Patents

Literature

40results about How to "For quick twist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

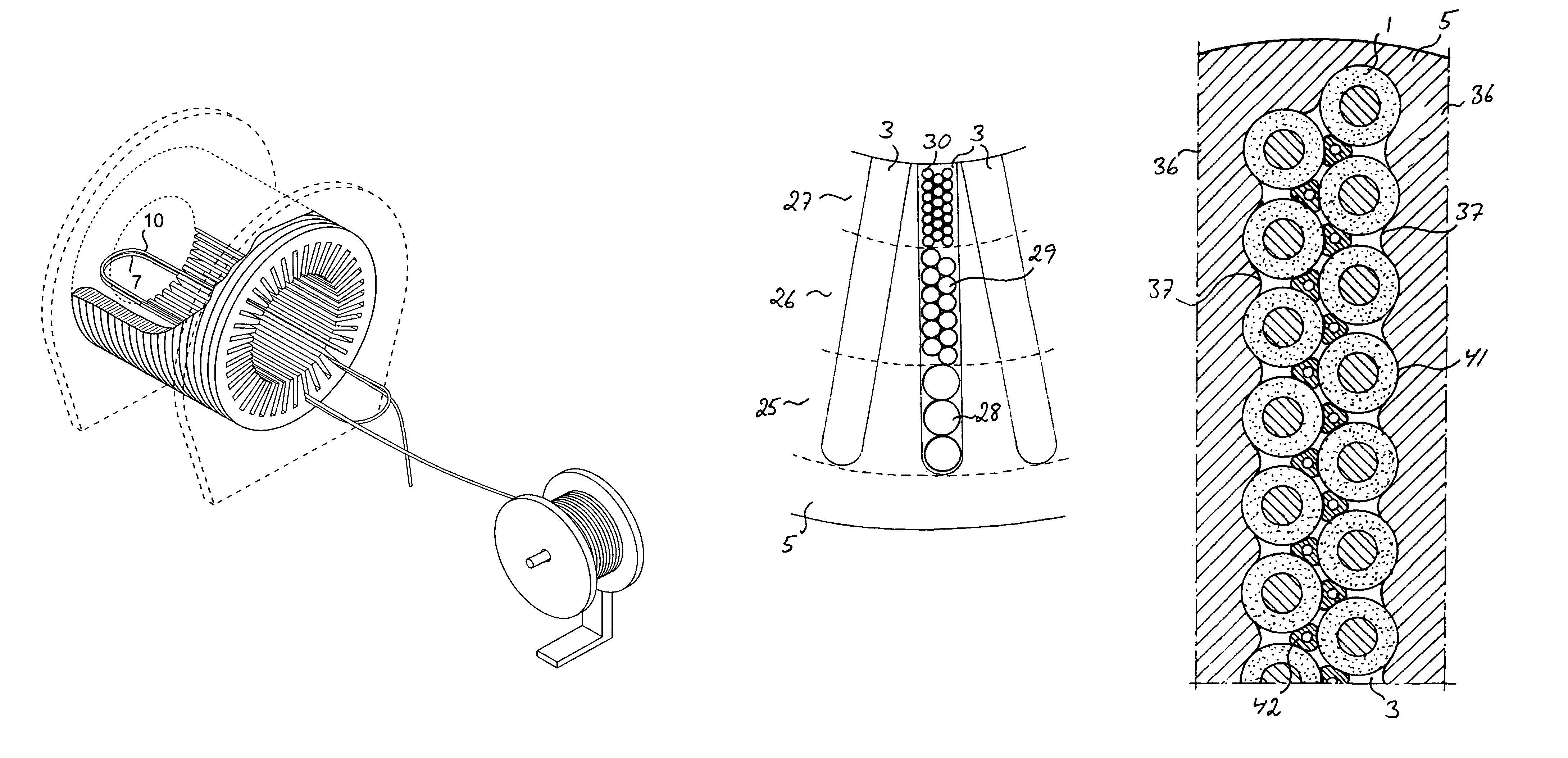

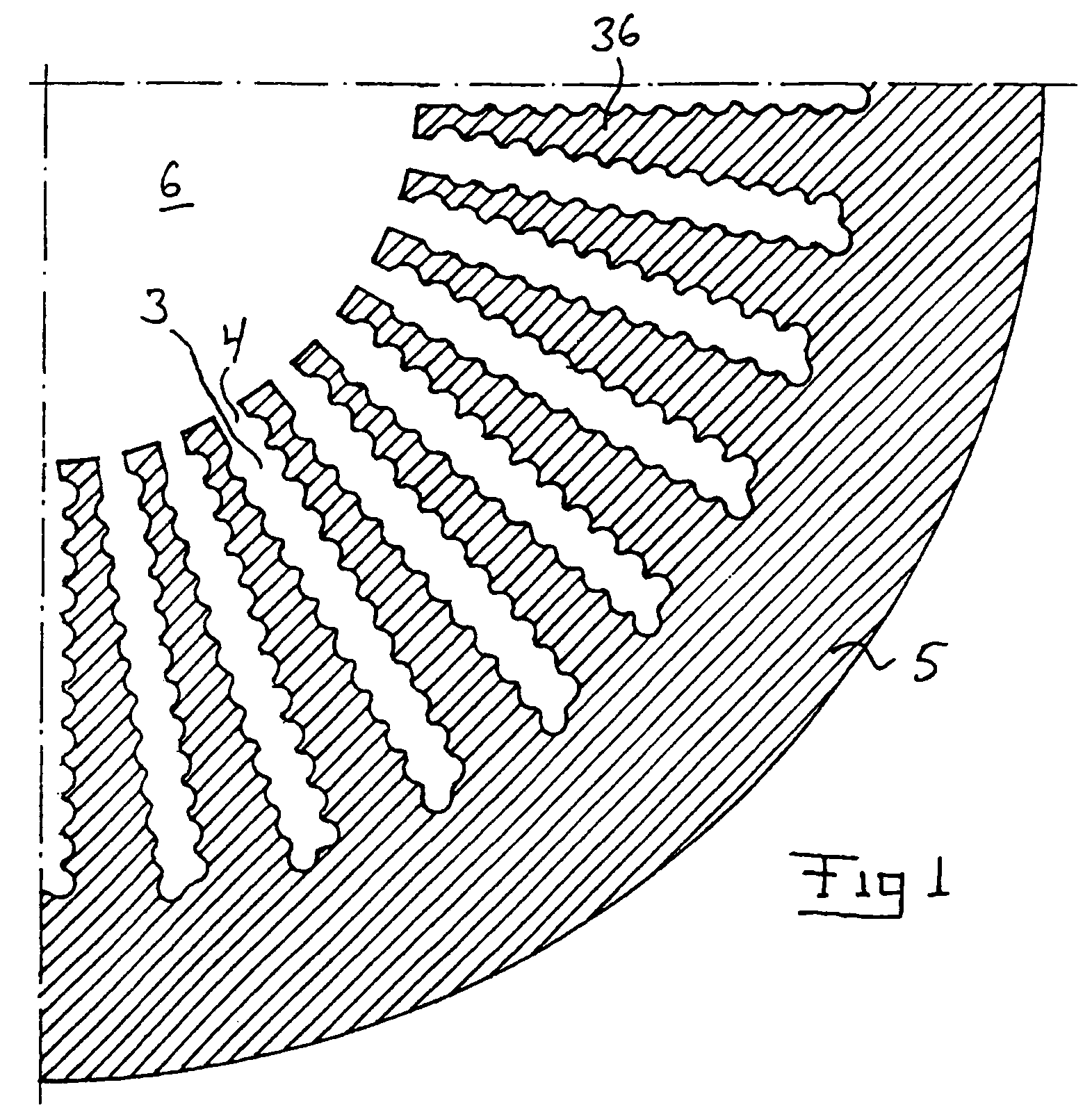

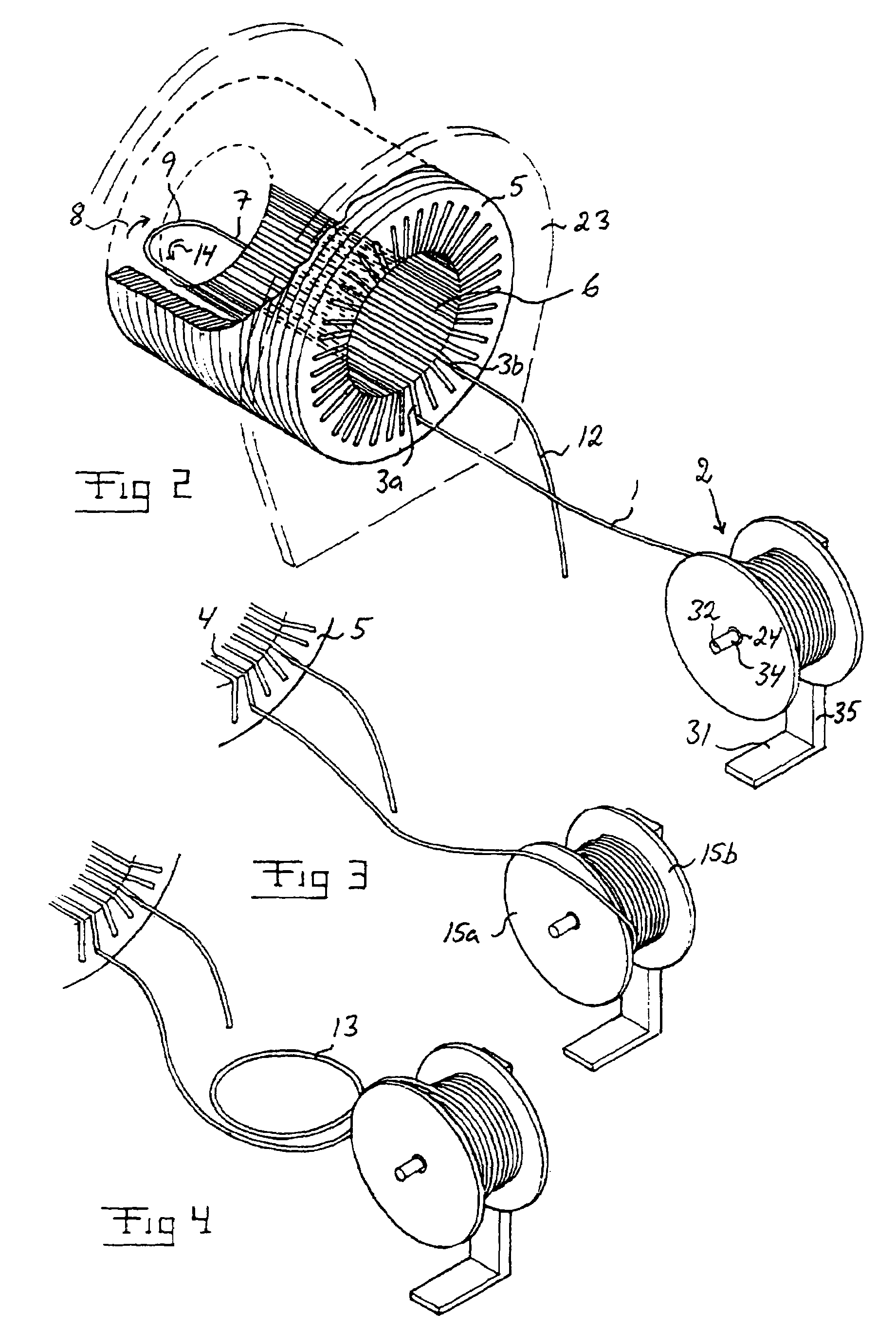

Method for installing a stator winding

InactiveUS7152306B2Reduce riskAvoid distortionMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringConductor Coil

A method for installing a stator winding in a stator core. A winding turn is formed by drawing a cable portion from a cable reel and inserting it into two winding slots. Each winding turn that is jointlessly connected to first winding turn and has the same winding direction as the first turn is formed by making this winding turn include a cable section corresponding to a turn on the reel that has been lifted off the reel by lateral movement over a gable of the reel. To form each winding turn that is jointlessly connected to the first winding turn and has a second winding direction opposite the winding direction of the first turn, the cable portion forming this winding turn is made to include a section corresponding to a turn on the reel that has been lifted off the reel by lateral movement over the other gable.

Owner:ABB (SCHWEIZ) AG

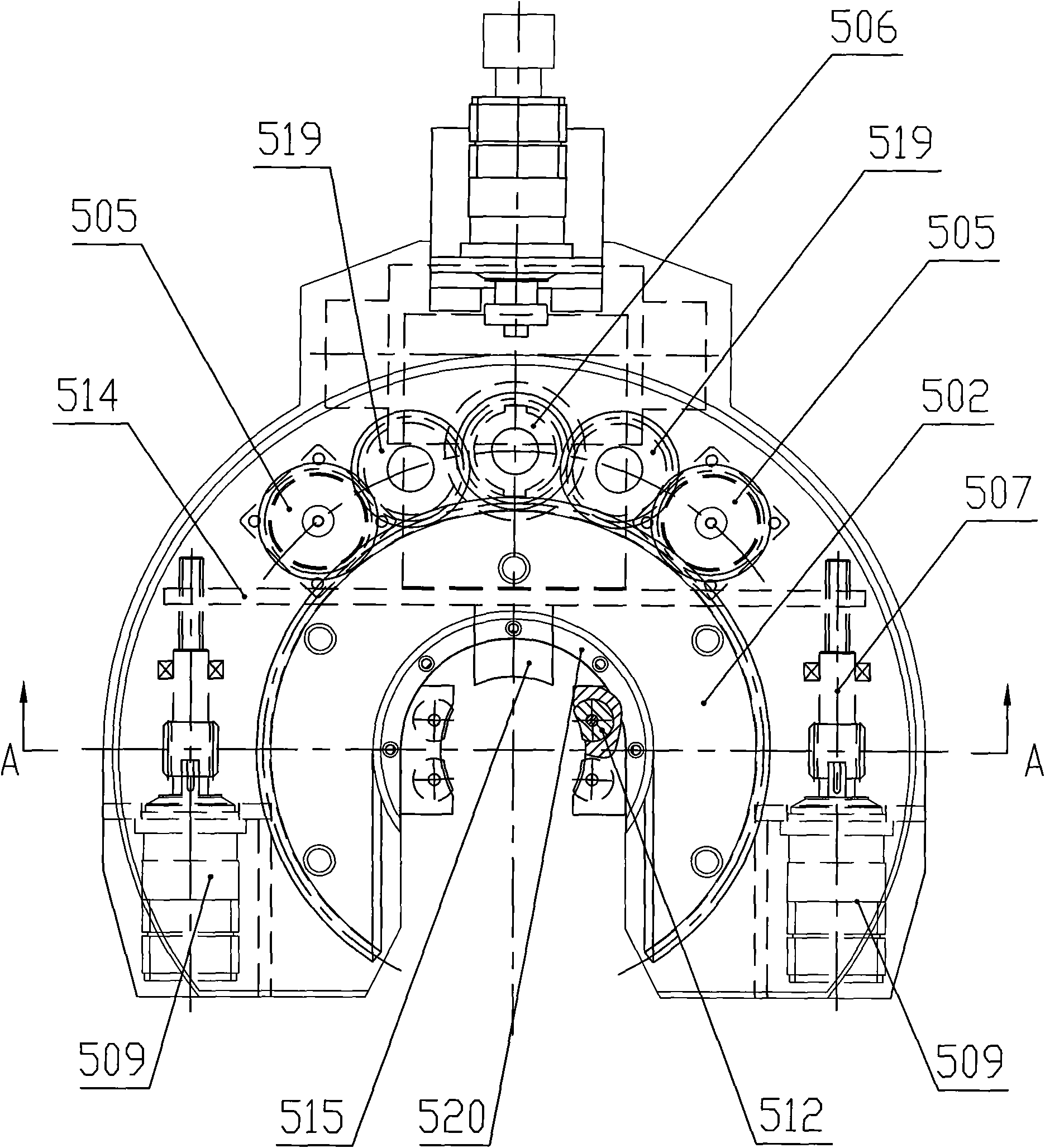

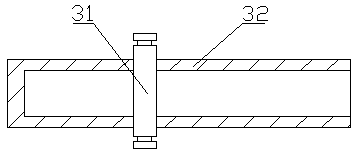

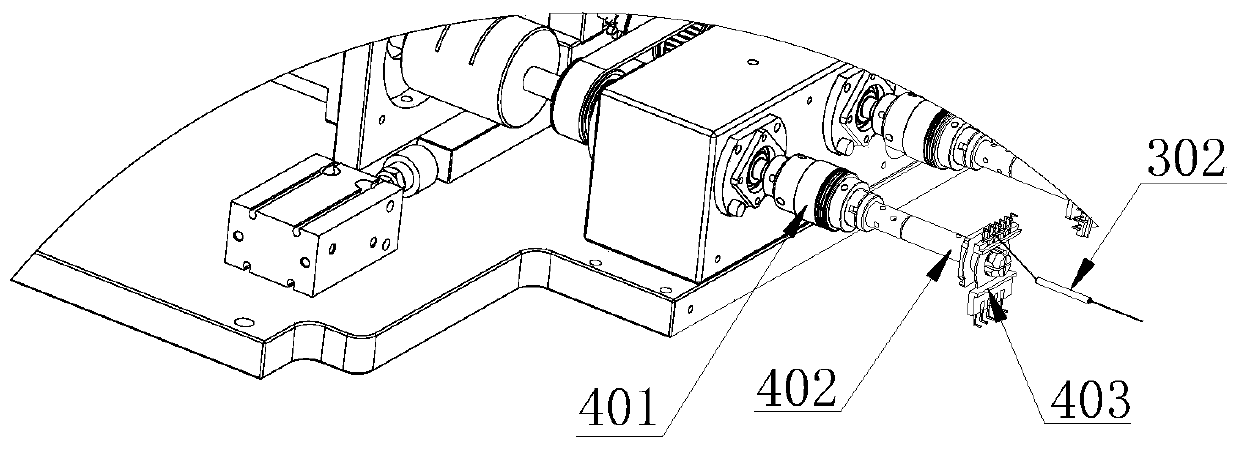

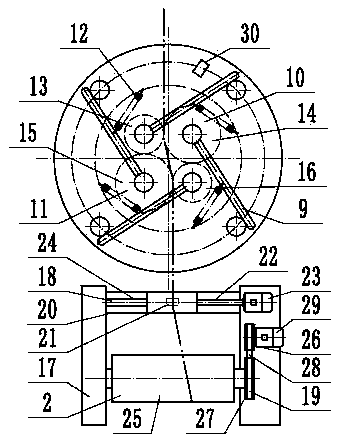

Screwing and buckling clamp for connecting and disassembling drill rod and sleeve pipe

InactiveCN101781975ASmooth rotationEvenly distributedDrilling rodsDrilling casingsDrive shaftEngineering

The invention discloses a screwing and buckling clamp for connecting and disassembling a drill rod and a sleeve pipe, which comprises a power clamp and a fixing clamp, wherein the power clamp and the fixing clamp can rotate relatively; a driving oil motor sliding seat is also arranged on a shell of the fixing clamp; a latch driving oil motor supporting plate is arranged on the driving oil motor sliding seat; a latch driving oil motor is arranged on the latch driving oil motor supporting plate; a power output connector of the latch driving oil motor corresponds to an input connector of a power transmission shaft in the power clamp; a supporting plate pushing oil cylinder is arranged on the driving oil motor sliding seat; and the pushing end of the supporting plate pushing oil cylinder is connected with the latch driving oil motor supporting plate. By the design of the screwing and buckling clamp in the scheme, the structure can accurately and quickly complete screwed connection of drill pipes, and the pipe connecting process is stable and quick, thereby improving the pipe connecting efficiency, reducing the labor intensity and the risk of workers.

Owner:CHENGDU SHIWEI TECH CO LTD

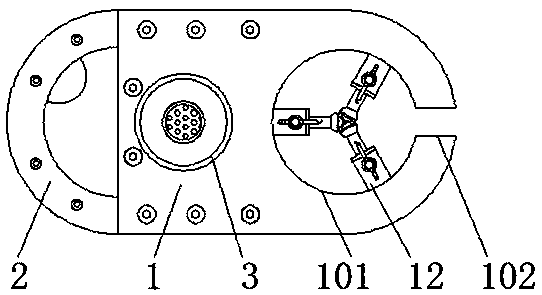

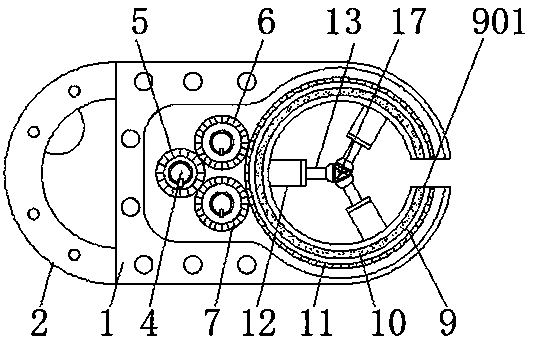

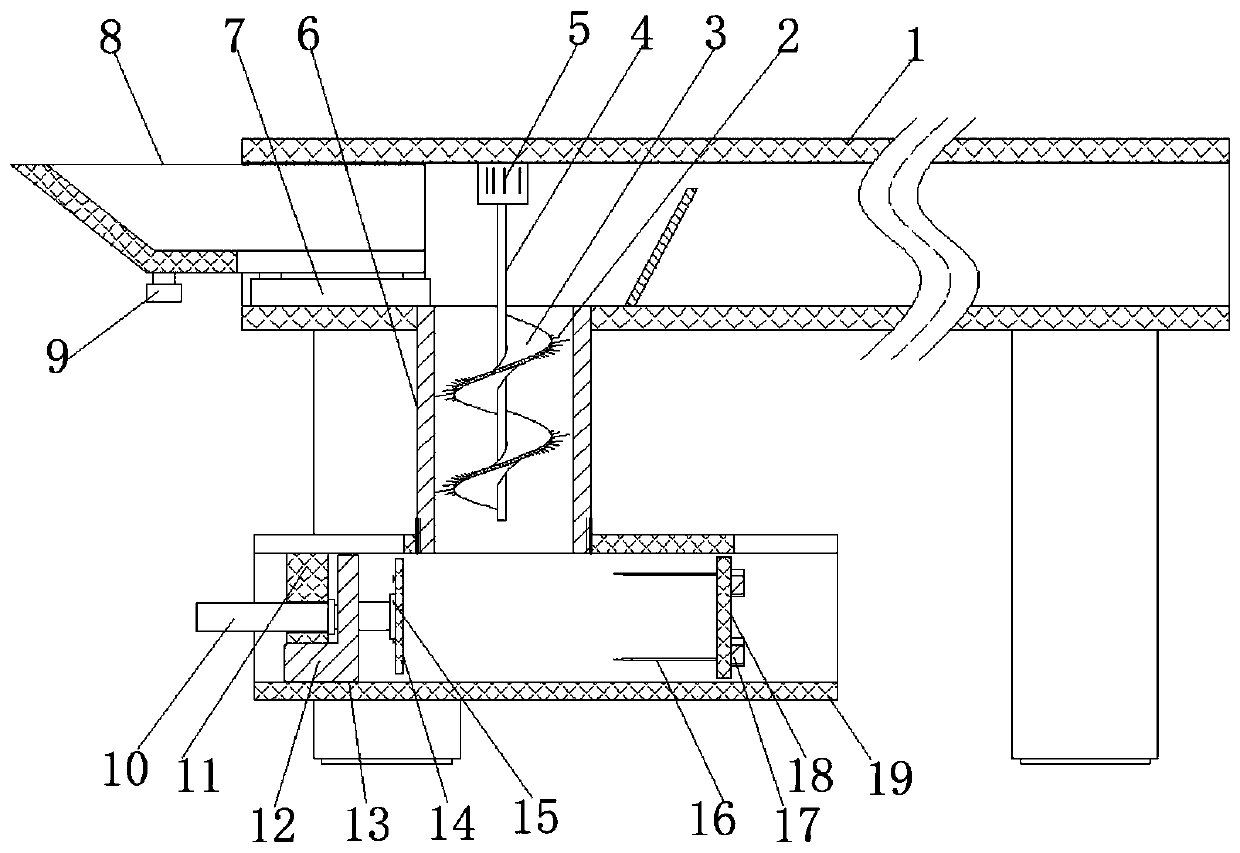

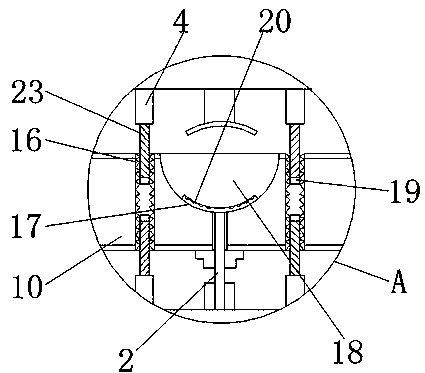

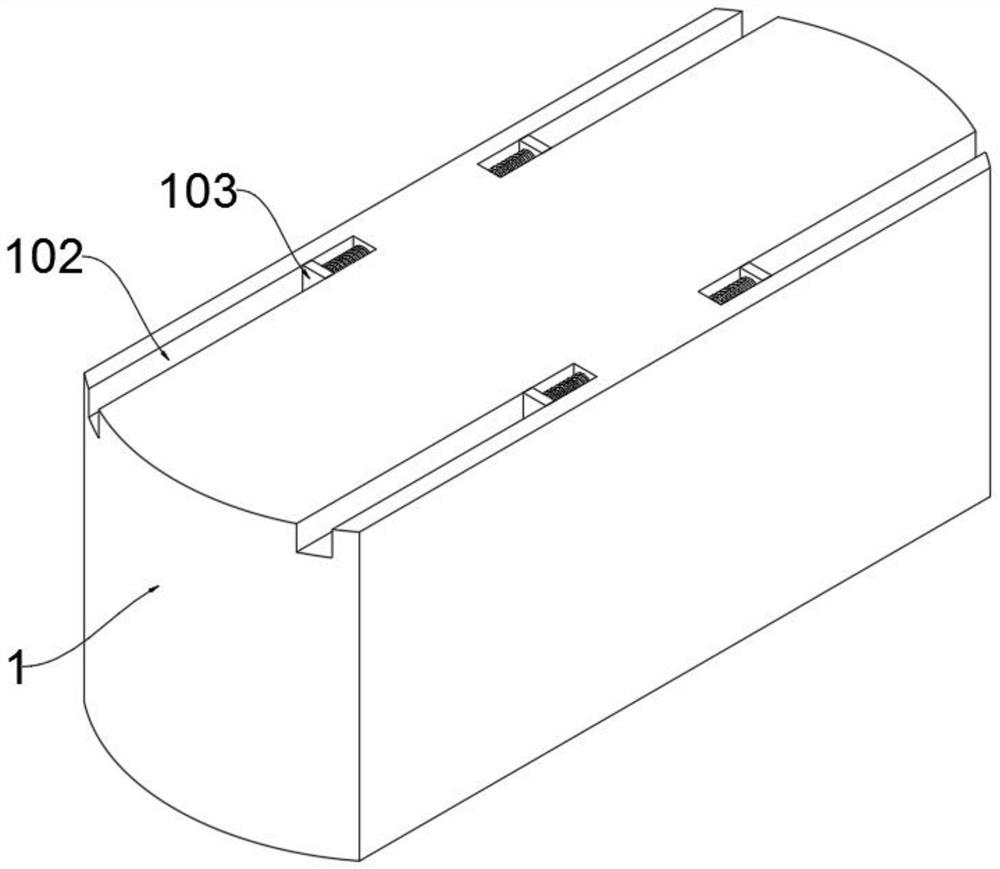

Rapid twisting device of cable joint for small electric power engineering construction

ActiveCN111276912AFor quick twistQuick twist connectionApparatus for joining/termination cablesGear wheelPower engineering

The invention discloses a rapid twisting device of a cable joint for small electric power engineering construction. The device comprises a shell, a small motor, a mounting ring, a limiting rod and a driving lever; a handle is installed on the left side of the shell. A first transmission gear and a second transmission gear are mounted on the upper side and the lower side of the interior of the shell through shafts correspondingly, and the first transmission gear and the second transmission gear are both connected with the power gear; a sliding rail is mounted in the right side of the shell through screws, a surface straight gear is arranged on the outer side face of the mounting ring, a groove is formed in the tail end of the limiting rod, a spring is arranged between the limiting rod and the sleeve, the tail end of the stud is in threaded connection with a shifting rod, the shifting rod penetrates through the stud, and a clamping groove is formed in the tail end of the shifting rod. The twisting device is provided with the sleeve and the limiting rod, and the limiting rod can be completely detached in the using process, so the shifting rod can clamp two or three cable cores throughthe clamping groove, winding connection of the multiple cable cores is conducted, and the application range of the device is widened.

