Reversible rotary jig with manual and electric operation modes

A working mode, electric technology, applied in the direction of wrenches, power tools, manufacturing tools, etc., can solve the problems of three-speed manual screwdrivers, insufficient efficiency of ratchet screwdrivers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings of the description.

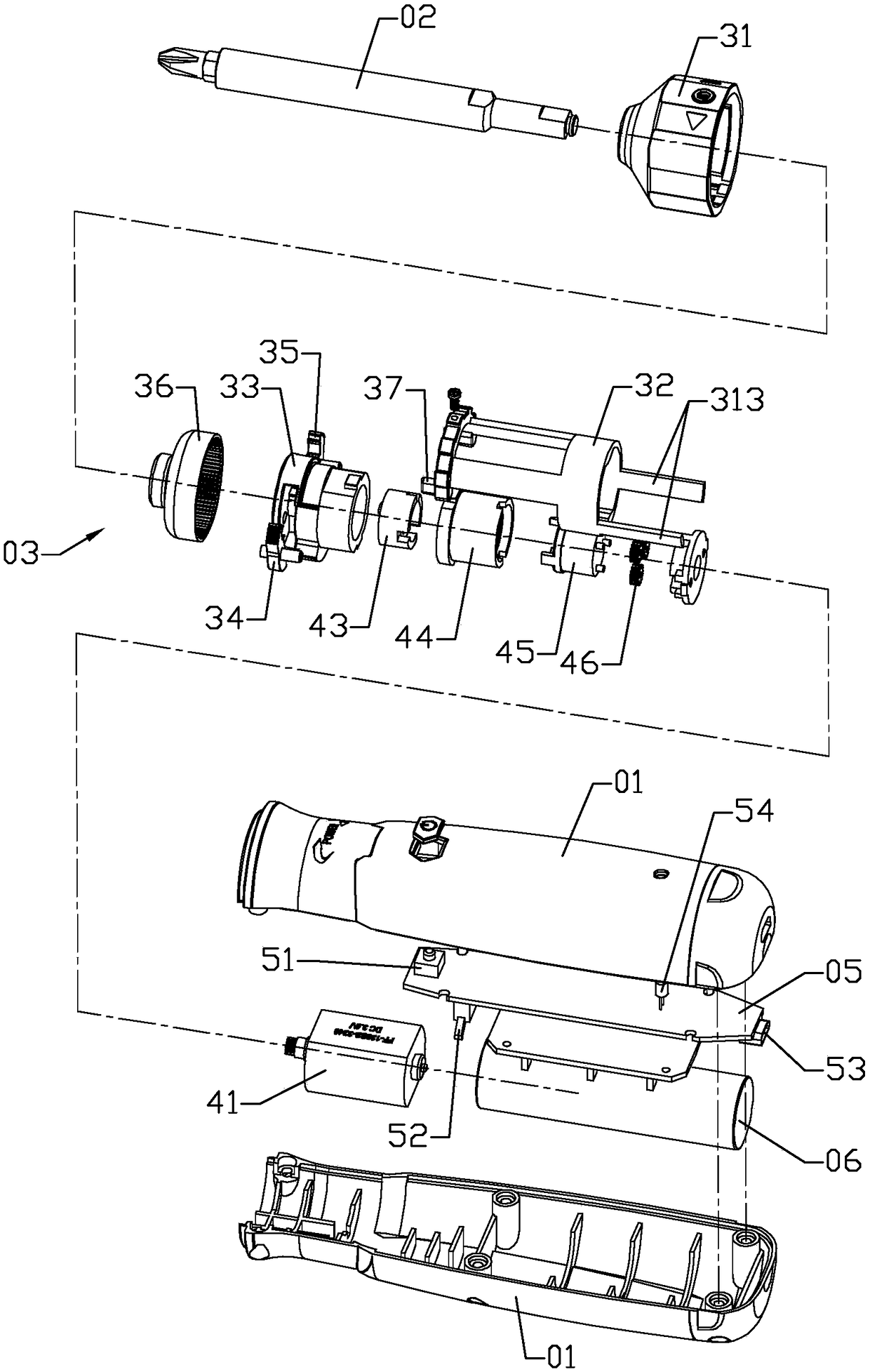

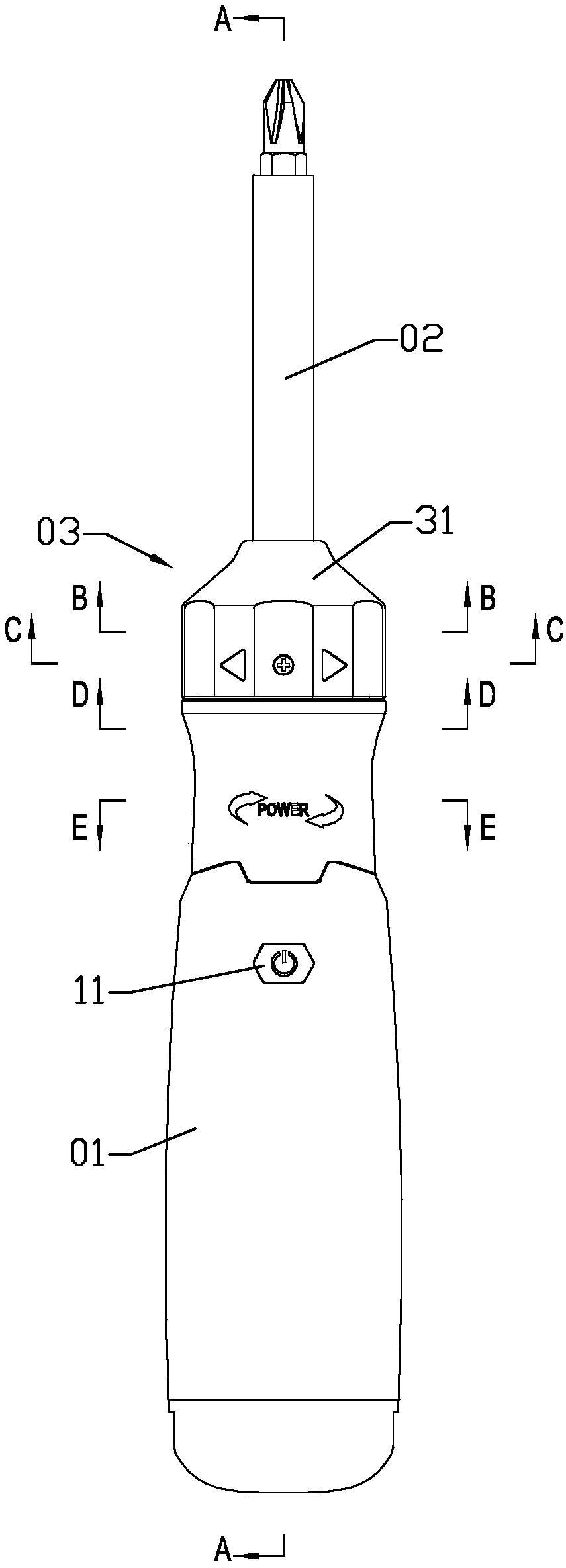

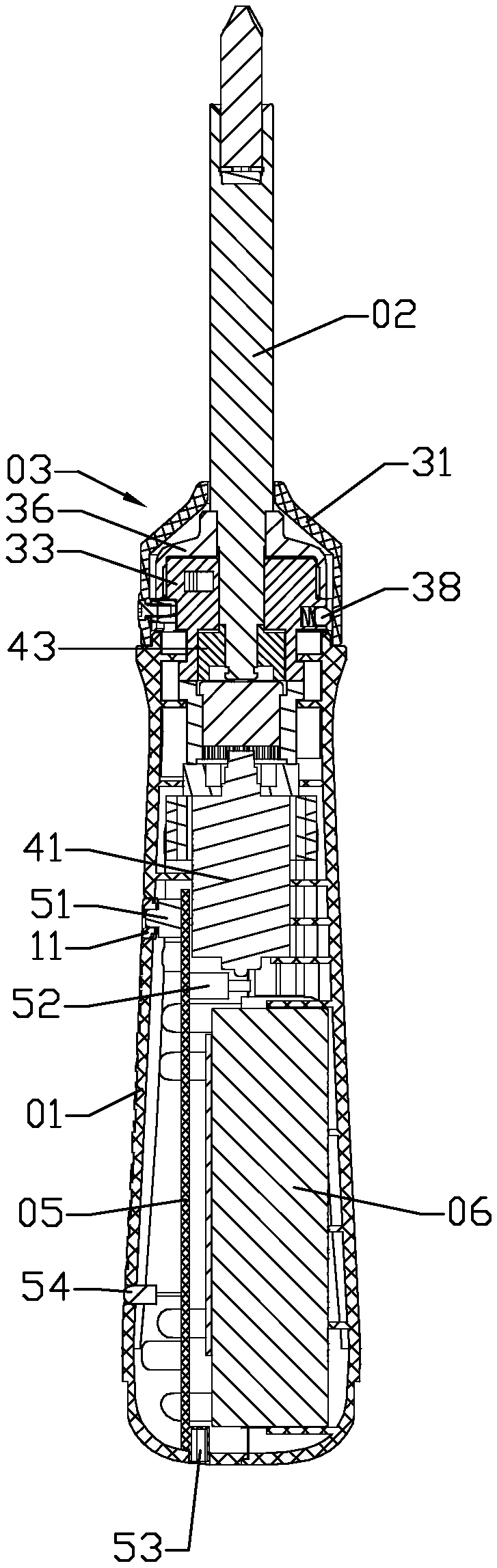

[0055] Such as Figure 1-10 , Figure 11-19 , Figure 20 Shown are the views of three embodiments of the reversible screwdriver with manual and electric working modes of the present invention, these embodiments all include a handle 01, a working rod 02 carried by the handle to realize manual torque output, The working rod 02 is assembled on the handle by the reversing mechanism 03 located at the front end of the handle and extends forward. The reversing mechanism 03 includes a reversing sleeve 31 and a reversing dial 32 driven by the reversing sleeve (see Figure 8 , Figure 13-15 ), turn the reversing sleeve relative to the handle and switch the reversing mechanism with the reversing dial to switch the manual torque output direction of the working rod; in other words, when the reversing sleeve is turned to a position relative to the handle, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com