Patents

Literature

111results about How to "Uniform treatment effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

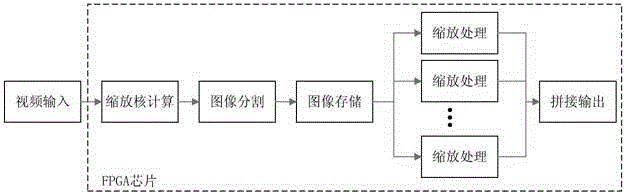

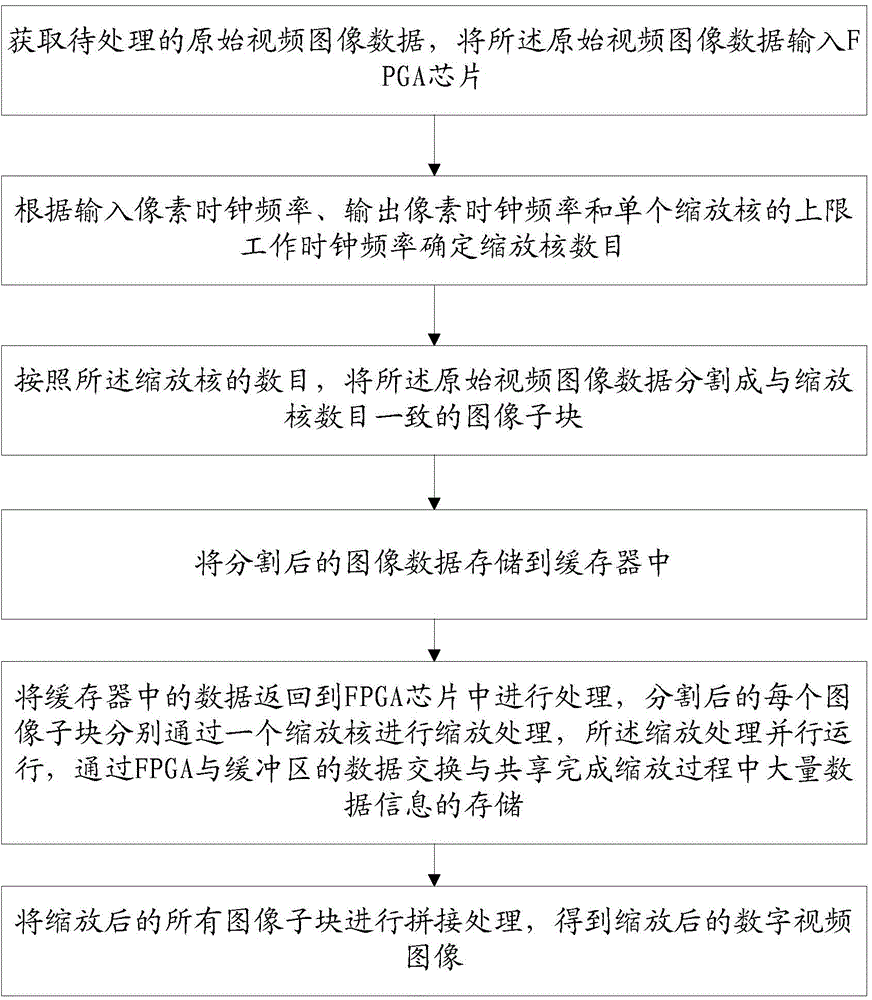

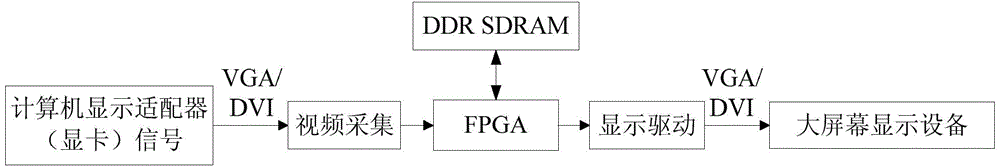

Parallel multi-core FPGA digital image real-time zooming processing method and device

InactiveCN104104888AReduce complexityGuaranteed uptimeTelevision system detailsColor television detailsDigital videoComputer graphics (images)

Provided is a parallel multi-core FPGA digital image real-time zooming processing method and device. The method comprises the steps that original video image data to be processed are acquired firstly. The original video image data are inputted to an FPGA chip and the number of zooming cores is confirmed, and the original video image data are divided into image sub-blocks having the same number with that of the zooming cores. Then the divided data are stored in a buffer, the data in the buffer are returned to the FPGA and parallel zooming processing is performed on each image sub-block via one zooming core respectively so that zooming is completed. All the image sub-blocks after zooming are displayed after splicing processing. The method has certain guiding effect on high throughput and high real-time application of digital video images.