Owner:湛江天汇综合能源服务有限公司

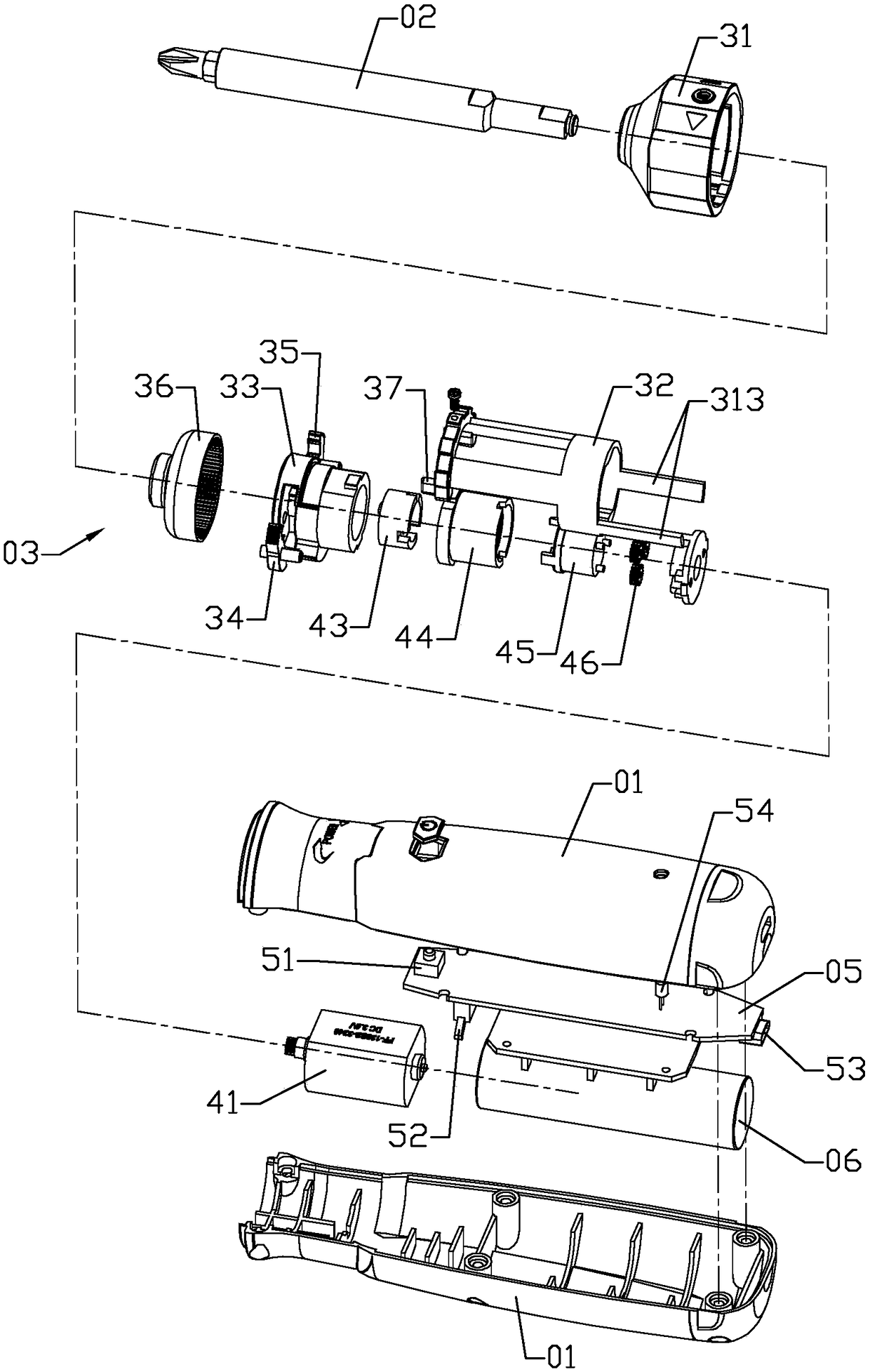

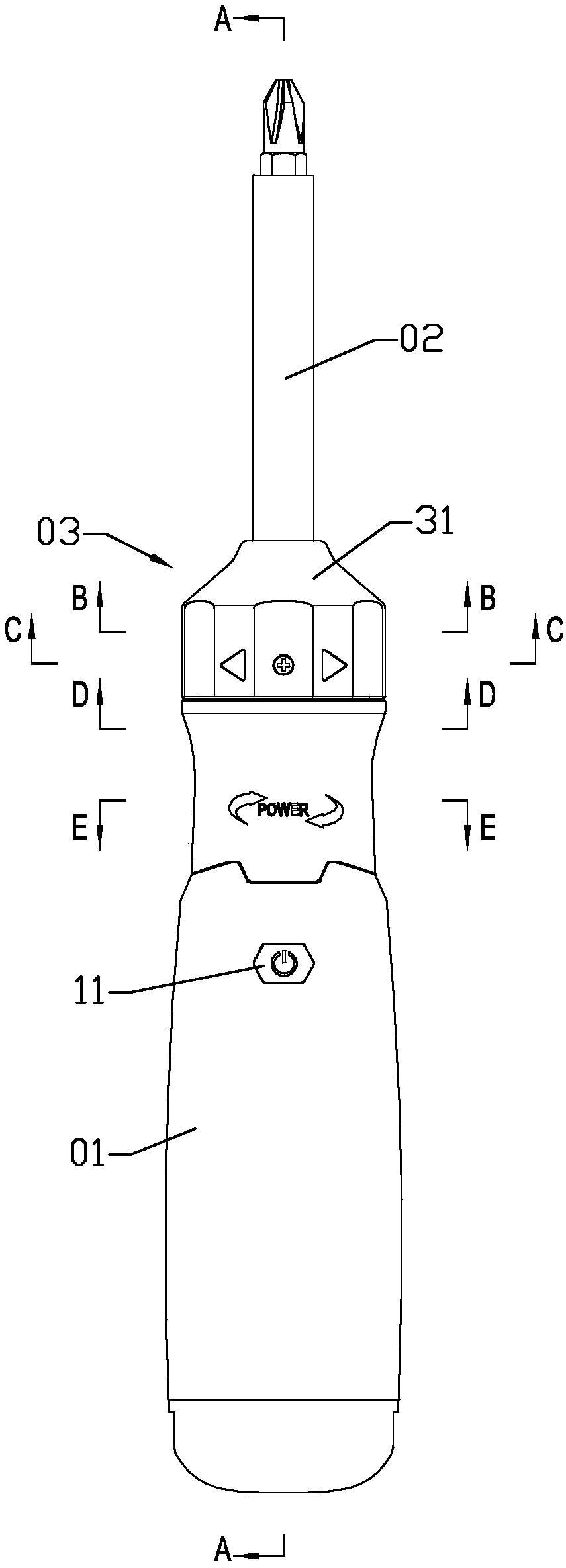

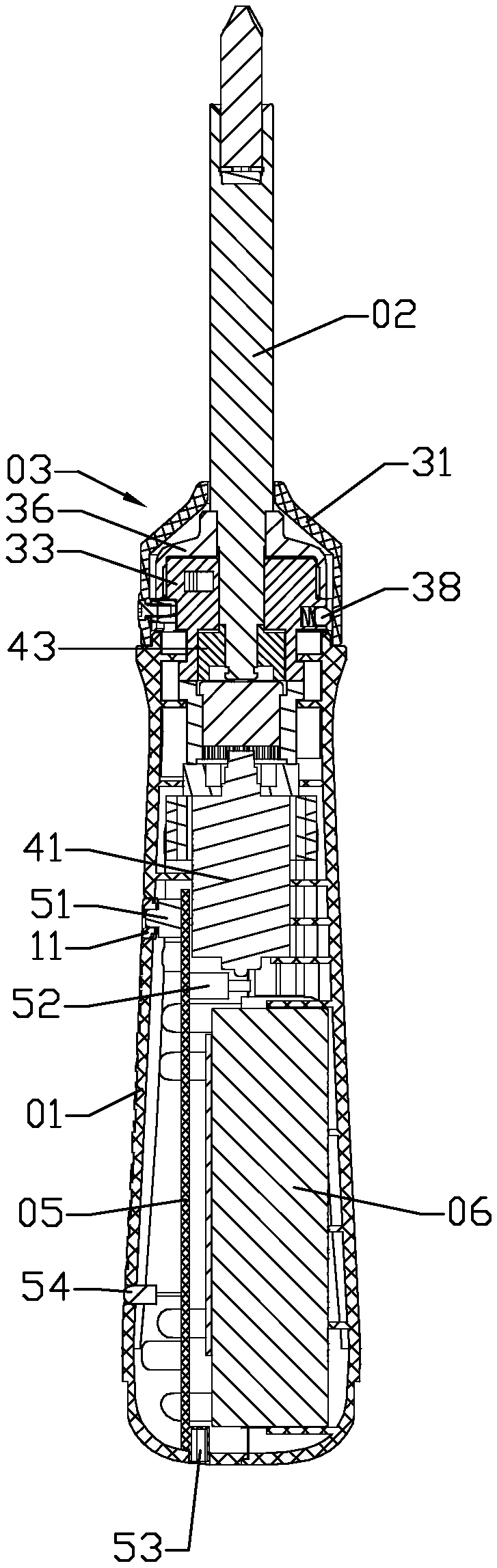

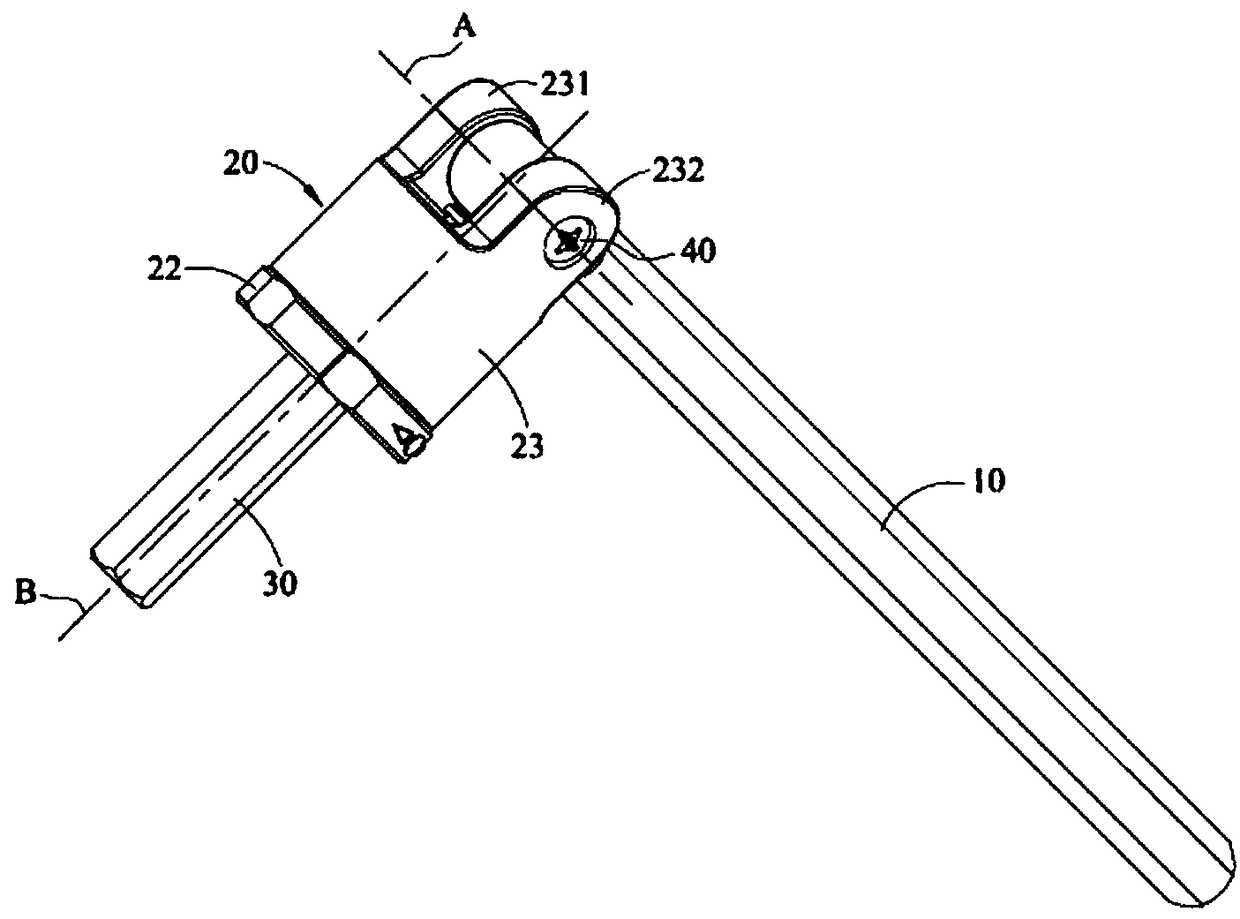

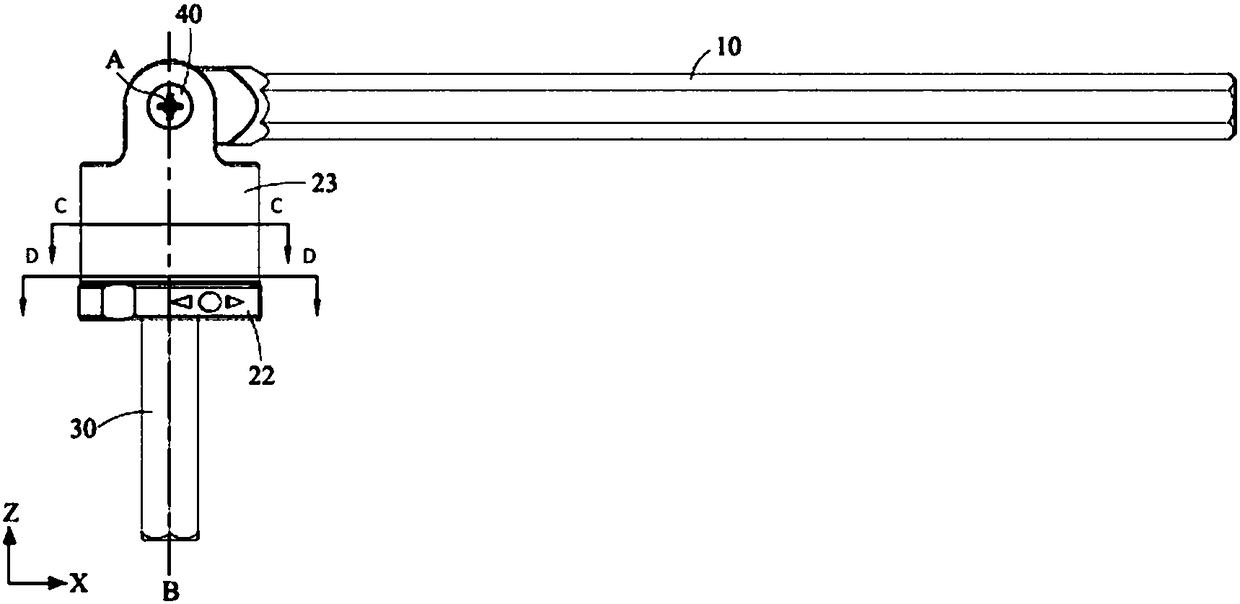

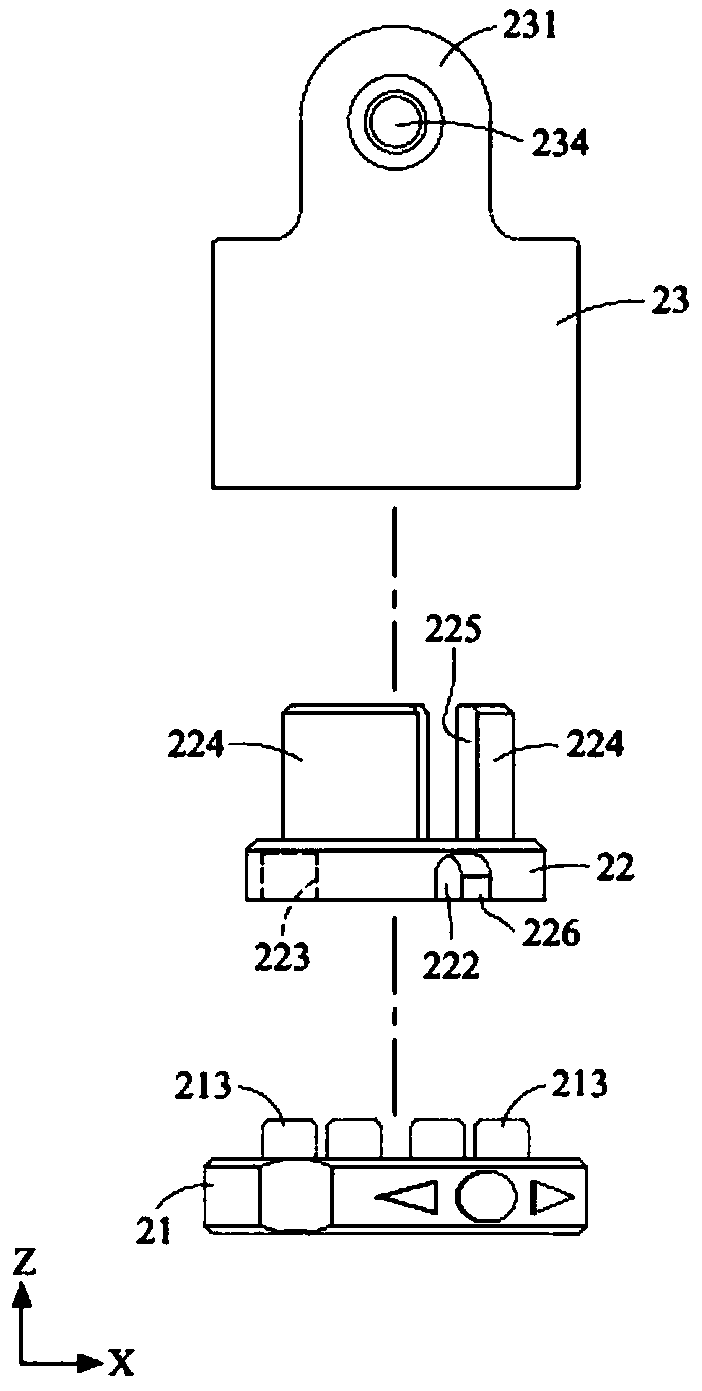

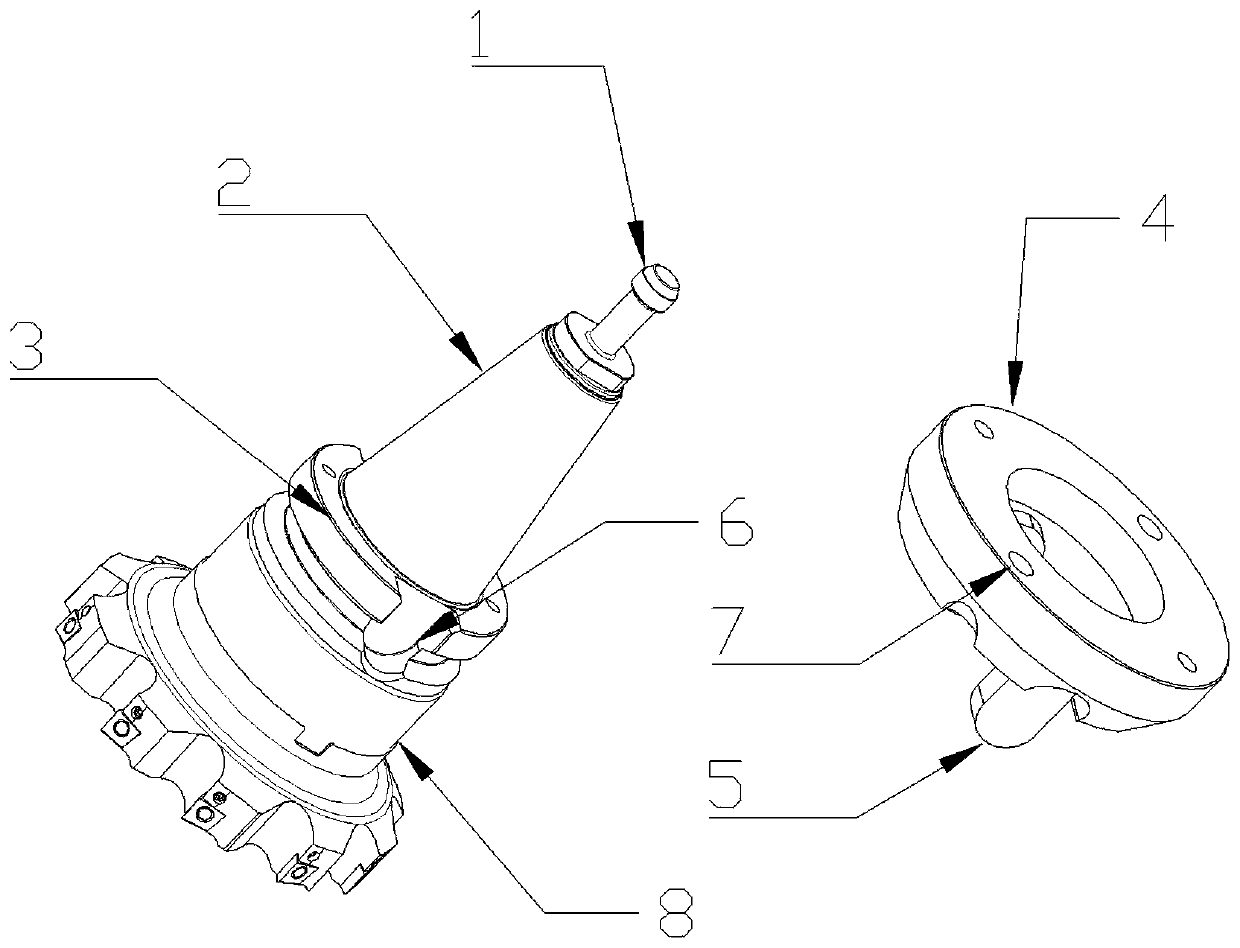

Reversible rotary jig with manual and electric operation modes

PendingCN109176377AOvercome the defect of insufficient batch efficiencyFor quick twistSpannersWrenchesOperation modePower tool

The invention discloses a reversible rotary jig with manual and electric operation modes and belongs to manual and electric tools. A ratchet wheel screwdriver of an existing manually-operated three-gear manual rotary jig is insufficient. A power source, a circuit board controlling the power source to rotate, and a power source for supplying power to the power source and the circuit board are arranged in a hand shank. The power source and an operation lever are in transmission connection so as to achieve electric torque output. The circuit board is connected with a control switch and a reversing switch. The hand shank is provided with a button corresponding to the control switch. A steering dial piece extends to the reversing switch and rotates relative to the hand shank, and a rotary reversing sleeve drives the reversing dial piece to switch the reversing switch so that the electric torque output direction of the operation lever can be switched. The manual torque output direction is the same with the electric torque output direction. A user can select the manual operation mode to output high torque or the electric operation mode for quick screwing according to demands.

