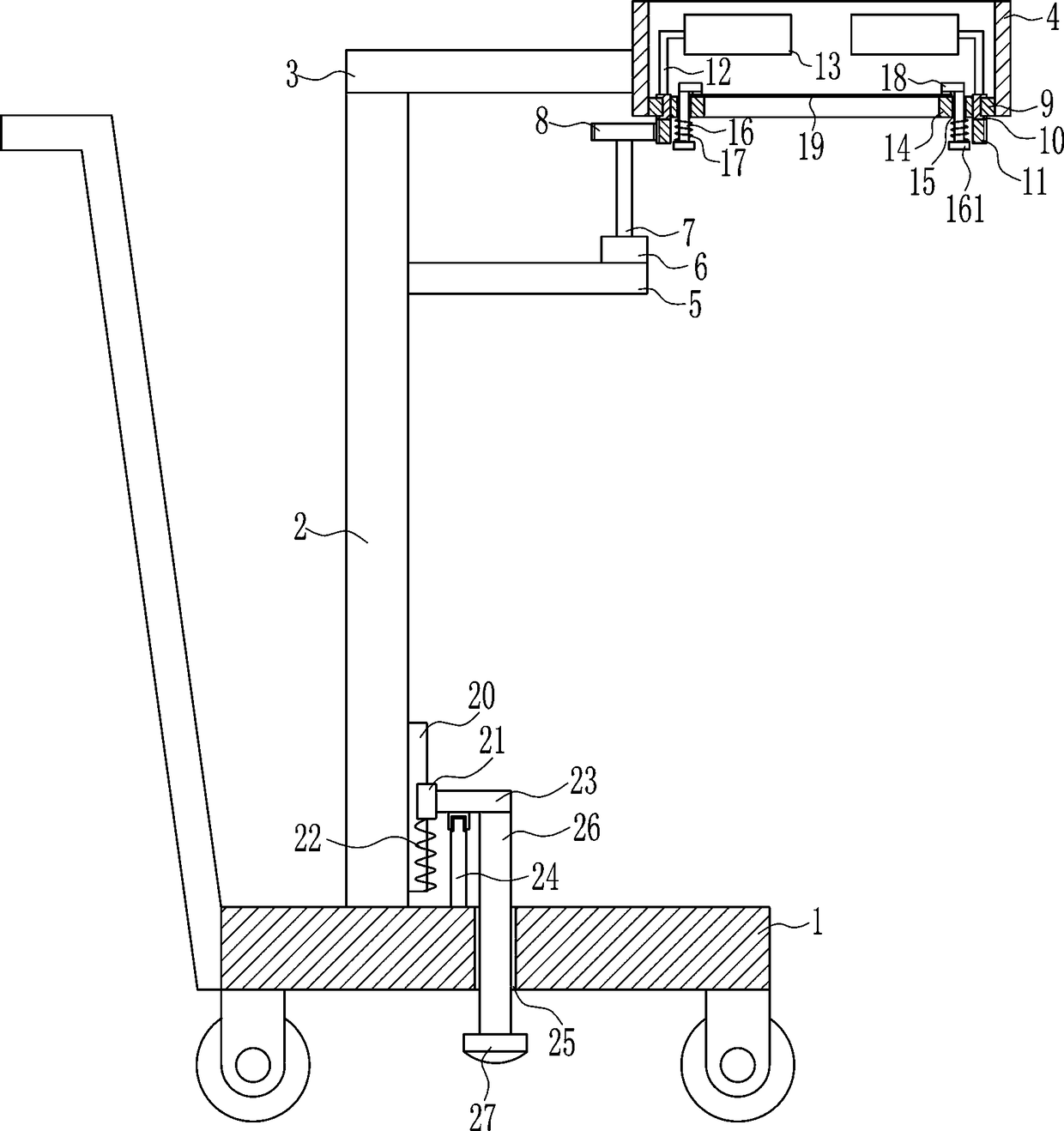

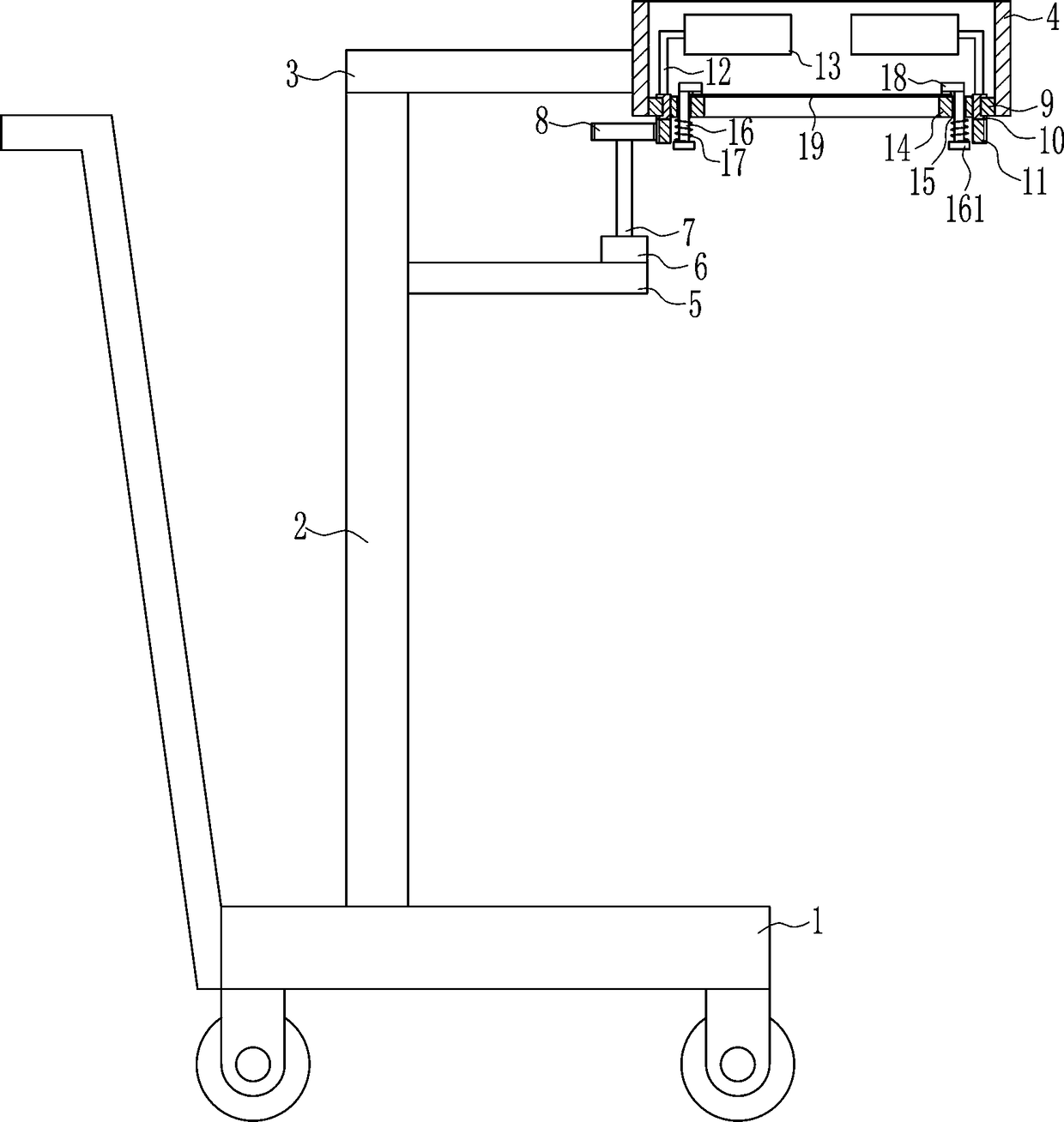

Shuttlecock collecting device for badminton training ground

The invention relates to a shuttlecock collecting device, in particular to a shuttlecock collecting device for a badminton training ground. The shuttlecock collecting device for the badminton training ground is high in collecting speed and small in working intensity. In order to achieve the technical purposes, the shuttlecock collecting device for the badminton training ground comprises a bottom plate, wheels, a supporting frame, a first bearing block, a first rotary shaft, a winding wheel, a rocking handle, a first fixed pulley, a push handle, a top plate, a sliding rail, a sliding block, a first pull line and the like. The supporting frame is welded to the left end of the top of the base plate, the upper portion of the left side of the supporting frame is connected with the first bearing block in a screw connection mode, and a bearing in the first bearing block is connected with the first rotary shaft in an interference connection mode. Through cooperation of a collecting hopper and a push plate, shuttlecocks are firstly swept into the collecting hopper, and the shuttlecocks in the collecting hopper are poured into the collecting frame by controlling rotation of a rotary motor.