Owner:DALIAN NATIONALITIES UNIVERSITY

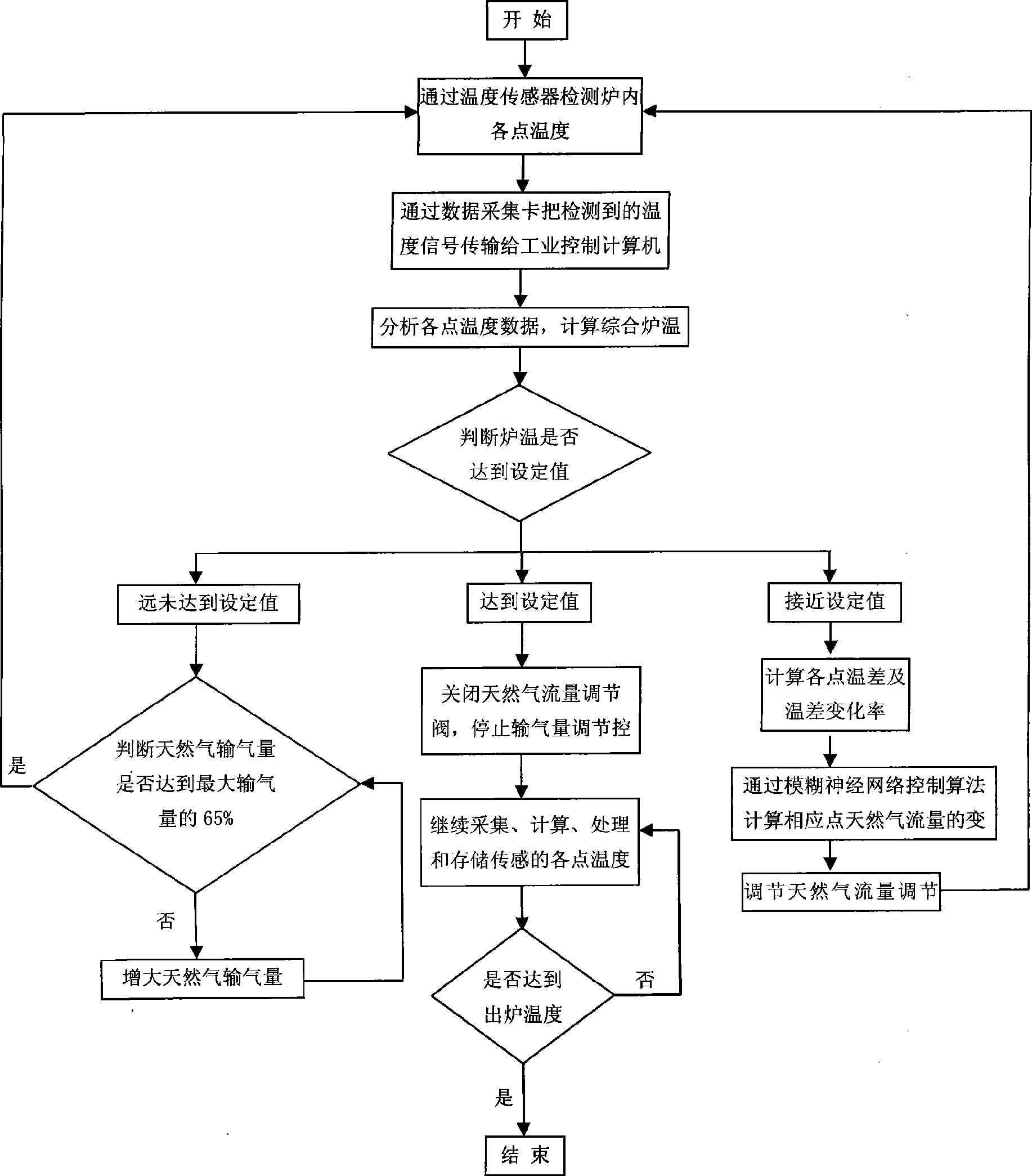

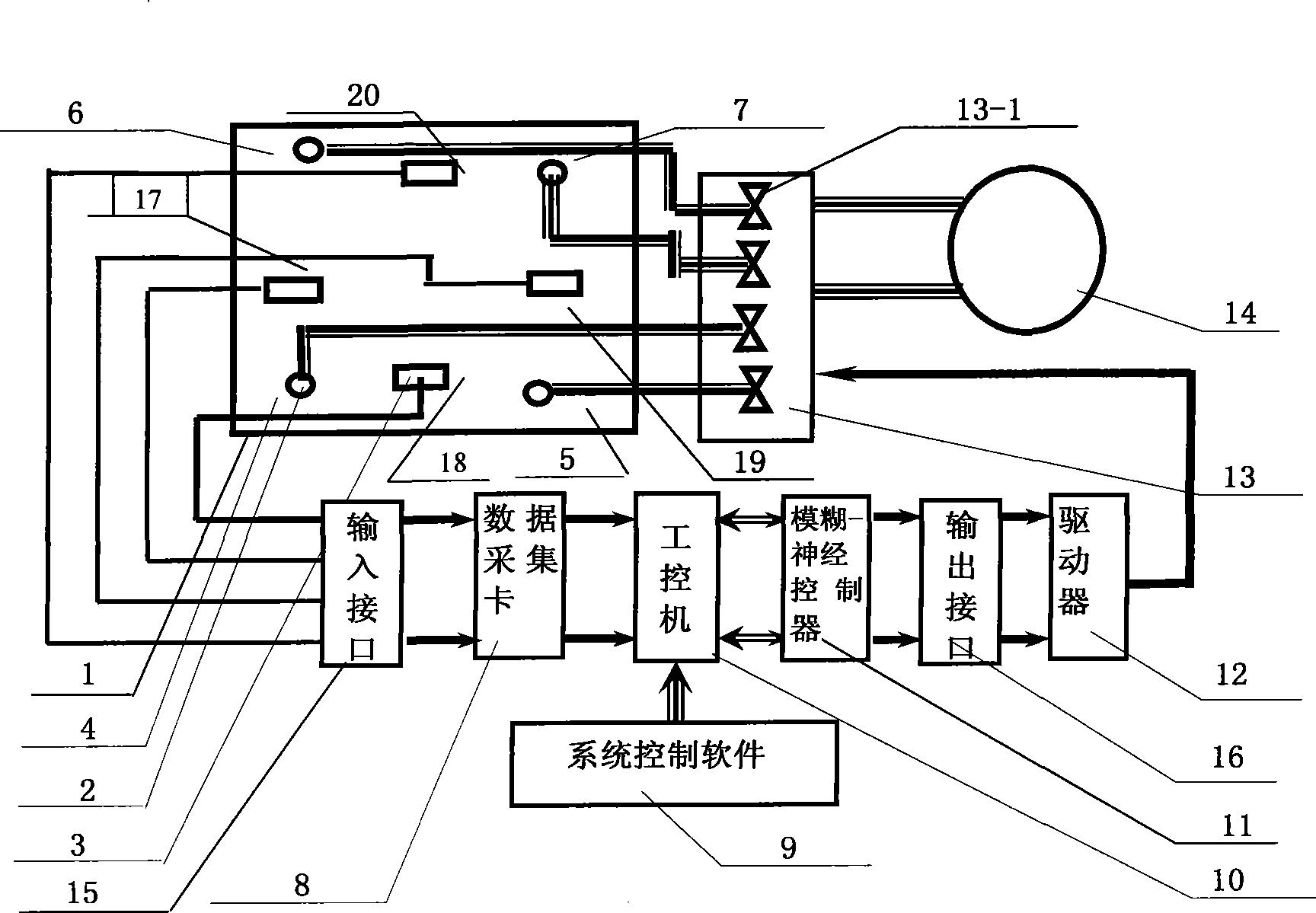

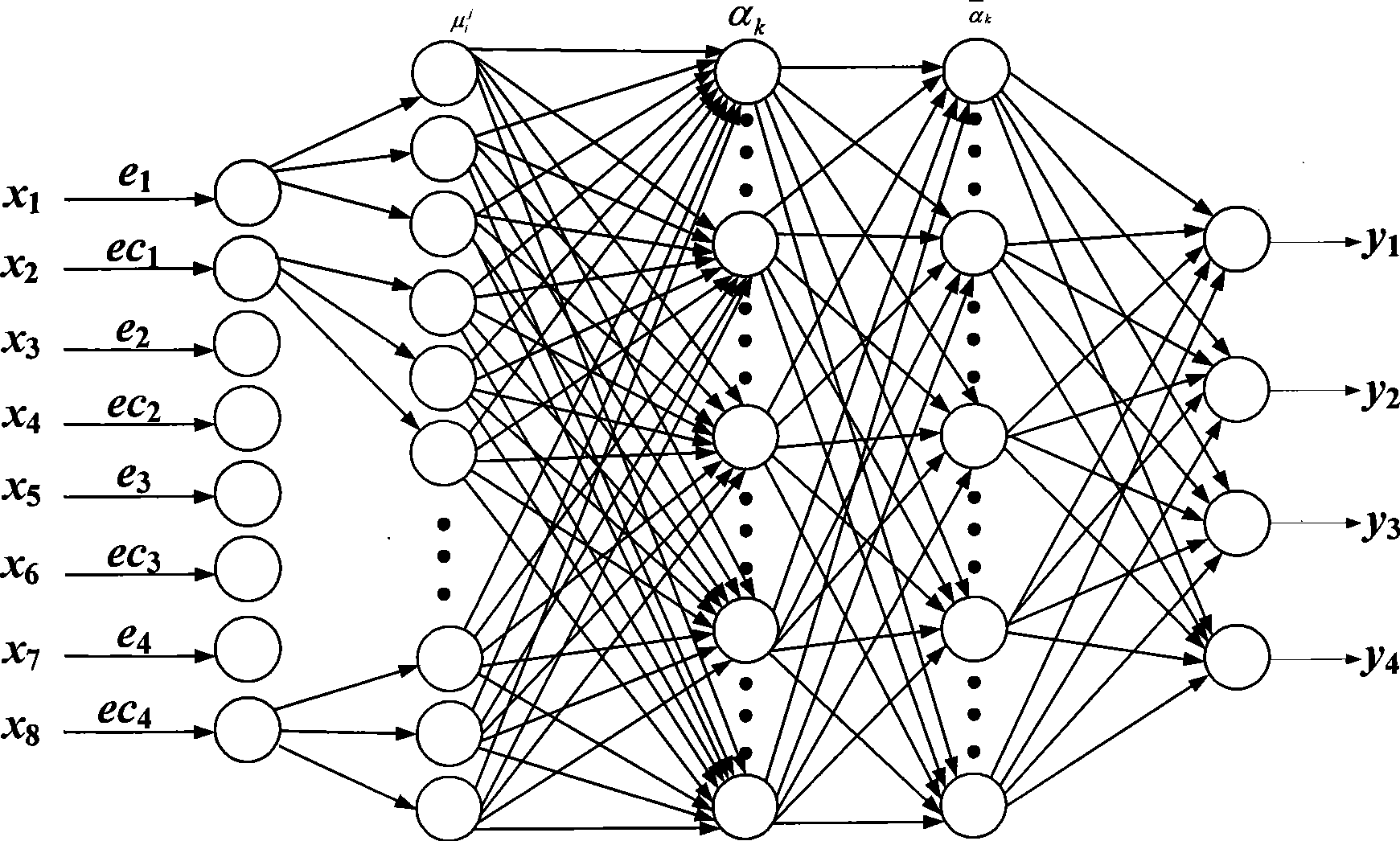

Multi-point sensing and intelligent control method for temperature of gas heating stove

ActiveCN101464096AGuaranteed temperatureGuaranteed uniformThermometer applicationsGas emission reductionControl softwareNatural gas

The invention discloses a method for multi-point sensing and intelligent controlling of the temperature of a gas heating furnace. The method comprises the following steps: firstly, temperature sensors evenly distributed in a natural gas heating furnace detects the temperature of each point in the heating furnace in a synchronous, real-time and continuous manner; then, an input interface and a data acquisition card transmit the detected temperature signals to an industrial control computer; the industrial control computer calculates, analyzes, and stores the temperature difference between each point and the change rate of the temperature differences through a system control software on a real-time basis, and calculates the integrated temperature in the heating furnace on a real-time basis; finally, whether the temperature of the furnace reaches the set value is judged, and treatment is carried out according to three conditions including reaching the set value, falling short of the set value, and approaching the set value, respectively. The invention can synchronously sense multi-point temperatures in a natural gas heating furnace, display furnace temperature change curves and temperature differences among areas on a real-time basis, and store the temperature change curves of each area in a database on a continuous and real-time basis. The invention adopts a fuzzy-neural network method to adjust each area temperature intelligently, thereby improving the quality of heavy forgings.