Owner:HANGZHOU GREAT STAR IND CO LTD

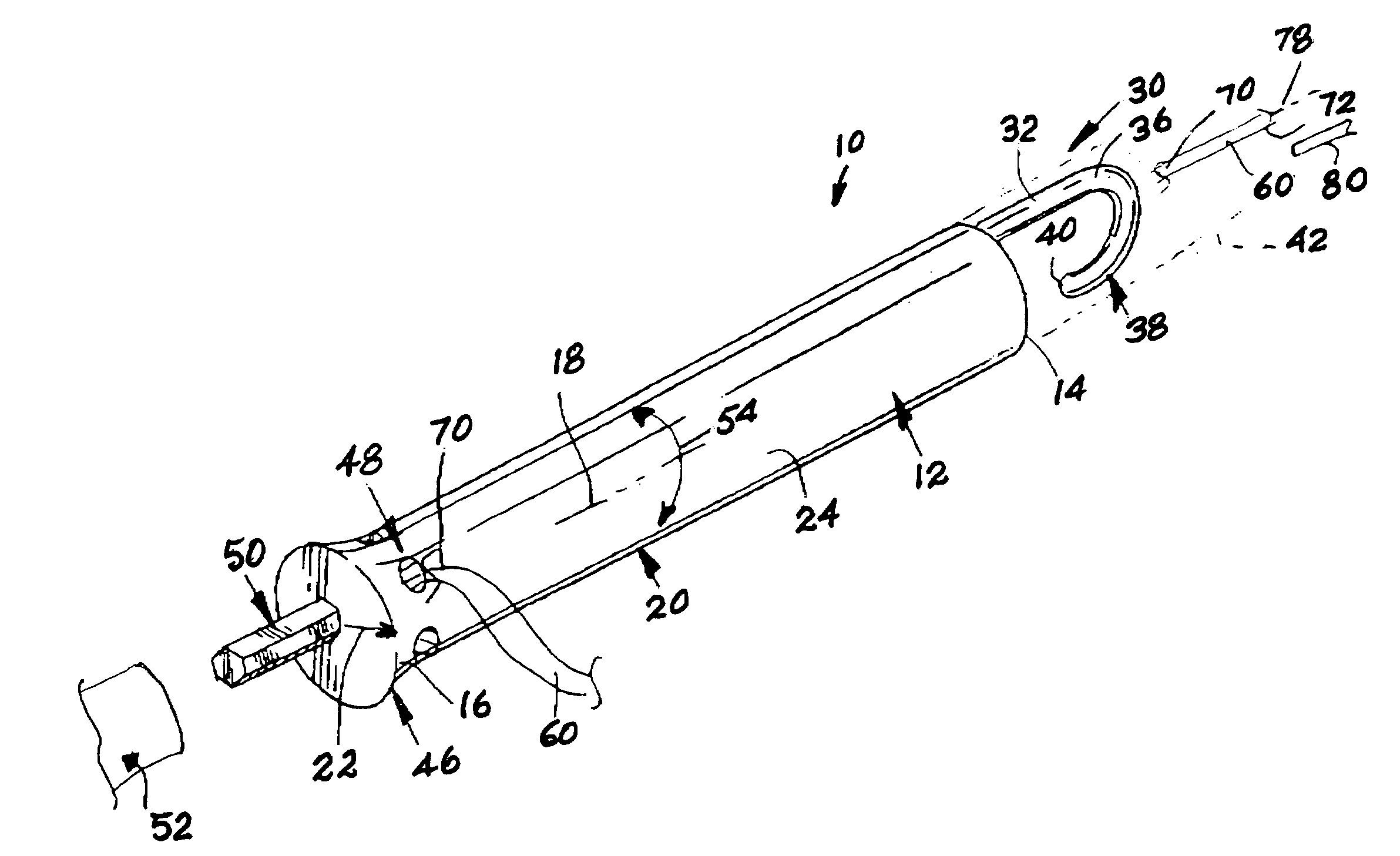

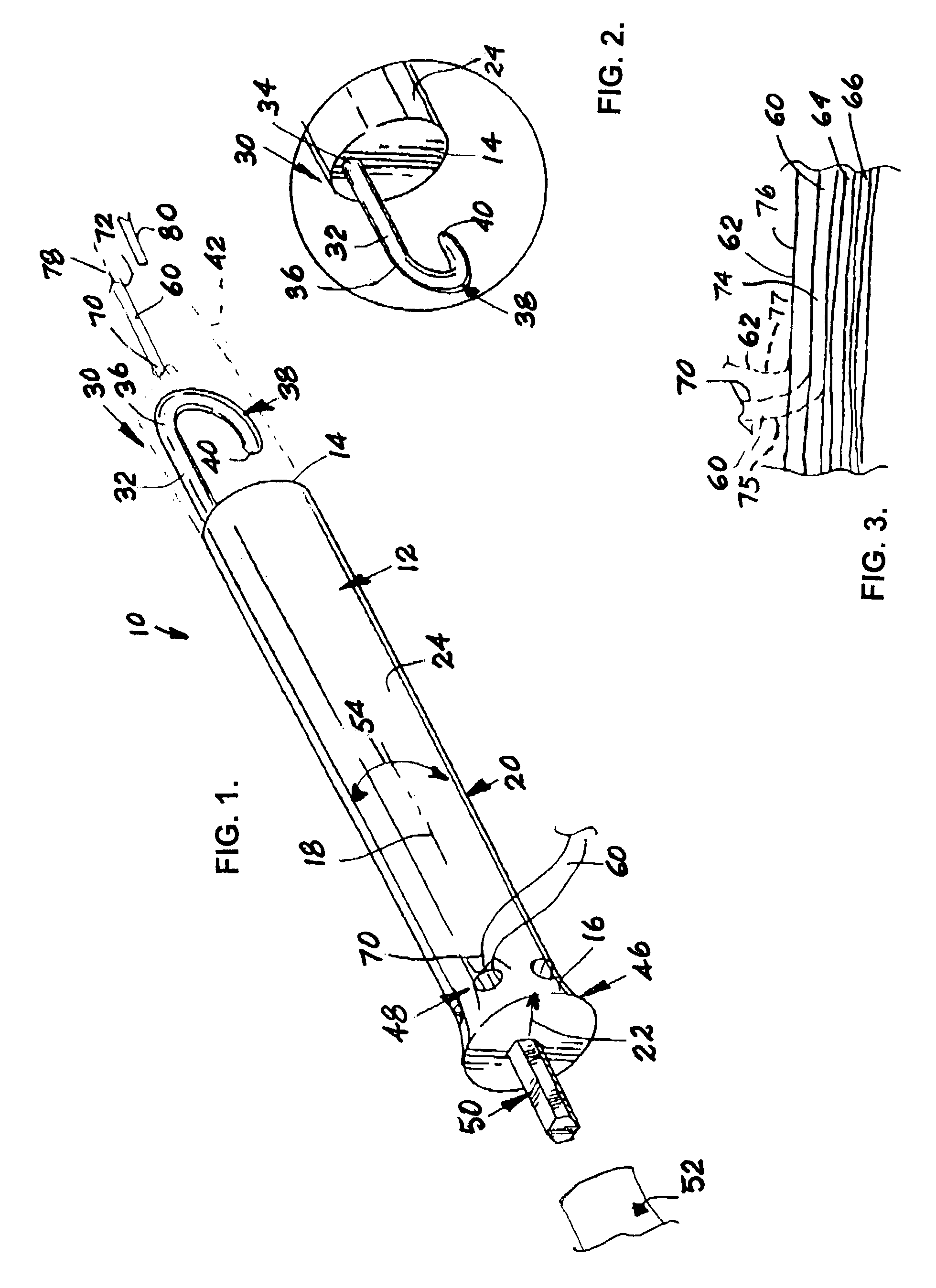

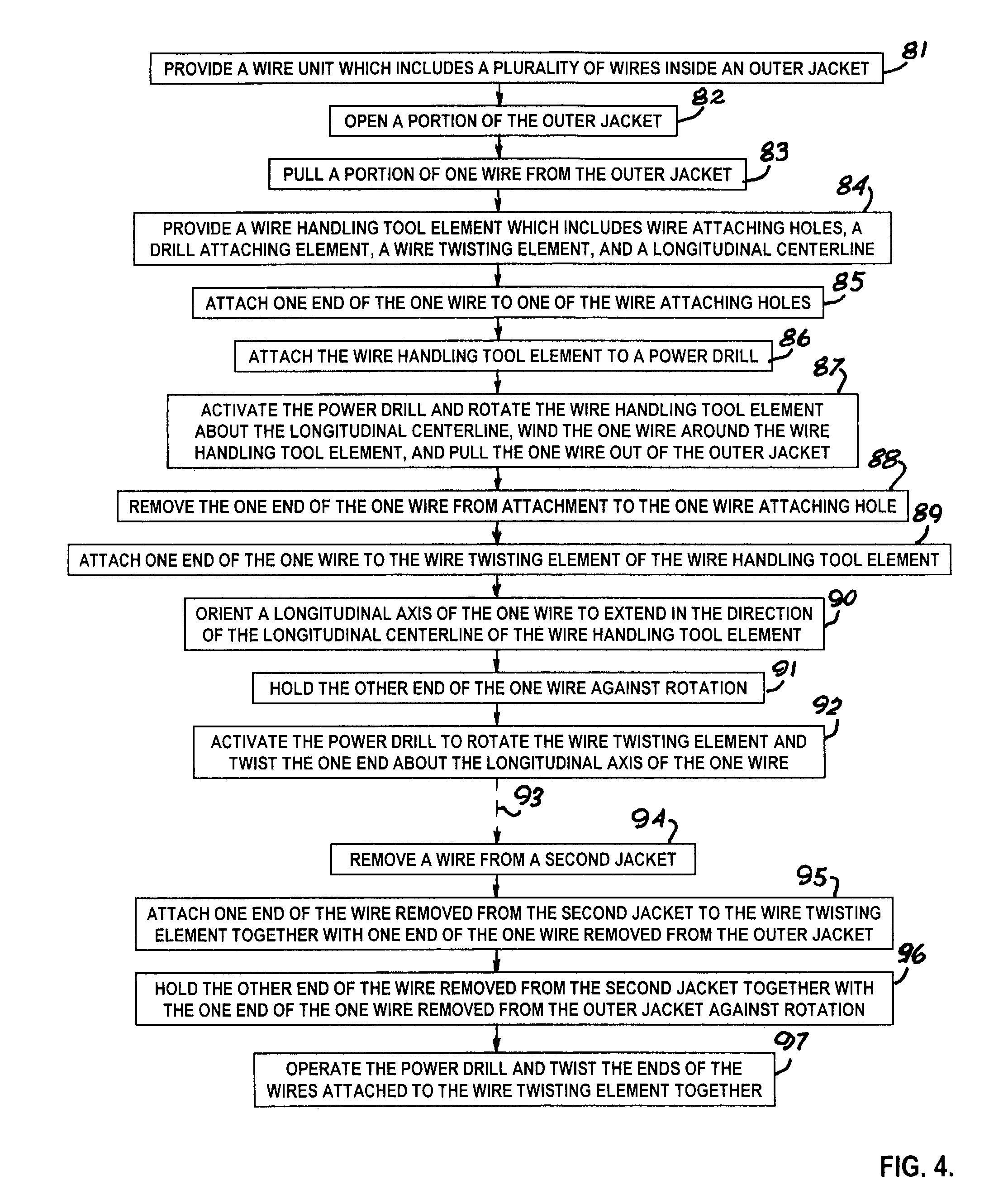

Wire handling tool element and method of use thereof

InactiveUS6962173B1Quickly twisted togetherSave human effortLine/current collector detailsApparatus for joining/termination cablesWire rodEngineering

A wire handling tool element includes a cylindrical body having a J-shaped hook on one end and a drill bit-type element on a second end. A wire is pulled out of a jacket containing a plurality of wires by attaching one end of that wire to the cylindrical body and attaching the cylindrical body to a power tool, such as a power drill, and causing the wire to be wrapped around the cylindrical body. This wrapping pulls the wire out of the jacket. Once the wire is pulled out of the jacket, one end of the wire is attached to the J-shaped hook and the other end of the wire is held against rotation and the power tool is operated thereby twisting the wire about its longitudinal axis. A plurality of wires can be attached to the J-shaped hook to be twisted together when the power tool is operated.

Owner:FISHGRAB DEWANE K

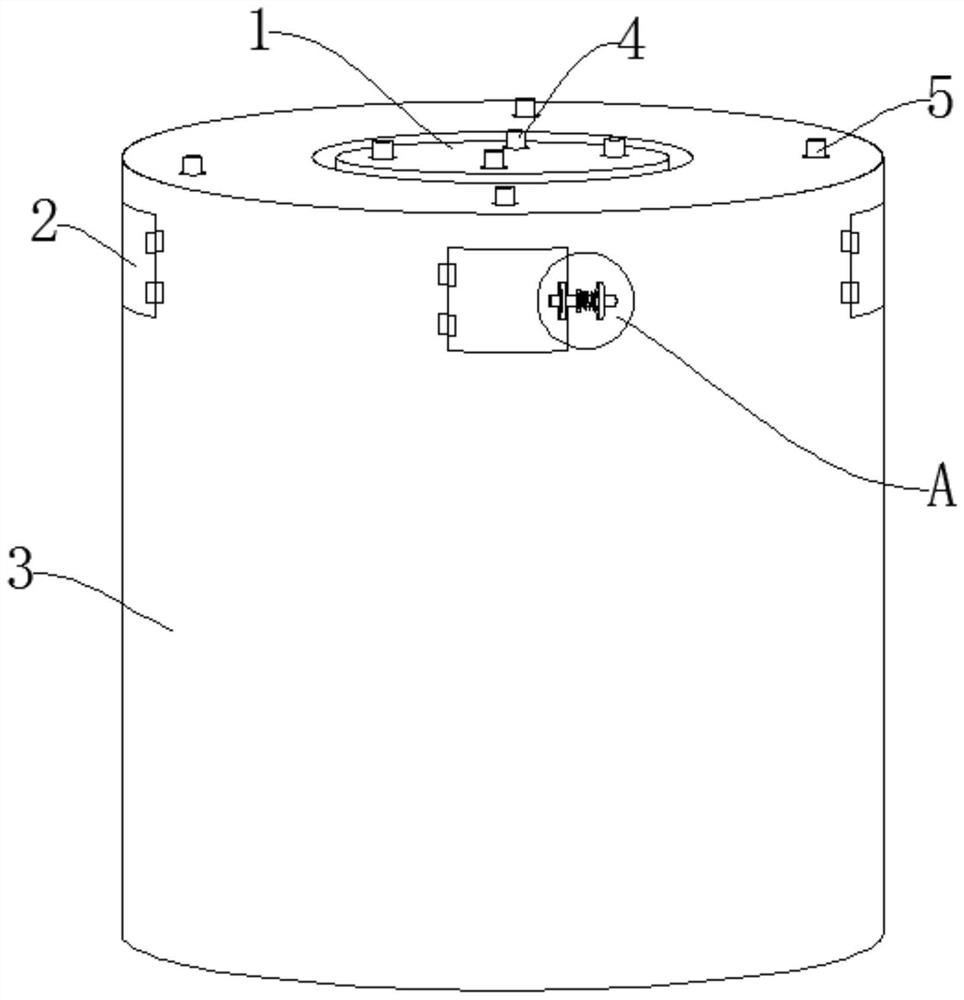

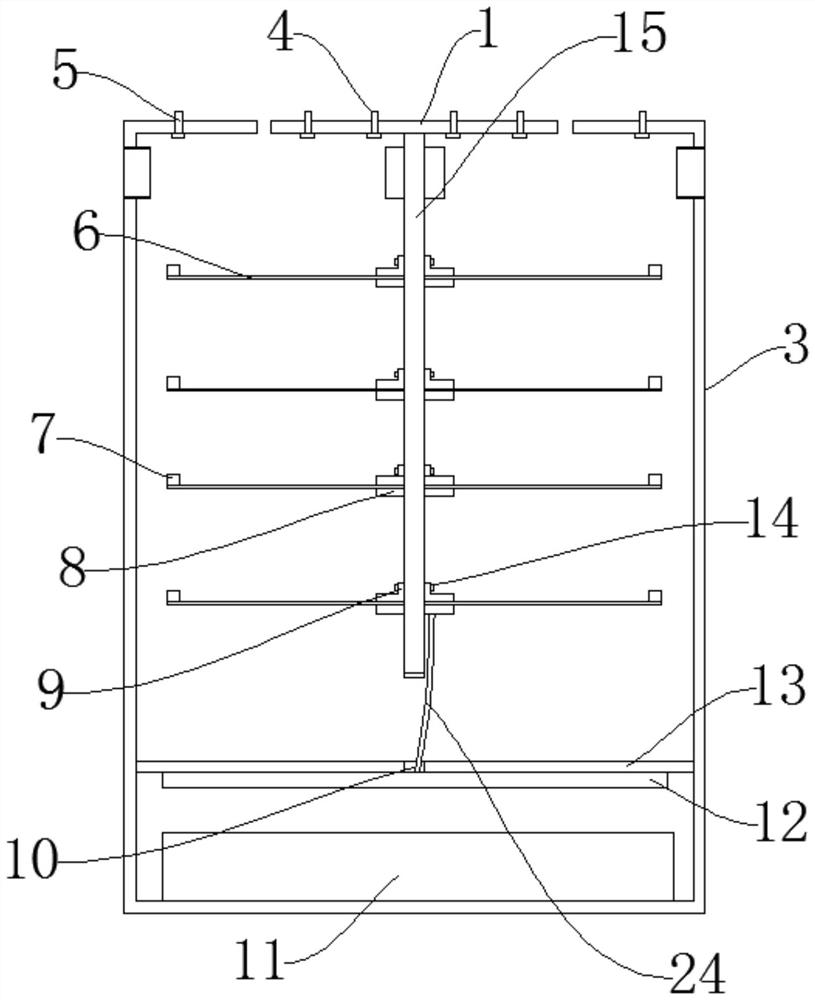

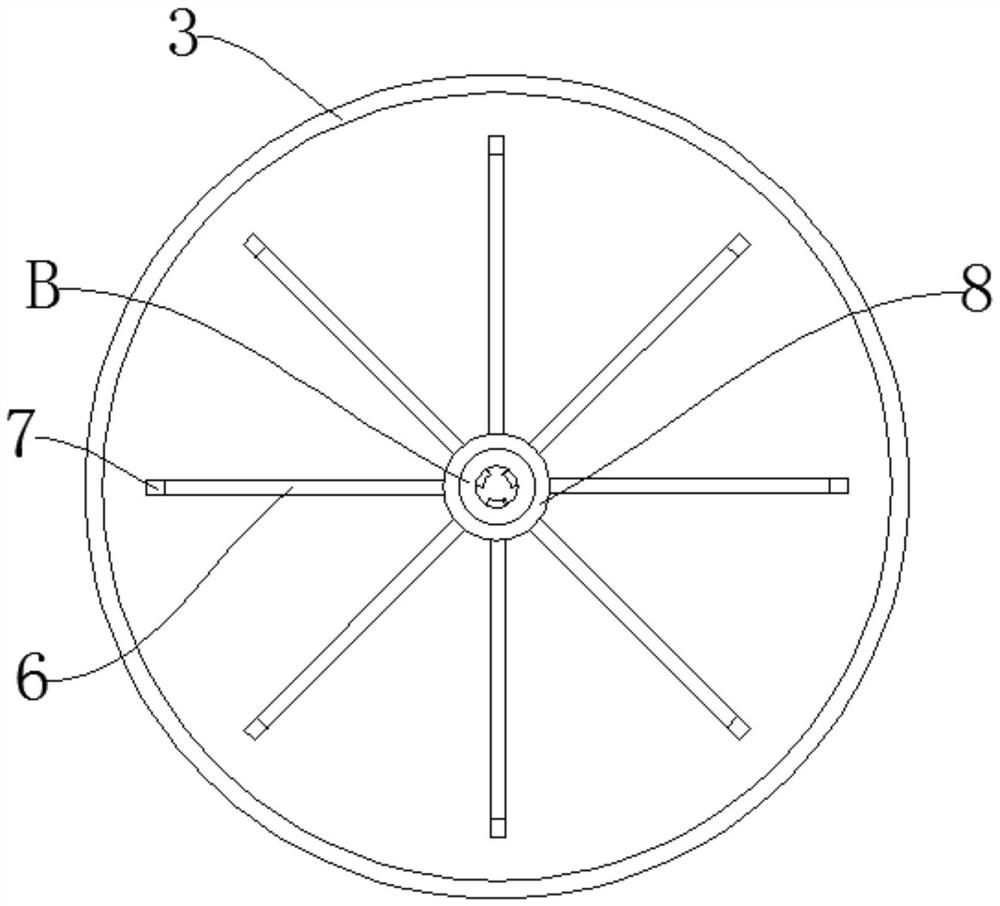

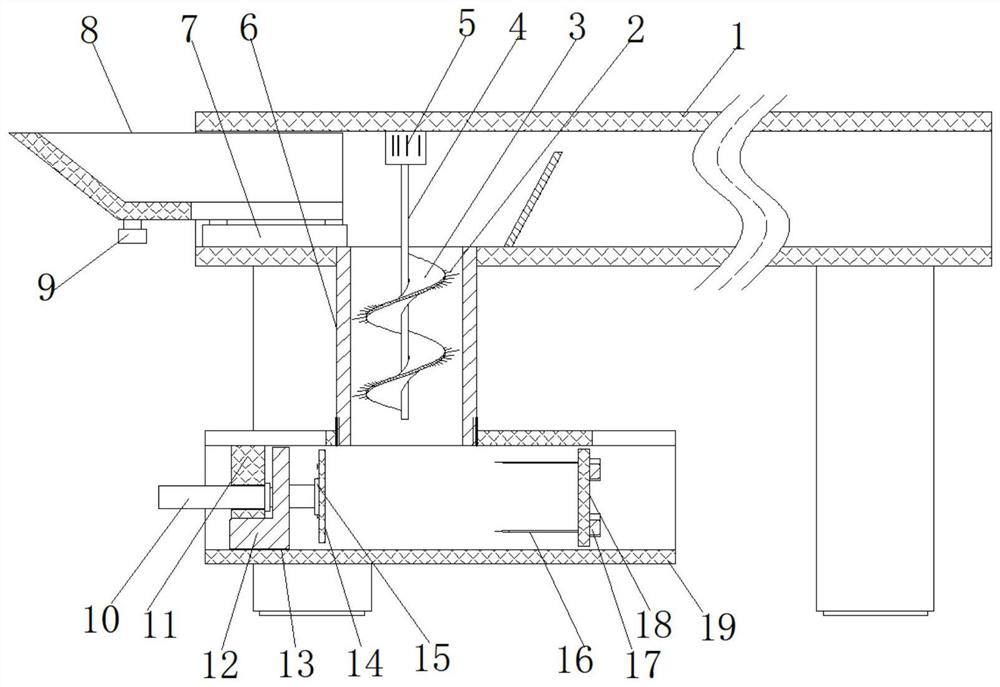

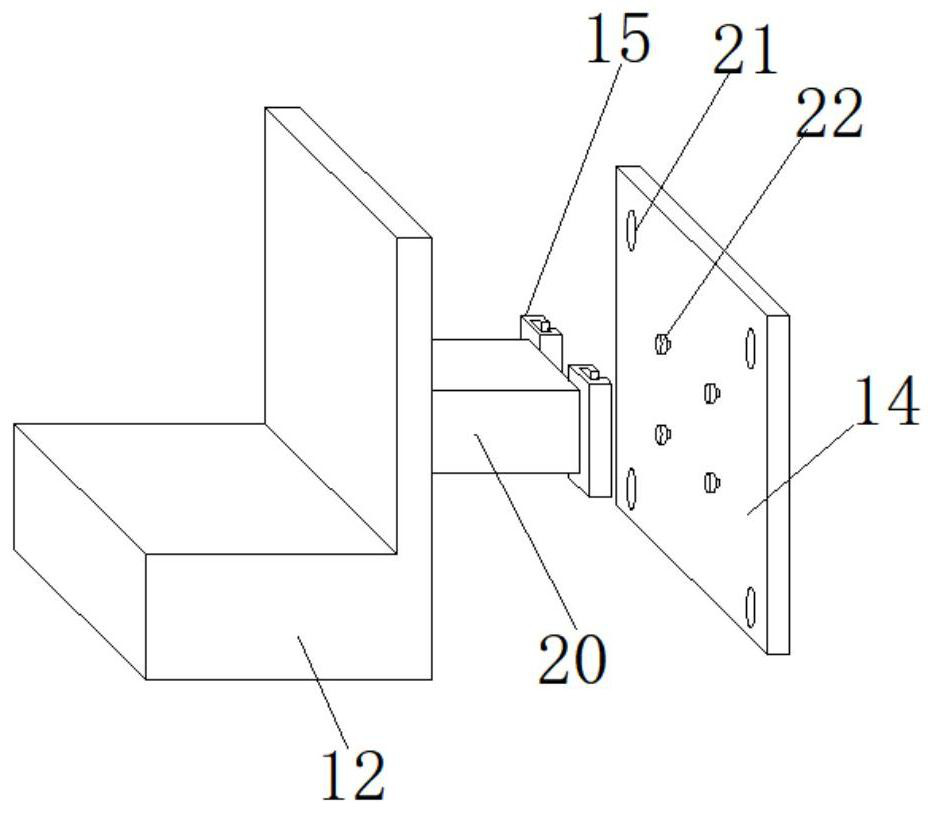

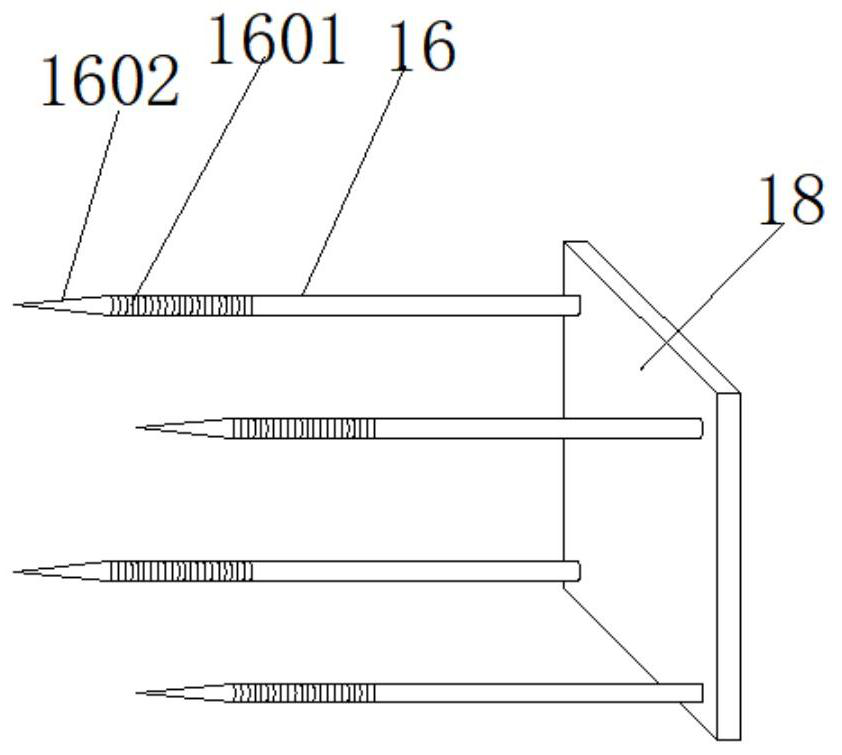

Scrap removing device for wood processing

InactiveCN111002405AEasy to clean upFor quick twistWood compressionDomestic articlesElectric machineryDrive motor

The invention belongs to the technical field of wood processing, in particular to a scrap removing device for wood processing, and aims at solving the problem that in wood processing at present, scraps are simply sucked into a collecting barrel for collecting and fluffy scrap occupy a large amount of space. The scarp removing device comprises a workbench of a square-tube-shaped structure and internally provided with a cavity, a round hole is formed in the position, close to the edge, of the bottom of the workbench, a discharging pipe is welded in the round hole, a driving motor is fixed over the position, close to the discharging pipe, of the inner wall of the top end of the workbench, a transmission rod is fixed to the top end of an output shaft of the driving motor through a coupler, anda spiral plate is arranged on the circumferential outer wall of the transmission rod. According to the scrap removing device, wood waste chips near the pipe opening of the discharging pipe can be rapidly twisted into the discharging pipe during rotation, scrap can be stopped in the discharging pipe when discharging is not needed, and cleaning work at an outlet is facilitated.