Owner:HUNAN NORMAL UNIVERSITY

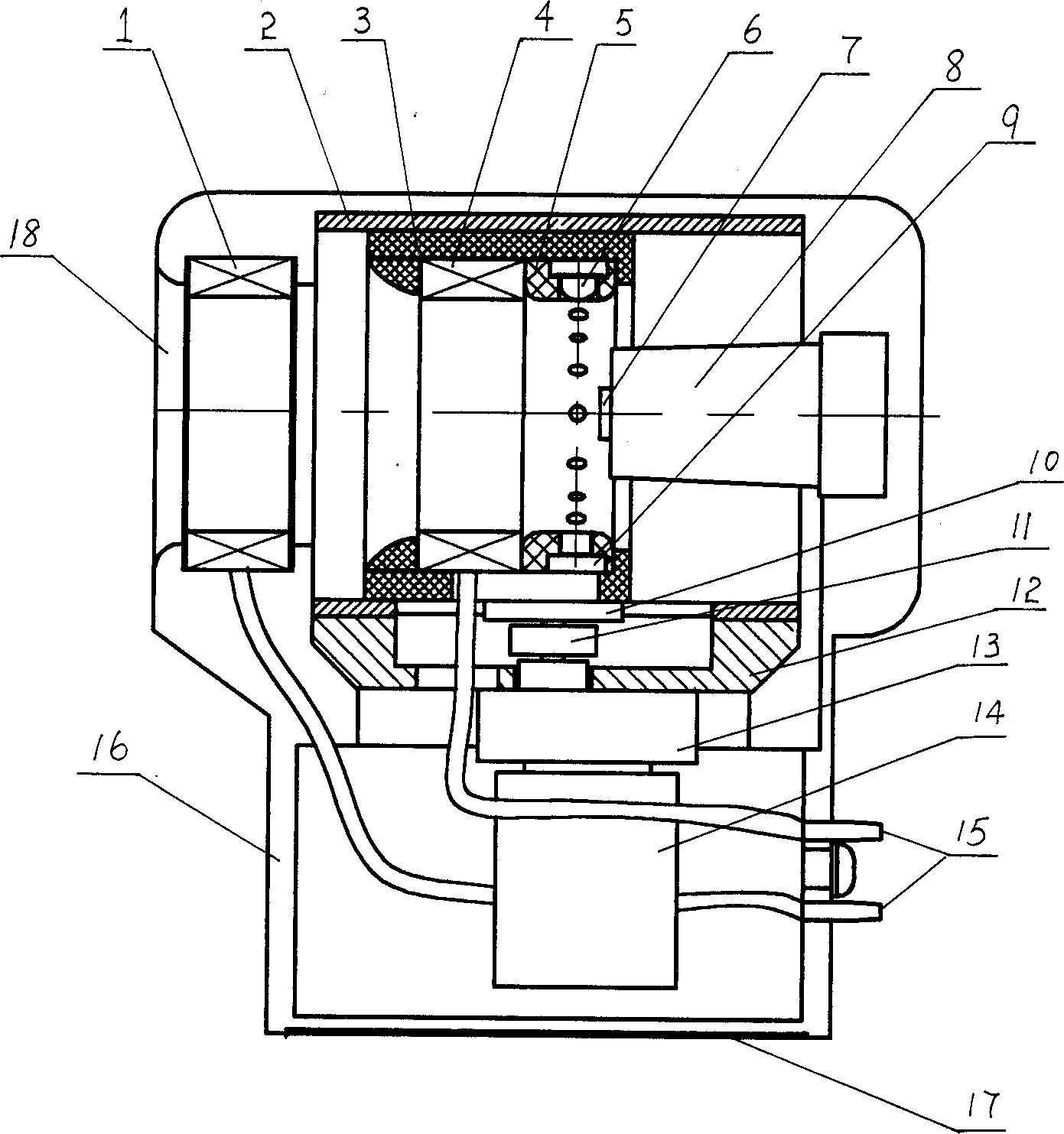

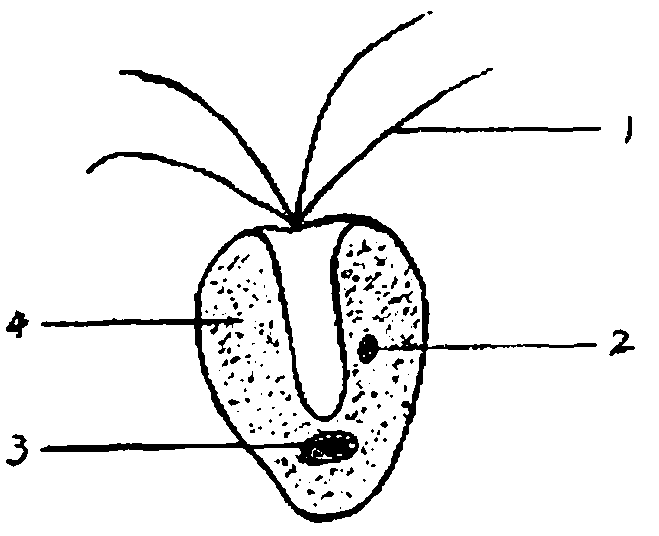

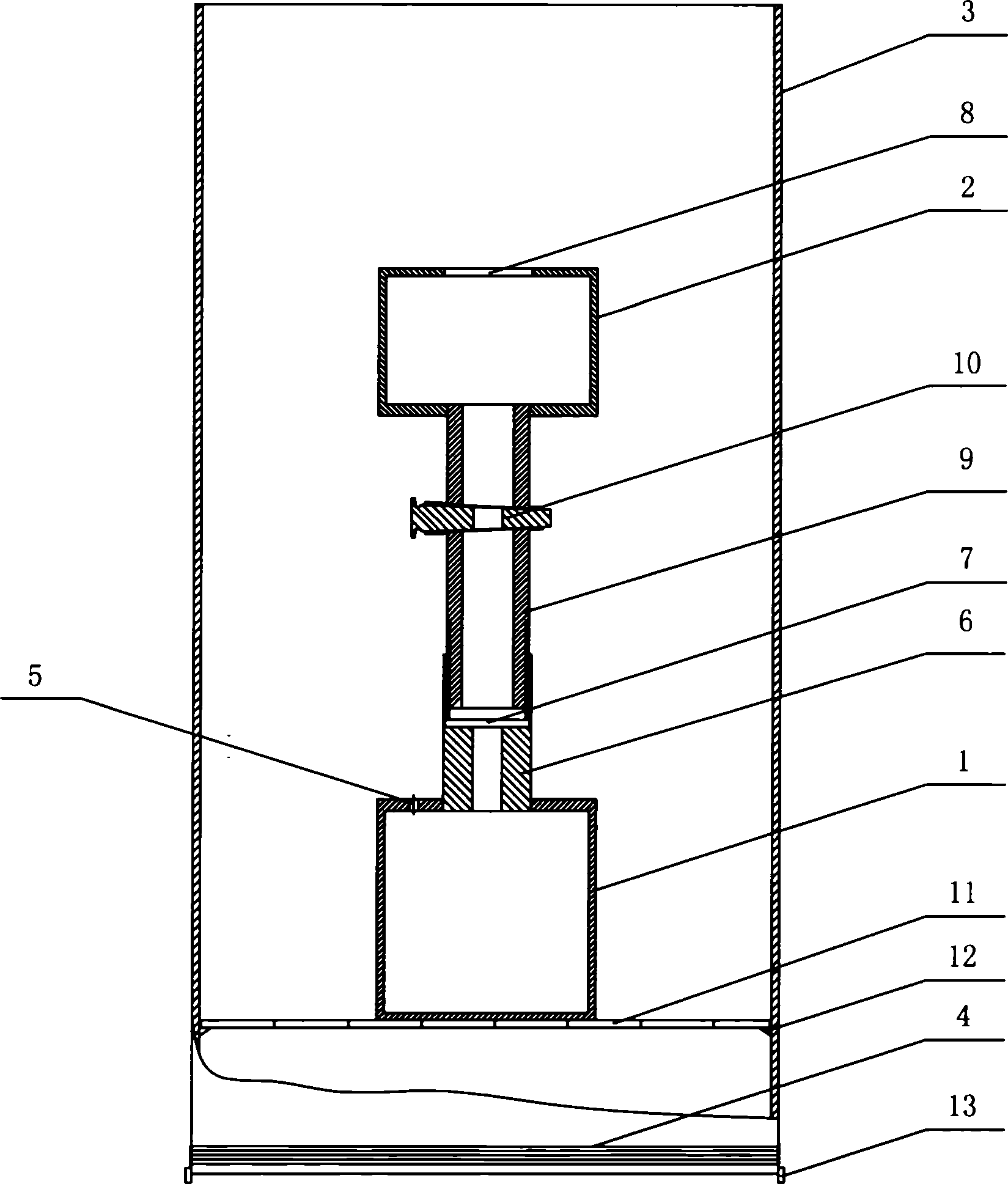

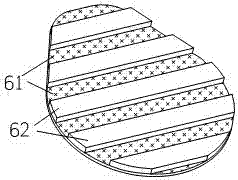

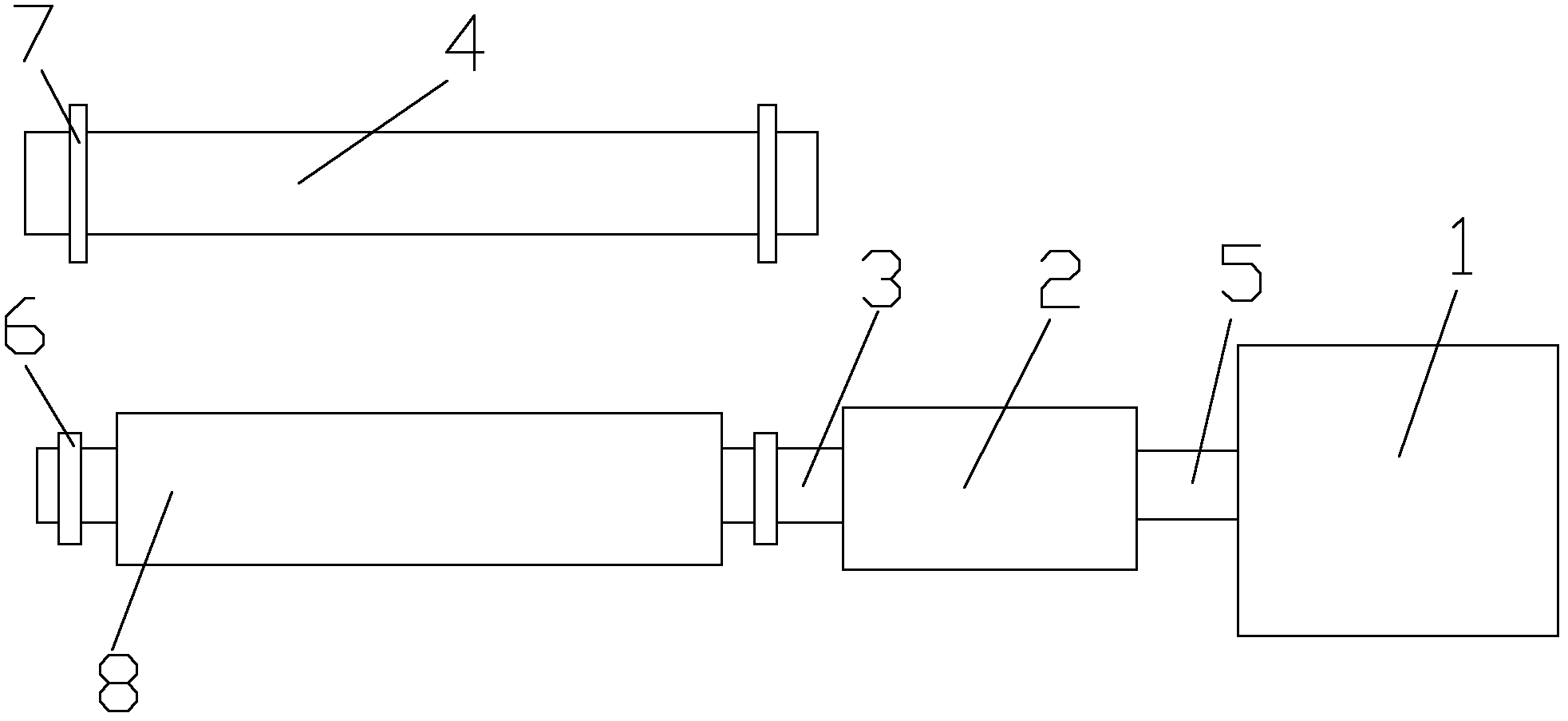

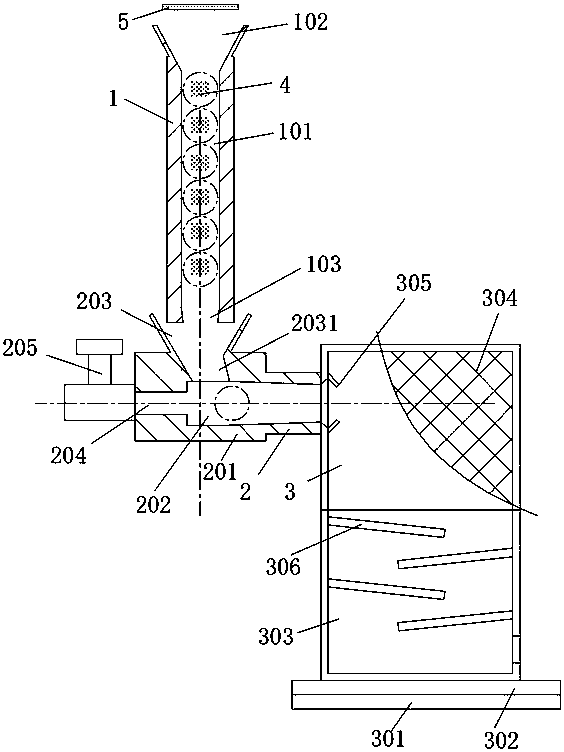

Magnetic bacteria fast-collection device

InactiveCN1880441ALow costEasy to manufactureBiological material testing proceduresStress based microorganism growth stimulationMembrane configurationEngineering

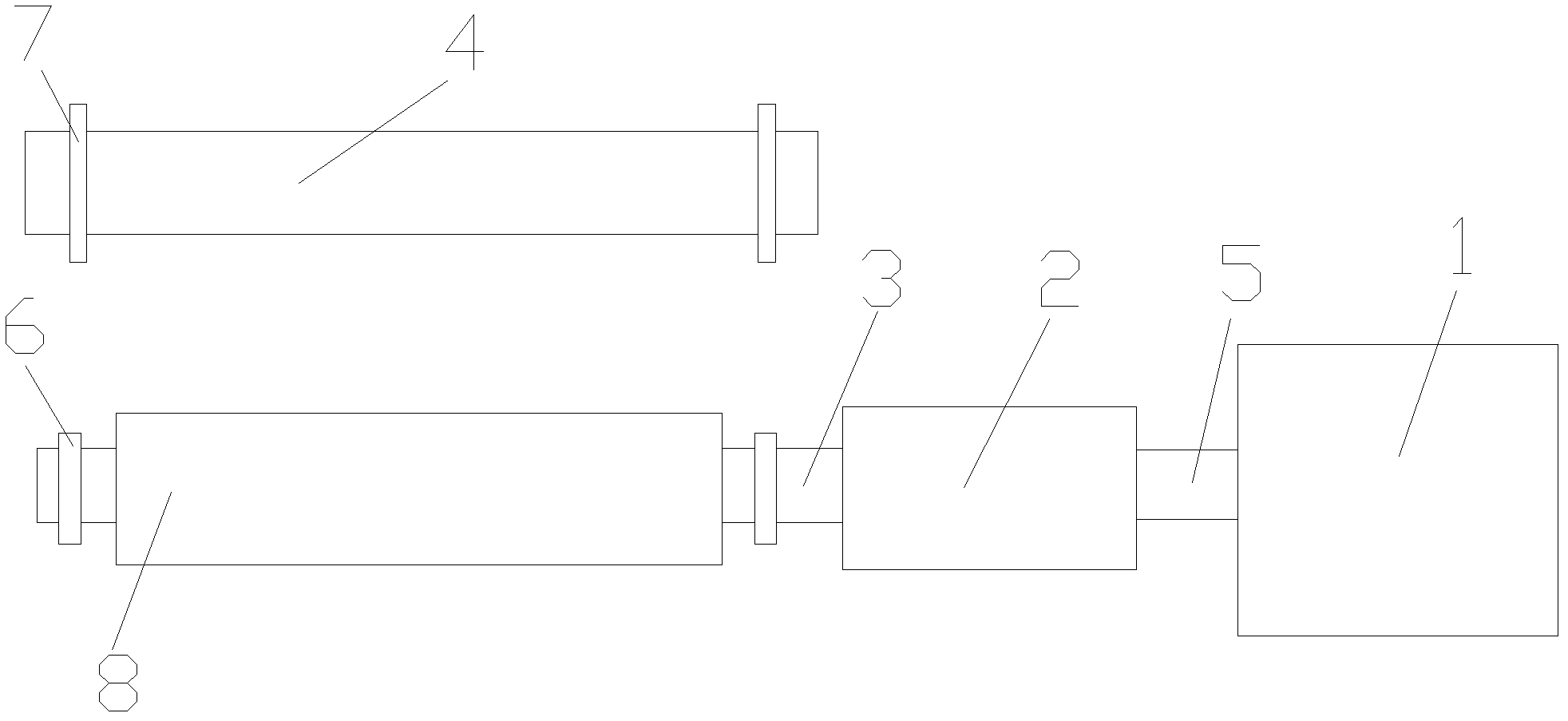

The invention discloses a rapid collecting device of magnetic bacteria, which comprises the following parts: enriched bin (1), collecting bin (2), cylinder (3) and coil (4), wherein the overflow hole (5) and enriched bin pipe (6) within filter membrane (7) are set on the top of enriched bin (1); the collecting hole (8) is set on the top of collecting bin (2), whose bottom contains collecting bin pipe (9); the control valve (10) is set on the collecting bin pipe (9); the enriched bin (1) and collecting bin (2) connect through enriched bin pipe (6) and collecting bin pipe (9); the enriched bin (1) is placed on the cribellum (11) in the cylinder (3), which is winded by coil (4).

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Rapid table tennis ball collecting device for physical education

InactiveCN108310734AReduce labor intensityKeep clean and tidyBall sportsRoad cleaningPhysical educationMotor drive

The invention discloses a rapid table tennis ball collecting device for physical education. The rapid table tennis ball collecting device comprises a base plate, a collecting box, a ball discharging pipe, a collecting frame, a supporting plate, an exhaust fan, a ball feeding pipe, a suction head, a rotating shaft, a floor sweeping brush, a first gear, a second gear and a motor. The exhaust fan exhausts air in the collecting box, negative pressure is generated in the collecting box, table tennis balls on the ground enter the ball feeding pipe from the suction head and then enter the collectingbox, operation is simple, convenient and rapid, a worker does not need to bend down and pick the balls and can continuously collect the balls, collecting speed is high, a large number of balls are collected, the labor intensity of the worker is relieved, working efficiency is improved, the motor drives the second gear to rotate, the second gear drives the rotating shaft to rotate through the firstgear, the rotating shaft drives the floor sweeping brush to rotate, the ground is cleaned after the table tennis balls are collected, and environments are kept clean and tidy.

Owner:黄健森

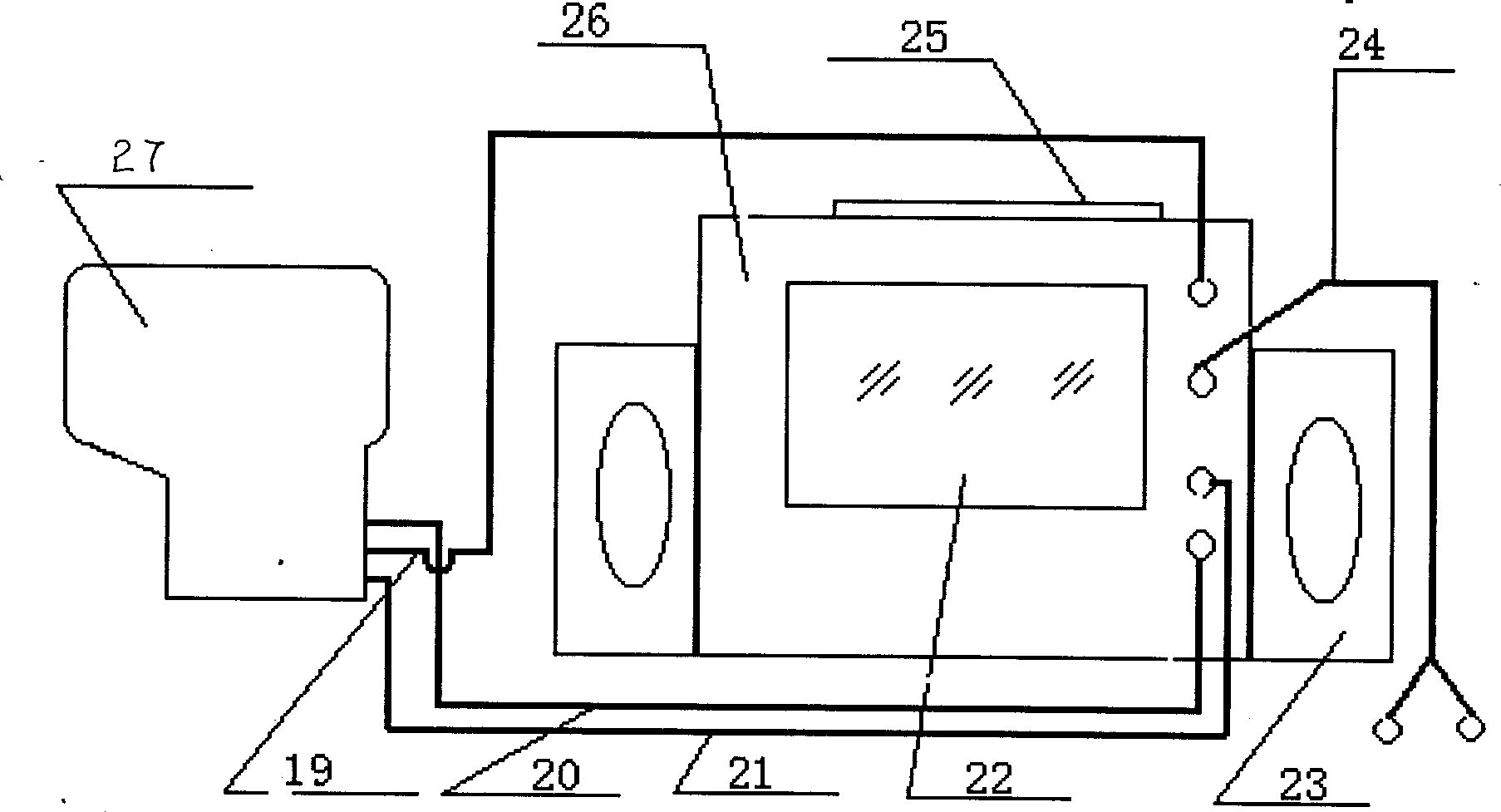

Optical MRI device

ActiveUS20100292563A1Fast collectionGood resultMaterial analysis by optical meansDiagnostics using tomographyImage resolutionMagnet

A dual modality imaging apparatus, comprising a magnetic resonance imaging (=MRI) system and a fluorescence molecular tomography (=FMT) system, for investigating a sample (42) located at a sample position (10), wherein the MRI system comprises a magnet (9) with a room temperature bore (8), with the sample position (10) located within the bore (8), and wherein the FMT system comprises means for directing a light beam (12, 17; 30) towards the sample position (10), and a position-sensitive detector (37) for collecting fluorescence light from the sample (42), is characterized in that the position-sensitive detector (37) is located within the bore (8), wherein at least part of the sample (42) is imaged onto the position-sensitive detector (37), and that the means for directing the light beam (12, 17; 30) comprise a focusing device for focusing the light beam (12, 17; 30) into a focal spot (41) on the sample (42), and a scanning device for scanning the focal spot (41) on the sample (42). The apparatus is simple in design and versatile in application, and in particular imposes less limitations on the maximum number of source / detector pairs during FMT imaging, thus allowing a better FMT image resolution.

