Grain collecting machine

A technology for collecting machines and grains, which is applied in the field of packaging equipment and material collection. It can solve problems such as clogged screen holes, and achieve the effects of strong airflow, fast grain collection, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the specific implementation manners of the present invention will be further described in conjunction with the accompanying drawings.

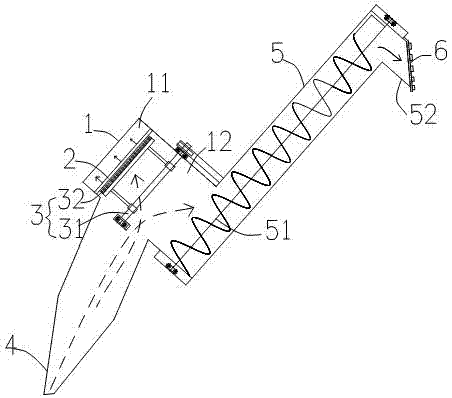

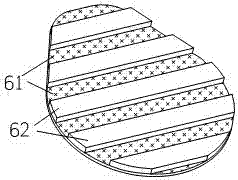

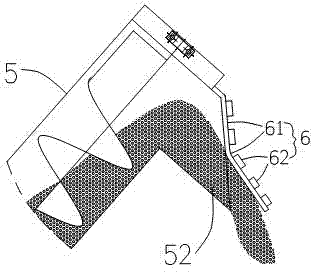

[0017] figure 1 It shows the embodiment of the first grain collector, which includes a grain collection bucket 1, and a filter screen 2 separates the inner cavity of the grain collection bucket 1 into a negative pressure chamber 11 and a grain collection chamber 12, and the scraping mechanism 3 driven by power reciprocates for cleaning The screen surface of the filter screen 2; the suction mechanism is connected to the negative pressure chamber 11, and carries out negative pressure suction on the grain collection chamber 12 through the filter screen 2; The nozzle 4 enters the grain collecting chamber 12, and the lower part of the grain collecting chamber 12 is airtightly connected to the feed port 51 of the screw auger lifter 5; Seal the discharge port 52.

[0018] After the suction mechanism is activated, a negative pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com