Owner:河北聚商智能科技有限公司

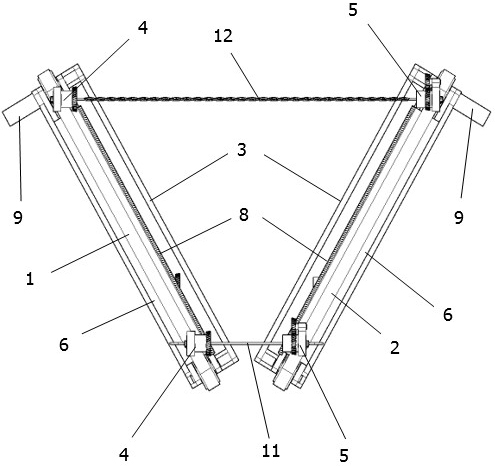

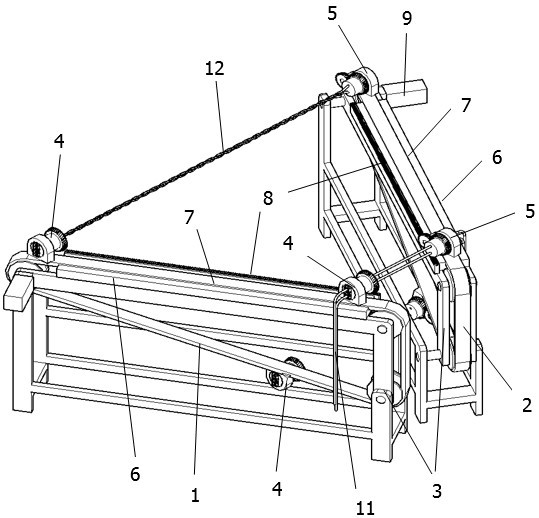

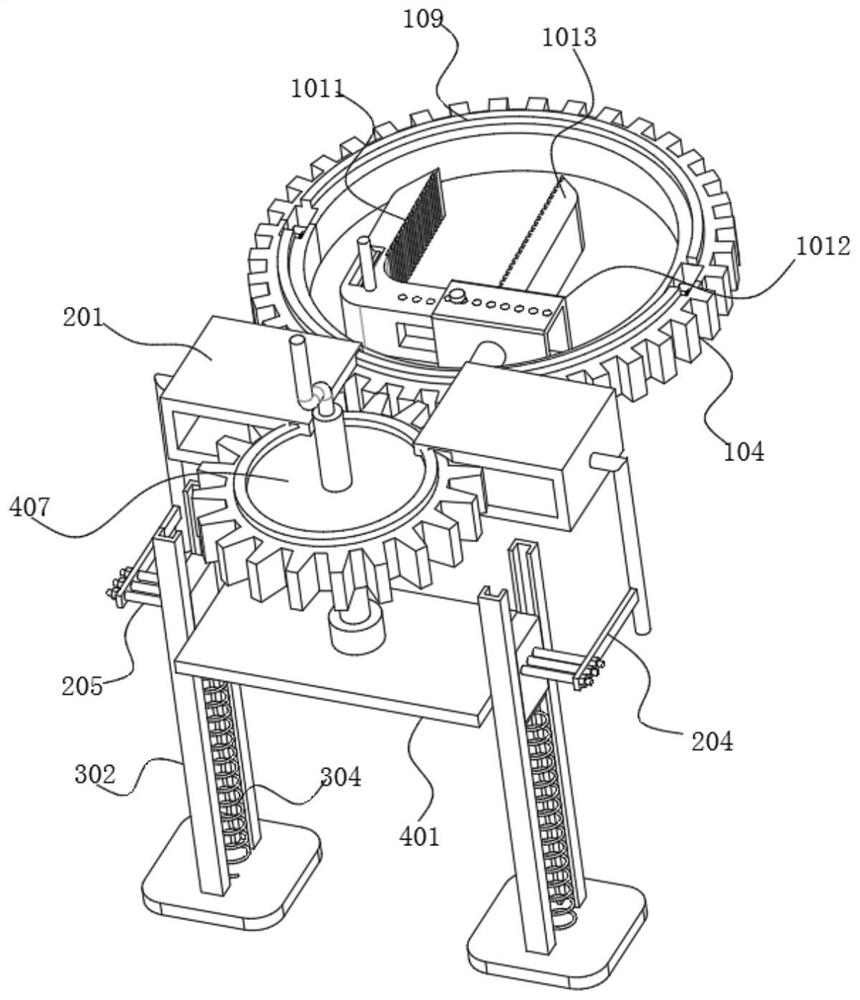

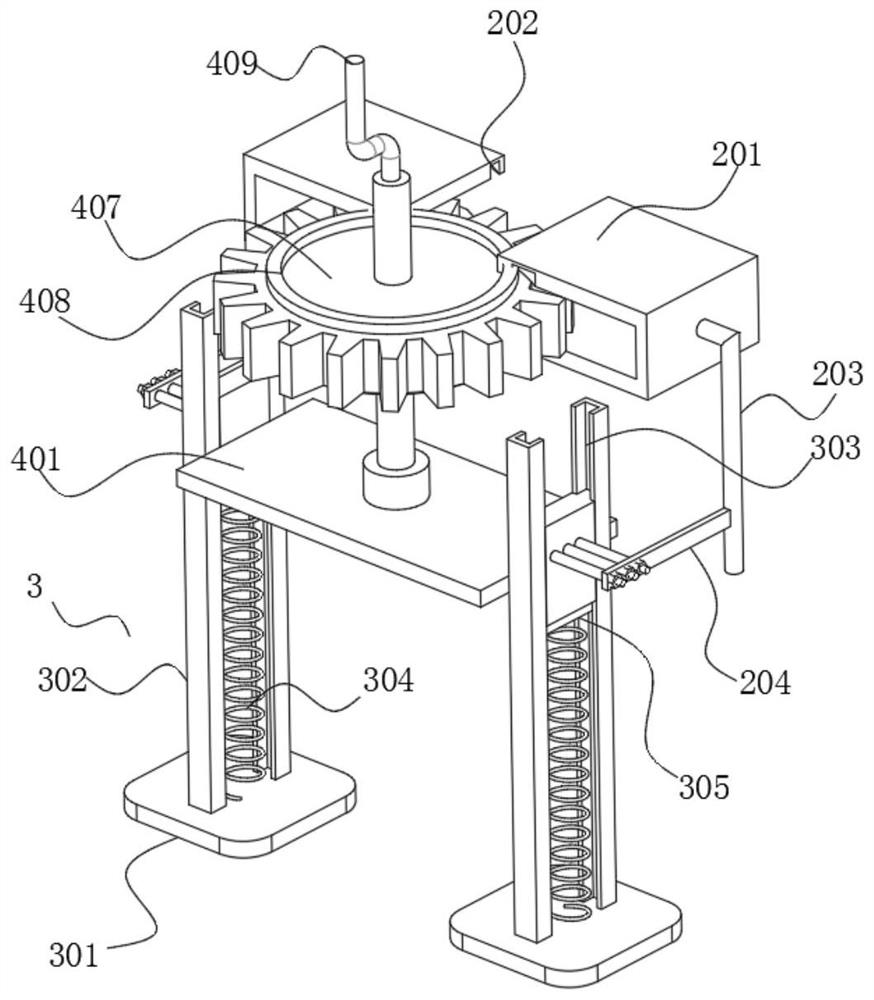

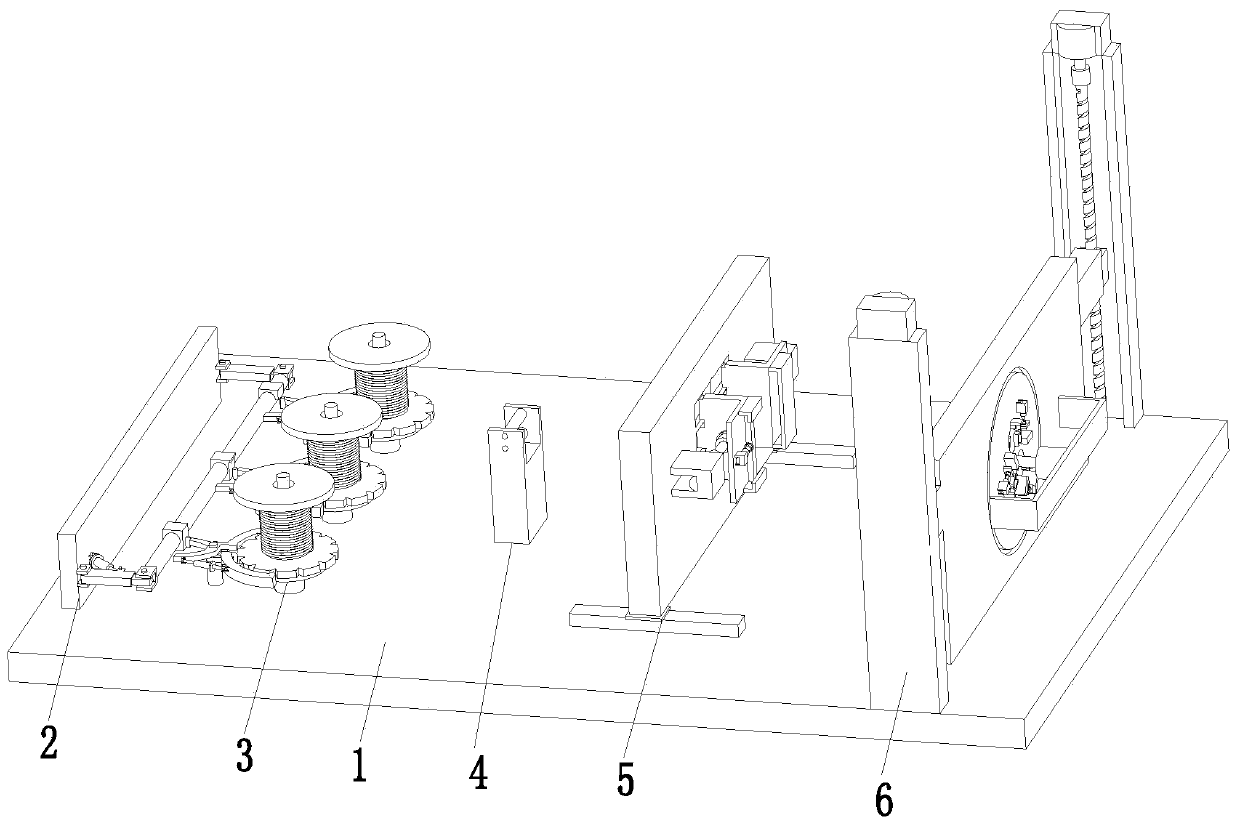

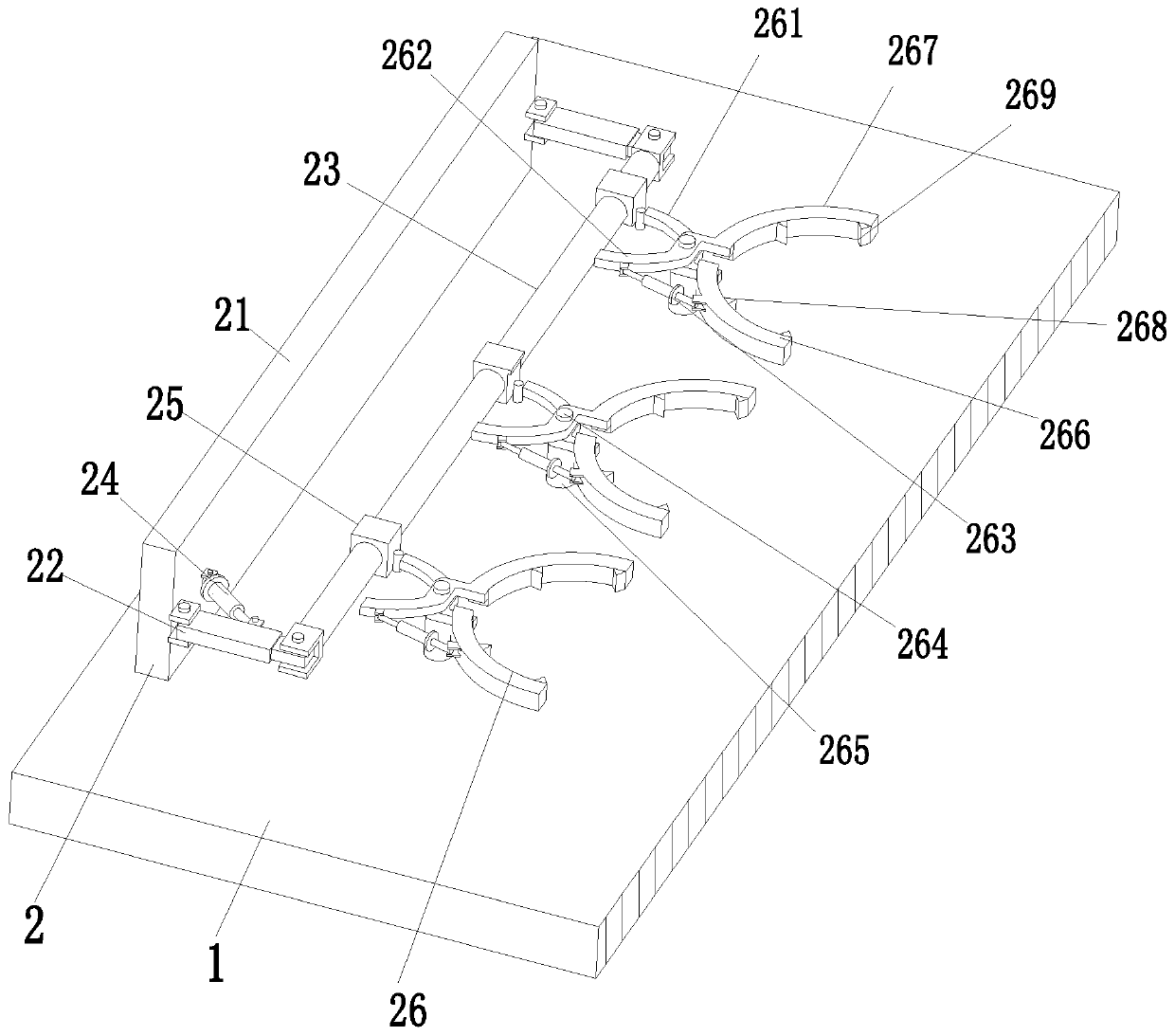

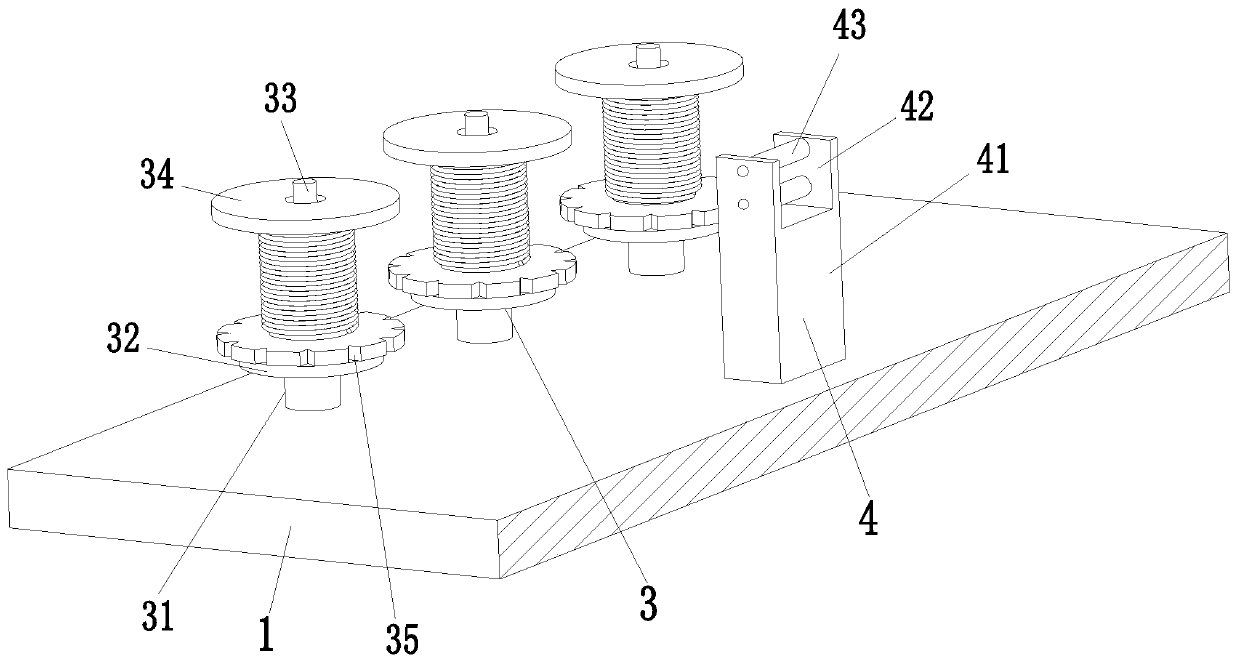

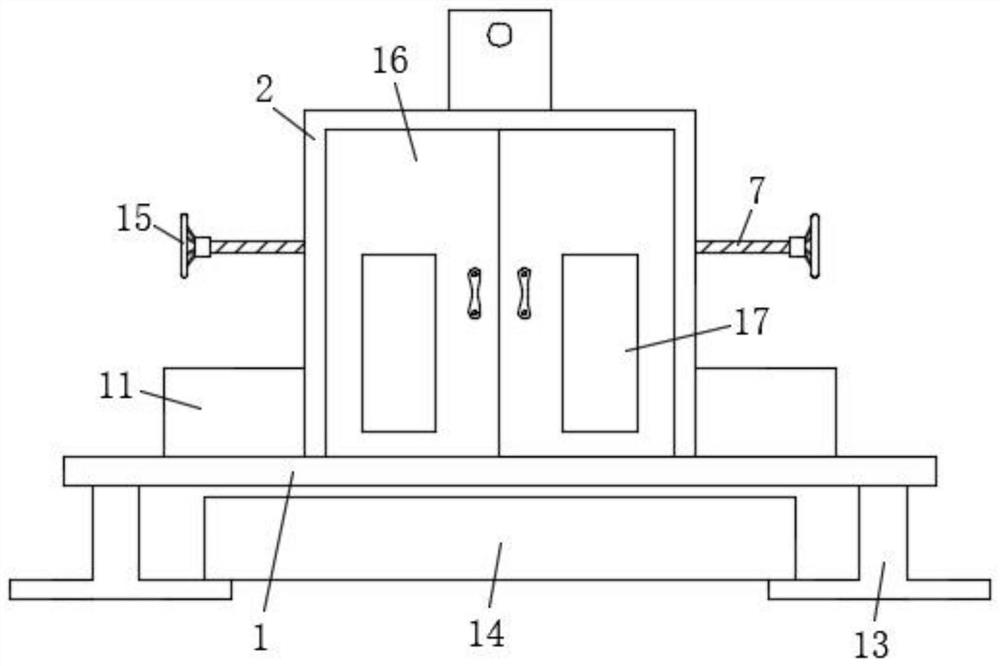

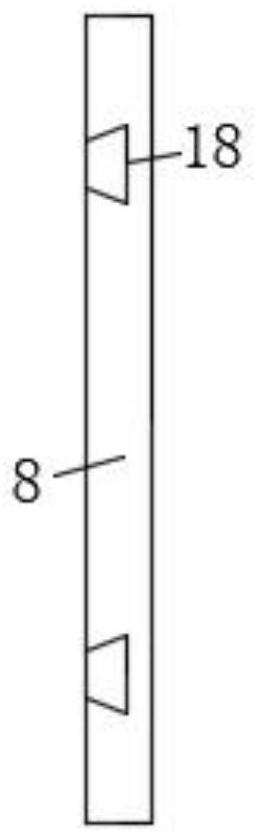

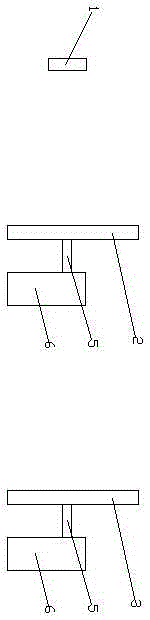

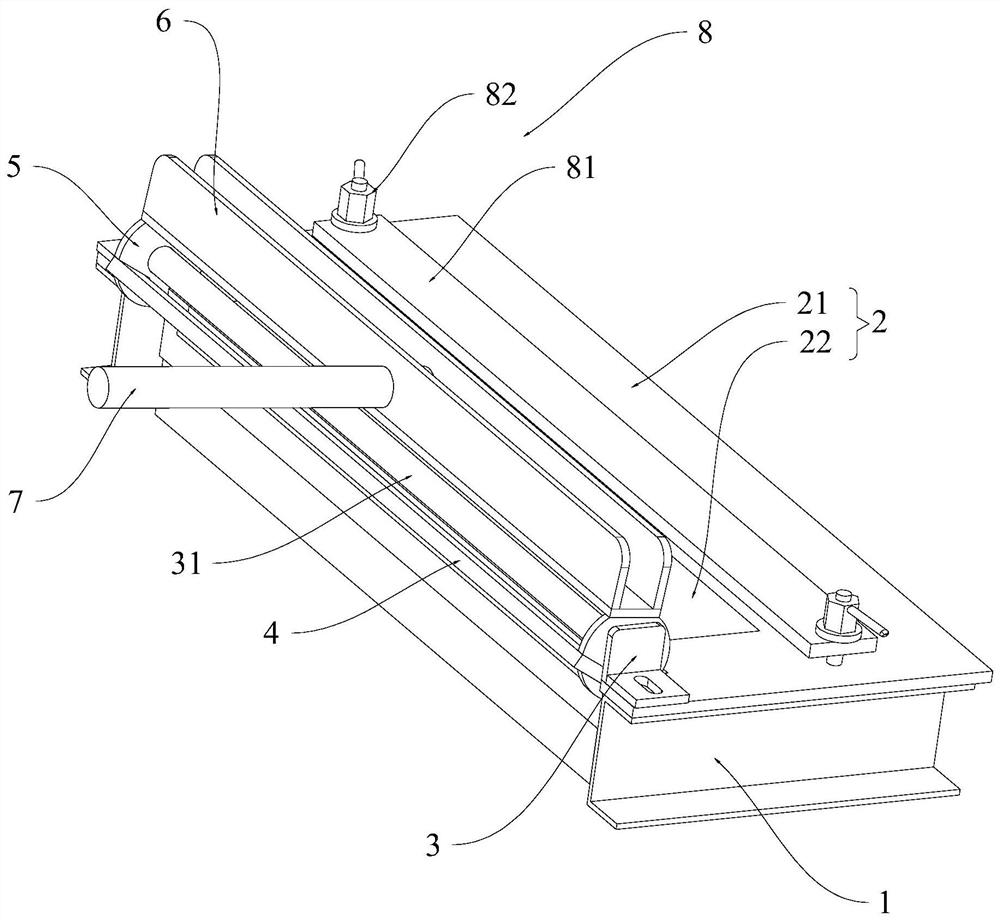

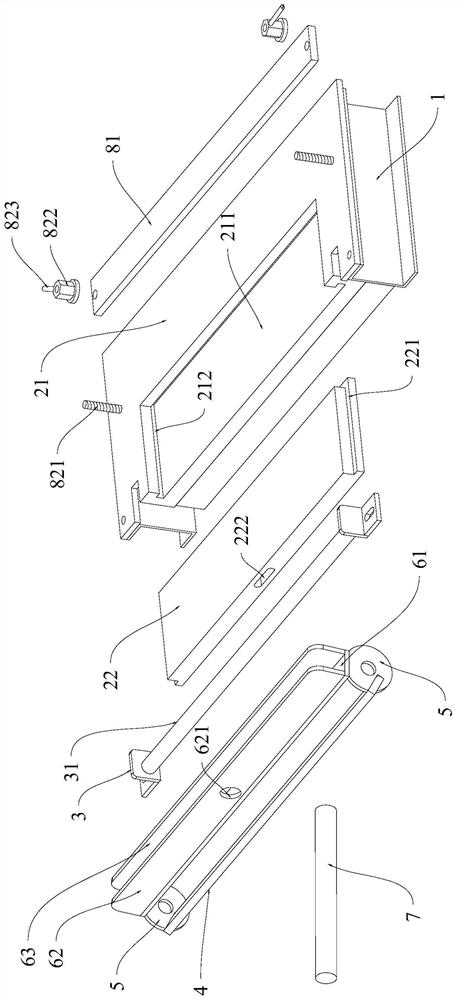

Conveniently and rapidly used tool capable of twisting reinforcing steel bars to be in braided shape automatically

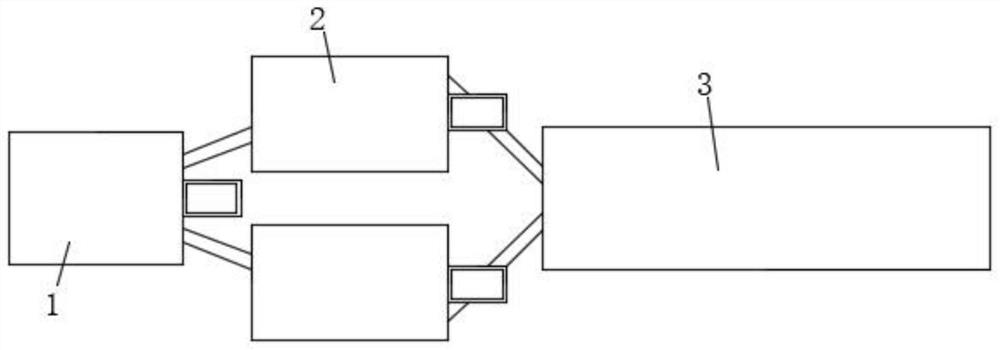

The invention discloses a conveniently and rapidly used tool capable of twisting reinforcing steel bars to be in a braided shape automatically, and belongs to the technical field of machining. The conveniently and rapidly used tool capable of twisting the reinforcing steel bars to be in the braided shape automatically is mainly composed of a pedestal, a turbine, a telescopic rod, a movable plate,traction devices and charging trays. Supporting blocks are arranged on the two sides of the pedestal, and two sliding chutes are formed between two supporting plates. The movable plate is installed inthe sliding chutes of the two sides. The turbine is installed on the right supporting block and further used for driving the reinforcing steel bars to rotate. The telescopic rod is installed on the movable plate and further used for limiting the twisting radian and length of each reinforcing steel bar. The number of the traction devices is two altogether and the two traction devices are symmetrically installed at the two ends of the left side of the pedestal separately and used for straightening and drawing the reinforcing steel bars. The number of the charging trays is also two altogether, and the two charging trays are located at the head ends of the traction devices correspondingly and used for containing reinforcing steel coils to be twisted.