Owner:UNIV ZURICH

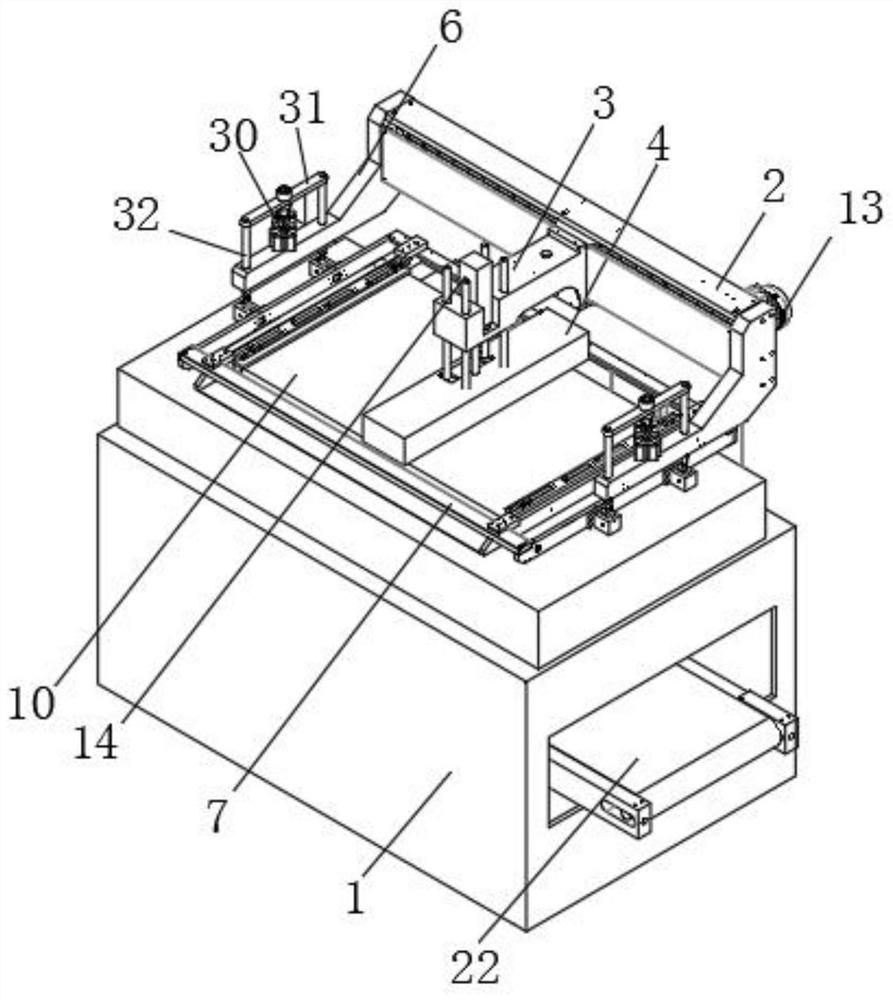

Excess material collecting equipment for wood processing and working method thereof

ActiveCN112207061APlay the role of covering the remaining materialEasy to disassembleDirt cleaningCleaning using toolsEngineeringBelt conveyor

The invention discloses excess material collecting equipment for wood processing and a working method thereof.The excess material collecting equipment comprises a base; a mounting base is fixedly mounted at the top of the base; a movable base is movably mounted on one side of the mounting base; a hair brush air cylinder is fixedly mounted at the top of the movable base; a hair brush mounting plateis arranged below the movable base; the bottom end of an output rod of the hair brush air cylinder is fixedly connected with the hair brush mounting plate; a hair brush is mounted at the bottom of the hair brush mounting plate; a through groove is formed in the upper wall of the base; a rotating plate mechanism is fixedly mounted inside the base; a working plate is mounted on the top of the rotating plate mechanism; and a belt conveyor is fixedly mounted inside the base. According to the excess material collecting equipment, excess materials can be automatically collected, meanwhile, cleanliness of the working plate is ensured, the working efficiency is high, a mounting frame can take an effect of shielding the excess materials so as to avoid a case that the excess materials are scattered, and the working plate in the excess material collecting equipment is convenient to disassemble so as to facilitate replacing and maintaining the working plate.

Owner:湖北东润木业有限公司

Scrap removing device for wood processing

InactiveCN111002405AEasy to clean upFor quick twistWood compressionDomestic articlesElectric machineryDrive motor

The invention belongs to the technical field of wood processing, in particular to a scrap removing device for wood processing, and aims at solving the problem that in wood processing at present, scraps are simply sucked into a collecting barrel for collecting and fluffy scrap occupy a large amount of space. The scarp removing device comprises a workbench of a square-tube-shaped structure and internally provided with a cavity, a round hole is formed in the position, close to the edge, of the bottom of the workbench, a discharging pipe is welded in the round hole, a driving motor is fixed over the position, close to the discharging pipe, of the inner wall of the top end of the workbench, a transmission rod is fixed to the top end of an output shaft of the driving motor through a coupler, anda spiral plate is arranged on the circumferential outer wall of the transmission rod. According to the scrap removing device, wood waste chips near the pipe opening of the discharging pipe can be rapidly twisted into the discharging pipe during rotation, scrap can be stopped in the discharging pipe when discharging is not needed, and cleaning work at an outlet is facilitated.

Owner:河北聚商智能科技有限公司

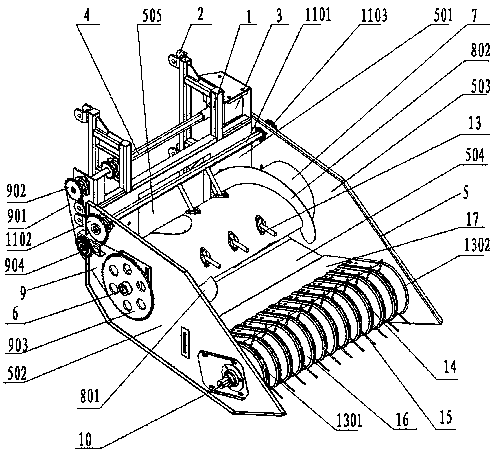

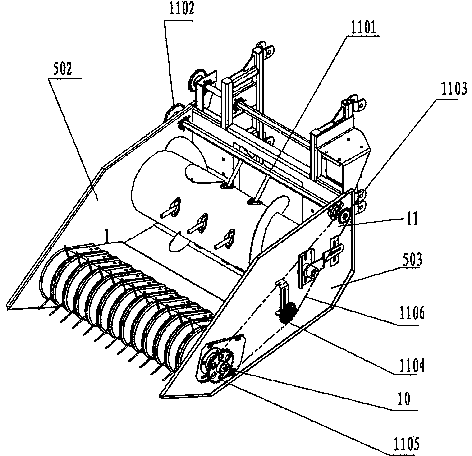

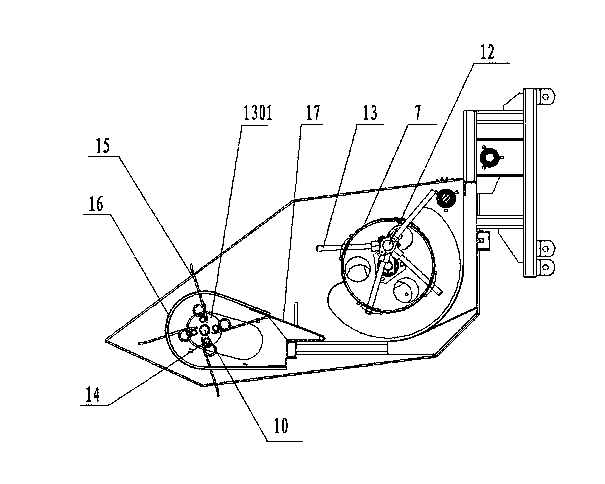

Peanut vine-pod collector

The invention relates to a peanut vine-pod collector comprising a mounting frame, connectors, and a collection shovel. The connectors are arranged at the rear end of the mounting frame. The collection shovel composed of a rear board, two side boards and a conveying board is fixed to the front end of the mounting frame. An output roller with spiral vanes is rotatably supported on the two side boards above the conveying board. A stirring shaft is rotatably supported between the two side boards at the front end of the conveying board. The stirring shaft reversely rotates relative to a roller shaft of the output roller. The peanut vine-pod collector is characterized in that a crank shaft is arranged inside an inner cavity of the output roller, stirring rods radially extending out of the surface of the output roller are arranged on the peripheral surface of the crank shaft, a plurality of fixed rods are arranged between two fixed discs on the stirring shaft, each fixed rod is correspondingly provided with a plurality of rows of peripheral spring stirring rods, an arc guard board is arranged between each two rows of spring stirring rods, and a guide board is arranged between the arc guard boards and the conveying board. The peanut vine-pod collector has the advantages that the spring stirring rods never affect peanut vines and pods, few peanut pods shed, the stirring rods are in fit with the spiral vanes of the output roller, and the peanut vines and pods are smoothly discharged.

Owner:RONGCHENG HAISHAN MECHANICAL MFG

Portable ball picking device for badminton hall

InactiveCN112755479AAchieve pickupReduce labor intensityBall sportsStructural engineeringMechanical engineering

The invention discloses a portable ball picking device for a badminton stadium. The portable ball picking device comprises a vehicle body, a connecting plate is further arranged in the vehicle body, an exhaust fan is arranged on the upper surface of the connecting plate, an air suction hood is arranged at the output end of the exhaust fan, and the opening direction of the air suction hood faces the direction of the feeding port; conveying belts are arranged on the front side and the rear side of the exhaust fan, the right ends of the conveying belts incline upwards, a collecting bin is arranged on the right sides of the conveying belts, a discharging port is formed in the left wall of the collecting bin and located on the right side of the right ends of the conveying belts, and front wheels and rear wheels are further arranged at the bottom of the vehicle body. The front wheels are connected through a second rotating rod, and the rear wheels are connected through a third rotating rod; when the shuttlecocks are picked up, the exhaust fan is used for exhausting air, the shuttlecocks are very light, the shuttlecocks are easily sucked into the vehicle body, then the shuttlecocks enter the collecting bin under the action of the conveying belt, the collecting speed is high, and the working intensity is small.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

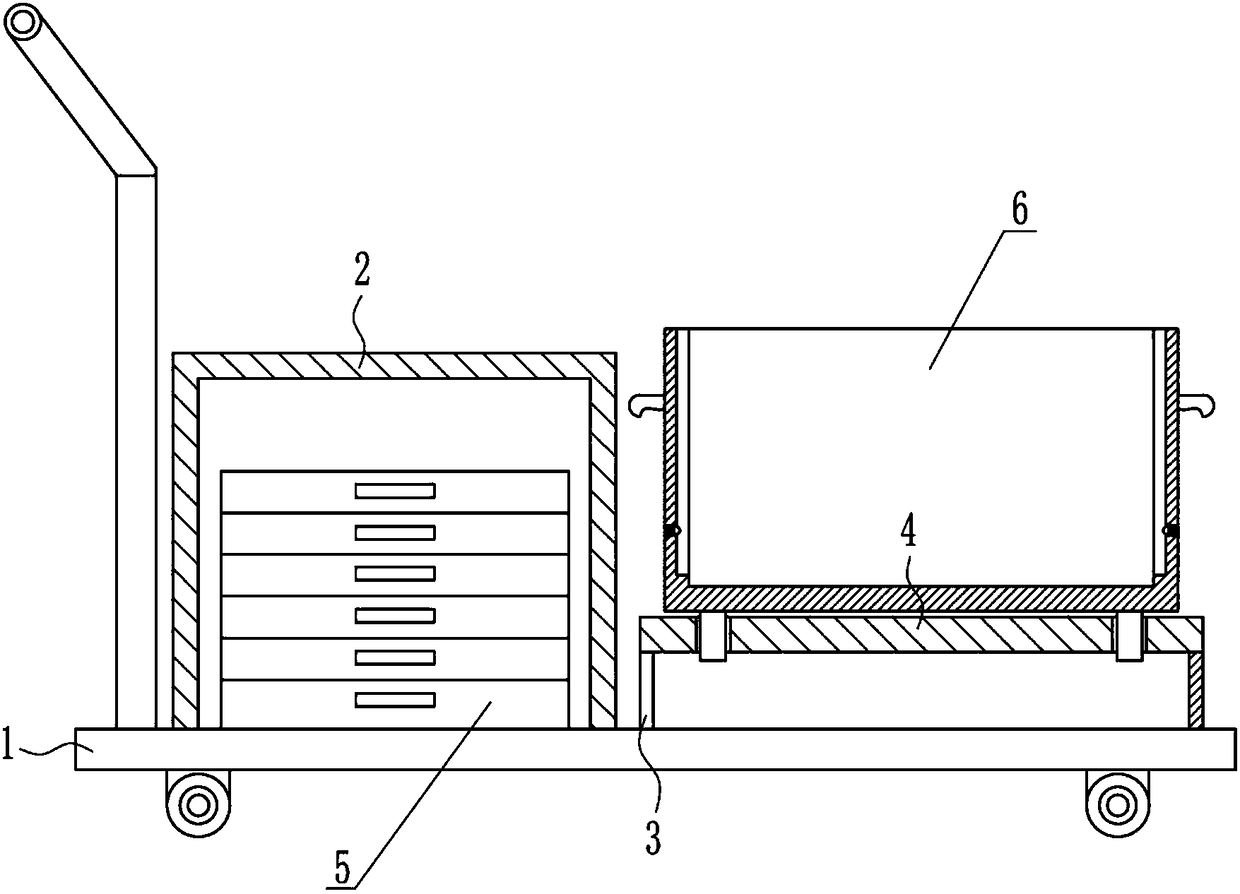

Egg collecting and protecting device for poultry farming

The invention relates to a collecting and protecting device, in particular to an egg collecting and protecting device for poultry farming. According to the egg collecting and protecting device for poultry farming, eggs are not prone to breakage, and the collecting speed is high. The egg collecting and protecting device for poultry farming comprises a trolley and the like. An n-shaped frame is mounted on the left portion of the top of a trolley plate of the trolley. A storing device is arranged in the n-shaped frame. A supporting leg is mounted on the right portion of the top of the trolley plate of the trolley. A transverse plate is mounted at the top of the supporting leg. A fixing device is arranged at the top of the transverse plate. According to the egg collecting and protecting devicefor poultry farming, the eggs are placed in the storing device, then the storing device fully filled with the eggs is placed in the fixing device, a pressing device is further arranged, thus the empty storing device can be pressed, and the effects that the eggs are not prone to breakage, and the collecting speed is high are achieved accordingly.

Owner:淮安市淮安区综合检验检测中心

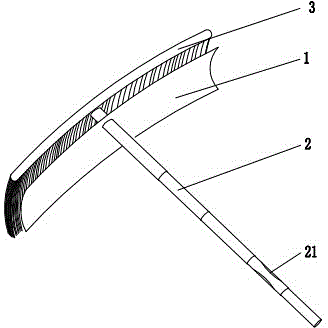

Rice collecting tool

The invention relates to a rice collecting tool which comprises a collecting plate and a connecting rod, wherein the connecting rod is connected with the collecting plate; a broom is connected to an extension end at the bottom of the connecting rod; the collecting plate is arc-shaped; the top part of the collecting plate concaves inwards; the connecting rod is a telescopic rod; a handheld groove is formed in the tail part of the connecting rod. The rice collecting tool is reasonable in structural design and convenient to operate and can save the labor; as the broom is connected with the extension end at the bottom of the connecting rod, when peasants collect rice, the rice is firstly piled in a central position through the collecting plate, secondly, the rice left after other rice is collected by using the collecting plate can be recollected by using the broom, then the rice can be completely collected at a time, the collection speed is fast, the effect is good, the situation that the rice is rained when being not collected in time can be avoided, and the loss can be reduced.

