Small grain airing granule collector

A grain harvester and grain technology, applied in the field of agricultural machinery, can solve the problems of time-consuming and laborious, grain wet, low efficiency, etc., and achieve the effect of shortening the collection time, speeding up the grain storage, and avoiding rainwater wet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

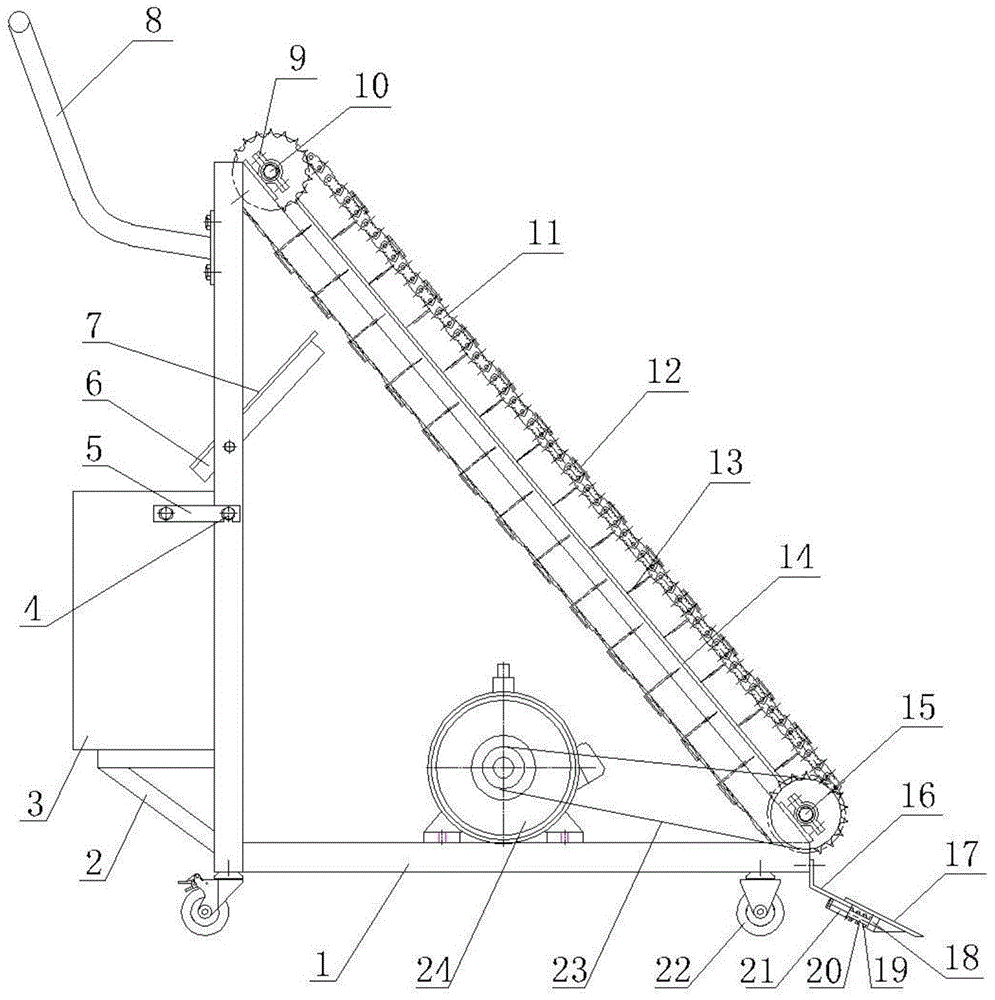

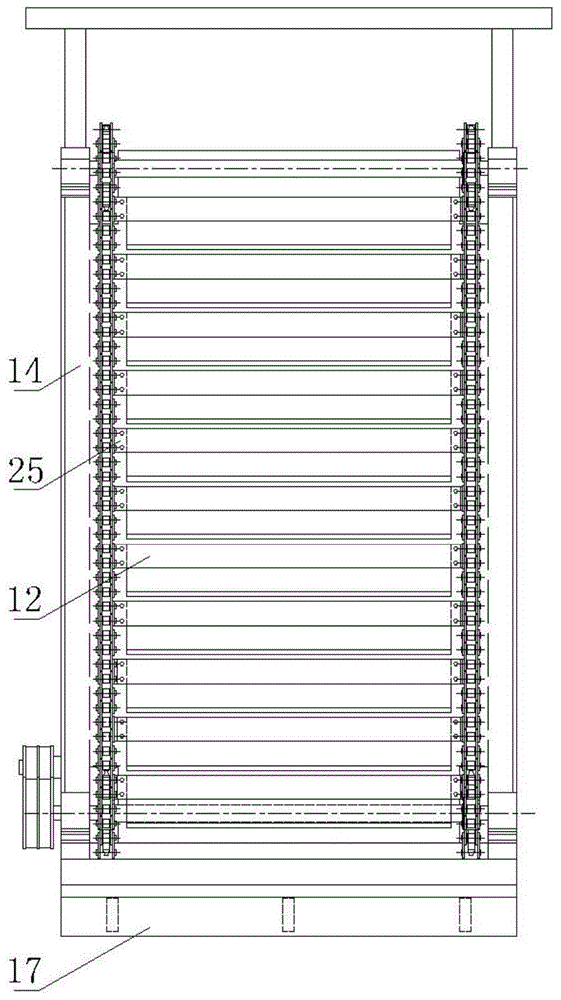

[0018] Such as figure 1 with figure 2 As shown, a small grain drying and harvesting machine related to the present invention includes a frame 1, which is formed by welding profiles and has a right-angled triangle section. A thin plate is fixed on the slope of the frame 1 The folded grain collecting plate groove 14 is fixed on the inclined surface of the frame 1 by pulling rivets. A rotatable driven shaft 10 and a driving shaft 15 are respectively installed on the inclined surface and lower end of the frame 1 in the grain collecting plate groove 14. The two ends of the driven shaft 10 and the driving shaft 15 are respectively mounted on the frame through the bearing seat 9 and the bearing 1 on. A chain transmission mechanism is installed between the driving shaft 15 and the driven shaft 10, and the chain transmission mechanism includes two sets of chain transmission mechanisms 11 symmetrically installed between the two ends of the driving shaft 15 and the driven shaft 10. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com