Owner:NANNING SHENGRUN TECH

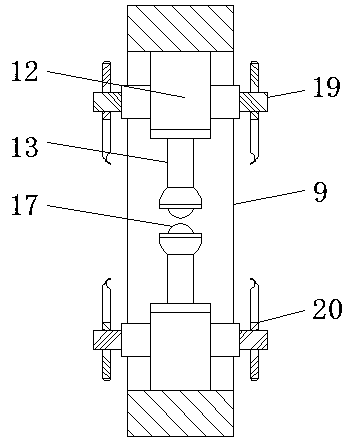

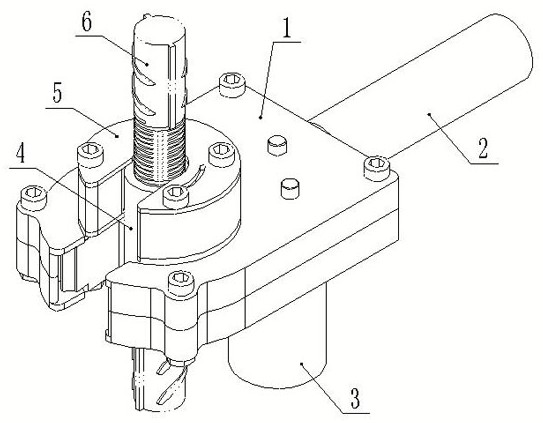

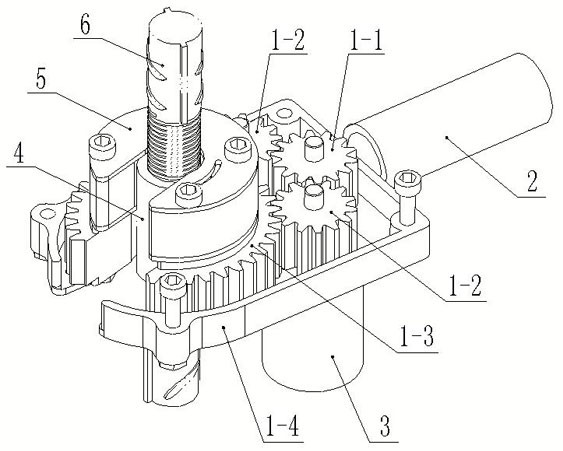

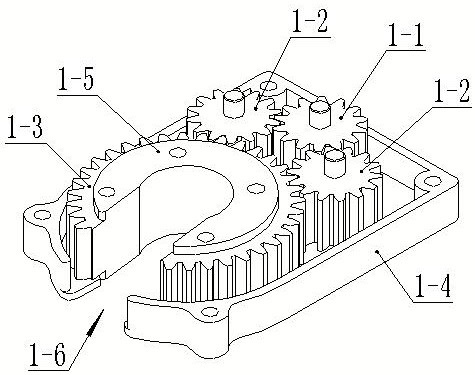

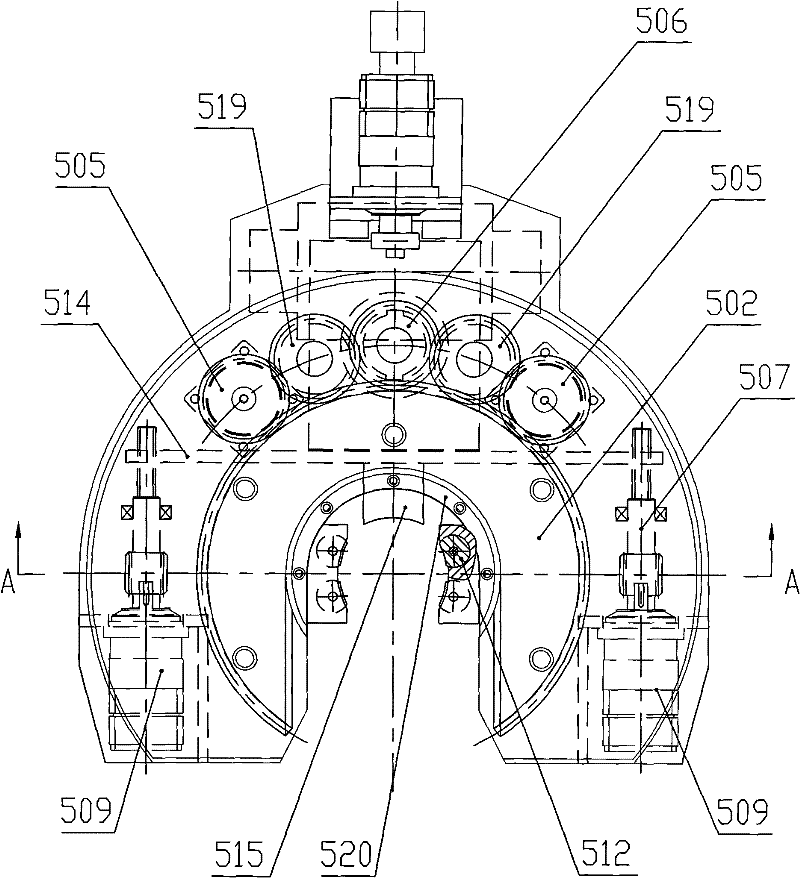

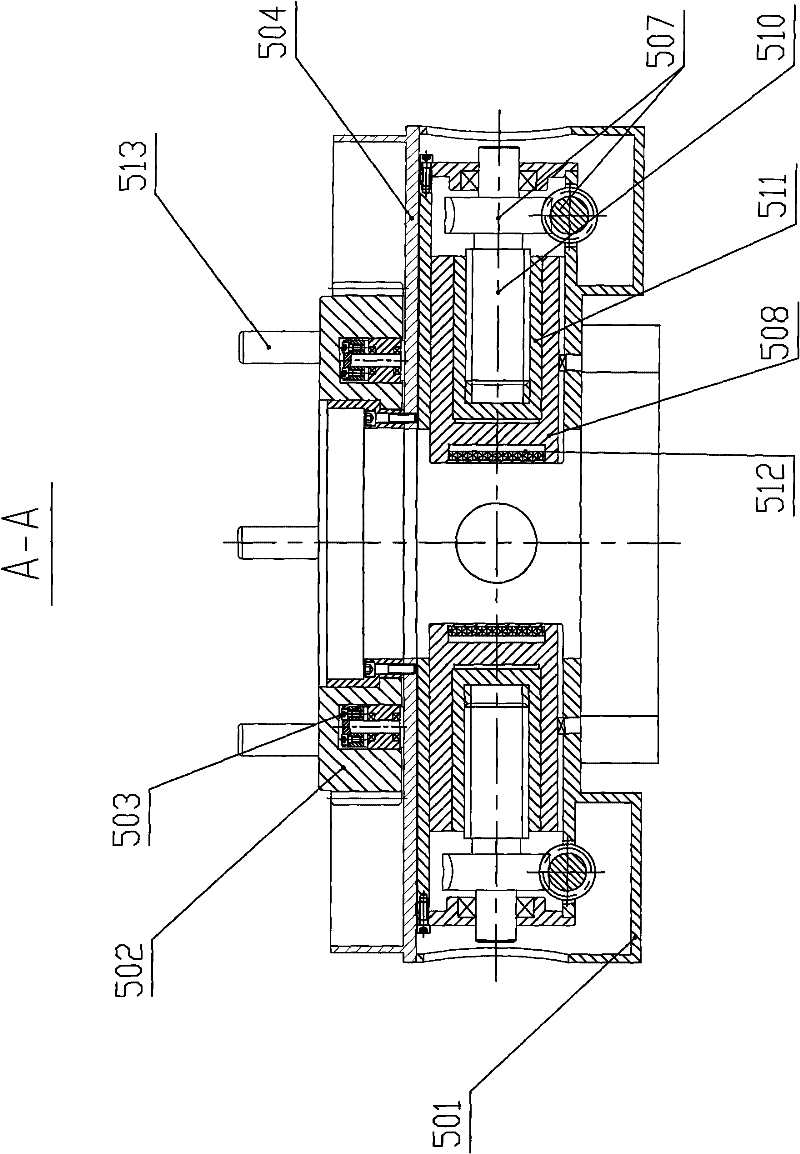

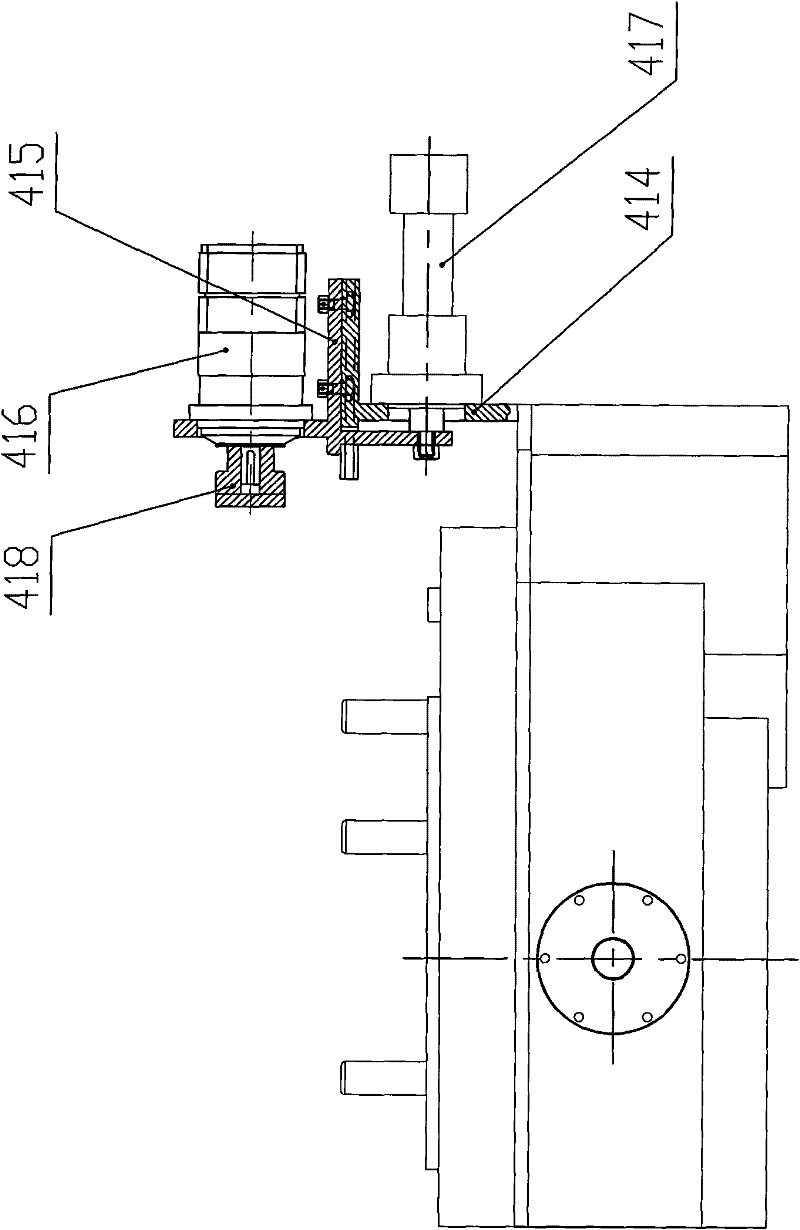

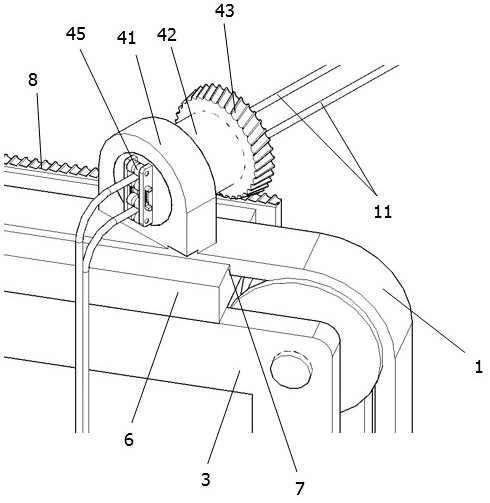

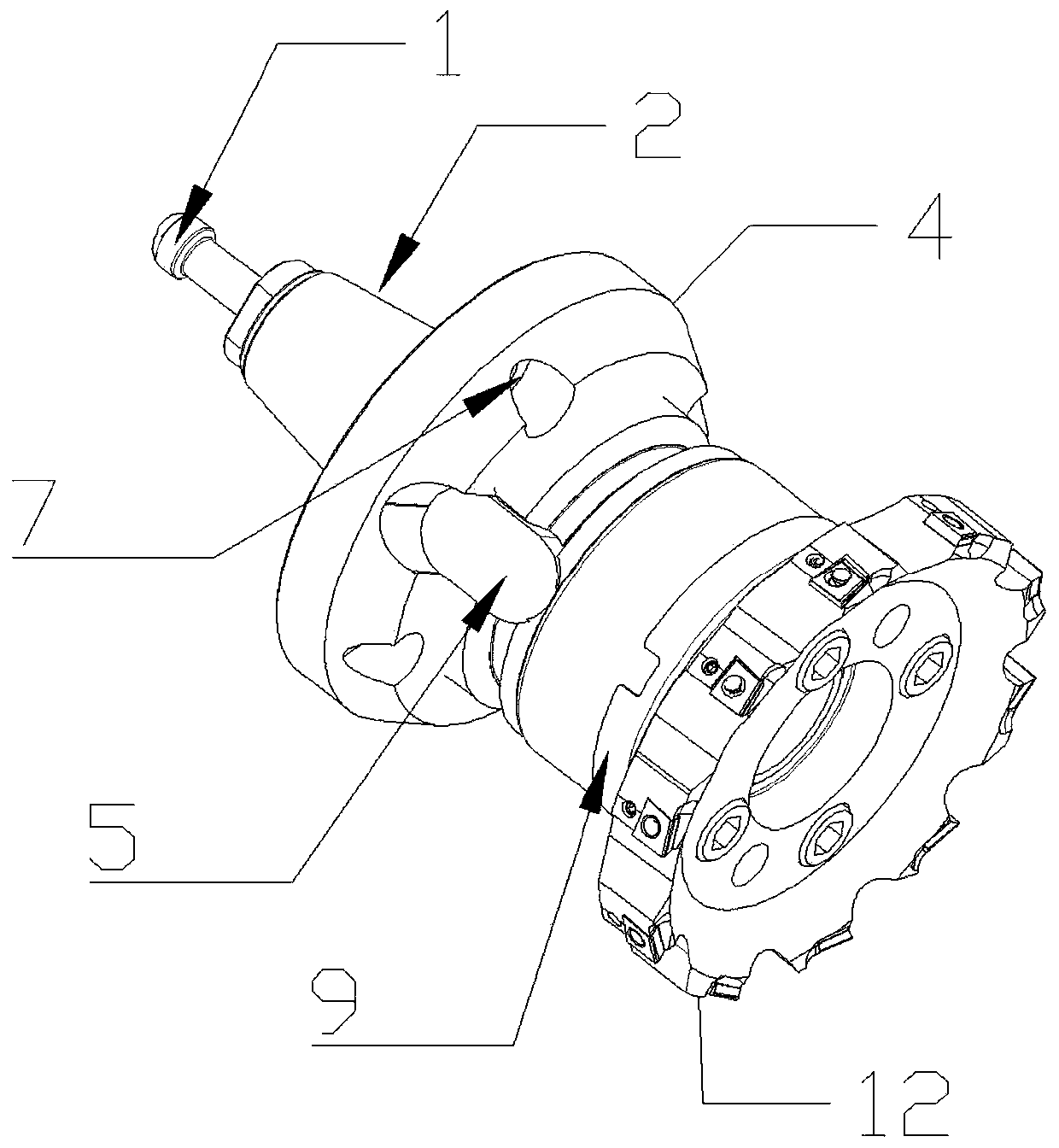

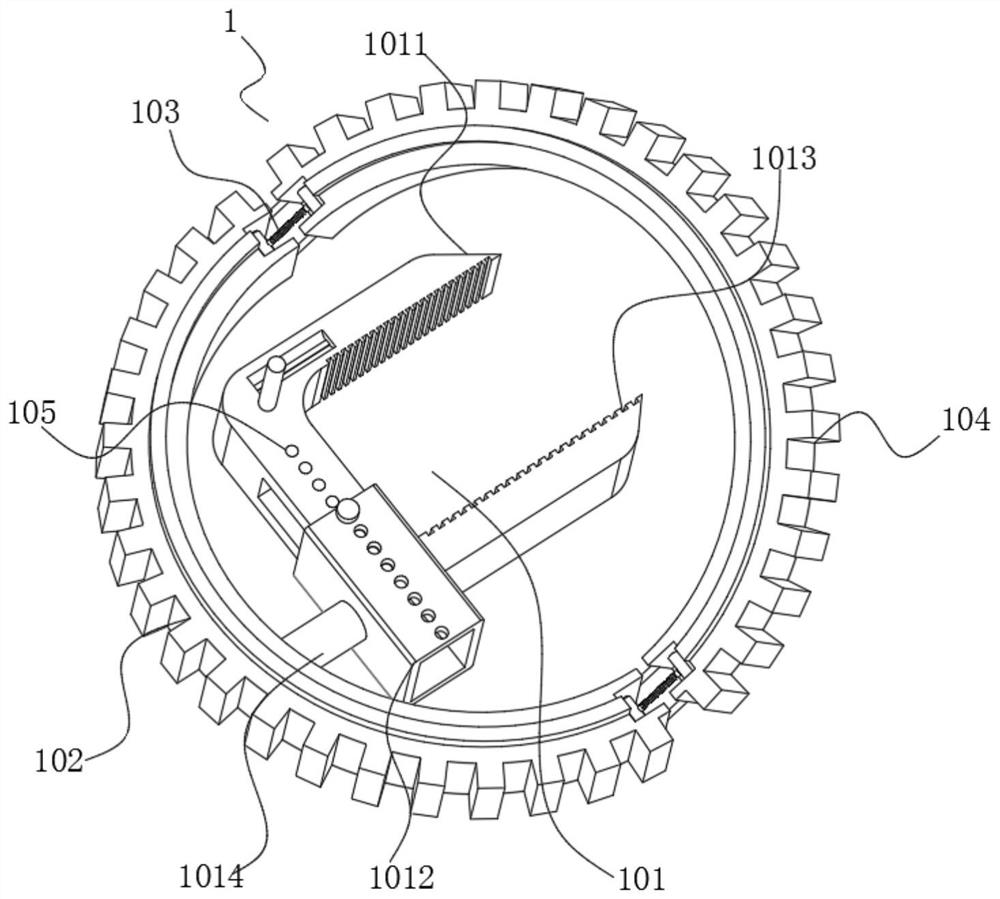

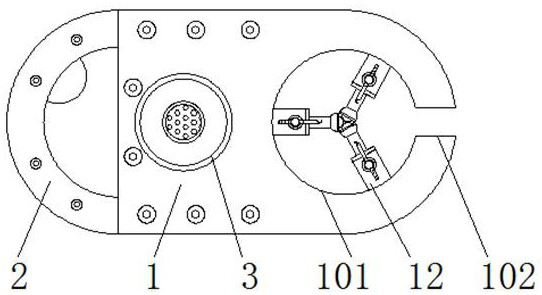

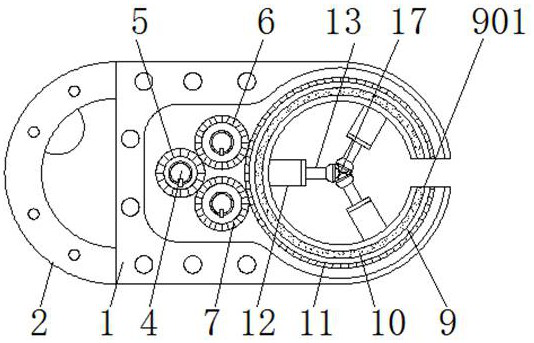

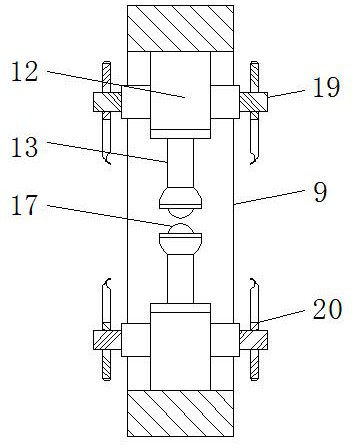

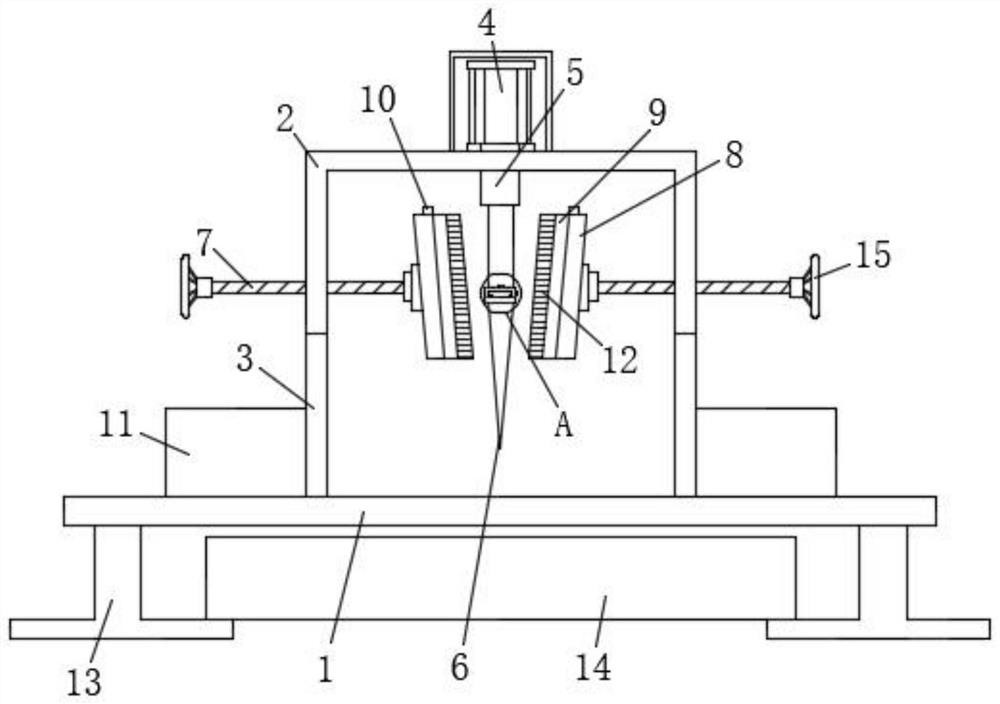

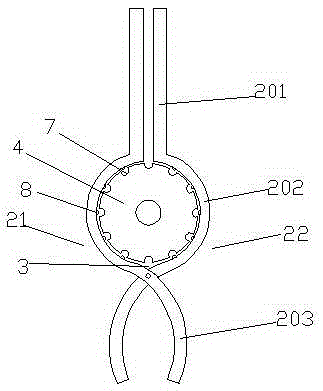

Steel bar splicing sleeve screwing pipe wrench

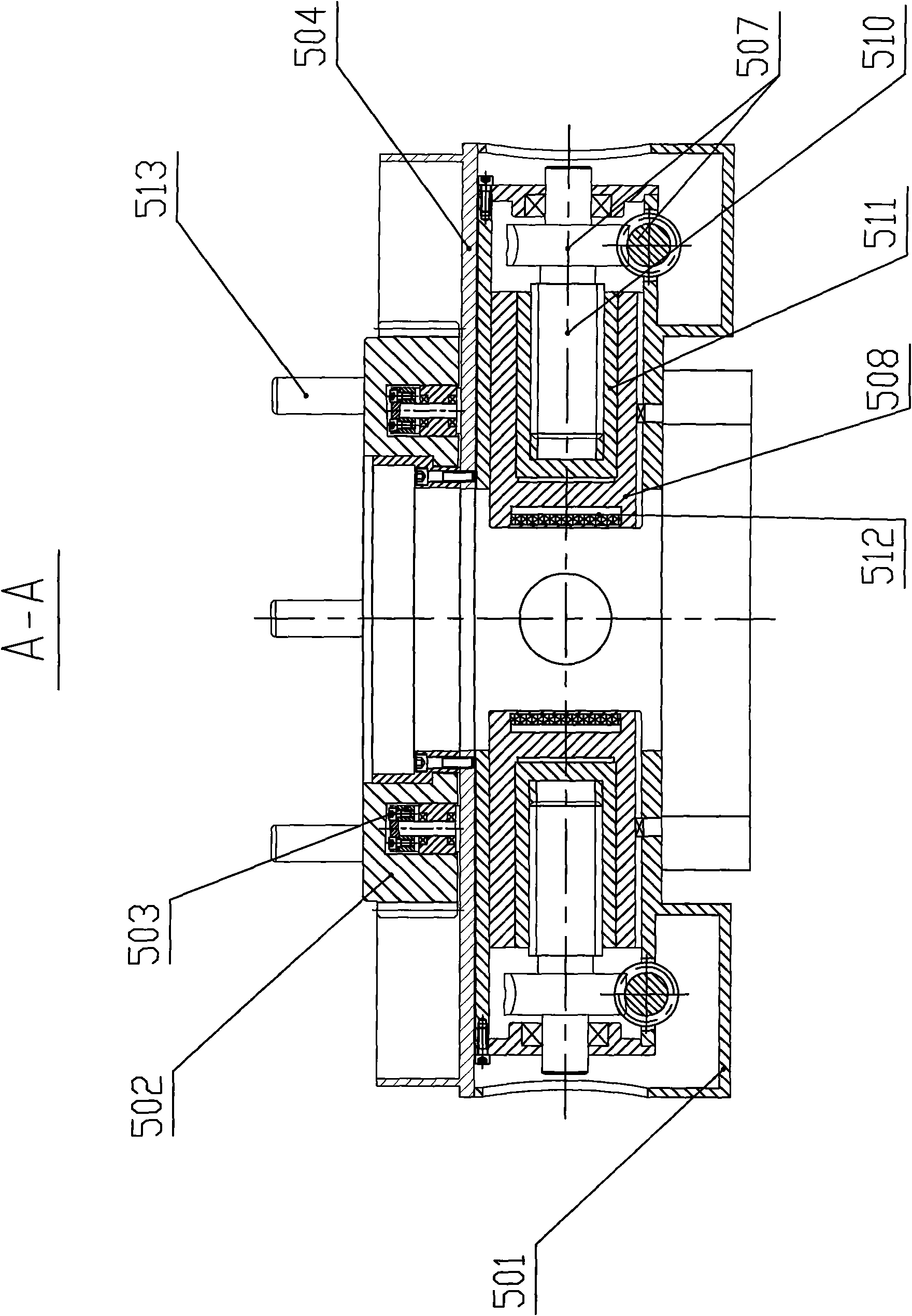

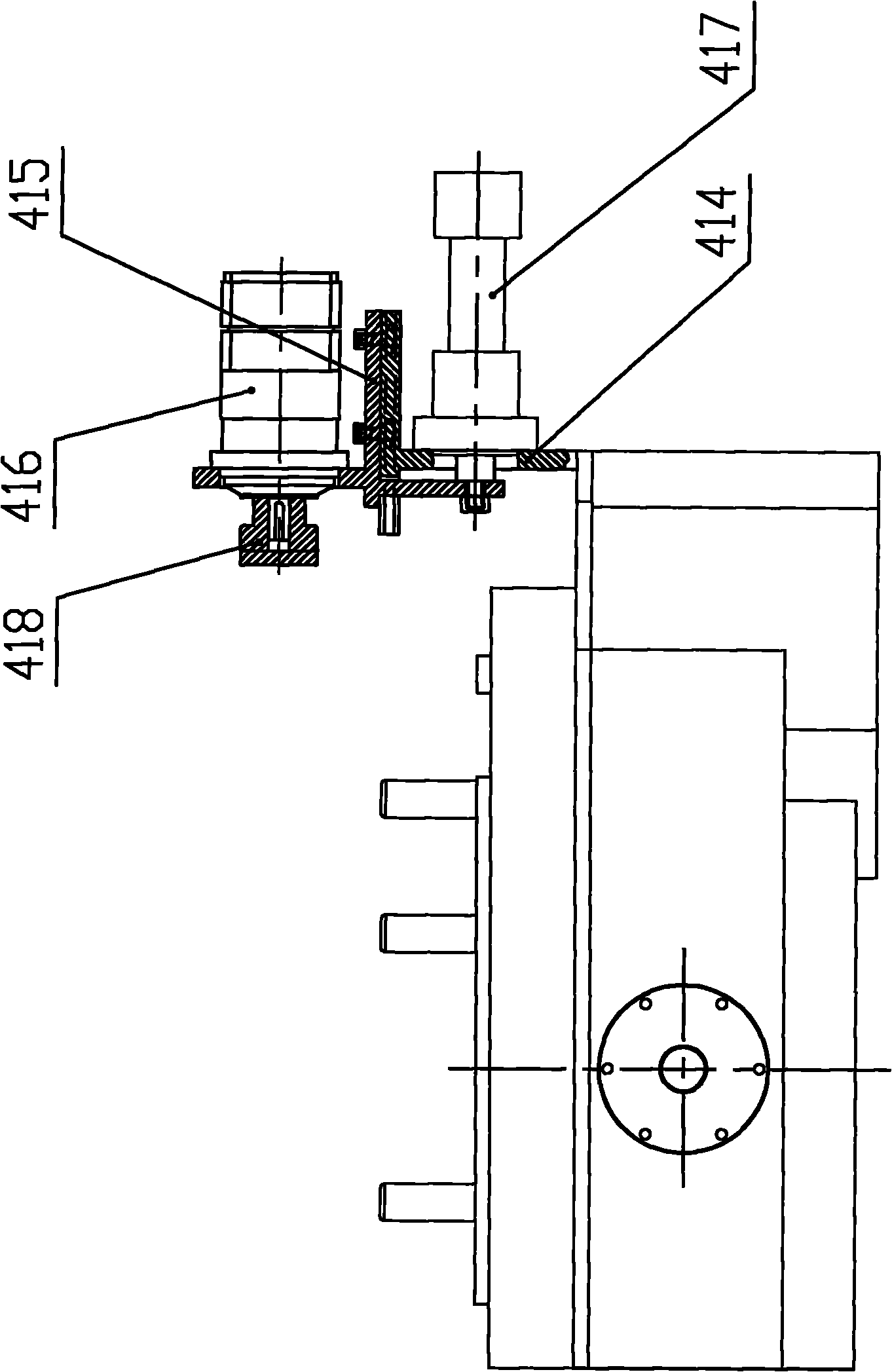

The invention discloses a steel bar splicing sleeve screwing pipe wrench, and aims to provide a steel bar splicing tool capable of realizing the connection of two sections of steel bar mesh cages. Thesteel bar splicing sleeve screwing pipe wrench comprises a power source, a gear reducer and a rotary chuck; the gear reducer (1) is composed of a driving gear (1-1), two idle gears (1-2) and an opening gear (1-3) which are installed in a gear box, a positioning circular hole (1-7) with a notch (1-6) is formed in the gear box, and the opening gear (1-3) is correspondingly positioned in the two circular holes (1-7) through two bosses (1-5) on the opening gear (1-3); the rotary chuck (5) is composed of a C-shaped chuck body (5-5) provided with a wedge-shaped groove (5-3) and a pin roller (5-2) which is located in the wedge-shaped groove (5-3) and installed on a retainer, the retainer is composed of C-shaped plates (5-1) fixed on the two end faces of the chuck body (5-5), a mandrel of the pinroller (5-2) extends into a corresponding guide groove (5-4), and the rotary chuck (5) is fixed on the opening gear (1-3); and the power source (3) is connected with the driving gear (1-1).

Owner:ROAD & BRIDGE INT +2

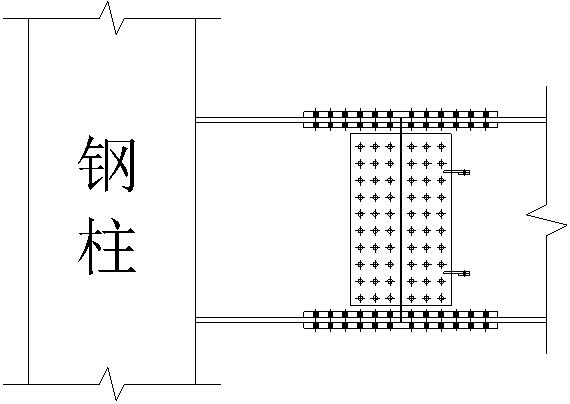

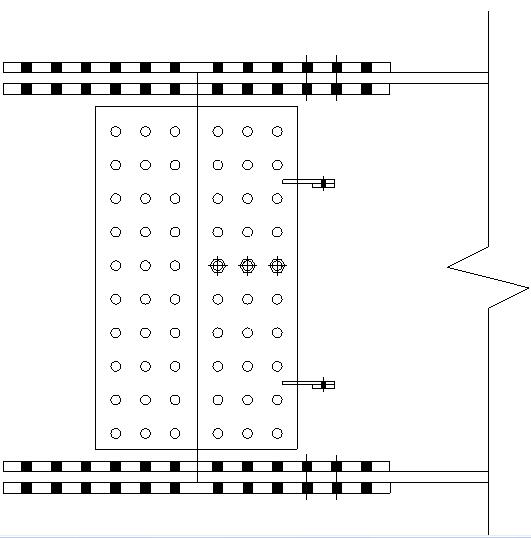

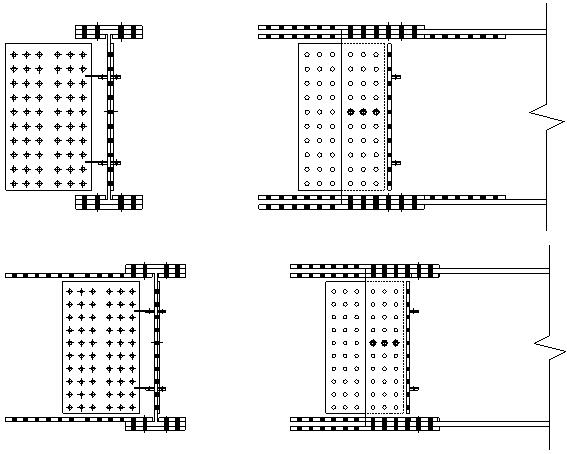

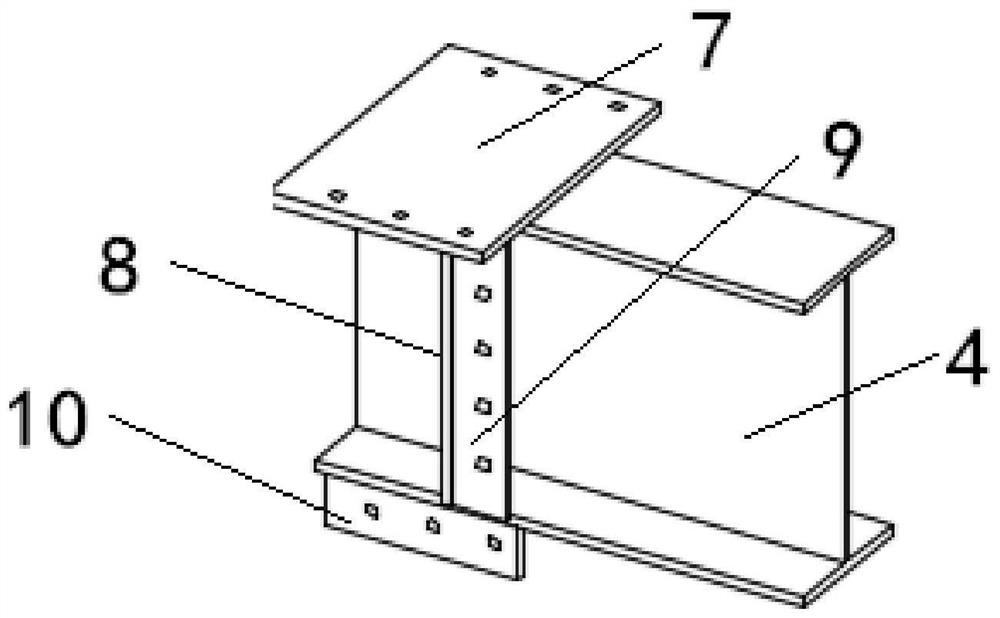

H-shaped steel beam bolt joint construction method

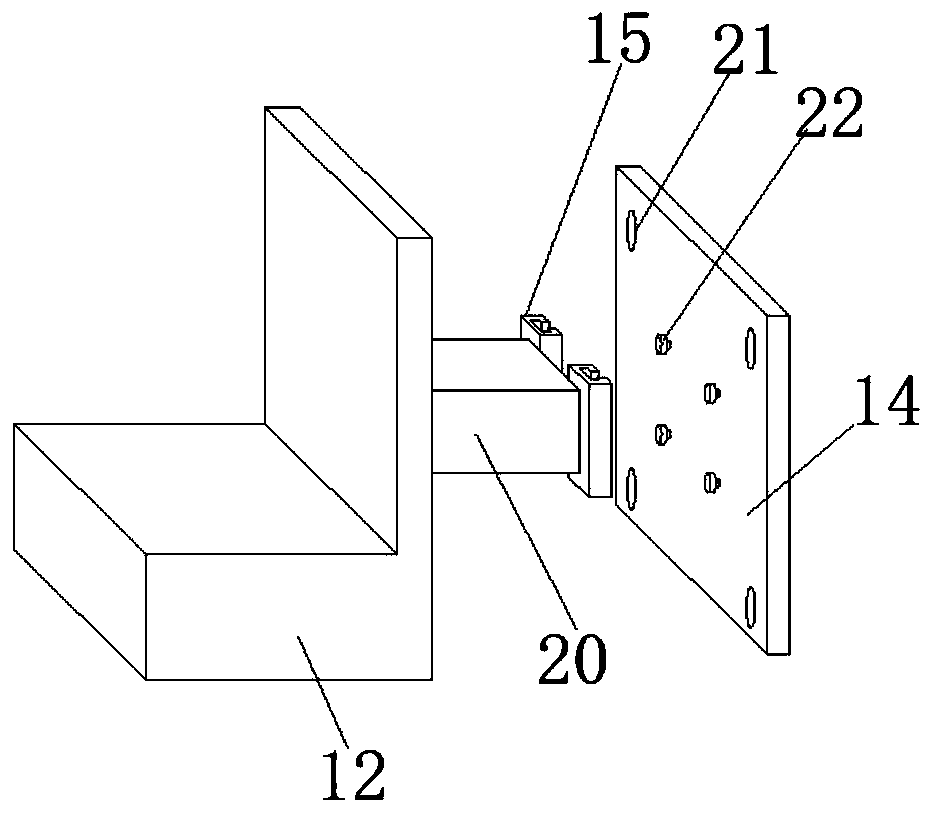

InactiveCN112376691ASimplify the construction processFor quick twistBuilding constructionsConstruction engineeringArchitectural engineering

The invention relates to an H-shaped steel beam bolt joint construction method. According to the H-shaped steel beam bolt joint construction method, in a steel structure deepening design stage, related simple measures are optimized into a design drawing, a processing factory conducts processing along with components, a connecting plate is fixed onto a steel beam by using a common bolt when the components leave the factory, part of mounting bolts are demounted during mounting on a site, the connecting plate is overturned, the steel beam is mounted, then high-strength bolt construction is conducted, mounting is quick, light and flexible, safety measures can be saved, and safety in the using process can be guaranteed; and by arranging temporary measures, on-site rapid positioning and mountingof full-bolt joints are guaranteed, meanwhile, the construction quality of the high-strength bolts is guaranteed, the construction cost is reduced while the working efficiency is improved, and the H-shaped steel beam bolt joint construction method is also suitable for construction of large steel beam web connecting plates.