Owner:JIANGSU JINYUAN FORGE +1

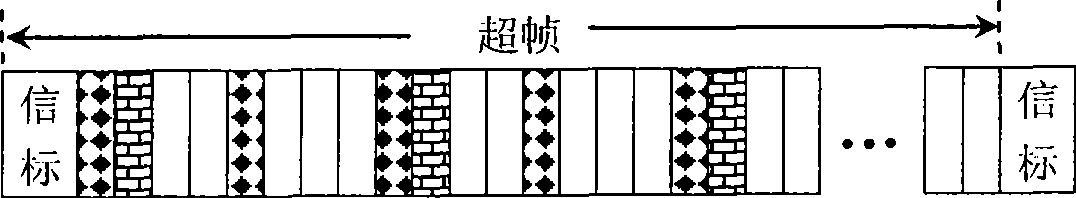

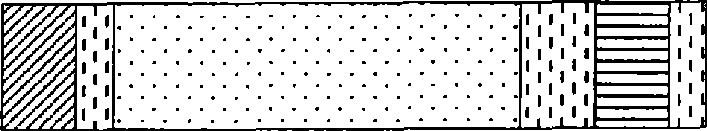

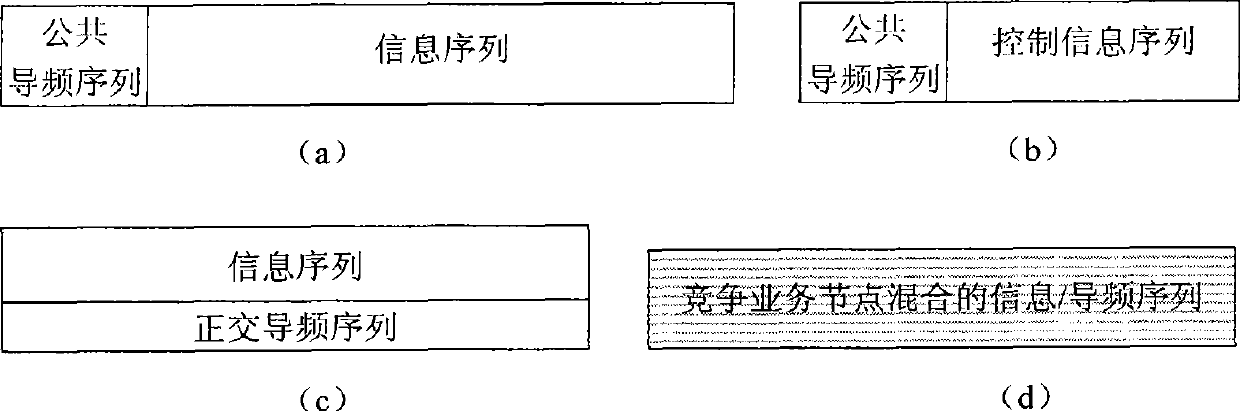

Hybrid media access control method based on collaborative collision decomposition

InactiveCN101399833AIncrease delayGuaranteed service qualityData switching networksTime division multiple accessCode division multiple access

The invention discloses a mixed media access control method of a wireless network. System channels are of time slot, and time slots with fixed cycle are distributed to non-competitive business nodes, non-competitive business data frame is transmitted in the mode of time division multiple access. Competitive business nodes transmit competitive business data frame in the competitive time slots by using the method of random competitive access. After the competitive business data frames conflict, the competitive business nodes send the competitive business data frame again under the condition that the estimated gain value of the channels is more than or equal to a given threshold. Or else the competitive business data is forwarded by a relay node; an access point buffers the signals received before, and realizes the data frame separation by methods of serial interference cancellation and minimum mean-square error detection. At the same time, a superimposed pilot channel estimation method is used by the competitive business data, no additional time slot is needed in the method, thus being convenient for orthogonal design. The method is suitable for the unexpected properties of competitive businesses and the cyclical properties of non-competitive businesses, and the mixed transmission of the two businesses can be supported.