Owner:张子祥

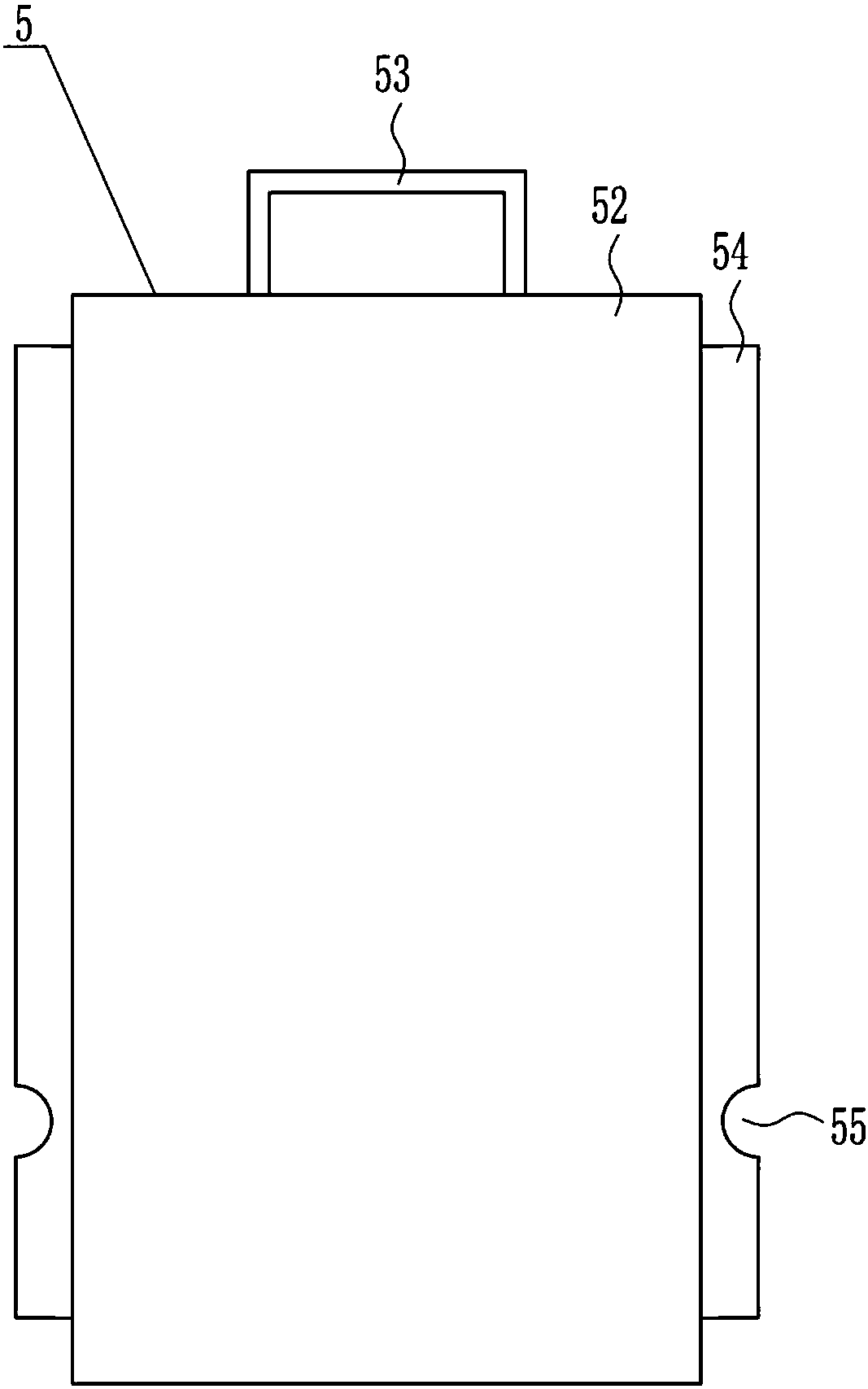

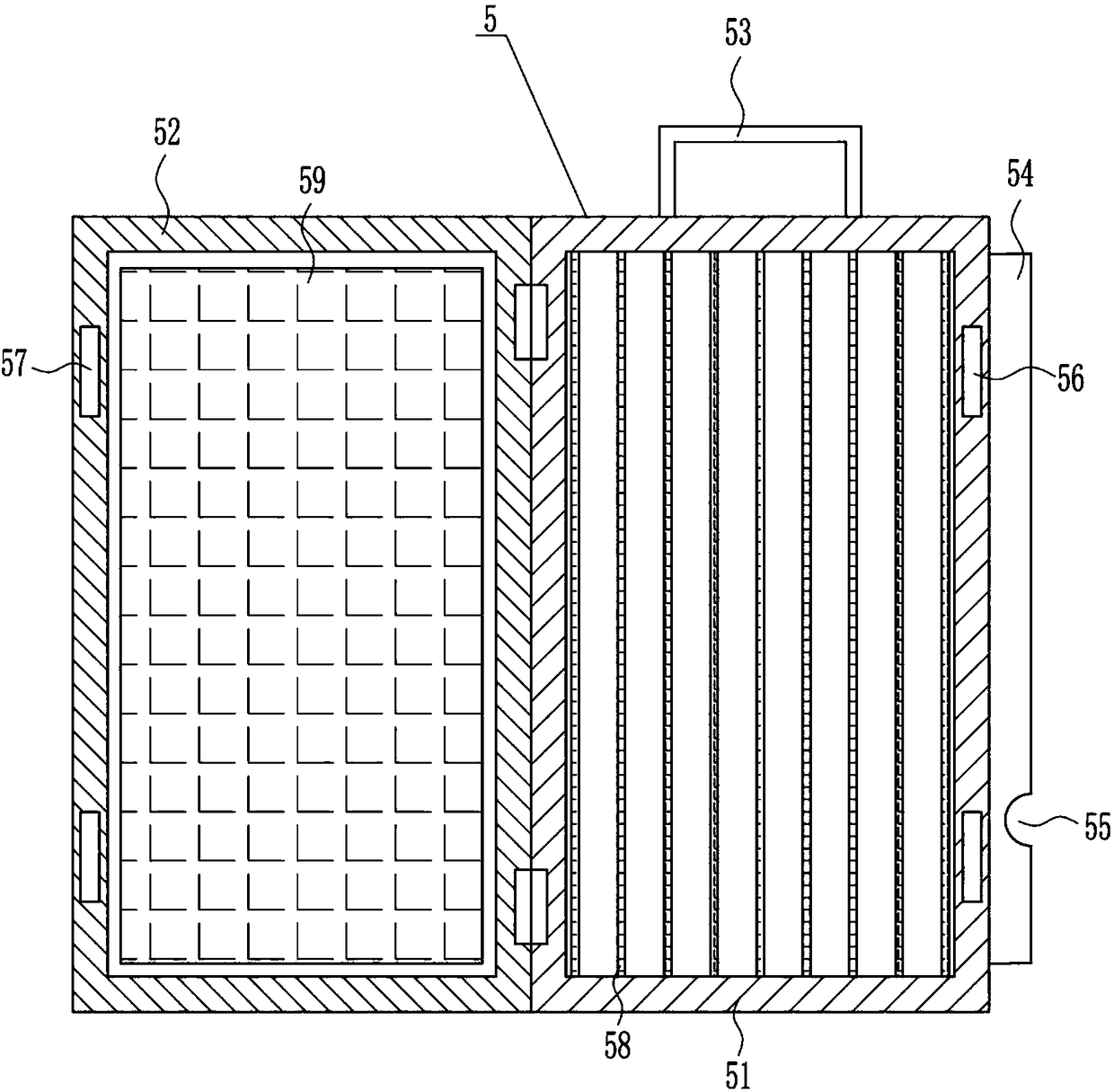

Grain collecting machine

A grain collecting machine, including a grain collecting barrel, a filter sieve divides the inner cavity of the grain collecting barrel into a negative pressure cavity and a grain collecting cavity, and a scraping mechanism driven by power reciprocates to clean the screen surface of the filter sieve; the suction mechanism is connected to the negative pressure cavity , and carry out negative pressure suction on the grain collection chamber through the filter screen; the front end of the grain collection chamber is connected to the suction nozzle, and the grain enters the grain collection chamber from the suction nozzle with the suction air flow, and the lower part of the grain collection chamber is sealed and connected to the spiral auger lifter Material inlet; the cover plate is movably connected to the outlet of the screw auger lifter, and is sealed by its own gravity. The technical scheme can eliminate the phenomenon that the impurities in the grain block the sieve holes, keep the airflow channel unobstructed from the beginning, the grain collection speed is fast, the efficiency is high, the power load is light, and the energy consumption is low.