Owner:中冶(上海)钢结构科技有限公司

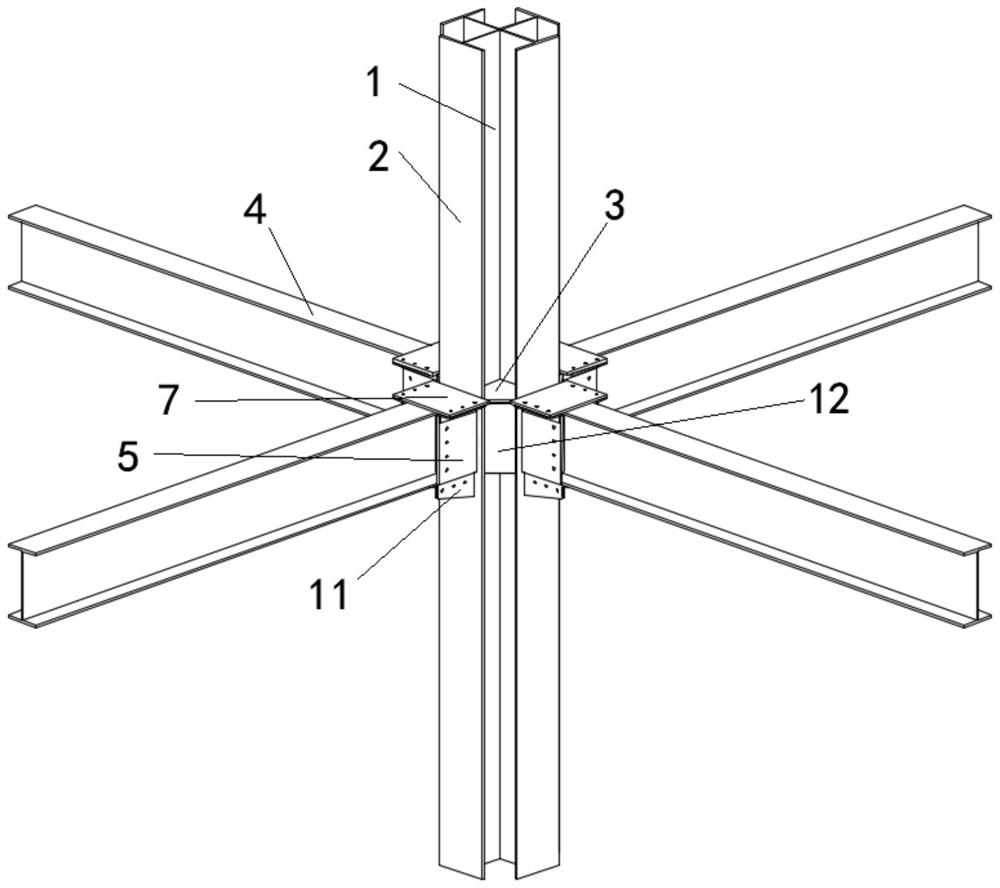

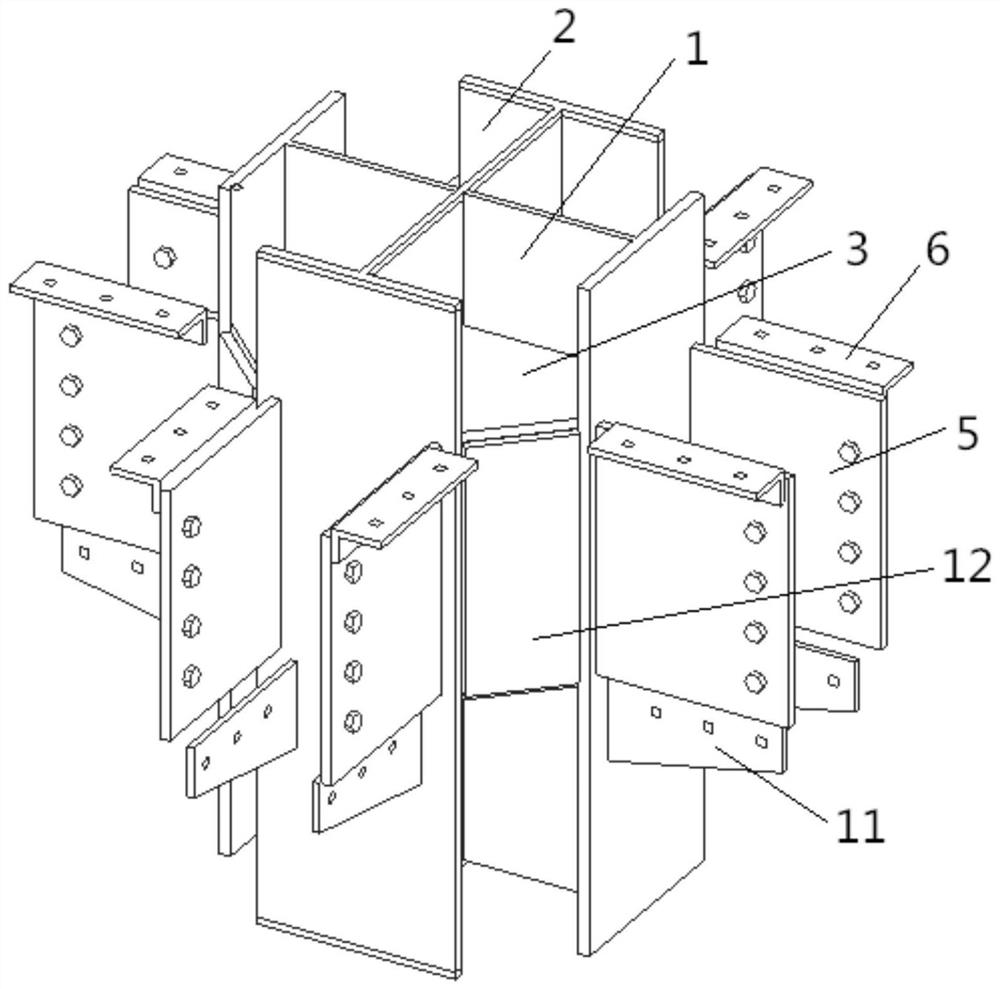

Cross-shaped steel rib column full-bolt rigid connection joint and construction method

PendingCN113931324AReduce workshop processingOperational flow to avoid transshipment punchingStrutsGirdersIndustrial constructionCruciform

The invention provides a cross-shaped steel rib column full-bolt rigid connection joint and a construction method. A cross-shaped steel rib column, a steel beam and corresponding connecting parts are prefabricated and machined in a factory in advance, the on-site welding construction workload is reduced, only bolts need to be adopted for assembling on site, rapid installation and screwing can be achieved through the high-strength bolts, bulk assembling of connecting plates is avoided, construction is convenient, efficiency is high, time and labor are saved, the risk of high-altitude welding operation is greatly reduced, and the core concept of green buildings and green construction in China is met. The cross-shaped steel rib column and the steel beam are mainly stressed components, the section integrity is kept, no bolt hole is formed in the section, no section is weakened, meanwhile, the connecting pieces can achieve design standardization and manufacturing standardization, and the industrial construction level is further improved. The joint belongs to strong-joint weak-rod piece connection, the defects of a traditional rigid connection joint are overcome, and the joint is supplementary extension of a beam column rigid connection joint in a national standard atlas 16G519.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

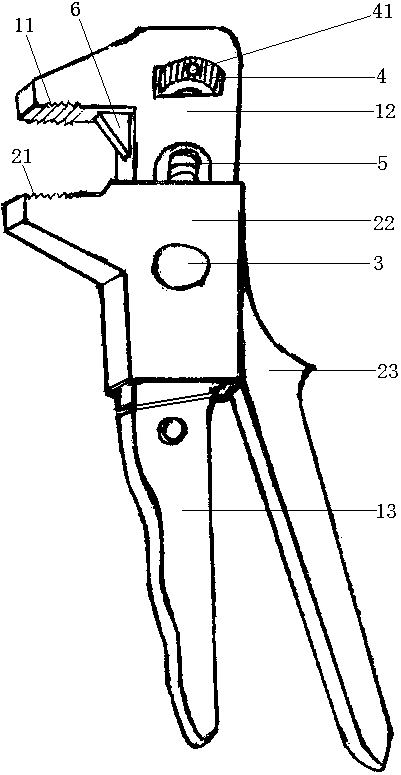

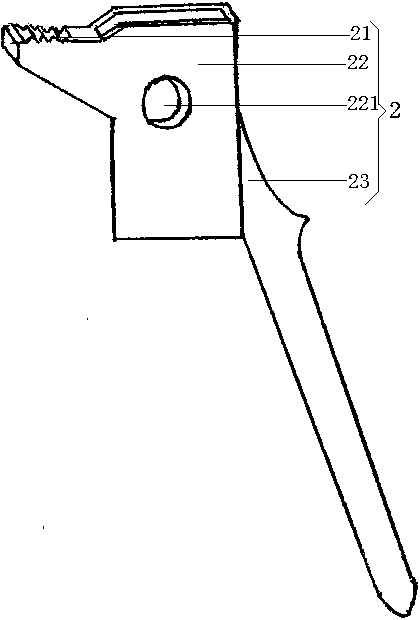

Adjustable spanner

The invention discloses an adjustable spanner which comprises a first arm and a ratchet wheel assembly rotationally assembled and connected with the first arm, wherein the ratchet wheel assembly comprises a reversing component and a pushing component; the ratchet wheel assembly is configured to be that when the reversing component is in a first position, the pushing component can allow the first arm to rotate in the first direction, and when the reversing component is in a second position, the pushing component can allow the first arm to rotate in the second direction; and the first directionand the second direction are mutually opposite. The ratchet wheel assembly provides torsion to the first arm, so that the first arm has a function similar to a one-way clutch. The adjustable spanner further comprises a second arm, and can be switched into a spanner state or a screwdriver state by adjusting an angle between the first arm and the second arm.