Owner:PLA UNIV OF SCI & TECH

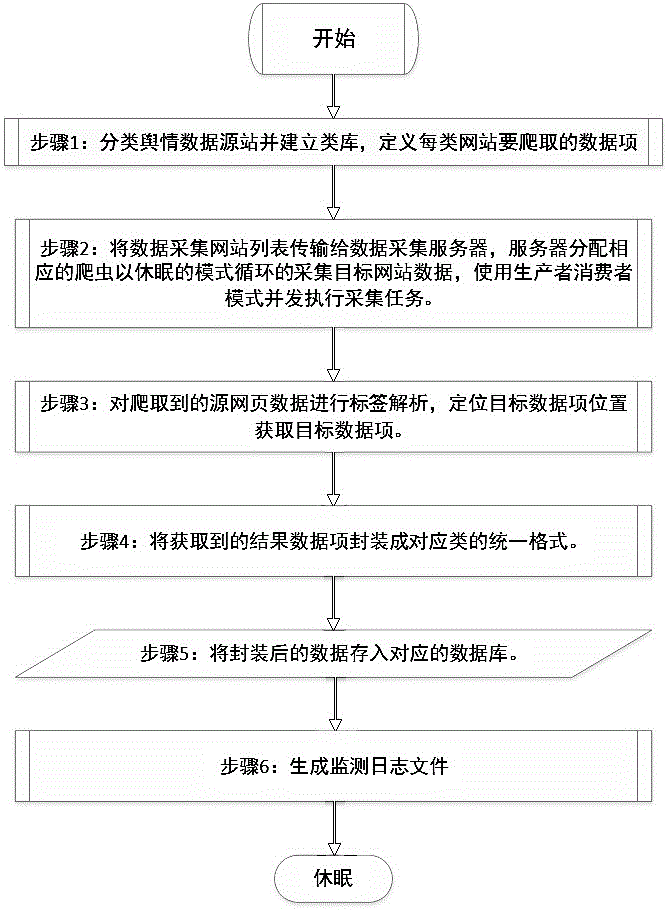

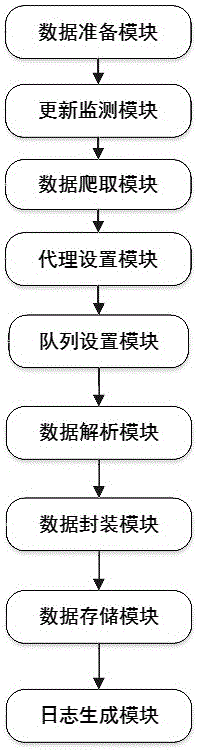

Public sentiment data real-time collecting method and system based on distribution

ActiveCN106096056AImprove reusabilityAdvanced architectureWeb data indexingRelational databasesExtensibilityWeb site

The invention discloses a public sentiment data real-time collecting method and system based on distribution. The method comprises the following steps that firstly, a public sentiment data website class library is established, and crawling data items are classified and defined; secondly, a data acquisition website list is transmitted to a data collection server, the server allocates corresponding crawlers to circularly crawl data in a dormant mode; thirdly, crawled source webpage data is subjected to label analysis, the position of a target data item is positioned, and the target data item is obtained; fourthly, an obtained result data item is encapsulated into a uniform format of a corresponding class; fifthly, the encapsulated data is stored into a corresponding database; sixthly, a monitoring log file is generated. According to the public sentiment data real-time collecting method and system based on distribution, the architecture is advanced, a factory mode is used as a main design mode of the system, new examples can be quickly generated, system core functions such as browser assess, log generating, data encapsulation, agent setting and queue setting are encapsulated, the expandability and transportability of the system are enhanced, and the reusability of codes and the maintainability of the system are improved.

