Peanut vine-pod collector

A technology for collectors and peanut seedlings, applied in applications, loaders, agricultural machinery and tools, etc., can solve the problems of fruit drop and poor discharge of peanut seedlings, etc., and achieve low loss of peanut fruit drop, fast collection speed, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

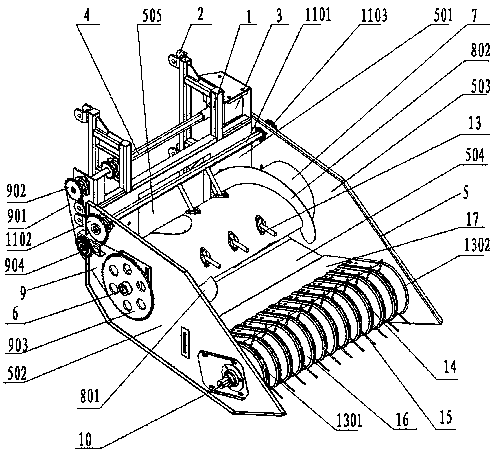

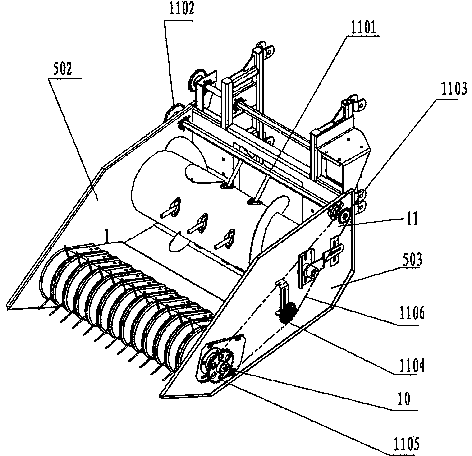

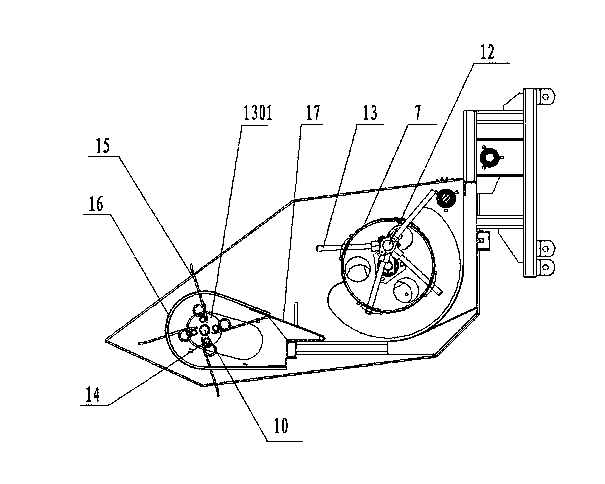

[0019] Such as figure 1 Shown, a kind of peanut seedling fruit collector, it comprises a mounting frame 1, is fixed with connector 2 at the rear end of this mounting frame 1, fixes a transmission box 3 on the mounting frame, on the output end of this transmission box A power take-off shaft 4 is assembled.

[0020] The transmission box 3 is provided with a transmission member connected to the power output shaft 4 . According to the transmission position of the power input and output, the transmission part is selected from conventional spur gears or bevel gears or other common transmission parts. In this embodiment, because the power output will realize the reversing transmission, the bevel gear is selected (the structure is not shown in the figure).

[0021] exist figure 1 Among them, a collecting shovel 5 is fixed at the front end of the installation frame 1 .

[0022] Such as figure 1 As shown, the collection shovel 5 is composed of a rear side plate 501, a first side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com