Owner:HANGZHOU GREAT STAR TOOLS +1

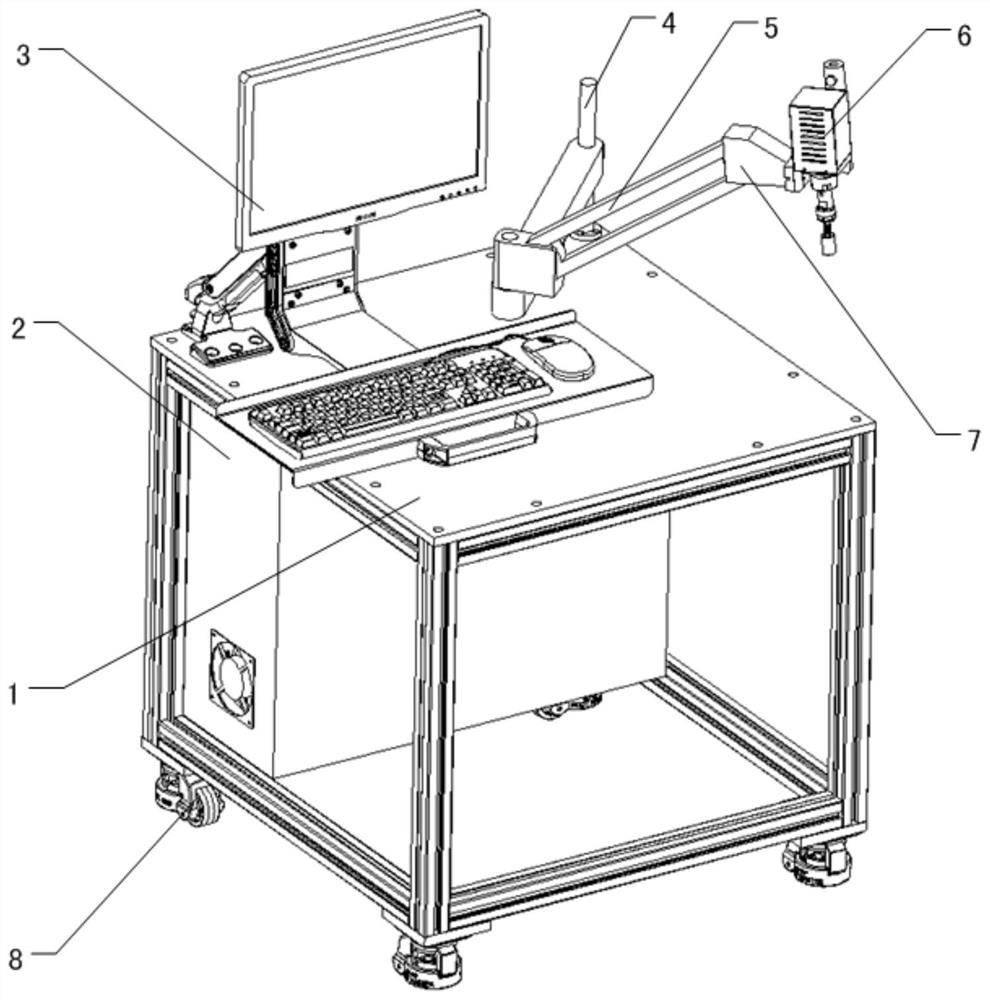

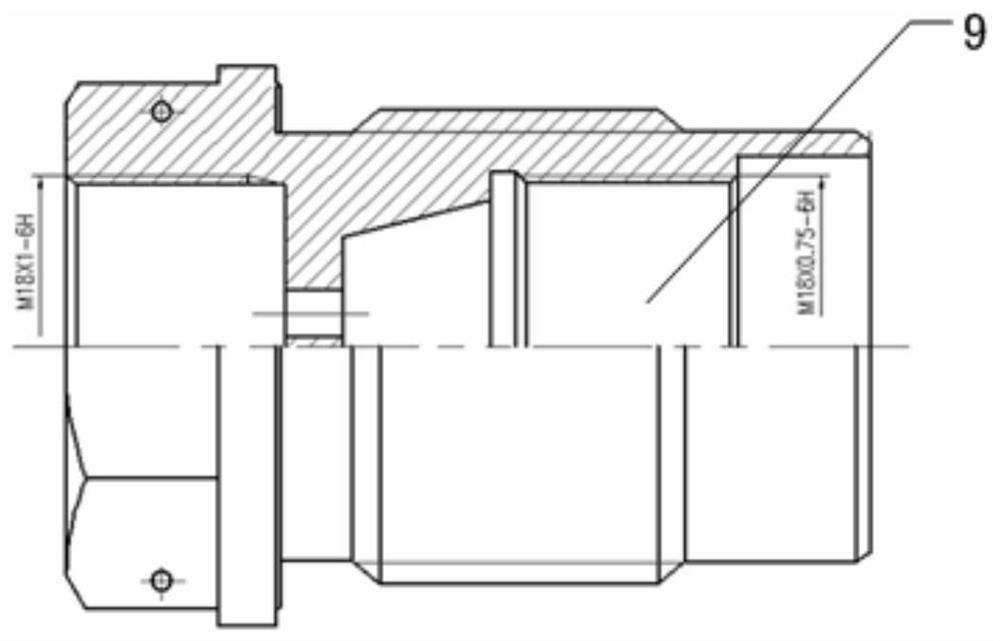

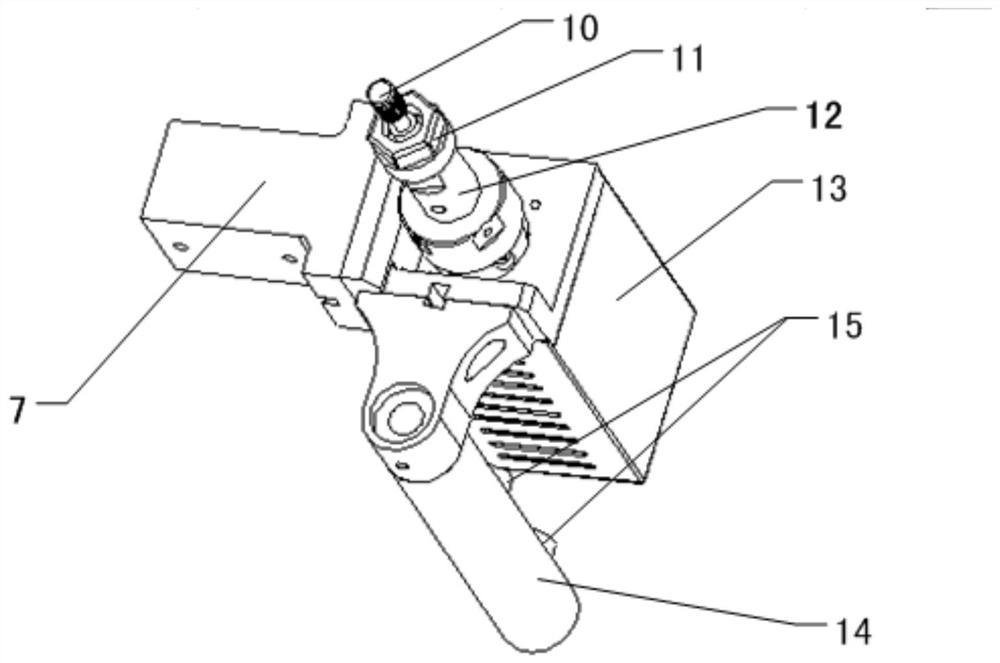

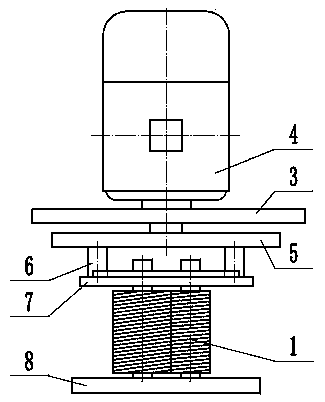

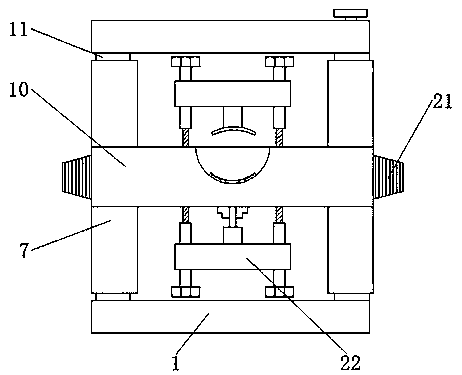

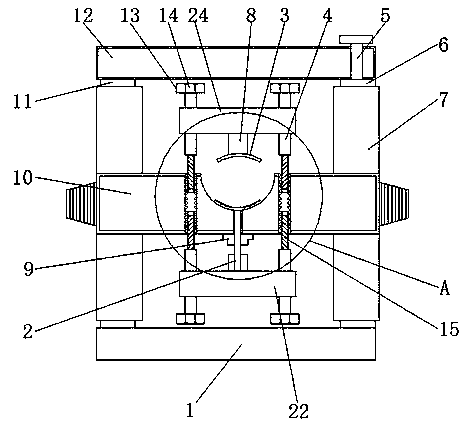

Movable semi-automatic internal thread detection device

PendingCN113899290AImprove detection efficiencyEffective screwingMechanical counters/curvatures measurementsPhysicsEngineering

A movable semi-automatic internal thread detection device is characterized in that a fixed column (4) is fixedly mounted on the upper surface of a device detection platform (1), and the fixed column (4), a pneumatic suspension arm (5), a connecting piece (7) and a thread detection mechanism (6) are sequentially connected; a display and input / output device (3) is connected with a control system (2) and is used for setting detection parameters and displaying a detection result; the control system (2) is arranged at the lower part of the device detection platform (1); the control system (2) is used for outputting a control instruction to the thread detection mechanism (6) according to detection parameters set by the display and input / output device (3); and the thread detection mechanism (6) is used for performing screwing detection on the product (9) according to the control instruction output by the control system (2). The internal thread flexibility semi-automatic detection device is light, convenient, efficient and movable, and is used for parts and components of a spaceflight pyrotechnic device.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

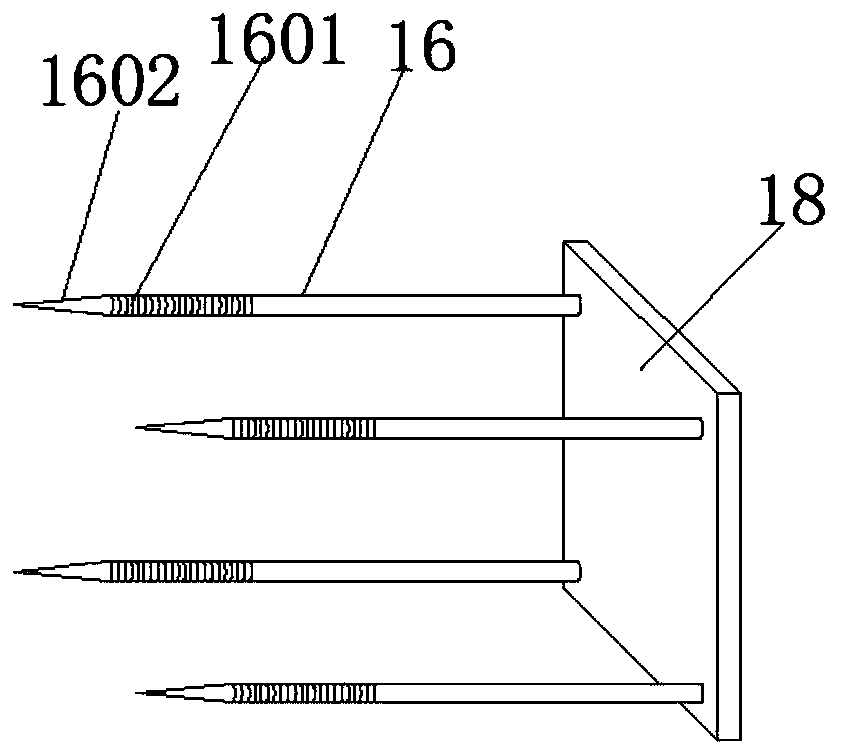

Wire twisting method of automatic sleeve penetrating equipment

A wire twisting method of automatic sleeve penetrating equipment is applied to an automatic multi-shaft penetrating insulation sleeve winding machine. A lower XYZ module is positioned below an upper XYZ module, a linear bearing is connected to a mounting rack, a main shaft module is arranged in the middle of the upper XYZ module, the lower XYZ module is positioned below the main shaft module, themain shaft module comprises a rotating main shaft and a rotating clamp, the rotating clamp is mounted at the tail end of the rotating spindle, a product with a symmetrical L-shaped pin is mounted on the rotary fixture, the lower XYZ module comprises an L-shaped bracket and a guide pin, a cross beam is arranged in the middle of the L-shaped bracket, two ends of the cross beam are rotationally connected with the L-shaped brackets, the guide pin is horizontally and vertically mounted on the rear side of the beam, at least two wires penetrate through the guide pin, one end of each wire is fixed toa pin of a product, the guide pin is located on the front side of the same axis of the rotating main shaft, the rotating main shaft rotates, the wires between the pin of the product and the guide pinrotate rapidly, rapid screwing of multiple strands of wires is achieved, and the manufacturing cost and the manufacturing difficulty of the multi-axis winding machine are reduced.

Owner:东莞市鑫华翼自动化科技有限公司

Wool yarn twisting apparatus

The invention provides a wool yarn twisting apparatus and belongs to the technical field of weaving machinery. The wool yarn twisting apparatus comprises a twisting mechanism and a yarn collecting mechanism, wherein pins of the twisting mechanism are arranged on the lower end of a driving round disc along the periphery at equal intervals; the top ends of a first left twisting roller, a second right twisting roller, a second left twisting roller and a second right twisting roller are respectively provided with a swinging rod; the external end of the swinging rod is tightly close to the corresponding pin; one end of a reset spring is fixed on a bearing support plate and the other end is installed on the swinging rod; the yarn collecting mechanism is formed by a rack, a yarn guide assembly and a yarn collecting assembly; a yarn guide bearer of the yarn guide assembly can left-right slidalbly arranged on a guide rail; a yarn guide ring is installed on the yarn guide bearer; an adjustable lead screw can be rotationally arranged on the rack; the adjustable lead screw is in a threaded connection with the yarn guide bearer; and a yarn collecting roller of the yarn collecting assembly can be rotationally arranged on the rack. Wool yarns can be quickly twisted; great effect can be achieved; and the wool yarn twisting apparatus is simply structured and requires low cost.

Owner:TONGXIANG HUIQUAN TEXTILE CO LTD

Screwing and buckling clamp for connecting and disassembling drill rod and sleeve pipe

InactiveCN101781975BPrevent disengagementAccurate screw connectionDrilling rodsDrilling casingsDrive shaftUltimate tensile strength

The invention discloses a screwing and buckling clamp for connecting and disassembling a drill rod or a sleeve pipe, which comprises a power clamp and a fixing clamp, wherein the power clamp and the fixing clamp can rotate relatively; a driving oil motor sliding seat is also arranged on a shell of the fixing clamp; a latch driving oil motor supporting plate is arranged on the driving oil motor sliding seat; a latch driving oil motor is arranged on the latch driving oil motor supporting plate; a power output connector of the latch driving oil motor corresponds to an input connector of a power transmission shaft in the power clamp; a supporting plate pushing oil cylinder is arranged on the driving oil motor sliding seat; and the pushing end of the supporting plate pushing oil cylinder is connected with the latch driving oil motor supporting plate. By the design of the screwing and buckling clamp in the scheme, the structure can accurately and quickly complete screwed connection of drill pipes, and the pipe connecting process is stable and quick, thereby improving the pipe connecting efficiency, reducing the labor intensity and the risk of workers.

Owner:CHENGDU SHIWEI TECH CO LTD

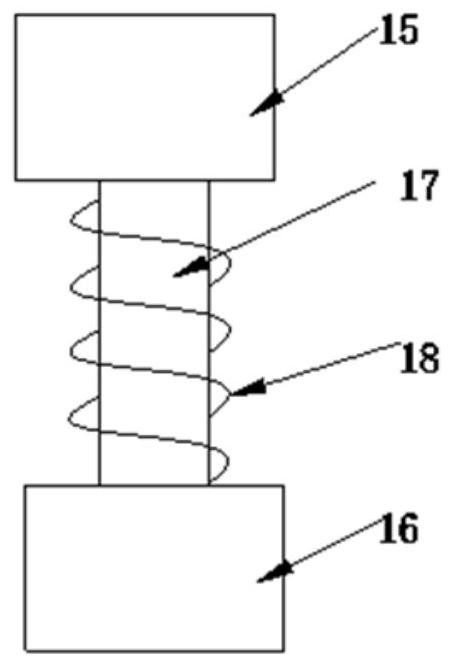

Method for realizing self power supply of bridge structure monitoring equipment

ActiveCN114094873AMeet the needs of normal useFull conversionBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesStructural monitoringEngineering

The invention discloses a method for realizing self power supply of bridge structure monitoring equipment. The method comprises a vibration base, a telescopic shaft, a piezoelectric plate and a rectification circuit board. The method has the beneficial effects that through the design of the vibration base, the telescopic shaft, the fixed seat, the piezoelectric plate, the balancing weight, the rectifying circuit board and the capacitor, the piezoelectric plate can swing by utilizing vibration of the bridge main body so that electric energy is generated and finally stored in the capacitor to be used by external monitoring equipment; not only can full conversion and utilization of energy be realized and the utilization rate of the energy be effectively improved, but also the device does not need additional wiring in use and meets the requirement of normal use of external monitoring equipment in a power shortage zone; and through the design of a movable door plate, a limiting ring, a limiting rod, a spring and a fixing ring, the operation space of the hand of a worker can be effectively increased when the box body is installed, rapid screwing of the worker is facilitated, and therefore the overall installing and fixing efficiency of the device is improved.

Owner:WUHAN MUNICIPAL CONSTR GROUP +2

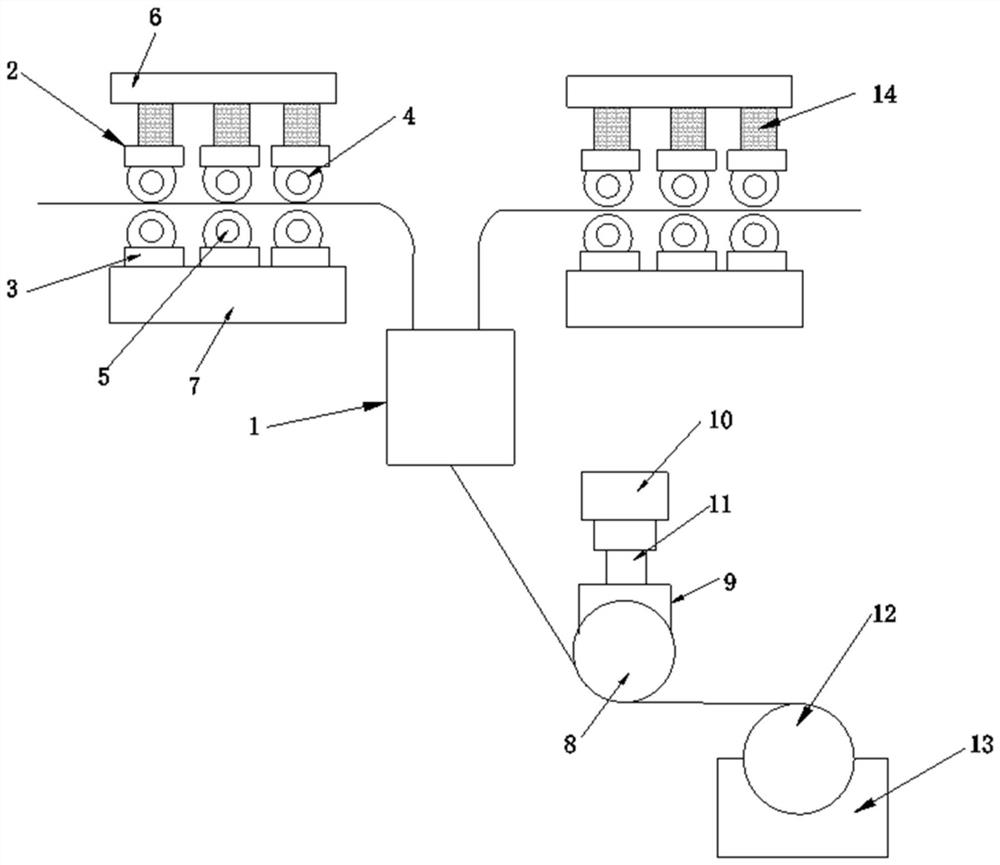

Twisted pair cable forming device and manufacturing method

ActiveCN111739697BFor quick twistIncrease productivityCable/conductor manufacturePower cableEngineering

The invention relates to the field of power cable production equipment, in particular to a twisted pair cable forming device and a manufacturing method. The first conveyor belt and the second conveyor belt are arranged at one end close to each other, and the other end is gradually separated in a figure-eight arrangement. They are respectively supported by two support frames. The upper ends of the support frames are equipped with supporting plates, and the upper end surface from one end to the other end is provided with U. shaped groove; the first conveyor belt and the second conveyor belt both have a plurality of traction and rotation mechanisms, and are set in pairs. In the present invention, the electric wires can be in tension between multiple traction and rotation mechanisms to avoid kinking; twisted wires of different lengths can be produced according to actual needs; the twisted wires can be automatically separated from the traction and rotation mechanisms to improve production efficiency.

Owner:山西新兴榆缆线缆有限公司

Front heater cable

InactiveCN108859664AFixedEasy to fixAir-treating devicesVehicle heating/cooling devicesWorking lifeArchitectural engineering

The invention provides a front heater cable, and relates to the field of automobile parts. The front heater cable comprises a base, wherein the two sides of the top of the base are fixedly connected with protective plates, cable seats are embedded in the front surfaces of the two protective plates, the two sides of the bottom of each cable seat are provided with threaded rods I, each cable seat isinternally provided with a threaded slideway, a limit slot is formed in the middle of the top of each cable seat, the bottom of each limit slot is movably connected with a support plate, the bottom of each support plate is fixedly connected with a support rod I, and the bottom ends of the support rods I penetrate through the cable seats and are fixedly connected with fixed seats I. The front heater cable is provided with the threaded rods I, threaded rods II, the support rods I, support rods II, anti-slip pressure plates and the support plates in cooperation, the cable seats can be fixed better, the fixing effect of the cable seats is improved, the working life of the cable seats is ensured, and the possibility of pull-off, deformation and displacement of the cable is lowered.

Owner:JIANGYIN CHANGJING CAR & SHIP ACCESSORY

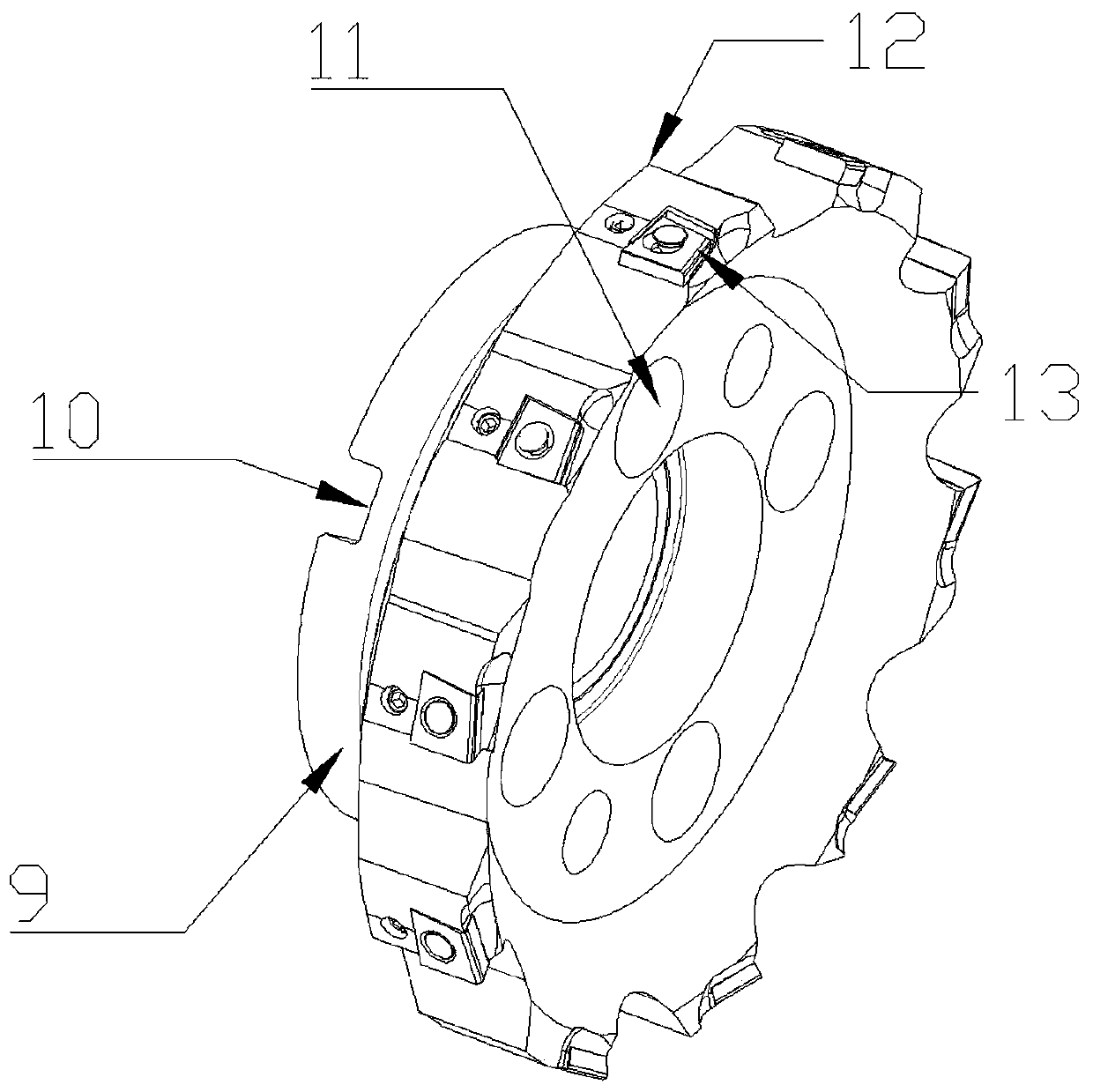

Milling cutter disc used for plate machining

The invention discloses a milling cutter disc used for plate machining. The milling cutter disc comprises a limiting column, a connecting column, a limiting ring, a chuck, a clamp block, a first buckle groove, connecting screw holes, a fixed column, a butt-joint column, a second buckle groove, fixed screw holes, a milling cutter disc body and milling cutter clamp grooves. The milling cutter disc has the beneficial effects that inward concave type screw holes are formed in the bottom ace of the fixed column, the screw holes are in one-to-one correspondence to the fixed screw holes, and screws can penetrate through the fixed screw holes conveniently to be rapidly screwed with the fixed column; the butt-joint column is in butt joint with the fixed column through the second buckle groove, andthe screws penetrate through the fixed screw holes to be screwed and fixed with the fixed column; through the corresponding screw holes, rapid fixing between the butt joint column and the fixed columnis achieved, and fastening is guaranteed; and fixed clamp sheets are arranged on the milling cutter clamp grooves, a milling cutter can be extruded and fixed through the clamp sheets, and the millingcutter can be conveniently replaced later through the manner of extrusion and fixing.

Owner:CHANGZHOU NAIZHILI TOOLMAKING

A waste removal device for wood processing

InactiveCN111002405BEasy to clean upFor quick twistWood compressionDomestic articlesCouplingAgricultural engineering

The invention belongs to the technical field of wood processing, in particular to a waste chip removal device for wood processing. For the collection of waste chips in existing wood processing, the waste chips are simply sucked into the collection bucket, and the fluffy wood chips will take up a lot of space. Problem, the following solution is proposed, including a workbench with a cavity in a square tubular structure, a round hole is opened at the bottom of the workbench near the edge, and a feeding pipe is welded in the round hole, and the top of the workbench A driving motor is fixed on the inner wall close to the upper part of the feeding pipe, and a transmission rod is fixed on the top of the output shaft of the driving motor through a coupling, and a spiral plate is arranged on the peripheral outer wall of the transmission rod. The invention can quickly twist the wood waste near the mouth of the feeding pipe into the feeding pipe when it is rotating, rotate when it needs to be discharged, and can stagnate the wood chips in the feeding pipe when it does not need to be discharged, which is convenient Cleaning up at the exit.

Owner:河北聚商智能科技有限公司

Adjustable wrench self-adaptive to nut size

InactiveCN114378753AFor quick twistImprove work efficiencySpannersWrenchesGear wheelOperation safety

The invention discloses an adjustable wrench self-adaptive to the size of a nut, and relates to the technical field of mechanical tools. The wrench comprises a wrench assembly, a fixing assembly and a supporting frame. The wrench assembly is in sliding fit with the fixing assembly; the wrench assembly comprises a wrench body, a first annular gear rack, a spring connecting piece and a second annular gear rack. The wrench body is fixedly mounted on the inner wall of the first annular gear rack; the first annular gear rack and the second annular gear rack are fixedly connected through a spring connecting piece; the two supporting frames are in sliding fit with a movable assembly. And the movable component is inserted and matched with the fixed component. After the nut is clamped and fixed through the wrench assembly, the wrench assembly is reset, the handle is rotated to drive the rotating gear to rotate, and the wrench assembly is driven to rotate together with the nut, so that the fixing assembly, the handle assembly and the nut move up and down along the supporting frame together, rapid screwing of the nut is achieved, the working efficiency is improved, and meanwhile the labor intensity of workers is reduced. And the operation safety is ensured.

Owner:陈先珍

Double-wire-end copper-tin alloy stranding device

InactiveCN111799042ANovel structural designFor quick twistCable/conductor manufactureEngineeringStructural engineering

The invention discloses a double-wire-end copper-tin alloy wire stranding device. The device comprises a first wire guiding assembly, a second wire guiding assembly, a wire stranding cylinder and a winding assembly, wherein the first wire guiding assembly and the second wire guiding assembly are symmetrically arranged on the two sides of the wire stranding cylinder, the winding assembly is installed on one side of the wire stranding cylinder, and the tensioning wheel assembly is arranged between the wire stranding cylinder and the winding assembly. The double-wire-end copper-tin alloy wire stranding device is novel in structural design, can achieve quick double-wire stranding, can conduct wire stranding on wire ends with different thicknesses, and improves the wire stranding efficiency.

