Apparatus to remove and collect waste papers of cup packing boxes

A collection device and packaging box technology, applied in metal processing, presses, manufacturing tools, etc., can solve the problems of low production efficiency, time-consuming and labor-consuming waste paper, and slow speed, so as to achieve fast collection speed and reduce labor load , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

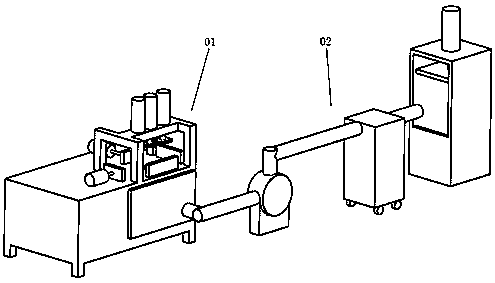

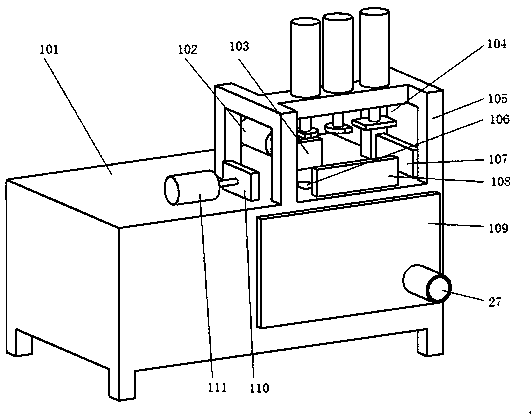

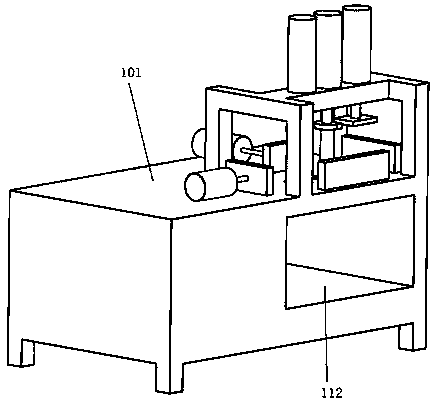

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 as well as Figure 7 As shown, the present invention includes an automatic removal device 01 and an automatic collection device 02, the automatic removal device 01 includes a frame 101, and the top surface of the frame 101 is provided with a front side baffle 108, a right side baffle 107, a lower Pressing bracket 105 and clamping device, frame 101 is provided with through hole A61, through hole B62 and through hole C63, and pressing down bracket 105 is provided with pressing down device 104; The automatic removal device 01 is connected, and the automatic collection device 02 includes an exhaust fan 21 and a briquetting machine 25. The outlet pipe 26 of the exhaust fan 21 is connected with the discharge pipe 24 through a hose 22, and the discharge pipe 24 is arranged on the mobile support. 23, the briquetting machine 25 is arranged beside the movable support 23, and the pressing device 104 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com