Milk making component

A component and milk preparation technology, which is applied in feeding bottles and other directions, can solve the problems of milk powder agglomeration and deterioration, difficult cleaning of milk powder, poor sealing performance of milk powder box, etc., and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

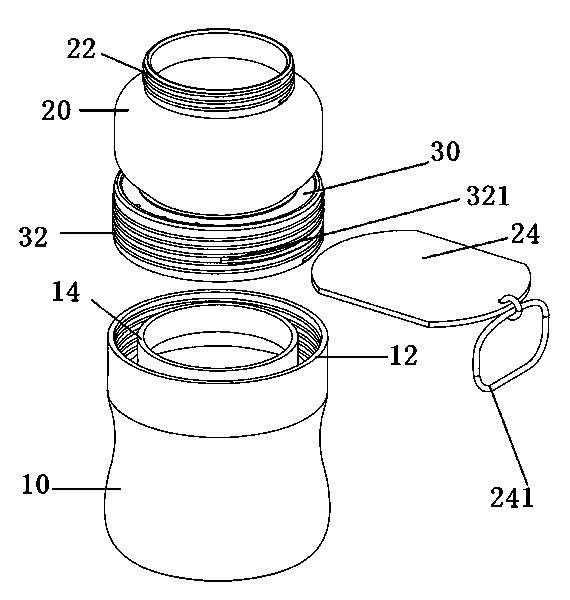

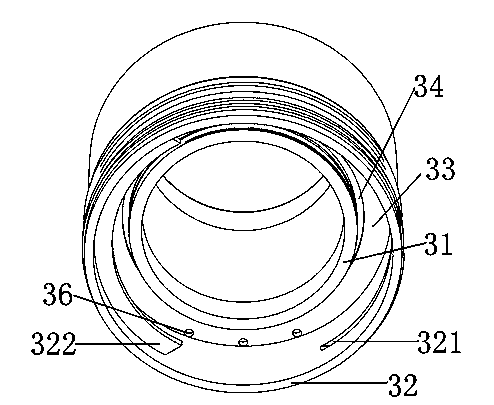

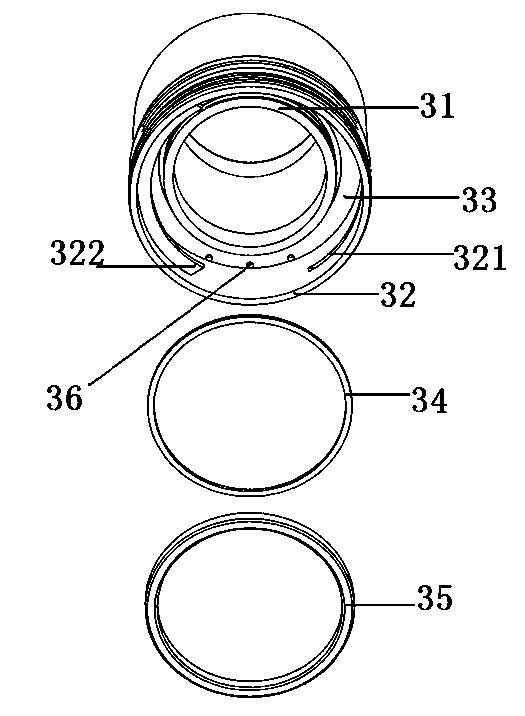

[0035] A milk preparation unit such as Figure 1 to Figure 3 As shown, it includes a feeding bottle 10, a milk powder box 20 and a connecting body 30. The upper end of the milk powder box 20 is provided with a connecting portion 22 that can be connected with a pacifier, and the lower end is threadedly connected to the feeding bottle 10 through the connecting body 30. The connecting body 30 is connected to the milk powder box 20. Formed in one piece. The upper part of the feeding bottle 10 (at the mouth of the bottle) is a double-layer structure, the inner layer is the first milk powder channel 14, and the outer layer is the bottle mouth wall 12. There is a gap between the two-layer structures, forming a first groove with an upward opening (not marked in the figure), wherein the bottle mouth wall 12 is flush with the upper port of the first milk powder channel 14 . The connecting body 30 is a double-layer structure, the inner layer is the second milk powder channel 31, and the...

Embodiment 2

[0041] The milk preparation assembly provided in this embodiment differs from the milk preparation assembly in Embodiment 1 in that: there are two sockets 321 on the interface wall 32, the inner wall of the interface wall 32 has no protrusion 322, and the stopper 24 It can be inserted from any one of the two jacks 321 and protruded from the other to form the movable bottom of the milk powder box 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com