Owner:胡克仁

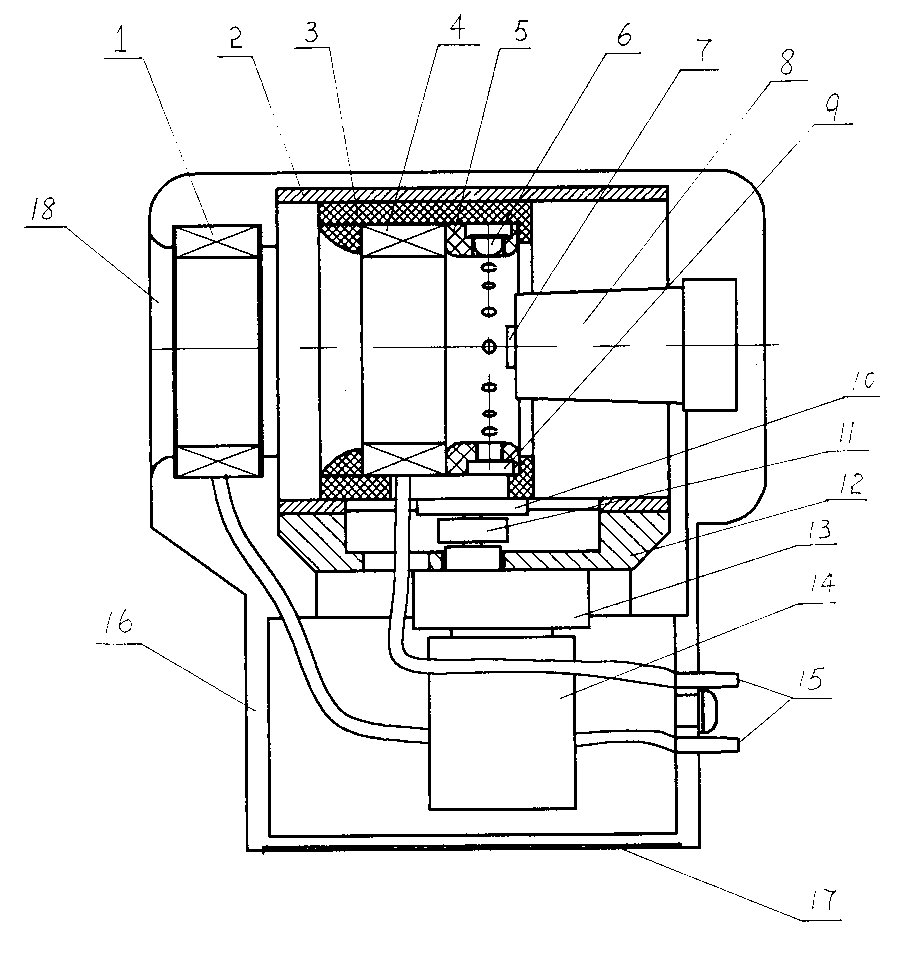

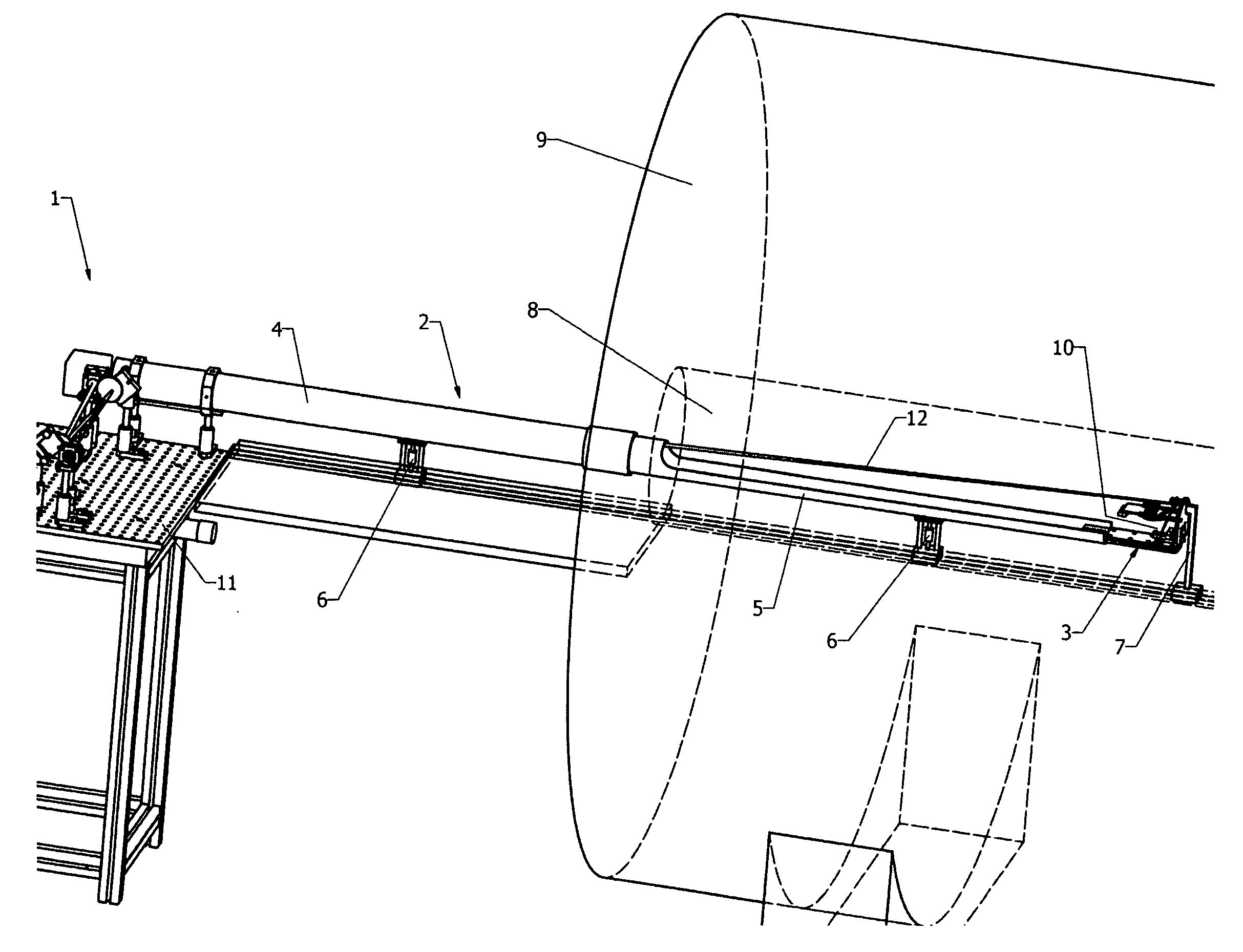

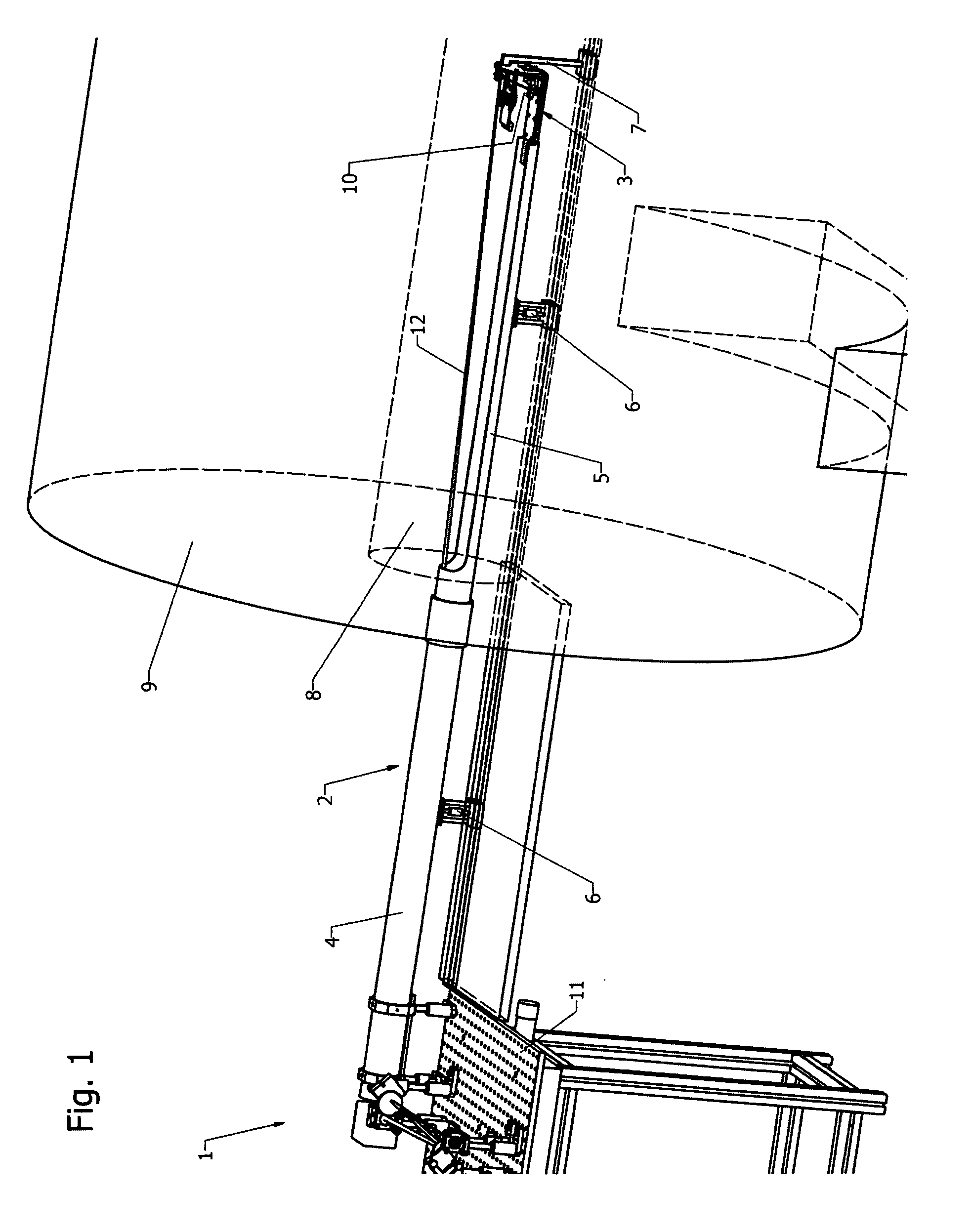

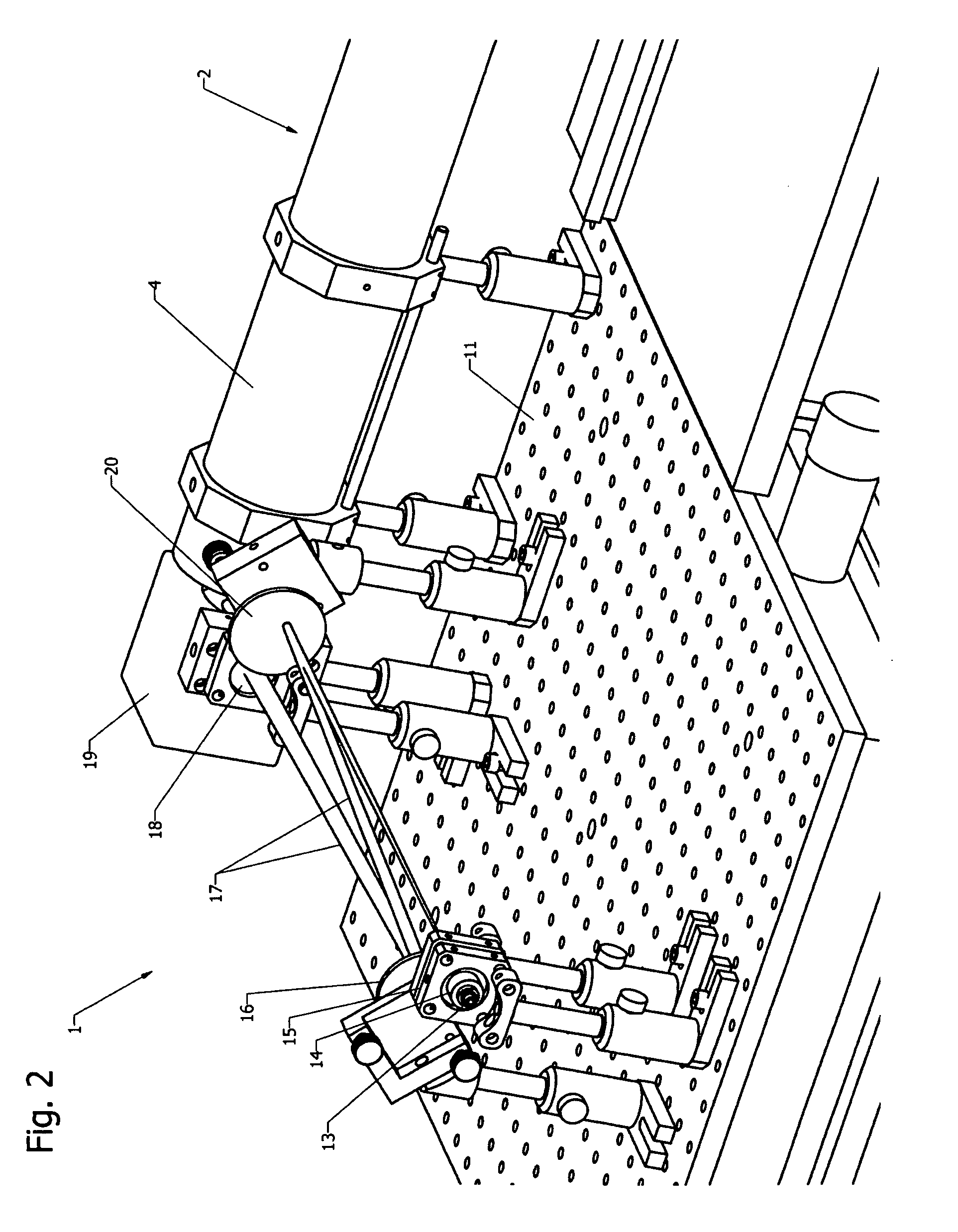

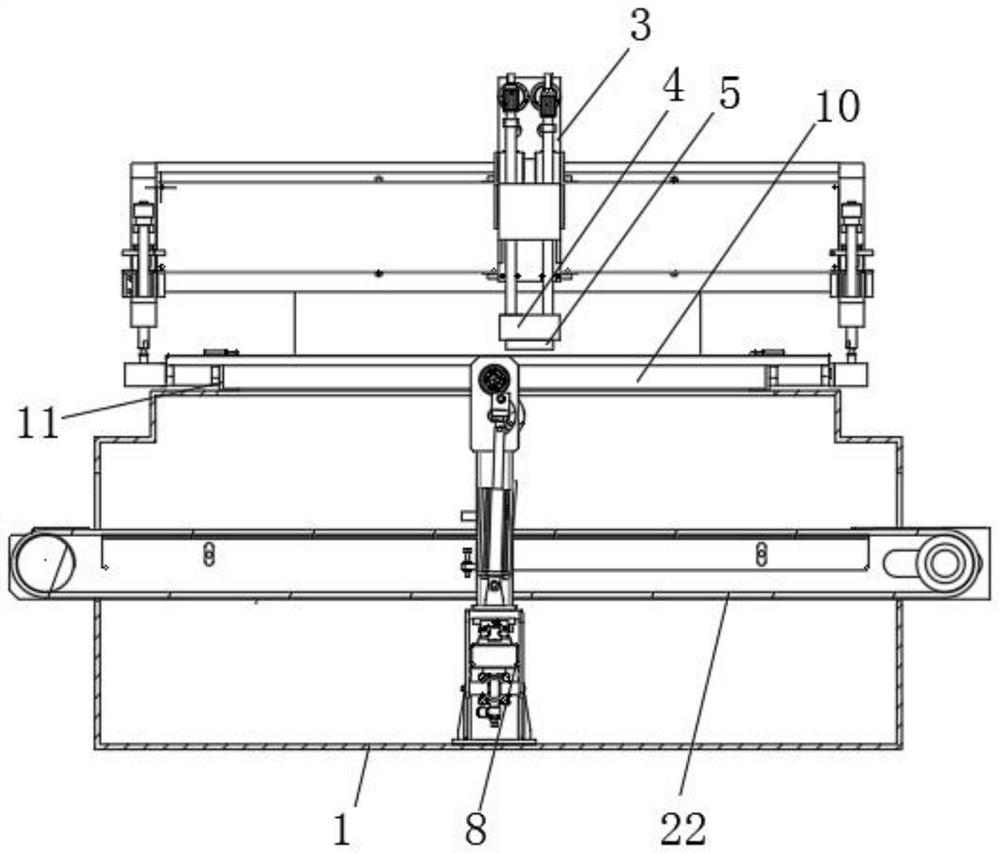

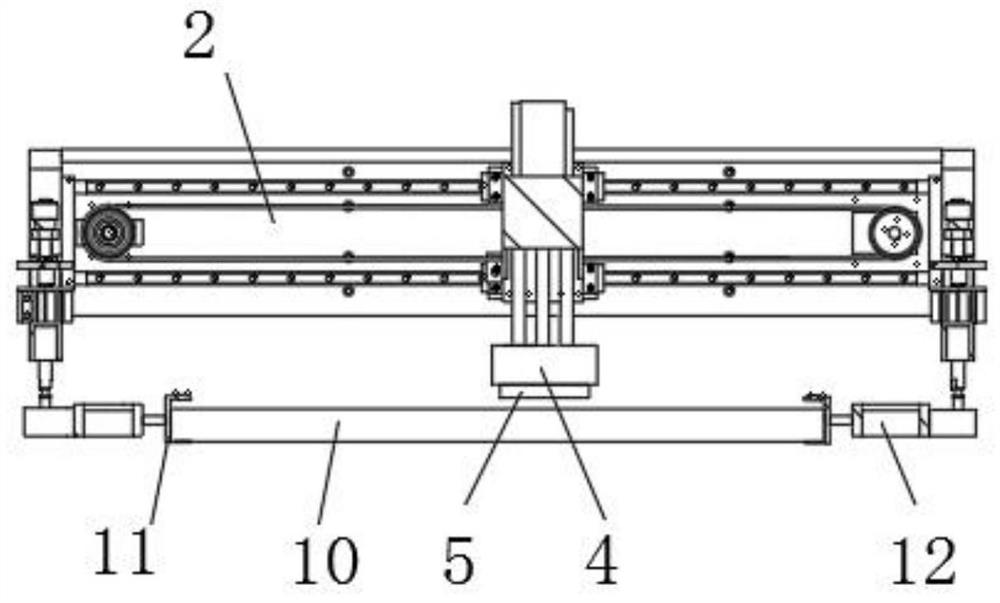

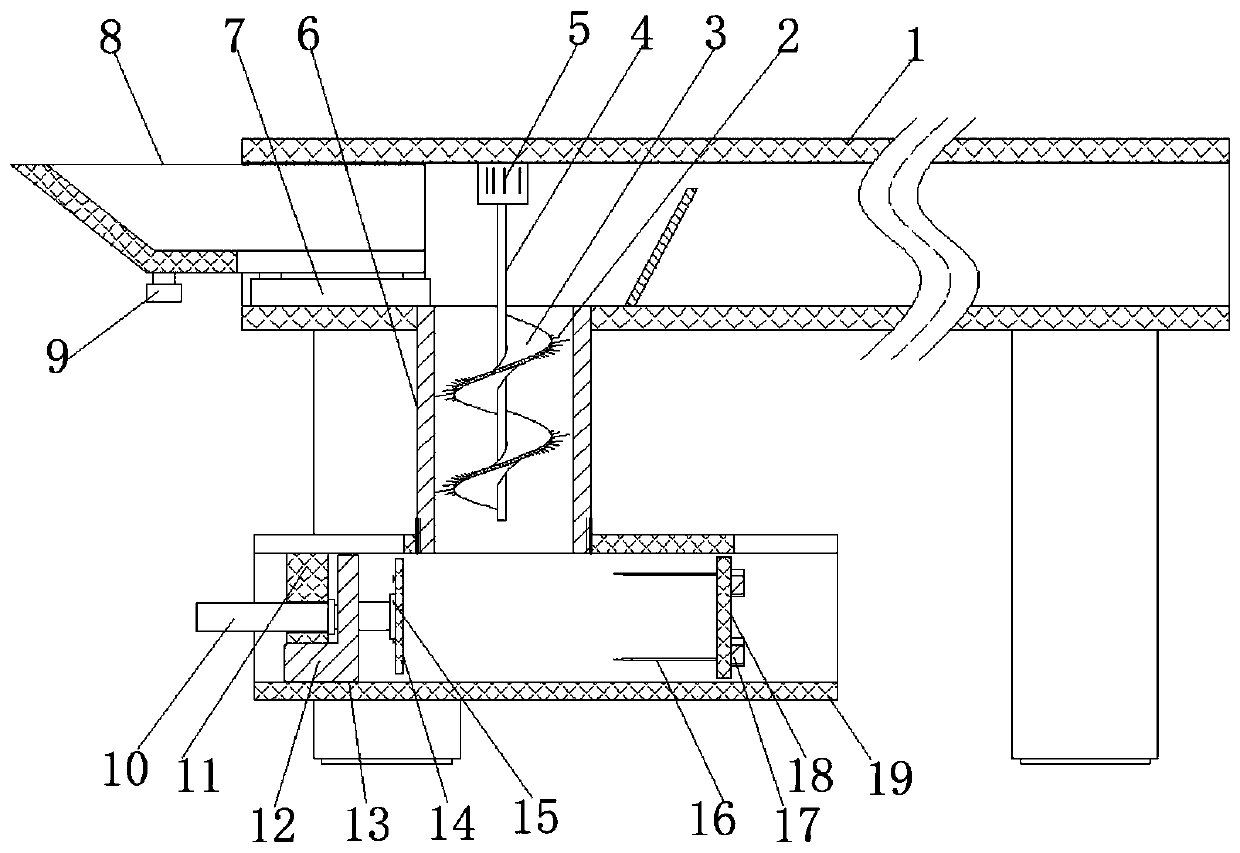

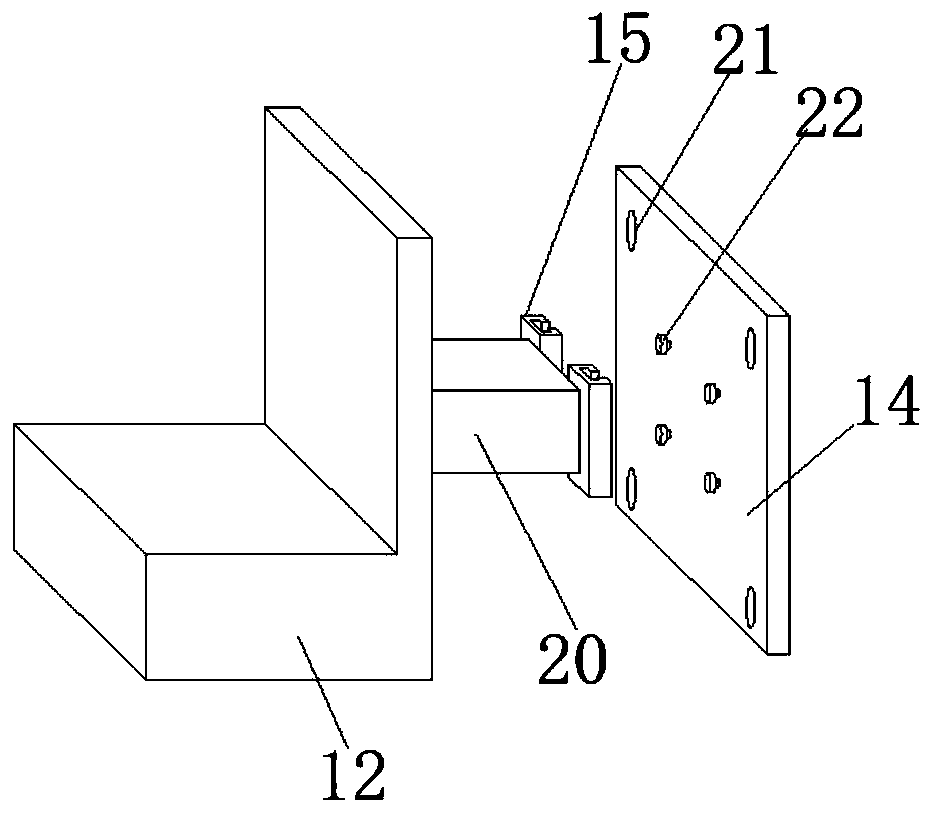

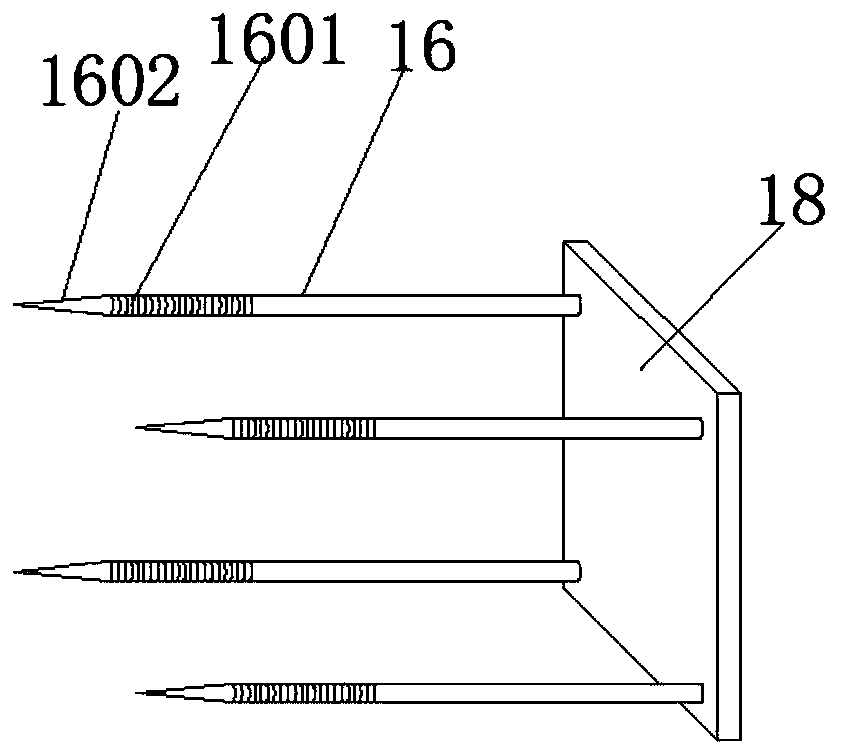

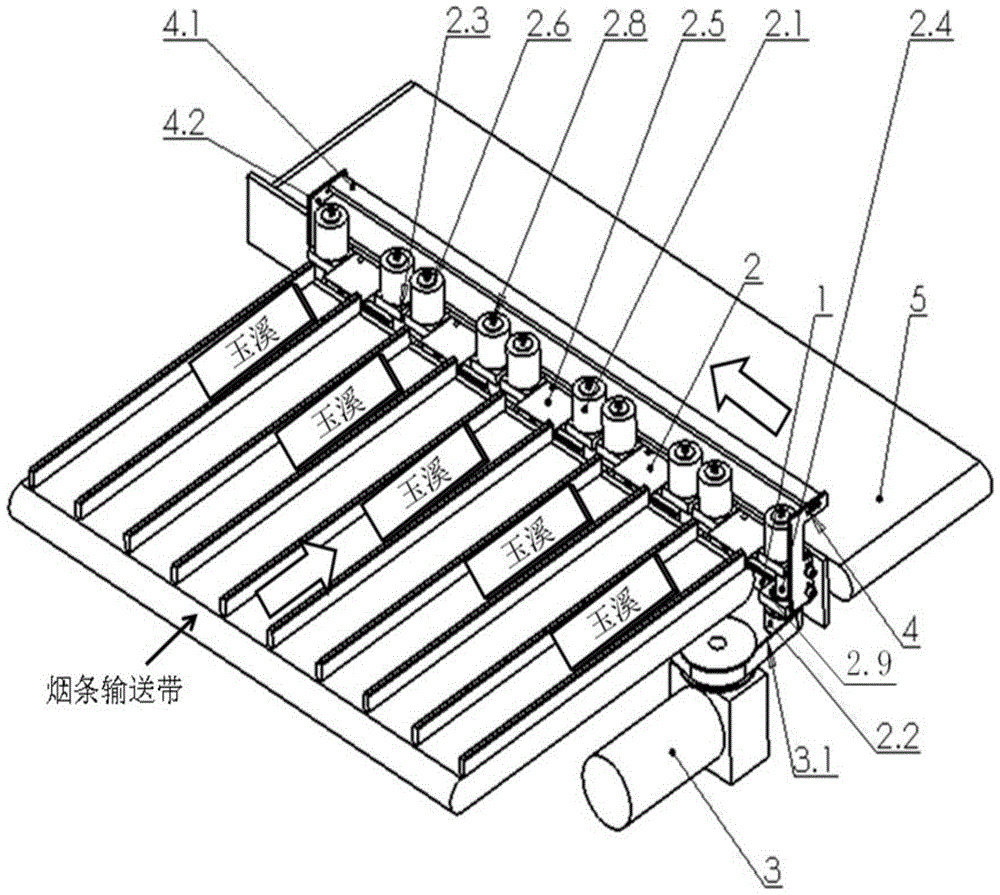

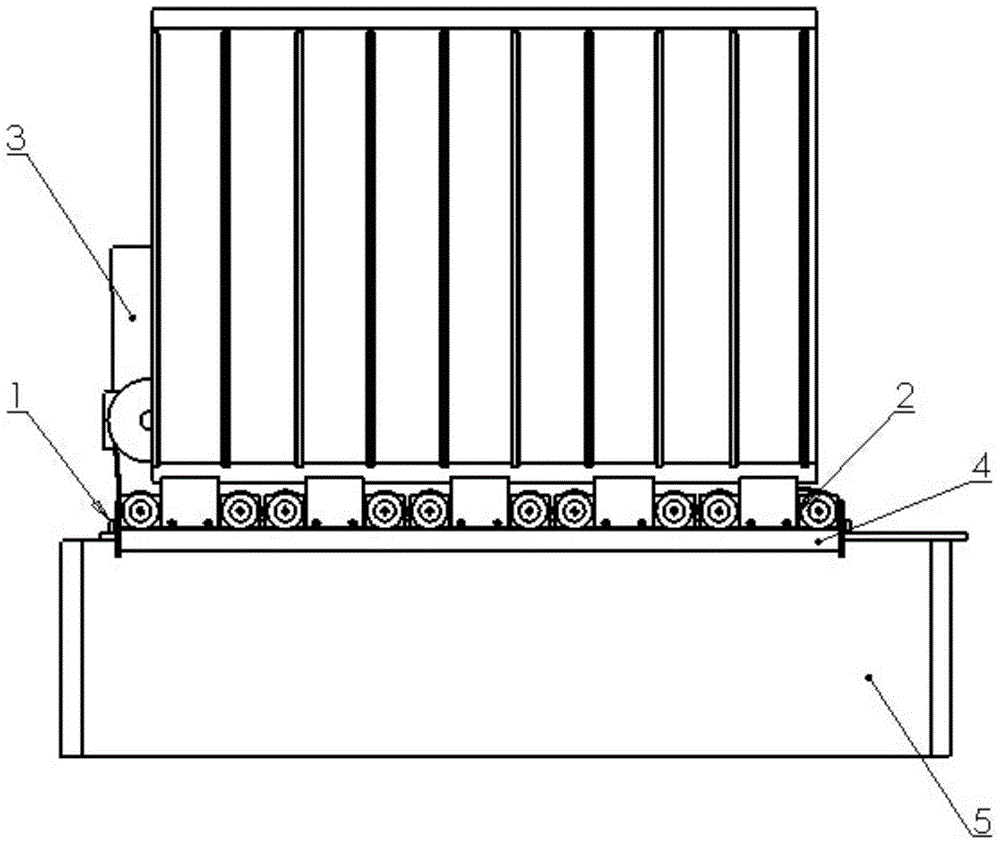

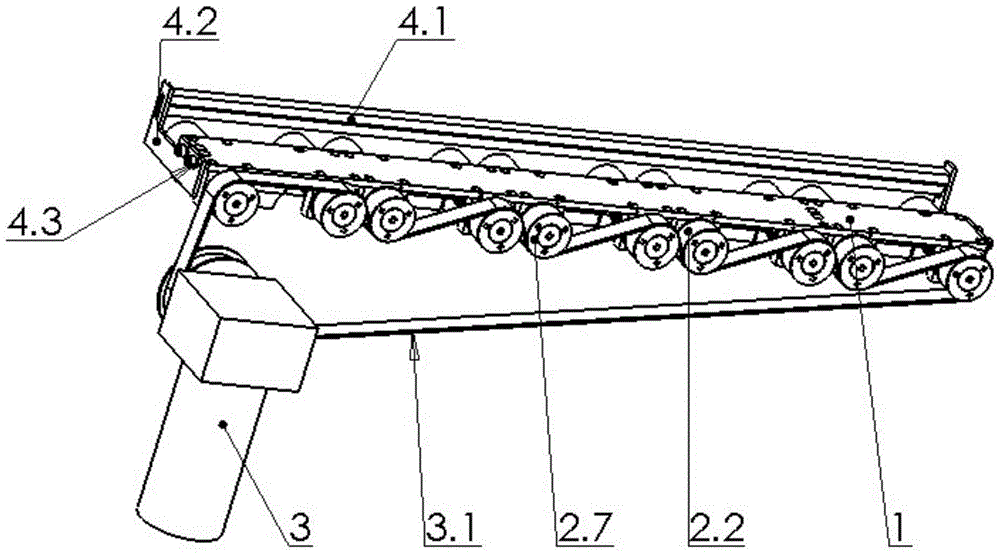

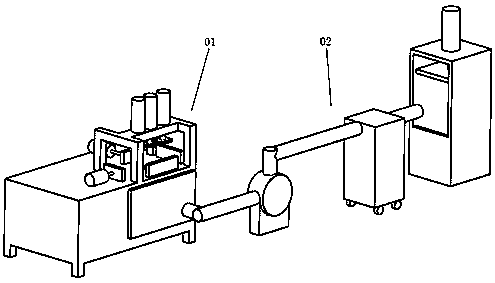

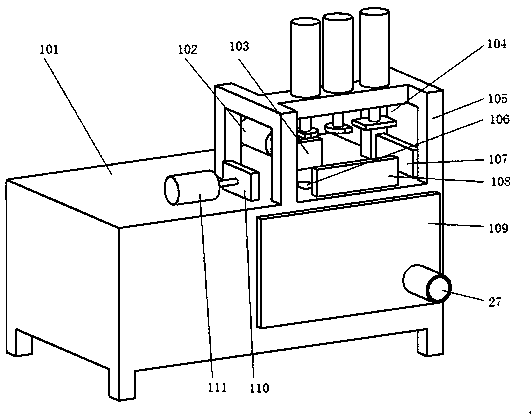

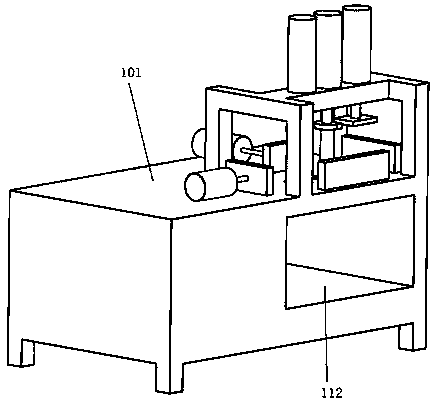

Perpendicular reversing device during cigarette carton transmission

The invention provides a perpendicular reversing device during cigarette carton transmission and relates to tobacco machinery, particularly to a device capable of reversing cigarette cartons in a 90-degree perpendicular manner and sealing the cigarette cartons in a case in a concentrating manner during the cigarette carton conveying process for wraparound production. The perpendicular reversing device is mounted at the inlet of a cartoning sealing machine and is composed of five systems namely a commutator rack, a commutator carton distribution device, a driving device, a buffer device and a cigarette carton outlet conveyer belt. The commutator rack is mounted at the outlet of the cigarette carton outlet conveyer belt; the commutator carton distribution device is mounted on the commutator rack and comprises carton distribution wheels, driven pulleys, and carton distribution wheel shafts vertically arranged; the driving device is connected with the driven pulleys; the buffer device is mounted at the end parts of two narrow sides of the commutator rack; the cigarette carton outlet conveyer belt is mounted at the rear of the commutator rack. The perpendicular reversing device cooperates with an upstream carton arrangement machine, and cigarette cartons in order are sent into the perpendicular reversing device to complete 90-degree reversing of the cigarette cartons through perpendicular slideways. The perpendicular reversing device reverses cigarette cartons in a pure mechanical drive manner and continuously moves, and is simple in structure, low in cost, and convenient to repair.

Owner:HONGTA TOBACCO GRP

Wallpaper winding device