Owner:常宁市隆源铜业有限公司

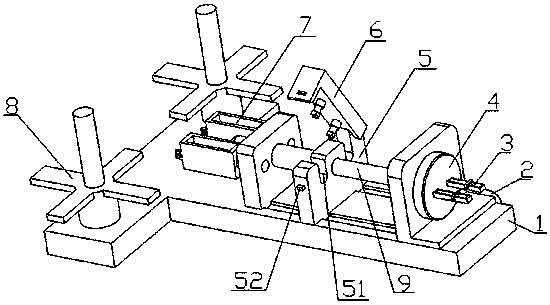

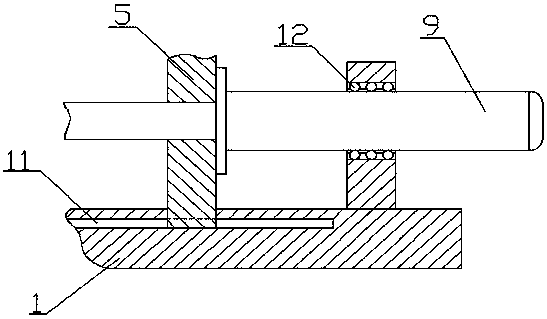

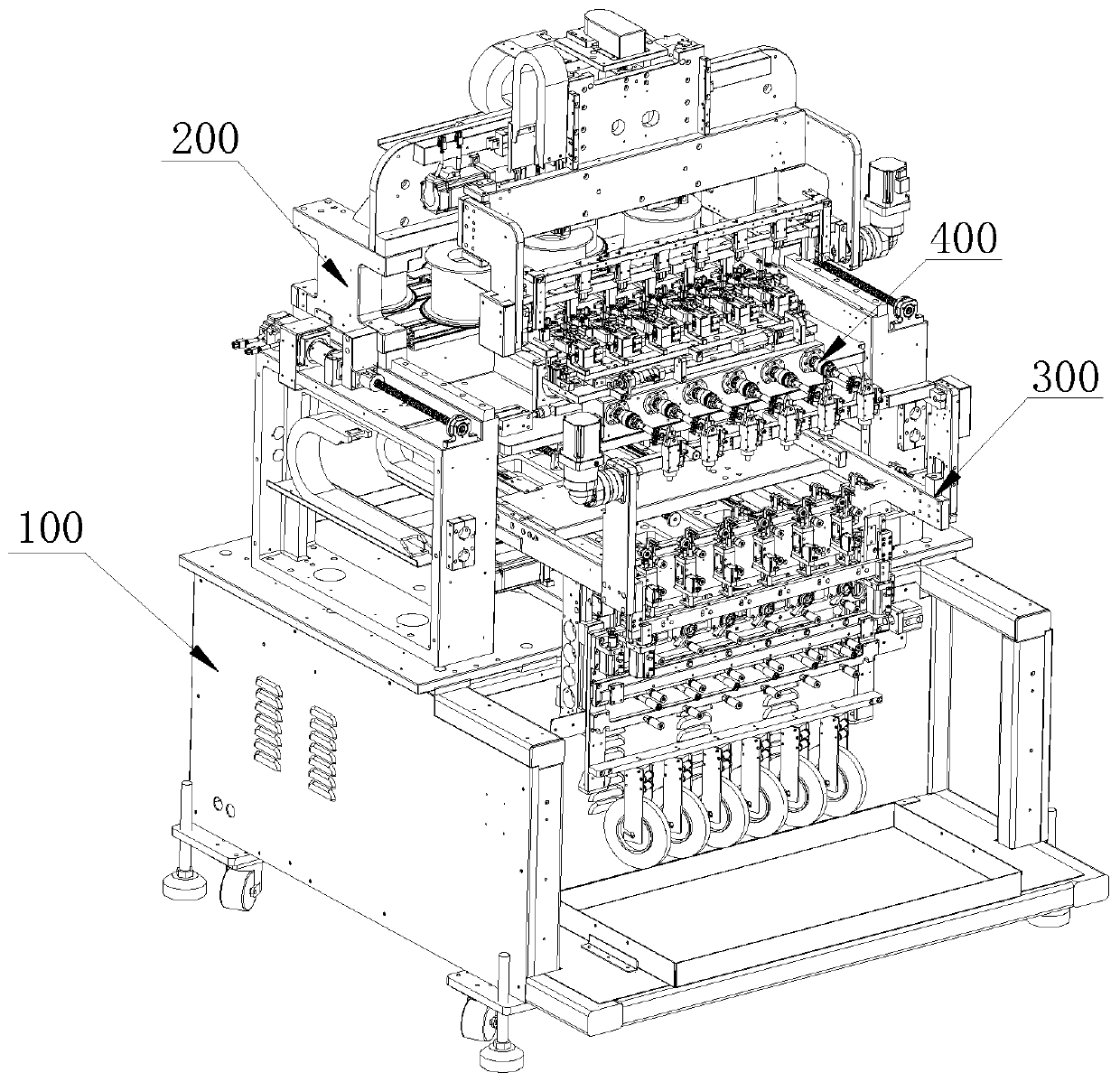

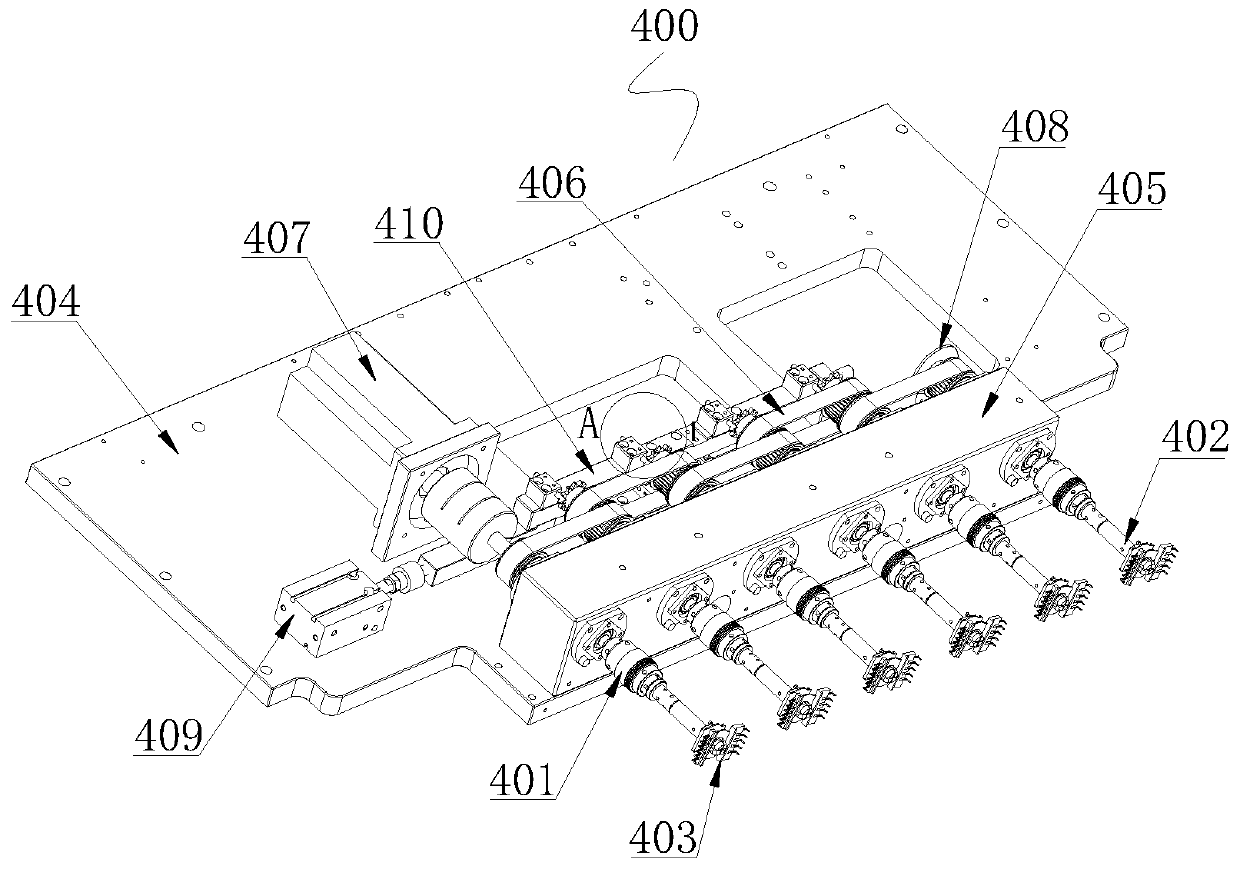

Stranding machine for wire harness manufacturing

ActiveCN109088297BAvoid Loose WiresAdaptableLine/current collector detailsCable harnessIndustrial engineering

A stranding system for manufacturing a wire harness and a method for manufacturing and processing the wire harness are disclosed, the system including a bottom plate, a clamping device, a release device, a conductor device, a wire clamping and cutting device and a stranding lifting device. The clamping device is arranged on the left side of the upper end of the bottom plate, the release device isarranged on the right side of the clamping device, the wire clamping and cutting device is arranged on the middle part of the upper end of the bottom plate, the conductor device is arranged between the wire clamping and cutting device and the release device, and the stranding lifting device is arranged on the right side of the upper end of the bottom plate. The invention can solve the problem thatin the conventional manufacturing process of the wire harness, conductors require manual stranding, the manual efficiency is low, the stranding of wire harness is poor and the wire harness is liableto spread out, and in the stranding process of the existing device, the conductors can-not be tensioned; the existing device can only process the wire harness of one length, cannot adjust the length of wire harness, and the adaptability effect is poor; in the cutting process, the cut of the wire harness is uneven, the operation is complex, the labor intensity is large, the production efficiency islow.

Owner:柳州诚飞汽车零部件有限公司

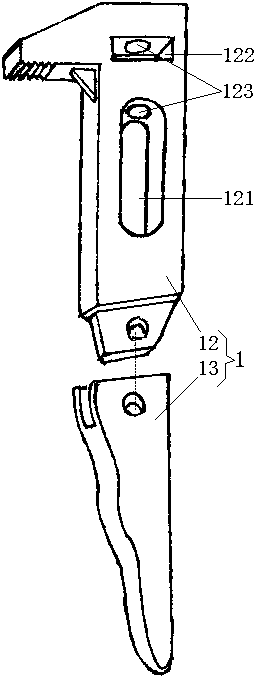

Semi-automatic multifunctional fast-screwing spanner

The invention relates to a semi-automatic multifunctional fast-screwing spanner. The semi-automatic multifunctional fast-screwing spanner comprises an upper spanner lip handle with an upper spanner lip and a lower spanner lip handle with a lower spanner lip. The lower spanner lip handle is further provided with a sleeving connection part. The lower spanner lip handle is matched with the upper spanner lip handle in a sleeving connection mode through the sleeving connection part, and a spanner opening is formed between the upper spanner lip and the lower spanner lip after sleeving connection matching is completed. A gap is reserved in the sleeving connection matching position between the inner surface of the sleeving connection part and the outer surface of the upper spanner lip handle and further serves as the rotating allowance allowing the lower spanner lip handle to rotate around the upper spanner lip handle through a rotating shaft. The size of the spanner opening located between the upper spanner lip and the lower spanner lip is changed along with the relative rotation position of the lower spanner lip handle and the upper spanner lip handle, so that a movable spanner opening is formed. According to the semi-automatic multifunctional fast-screwing spanner, an adjustable spanner and pliers are ingeniously combined, the spanner functions are achieved and meanwhile the openingand closing characteristic of the pliers can fused; and compared with an original monkey spanner, the semi-automatic multifunctional fast-screwing spanner is made faster. Meanwhile, the functions ofthe pliers and pincers can be achieved, and the spanner also can be used as pipe tongs.

Owner:李学军

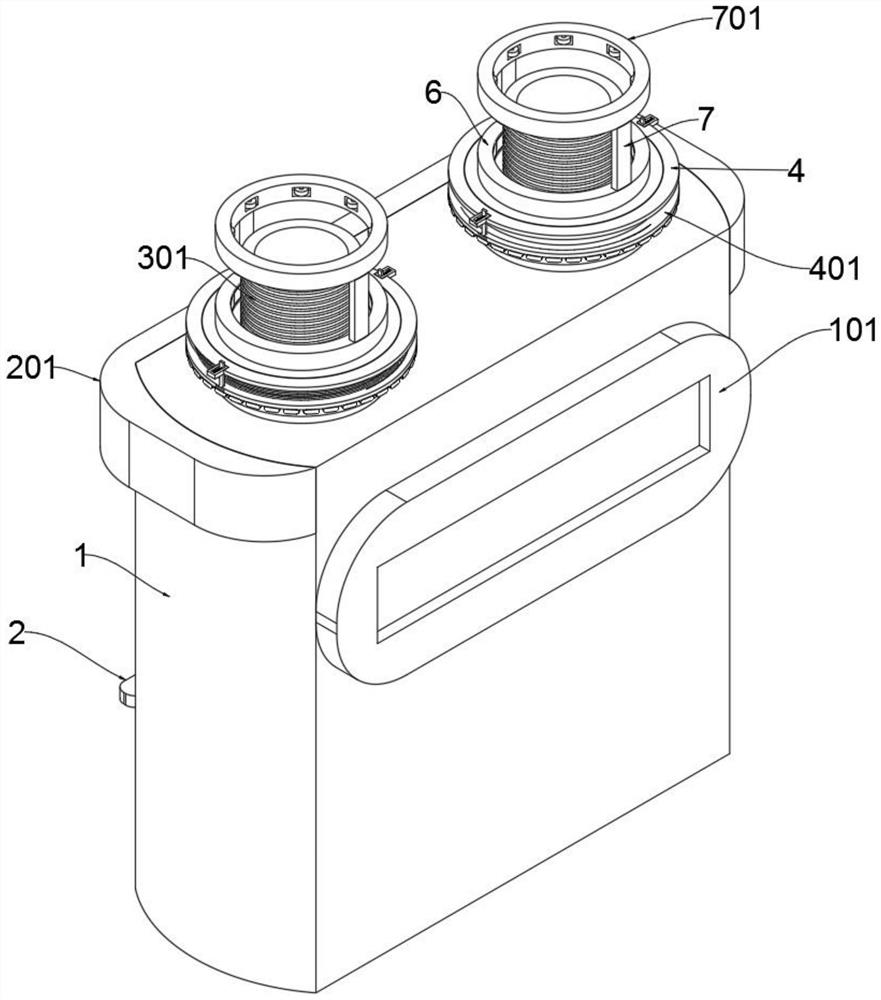

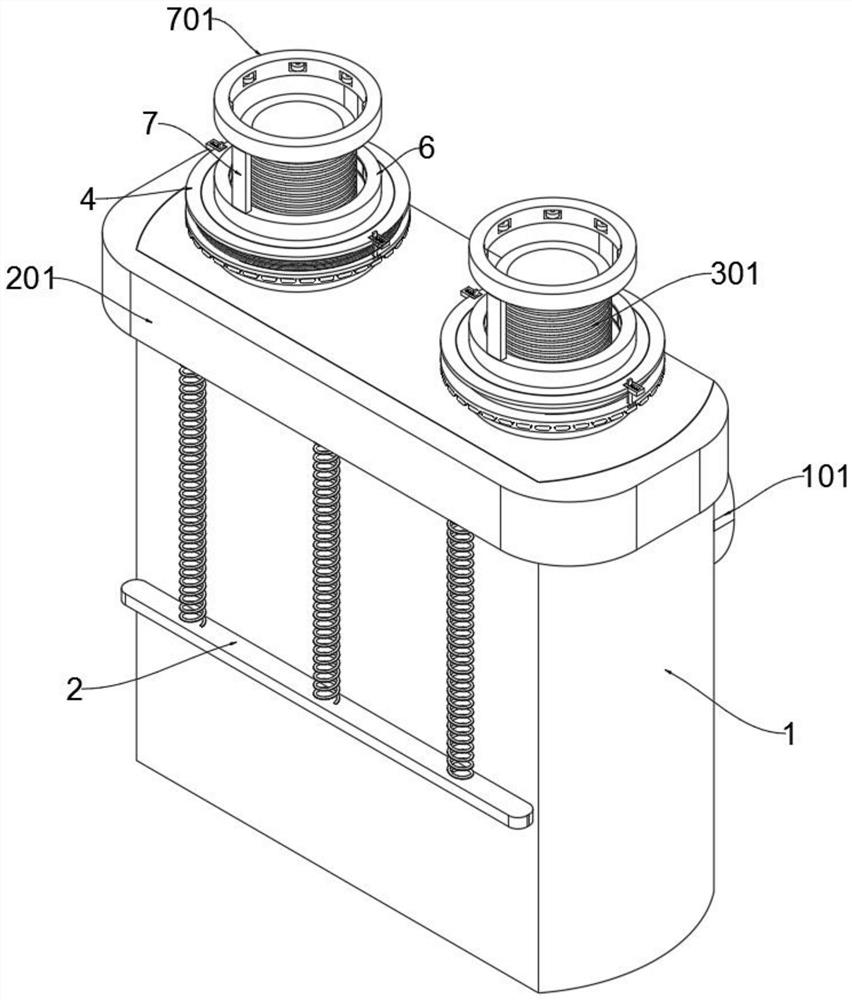

Meter connector welding structure of internet-of-things gas meter shell

The invention discloses a meter connector welding structure of an internet-of-things gas meter shell, relates to the technical field of gas meters, and solves the problem that when an existing meter connector is connected with a movable connector, the movable connector is prone to inclination, so that the position needs to be manually and repeatedly calibrated. The meter connector welding structure of the internet-of-things gas meter shell comprises a gas meter body, connectors and a top ring; the two connectors are symmetrically arranged at the top of the gas meter body, the circumferential outer walls of the two connectors are each provided with an installation disc, and the two installation discs are of a circular ring structure; two side grooves are symmetrically formed in the top of each of the two installation discs, and a side block is arranged in each of the four side grooves; the tops of the two connectors are each provided with a top ring, and the tops of the two top rings are each symmetrically provided with two vertical plates. The two movable connectors are held through the two positioning rings, so that the two movable connectors are kept in a vertical state all the time, and the two movable connectors are prevented from inclining.

Owner:郑会利

A quick twisting device for cable joints used in small electric power engineering construction

ActiveCN111276912BFor quick twistQuick twist connectionApparatus for joining/termination cablesGear wheelEngineering

The invention discloses a quick twisting device for cable joints used in small-scale electric engineering construction, which comprises a housing, a small motor, a mounting ring, a limit rod and a driving rod. A handle is installed on the left side of the housing, and the housing The first transmission gear and the second transmission gear are installed on the upper and lower sides of the inside of the body, and the first transmission gear and the second transmission gear are connected to the power gear, and the inner screw on the right side of the housing is equipped with a slide rail , the outer surface of the mounting ring is provided with a surface spur gear, the end of the limit rod is provided with a groove, a spring is arranged between the limit rod and the sleeve, and the end of the stud is screwed with a dial rod, and the driving rod runs through the stud, and the end of the driving rod is provided with a card slot. The quick twisting device of the cable joint for small electric power engineering construction is provided with a casing and a limit rod. The cable core is used to perform winding connection of multiple cable cores and increase the range of use of the device.

Owner:湛江天汇综合能源服务有限公司

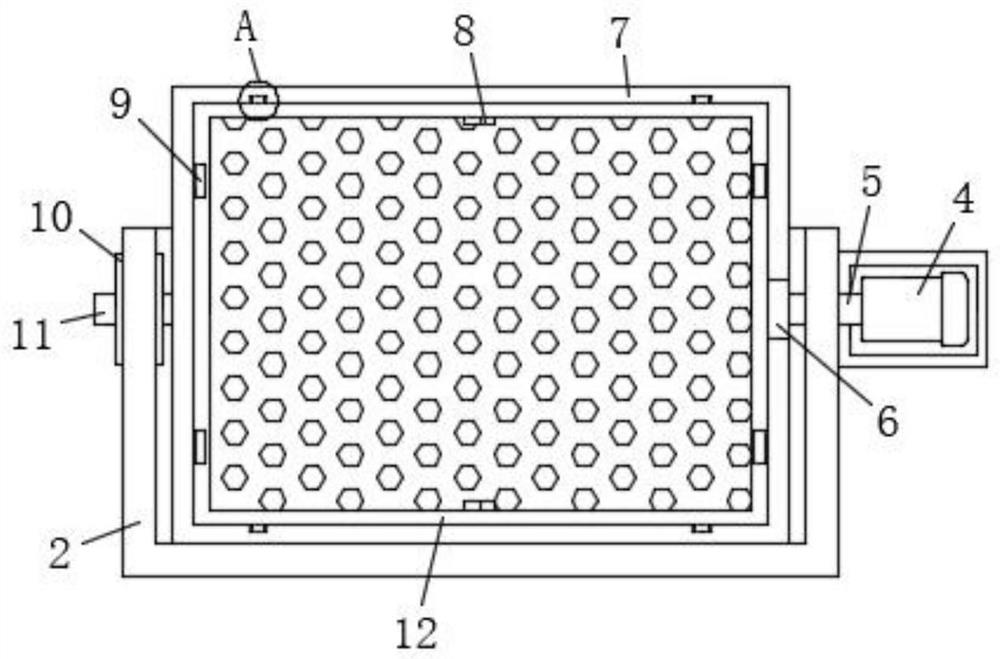

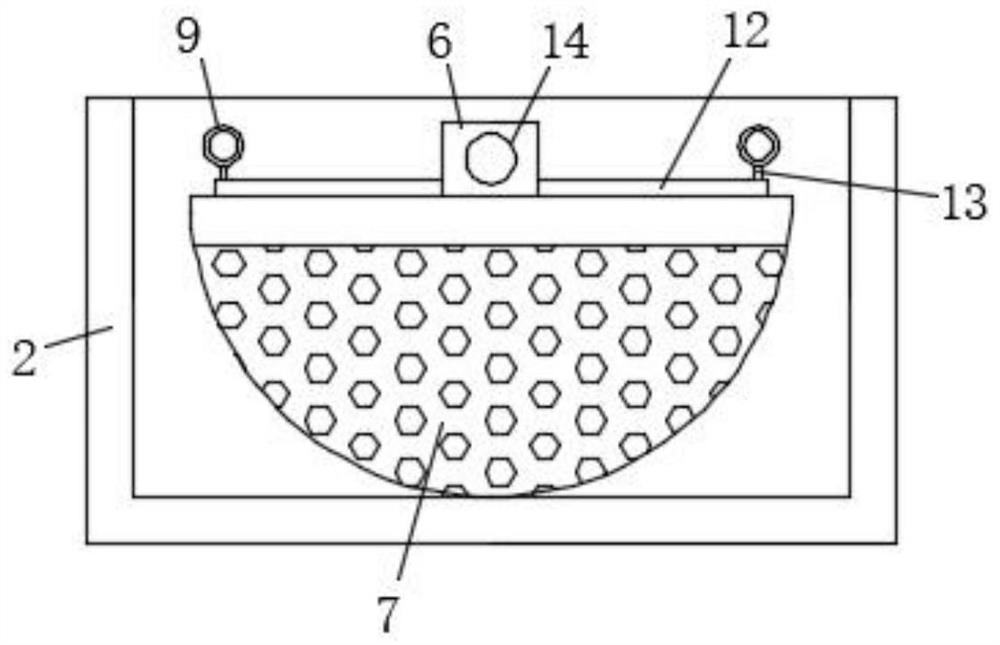

Rural domestic sewage treatment system based on small watershed form

InactiveCN113248051AEfficient collectionEasy to removeFatty/oily/floating substances removal devicesSpecific water treatment objectivesTreatment pondMechanical engineering

The invention belongs to the technical field of sewage treatment, and discloses a rural domestic sewage treatment system based on a small watershed morphology, the rural domestic sewage treatment system comprises a temporary storage tank, a filter tank, a treatment tank, a movable residue filtering assembly and a pushing assembly, the temporary storage tank, the filter tank and the treatment tank are connected through a pipeline, and the movable residue filtering assembly is arranged in the filter tank and comprises a filtering assembly and a rotating assembly; the filtering assembly is used for filtering solid impurities in sewage, the filtering assembly comprises an inner filter part and an outer filter part, the filtering assembly composed of the inner filter part and the outer filter part can effectively collect the solid impurities in the sewage, and after the inner filter part is full of the solid impurities, the filtering assembly can be rotated by utilizing the rotating assembly consisting of a motor, a fixed block, a bearing and the like, so that the opening of the filtering assembly faces upwards, and then the fastening screw between the inner filter cone and the outer filter cone is dismounted, so that the inner filter cone can be lifted out for removing solid impurities, and filtered garbage is relatively convenient to remove.

Owner:保定市水土保持试验站

Bread production line and dividing mechanism thereof

PendingCN114147784AGuaranteed segmentation effectReduce resistanceMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of bread production, and discloses a dividing structure which comprises a shelf, a powder scraping assembly, a driving assembly and a limiting assembly, a frame is arranged on the upper surface wall of the shelf, through holes are formed in the lower ends of the two side walls of the frame, an air cylinder is installed at the top end of the frame, and a telescopic rod is installed at the bottom end of the air cylinder; according to the bread cutting device, the flour scraping assemblies are additionally arranged, when the air cylinder drives the cutter to move up and down to cut bread, a scraping plate fixedly provided with bristles can scrape off flour accumulated on the outer wall of the cutter, and the flour scraping assemblies are arranged on the two sides of the cutter, so that the bread cutting device has the advantages that the flour scraping assemblies are additionally arranged, and the bread cutting efficiency is improved; flour is prevented from being adhered to the outer wall of the cutter, the resistance of the outer wall of the cutter is reduced, the cutting effect of the cutter can be continuously kept, in addition, when the flour scraping assembly is damaged and needs to be replaced, the mounting plate can be directly pulled upwards, the dovetail insertion block is pulled out from the interior of the dovetail insertion groove, disassembly and replacement are rapid and convenient, and time and labor are saved.

Owner:HEBEI CHEM & PHARMA COLLEGE

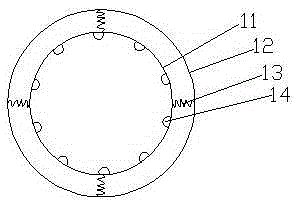

Jig capable of machining steel wire ropes quickly

The invention discloses a jig capable of machining steel wire ropes quickly. The jig comprises a fixing part, a first jig body and a second jig body which are used cooperatively. The first jig body and the second jig body are each composed of a left clamping plate and a right clamping plate which are connected in a crossed mode, wherein the same ends of the left clamping plate and the right clamping plate are each in a circular arc shape and form a containing cavity together, a disc is contained in the containing cavity, a rotating shaft is arranged in the middle of the disc and can rotate in the containing cavity, and a plurality of grooves are evenly formed in the outer surface of the disc. The diameter of the disc of the first jig body is different from that of the disc of the second jig body. The fixing part is composed of a circular-ring-shaped inner layer and a circular-ring-shaped outer ring, the inner layer is an elastic part, and springs are arranged between the inner layer and the outer layer. The steel wire ropes can be rapidly twisted through the jig.

Owner:江苏锐金钢丝绳索具有限公司

Arc-shaped handicapped maneuvering box tool clamp

PendingCN113732121ASimple structureLow costMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention discloses an arc-shaped handicapped maneuvering box tool clamp. The arc-shaped handicapped maneuvering box tool clamp comprises a base, wherein a platform with a flat upper surface is arranged on the base, a fixing frame is arranged on the front portion of the platform, a bending roller is connected to the fixing frame, a bending assembly is connected to the bending roller, and a gap allowing a maneuvering box plate to penetrate through is formed between the bending roller and the platform; and the bending assembly comprises a bending plate capable of overturning around the axis of the bending roller, a gap allowing the maneuvering box plate to pass through is formed between the bending plate and the bending roller, rotating plates are arranged at the two ends of the bending plate, and the rotating plates are rotationally connected to the bending roller. The arc-shaped handicapped maneuvering box tool clamp has the advantages of being simple in structure, low in cost, easy to operate and capable of rapidly bending the arc-shaped edge of a handicapped maneuvering box.

Owner:MATIZ INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com