Tilting high-temperature rotary tube furnace for continuous heat treatment

An inclined and tube furnace technology, applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of low applicable temperature, service life of brittle containers, difficult to remove, etc., to reduce loss and improve uniformity of heat treatment Non-toxic, non-residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

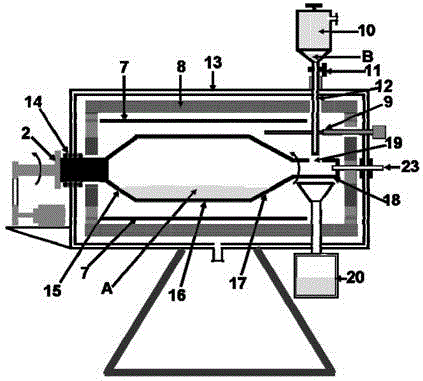

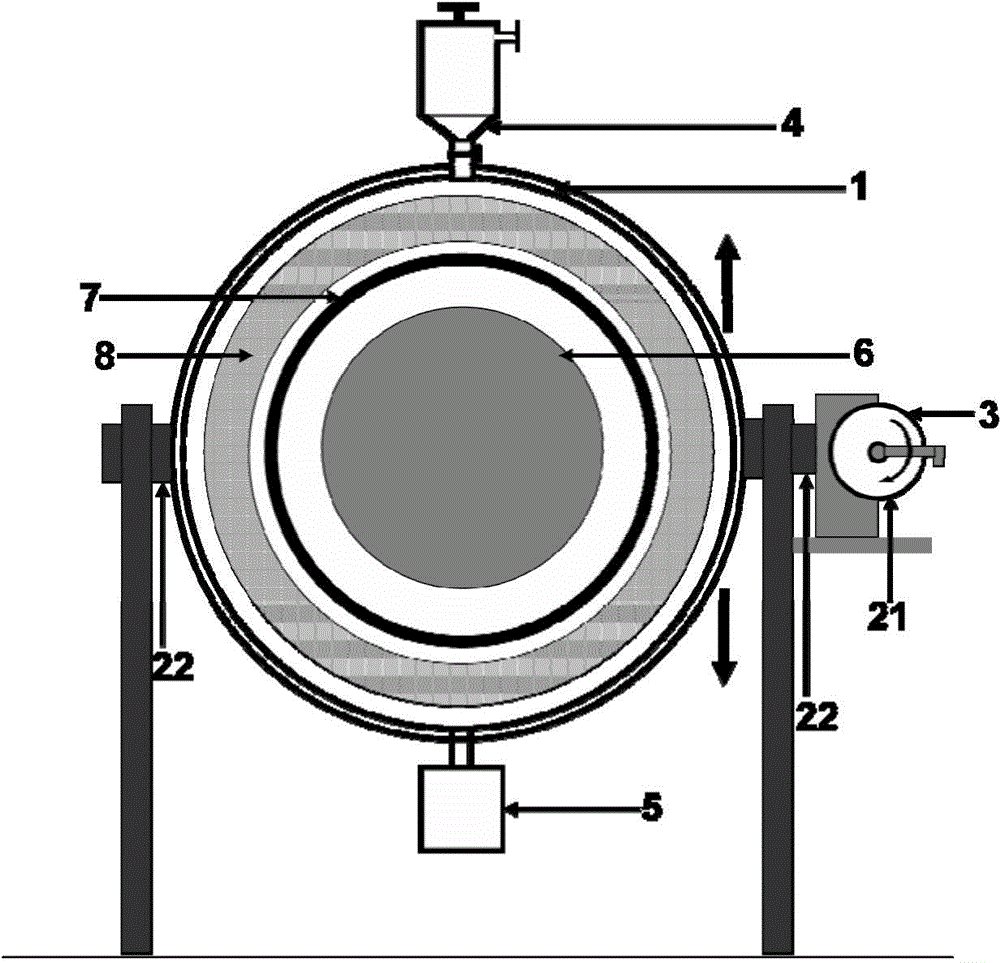

[0048] The structure of the inclined high-temperature rotary continuous heat treatment tube furnace (hereinafter referred to as "tube furnace") is as described above, such as figure 1 , figure 2 As shown, the tube furnace is mainly composed of a furnace body 1, a rotating mechanism 2, and a tilting device 3. The furnace body 1 is provided with an airtight furnace, with a feeding device 4 at its upper end and a receiving device 5 at its lower end. The rotating mechanism 2 is connected with the graphite furnace 6 to make it rotate and drive the material A in the furnace to move. The furnace body 1 is also provided with a heating body and a heat insulating device composed of a graphite heating body 7 and a graphite soft felt heat shield 8, and a temperature measuring device composed of a thermocouple 9, which can raise the temperature of the furnace to the target temperature. Material device 4, with the assistance of tilting device 3, the material B to be heat treated is trans...

Embodiment 2

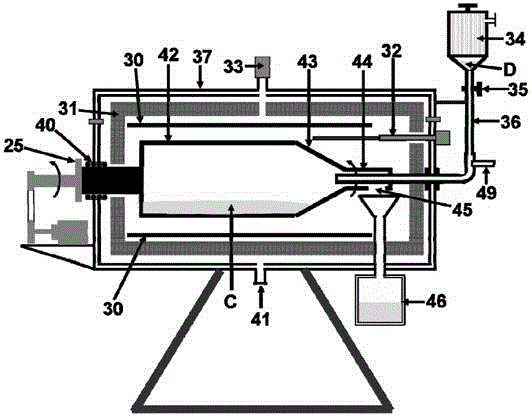

[0061] The structure of the inclined high-temperature rotary continuous heat treatment tube furnace (hereinafter referred to as "tube furnace") is as described above, such as image 3 , 4 As shown, the tube furnace is mainly composed of a furnace body 24 , a rotating mechanism 25 and a tilting device 26 . The furnace body 24 is provided with an airtight furnace, the upper end of the furnace body is provided with a feeding device 27 , and the lower end is provided with a receiving device 28 . The rotating mechanism 25 is connected to the high-purity BN furnace 29 to make it rotate and drive the material C in the furnace to move. The body of furnace 24 is additionally provided with a heating body and a heat insulating device composed of a graphite heating element 30 and a graphite soft felt heat shield 31, a temperature measuring device composed of a thermocouple 32 and an infrared thermometer 33, which can raise the temperature of the furnace. To the target temperature, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com