The invention discloses a wallpaper winding device comprising a motor and a shaft coupler. The wallpaper winding device is characterized by further comprising a drive shaft and a winding drum, wherein one end of the drive shaft is connected with the output shaft of the motor via a shaft coupler; the winding drum is sleeved on the drive shaft; and two detachable limit blocks are arranged on the drive shaft and outside the winding drum. A driven shaft is arranged at a front position above the drive shaft; and stop blocks are arranged at the both ends of the driven shaft. The winding drum is made of a metal material or a plastic material. The wallpaper winding device disclosed by the invention can be used for solving the problems of slow collection speed, low efficiency, high manpower cost consumption and high possibility of wallpaper damage during collection in manual collection, and is simple in structure, convenient in use, low in cost and capable of rapidly collecting wallpaper without damage.

Owner:WUJIANG WALLMATE DECORATION MATERIALS

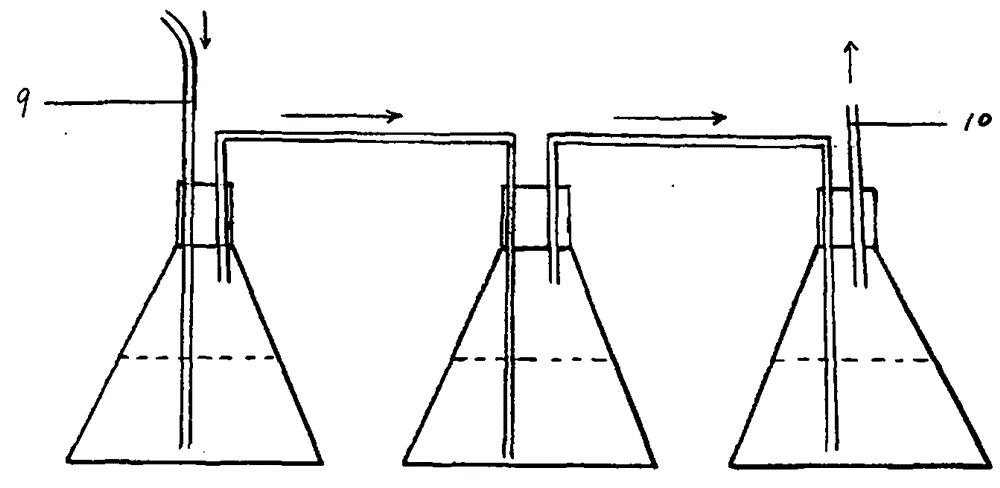

Bubble evenly mixing apparatus

InactiveCN108414338AAchieve mixingTo achieve the purpose of waste liquid collectionPreparing sample for investigationElectromagnetic valveReagent

The invention discloses a bubble evenly mixing apparatus, which comprises a reaction tank, a first electromagnetic valve, an air source, a firs connection device, a waste liquid collection device, anda controller. The reaction tank is communicated with the common port of the first electromagnetic valve through the first connection device. The air source is communicated with the normally open endof the first electromagnetic valve. The waste liquid collection device is communicated with the normally closed end of the first electromagnetic valve. The first electromagnetic valve, the air source,and the waste liquid collection device are all connected to the controller. The air source supplies air to the reaction tank to form bubbles. The bubbles rise in the reaction tank, thus reagents in the reaction tank are evenly stirred; moreover, by switching, opening, or closing the first electromagnetic valve, the bubble mixing function and waste liquid collection function are switched; throughsimple operation, reagents are evenly mixed, waste liquid is collected; the structure is simple, the cost is low, and the mixing speed and waste liquid collection speed are quick.

Owner:DIRUI MEDICAL TECH CO LTD

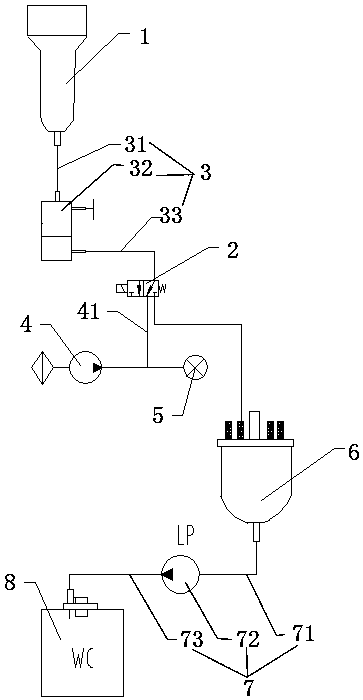

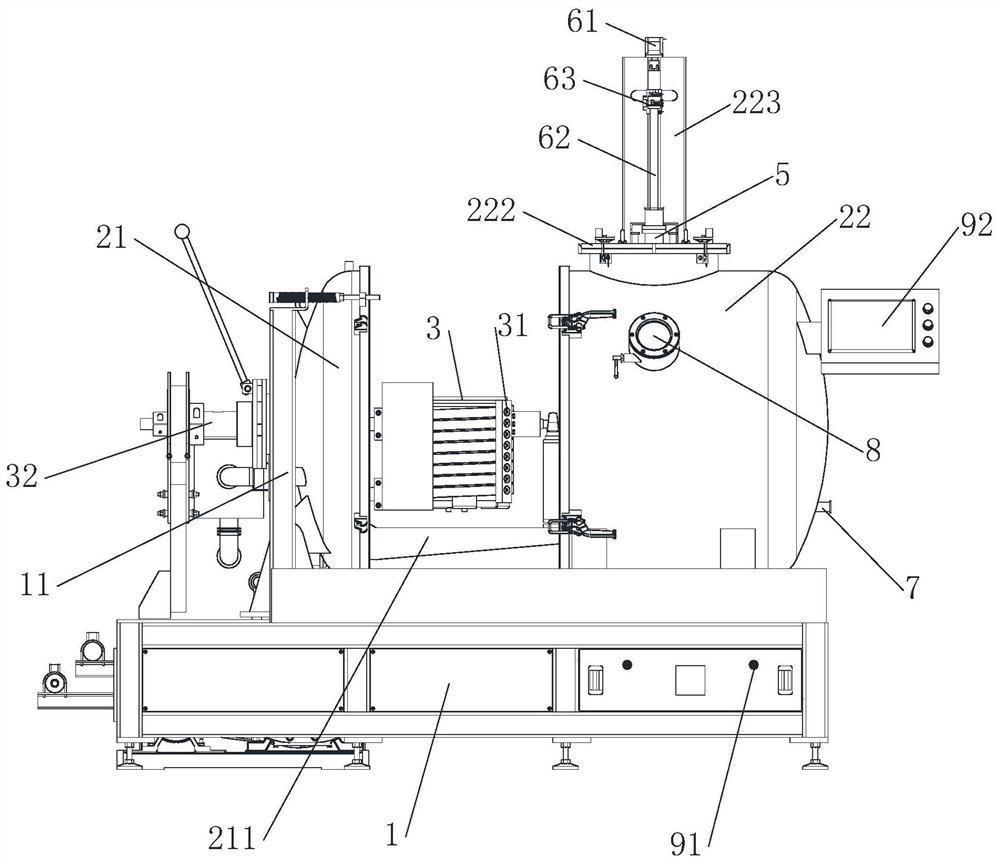

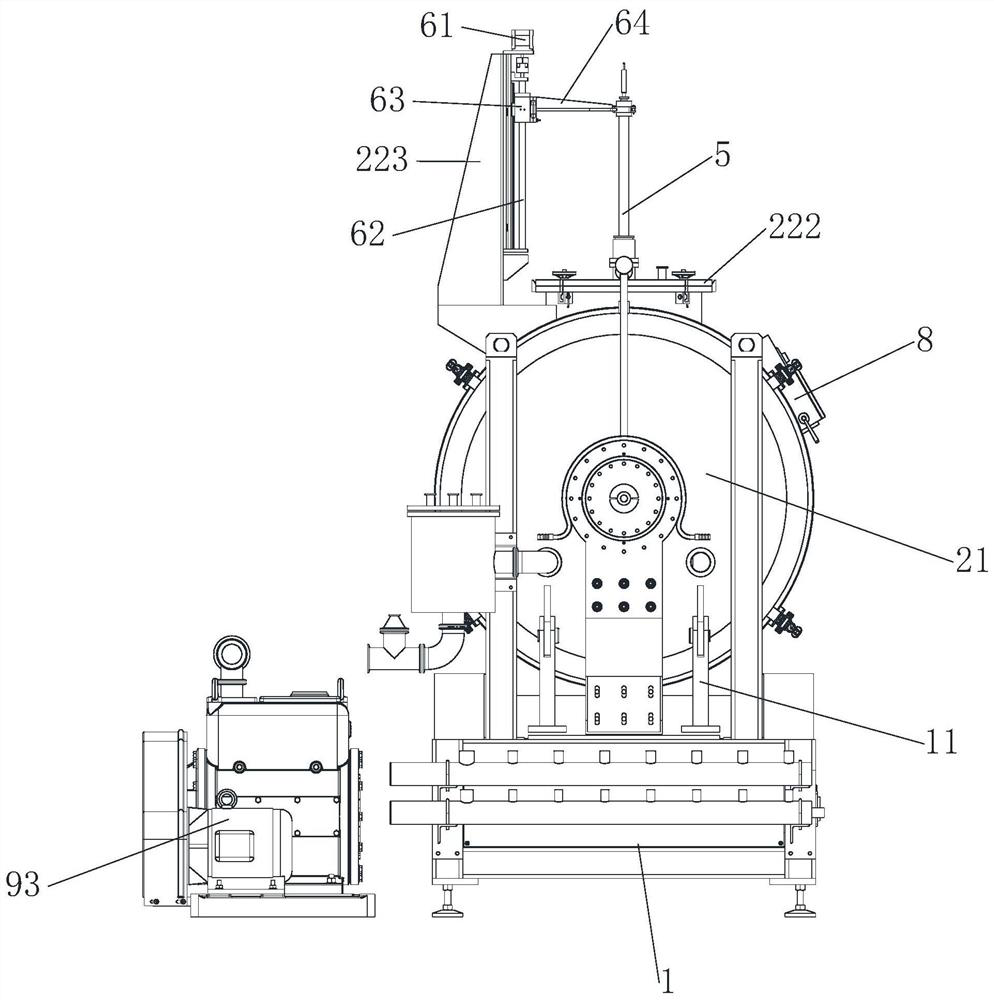

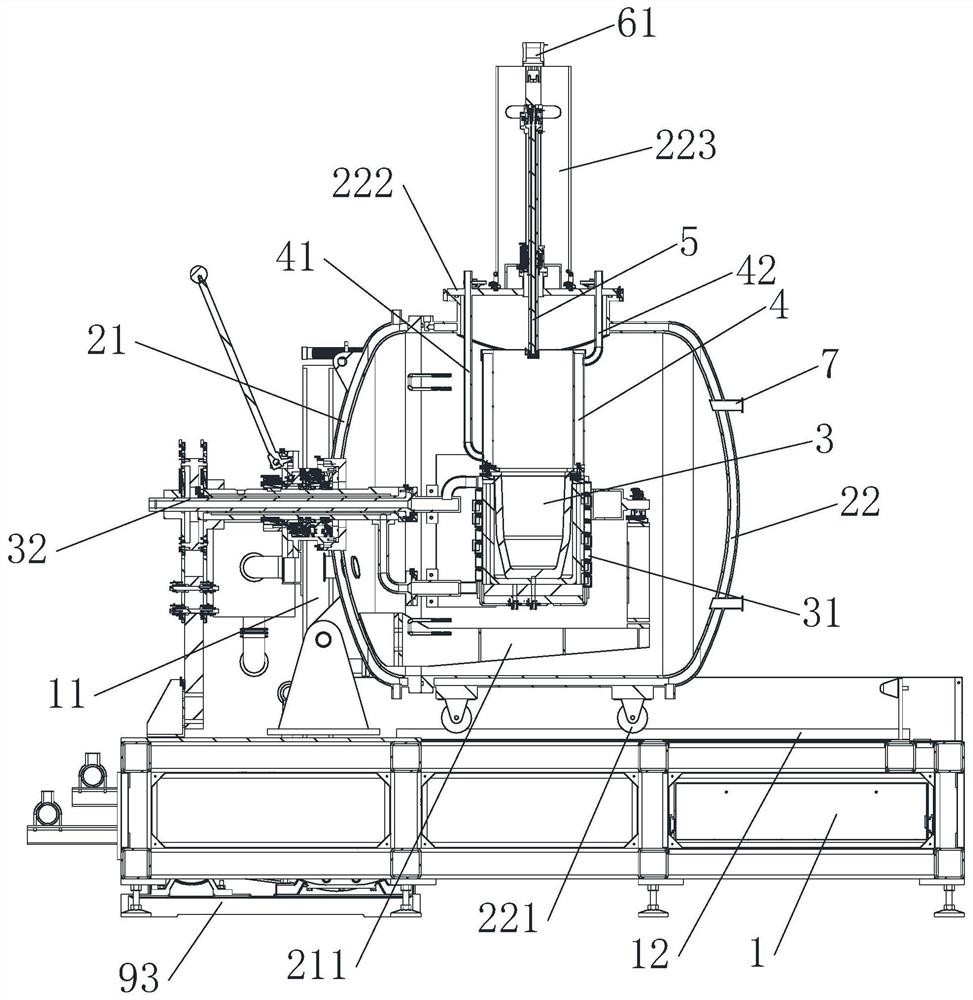

Vacuum induction distillation furnace

InactiveCN111928652AFast collectionGood collection effectIncreasing energy efficiencyCrucible furnacesVacuum furnaceElectrical control

The invention relates to the technical field of distillation furnaces, in particular to a vacuum induction distillation furnace. The furnace comprises a base and a furnace body, the furnace body is arranged on the base, a crucible and a condensation cover are arranged in the furnace body, the condensation cover covers the open end of the crucible, the furnace body is a vacuum furnace, a high-frequency induction coil is arranged around the crucible, the high-frequency induction coil is connected with an electrode interface extending out of the furnace body, the condensation cover adopts a watercooling mode, a thermocouple is arranged on the condensation cover, one end of the thermocouple extends into the condensation cover and is connected with the condensation cover, the other end of thethermocouple extends out of the furnace body and is connected with the furnace body, the furnace body comprises a furnace cover and a furnace stack, the furnace stack is in sliding fit with the base,the furnace cover is fixedly connected to the base, the crucible is connected with the furnace cover, the condensation cover is connected with the furnace stack, a control part is arranged on the base, the control part adopts a mode of combining PLC control, operation buttons and an operation interface, and an electric control box is arranged on one side of the base. According to the furnace, by arranging the crucible subject to induction heating by the high-frequency coil, the furnace cover capable of being opened in a sliding mode and the condensation cover capable of being lifted, the separation and purification on rare metal are achieved in a vacuum environment, and the purification effect is good.

Owner:河南酷斯特仪器科技有限公司

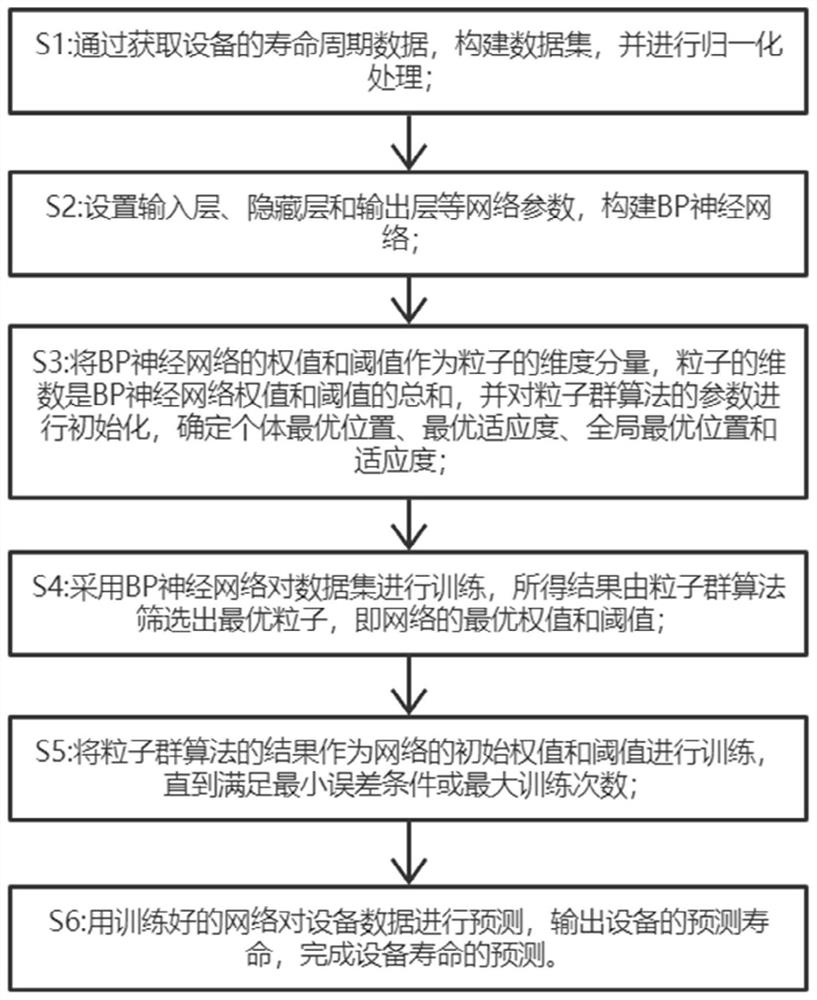

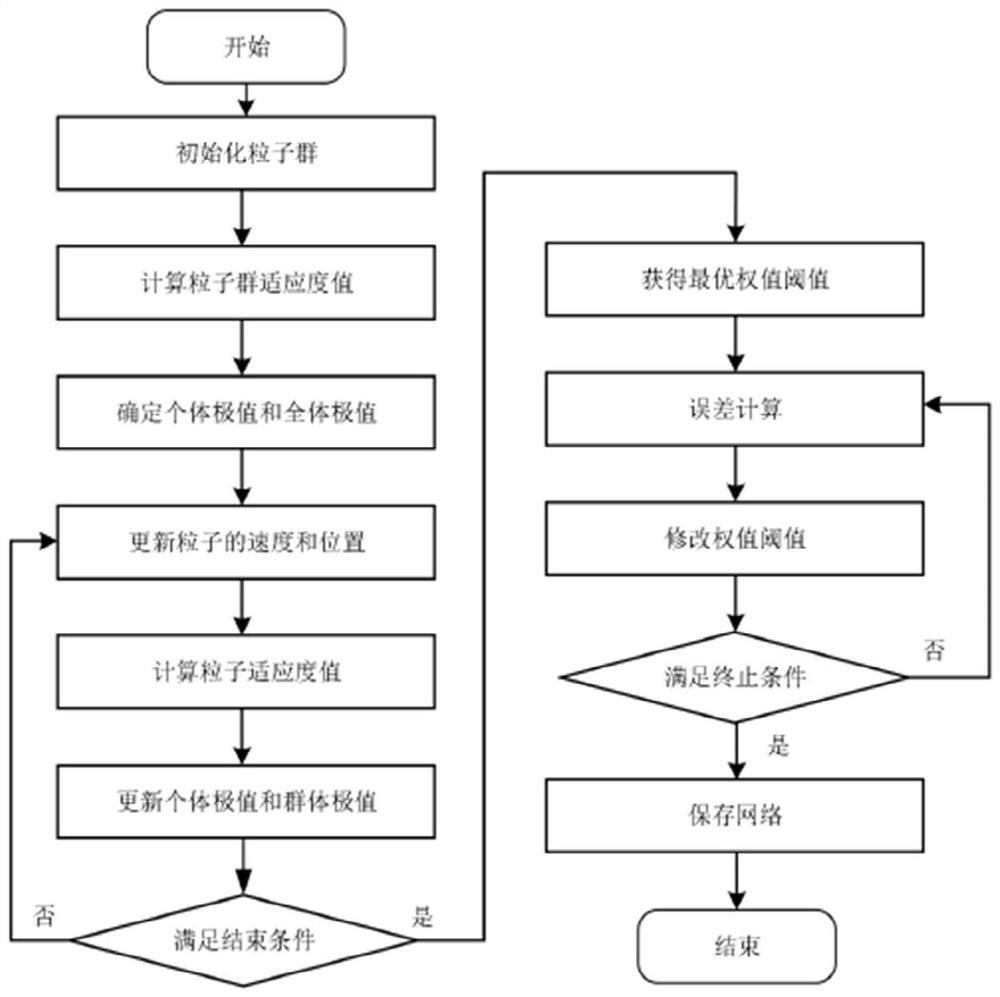

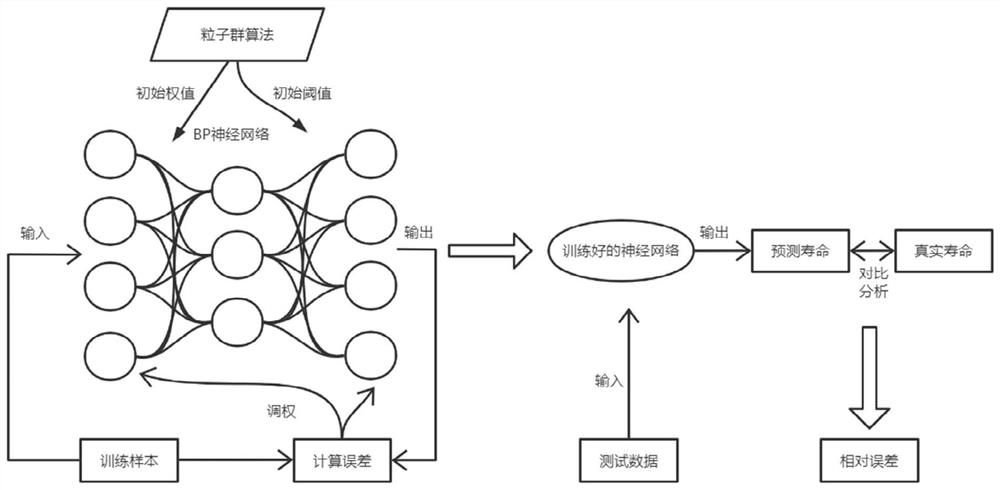

Equipment lifetime prediction method and system based on PSO-BP neural network

PendingCN113743011AOptimize nonlinear mapping capabilitiesStrong non-linear mapping abilityArtificial lifeDesign optimisation/simulationData setSimulation

The invention discloses an equipment lifetime prediction method and system based on a PSO-BP neural network, and belongs to equipment lifetime prediction. The method comprises the following steps: 1) constructing a data set by acquiring lifetime cycle data of equipment, and performing normalization processing; 2) constructing a BP neural network; 3) taking the weight and the threshold of the BP neural network as dimension components of particles, initializing parameters of a particle swarm algorithm, and determining an individual optimal position, an optimal fitness, a global optimal position and a fitness; 4) training the data set by adopting the BP neural network, and screening out optimal particles, namely the optimal weight and threshold value of the network, from an obtained result through the particle swarm algorithm; 5) taking the result of the particle swarm algorithm as an initial weight and a threshold value of the network for training until a minimum error condition or a maximum training frequency is met; and 6) predicting equipment data by using the trained network, and outputting the predicted service lifetime of the equipment. Compared with other technologies, the method has the advantage that the service lifetime of the equipment can be quickly and accurately predicted.

Owner:HUAZHONG UNIV OF SCI & TECH +1

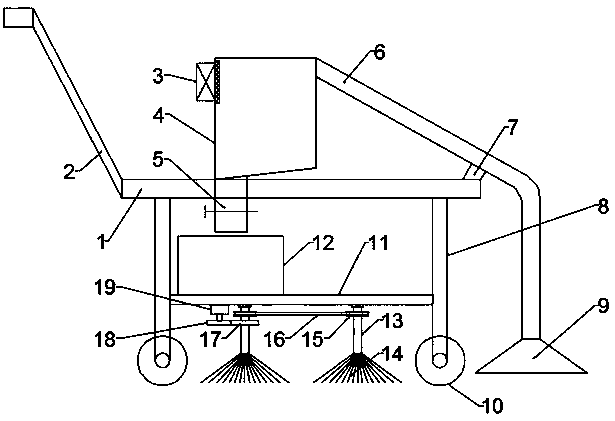

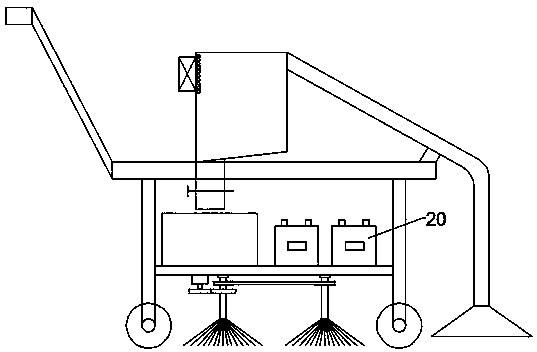

Particulate matter collection equipment for detecting air of factory

ActiveCN108801717AFlexible moving processClean up thoroughlyWithdrawing sample devicesParticulatesEngineering

The invention relates to collection equipment and in particular relates to particulate matter collection equipment for detecting the air of a factory. Therefore, aiming at solving the technical problems, the invention provides the particulate matter collection equipment for detecting the air of the factory, which is relatively simple to operate, has a relatively high collection speed and has relatively long equipment service life. According to the technical scheme, the particulate matter collection equipment for detecting the air of the factory comprises a cart, a bracket, a mounting rod, a column-shaped frame, a mounting plate, a motor, a rotary shaft, a gear, an annular sliding rail, an annular sliding block, an outer tooth ring, an L-shaped rod, a blade and the like; the bracket is arranged at the left part of the upper side of a vehicle plate of the cart; the mounting rod is connected with the top of the bracket; the column-shaped frame is mounted at the right side of the mountingrod; the mounting plate is arranged at the upper part of the right side of the bracket. The particulate matter collection equipment for detecting the air of the factory, provided by the invention, hasthe effects of relatively simple operation, relatively high collection speed and relatively long equipment service life. The blade is arranged so that particulate matters in the air can be relativelyrapidly collected when the blade rotates, and the relatively high collection speed is realized.

Owner:SHANDONG IRON & STEEL GRP YONGFENG LINGANG CO LTD

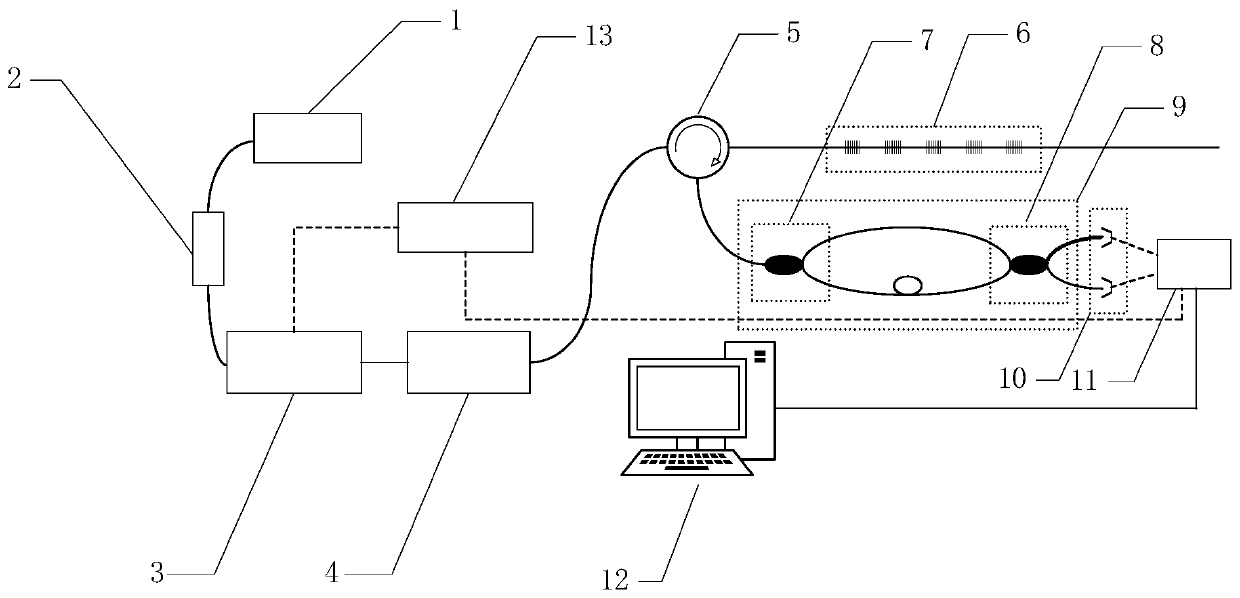

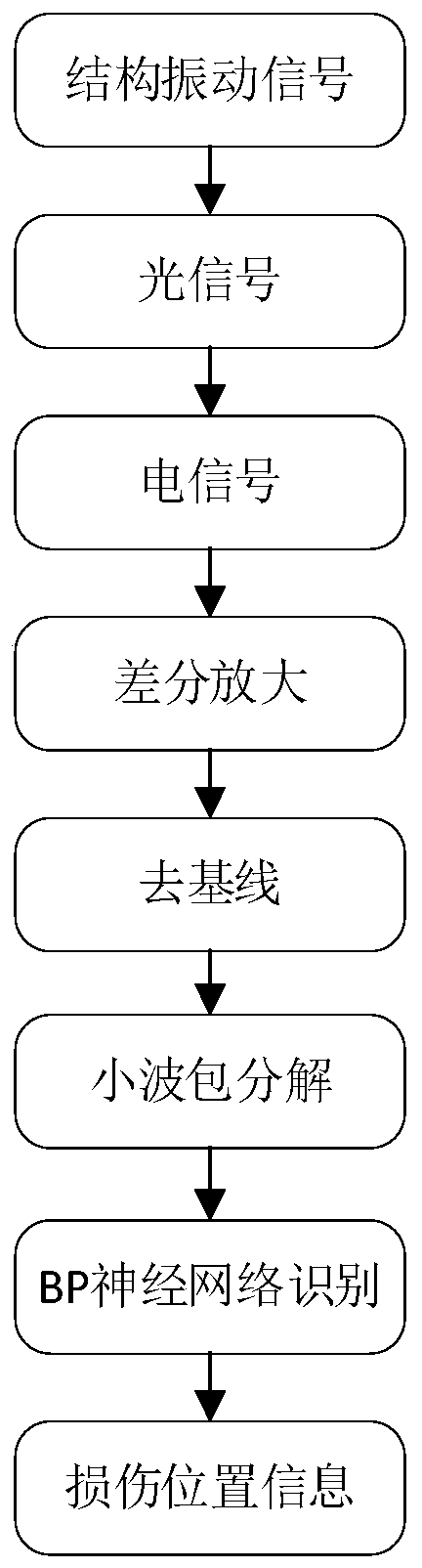

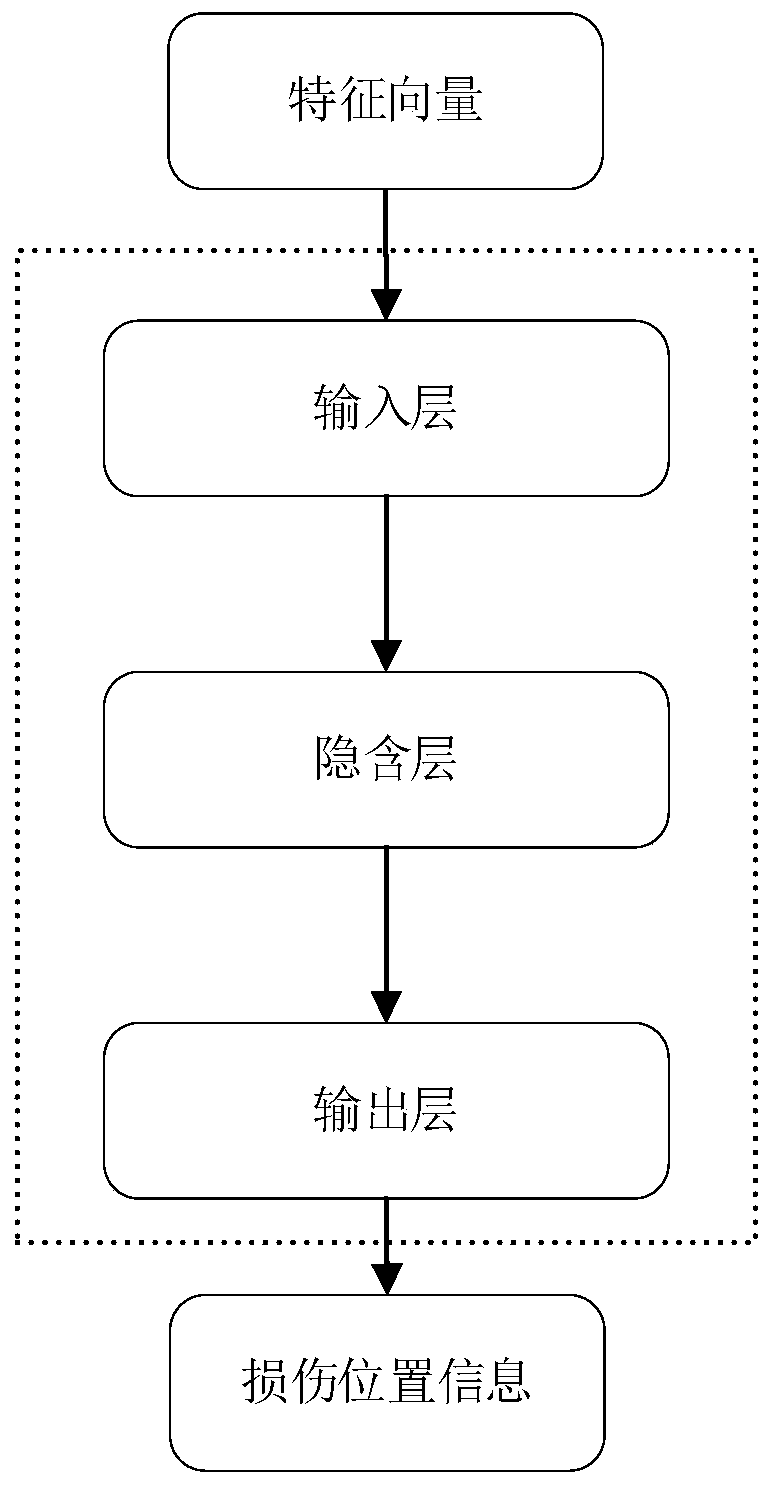

Single fiber grating and neural network based structural damage position identification system

ActiveCN110412038AReduce complexityFast collectionCharacter and pattern recognitionOptically investigating flaws/contaminationGratingErbium doping

The invention discloses a single fiber grating and neural network based structural damage position identification system which comprises a broadband light source, a fiber isolator, a tunable F-P filter, an erbium-doped fiber amplifier, a fiber circulator, a fiber grating sensing array, an unbalanced M-Z interferometer, a photoelectric detector array, a data collection card, a data processing unitand a signal generation module. One fiber grating sensor in the fiber grating sensing array is mounted in each structure area to be detected, is used to collect a vibration response signal under excitation of an active signal of the structure; and a wavelet decomposition technology is used to decompose the collected signal to obtain a characteristic vector including damage position information, the characteristic vector is input to the neural network for training, and the structural damage position can be identified accurately via the trained neural network. The system cost and the sensor network complexity are reduced, and the correct identification rate can reach 96%.

Owner:TIANJIN UNIV

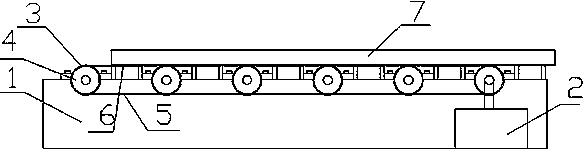

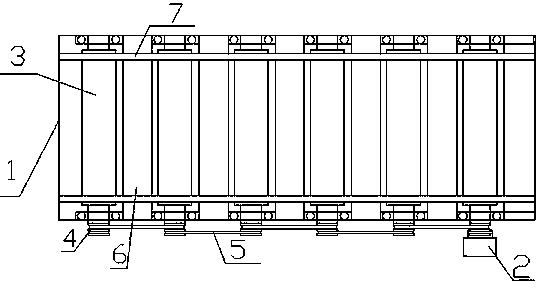

Steel plate cutting discharging and collecting device

InactiveCN103625831AReduce labor intensityEasy to makeRoller-waysEngineeringUltimate tensile strength

The invention discloses a steel plate cutting discharging and collecting device which comprises a platform and a cutting machine. The cutting machine is fixed to the platform, a feed device is arranged below the platform and comprises collecting frames, a motor and a chain, the collecting frames arranged in parallel are fixedly arranged below the platform, transmission rods are arranged on the left side and the right side of each collecting frame respectively, the motor is connected with a transmission gear on one transmission rod, the chain passes through each collecting frame, and the two ends of the chain are connected with the corresponding gears respectively. The steel plate cutting discharging and collecting device has the advantages that design is reasonable, cut steel plates are directly conveyed to a collecting position, the number of the conveyed steel plates is large, work efficiency is improved, and the labor intensity of work personnel is reduced.

Owner:JIANGSU HONGCHENG STAINLESS STEEL PROD

Earthworm trapping agent and preparation method and applications thereof

InactiveCN107373101AImprove physiological activityStrong attractionAnimal feeding stuffAccessory food factorsTrappingSugar

The invention discloses an earthworm trapping agent and a preparation method and applications thereof, and belongs to the technical field of earthworm collection. The earthworm trapping agent comprises the following components in percentage by weight: 77 to 81% of water, 0.75 to 0.95% of vinegar, 7 to 9% of sugar, 0.1 to 0.2% of fruit essence, and 11 to 13% of flour. The preparation method comprises a step of dissolving vinegar, sugar, fruit essence and flour into water. The preparation method is simple, and the earthworm trapping agent has a strong trapping effect on earthworm. The earthworm trapping agent is sprayed on an earthworm bait so as to trap earthworms, the trapping operation is simple, a large amount of earthworms can be trapped in a short time, the trapping speed is quick, the amount of trapped earthworms is large, and time and labor are saved.

Owner:黔东南苗族侗族自治州农业科学院

Ping-pong collection equipment

Owner:刘洋

Apparatus to remove and collect waste papers of cup packing boxes

PendingCN107775713ASimple structureAutomatic removalMetal working apparatusPressesProcess engineeringWaste paper

The invention discloses an apparatus to remove and collect waste papers of cup packing boxes, comprising an automatic removal device and an automatic collection device. The apparatus is simple in structure, multiple indented packing papers are stacked on a frame and positioned via a front retainer and a rear retainer and are clamped via a clamping device, a hold-down device then holds down the waste papers above through hole A, through hole B and through hole C into a collection trough, waste papers of thermos cup packing boxes are automatically removed, and production efficiency is improved accordingly; the through hole A, the through hole B and the through hole C are communicated with the collection trough below, the waste papers held down drop into the collection trough, and recycling is facilitated accordingly; the waste papers are fed into a briquetting machine via a suction fan and are compressed by the briquetting machine, automatic collection and briquetting of waste papers isachieved, and labor intensity of workers is reduced; collection speed is high, and production efficiency is improved accordingly.

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com