Owner:SOUTHWEST PETROLEUM UNIV

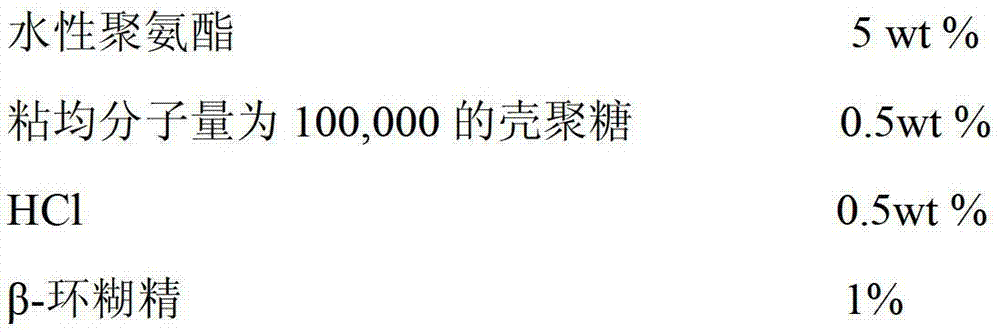

Compound finishing agent and preparation method thereof

The invention relates to a compound finishing agent and a preparation method thereof. The method comprises a step of compounding chitosan and waterborne polyurethane: dissolving chitosan with an HAc or HCl solution, and adding into a polyurethane aqueous solution with certain concentration. The application is as follows: natural fiber and synthetic fiber fabric and the blended or interlaced fabric thereof are processed to obtain anti-wrinkle / anti-felting / anti-bacterial functions, and the biodegradability of the fabric is improved at the same time. The fabric is soaked and rolled twice in the compound finishing agent, the liquid carry rate is 60-90%, and then the fabric is pre-dried in a heat settling machine before curing. The finished wool textile reaches the machine-washable anti-felting standard of ISO6330 and IWSTM No.31 of International Wool Secretariat; the longitude-latitude wrinkle recovery angel of the finished cotton fabric is 200-210 degrees, the retention rate of the fabric strength is at least 110%, and antibacterial property is obtained; and meanwhile, the hand feeling and biodegradability of the finished fabric are improved, and remarkable economic and environmental benefits are realized.

Owner:DONGHUA UNIV

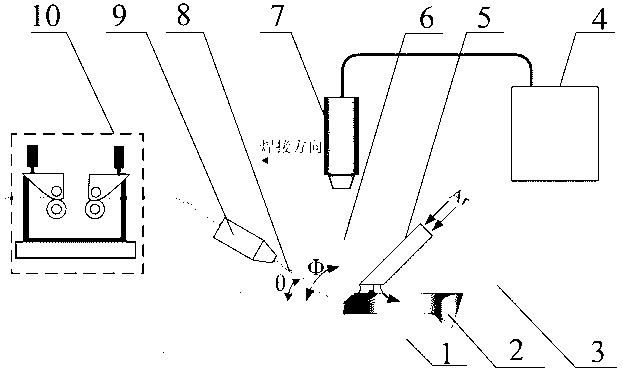

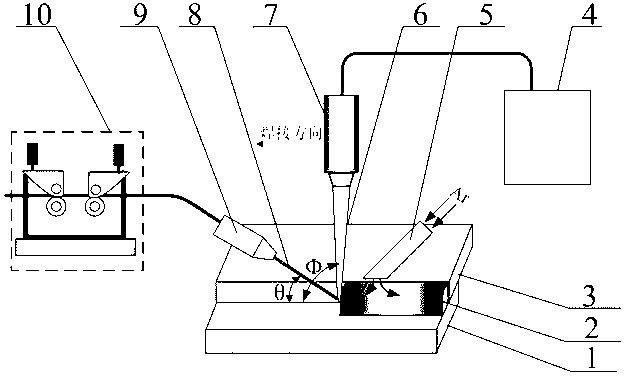

Magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and welding method

ActiveCN102699535AFull overflowReduce or avoid the generation ofWelding/cutting media/materialsWelding/soldering/cutting articlesLaser beamsMaterials science

The invention provides a magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and a welding method. The welding method comprises the following steps of: forming a beveled edge on a part to be welded of a magnesium alloy and a steel workpiece, and removing oil dirt and an oxidation film from the surface of the workpiece; fixing the magnesium alloy and the steel workpiece on a welding fixture, adjusting the position and the angle of a wire feeding device, automatically feeding the welding wire at a certain angle in front of a laser beam, and protecting a welding seam through argon, wherein the welding wire comprises the following components in percentage by weight: 2 to 10 percent of Al, 0.5 to 5 percent of Zn, 0.1 to 1 percent of Sr, 0.05 to 0.2 percent of B, 0.5 to 2 percent of RE and the balance of Mg; and placing the laser beam on one side of the magnesium alloy workpiece in a slightly deviating way, and heating the welding wire and the magnesium alloy workpiece by using superaudio frequency pulse laser to form a smelting pool, wherein the steel workpiece is kept in a solid state substantially in a welding process and acts with liquid magnesium alloy to form a welding joint. The key and common problem that the improvement of the welding quality of Mg / Fe and Mg / Ti immiscible heterogeneous metal is limited is solved, and the application range of laser smelting braze-welding is expanded.

Owner:哈尔滨哈船特装科技发展有限公司

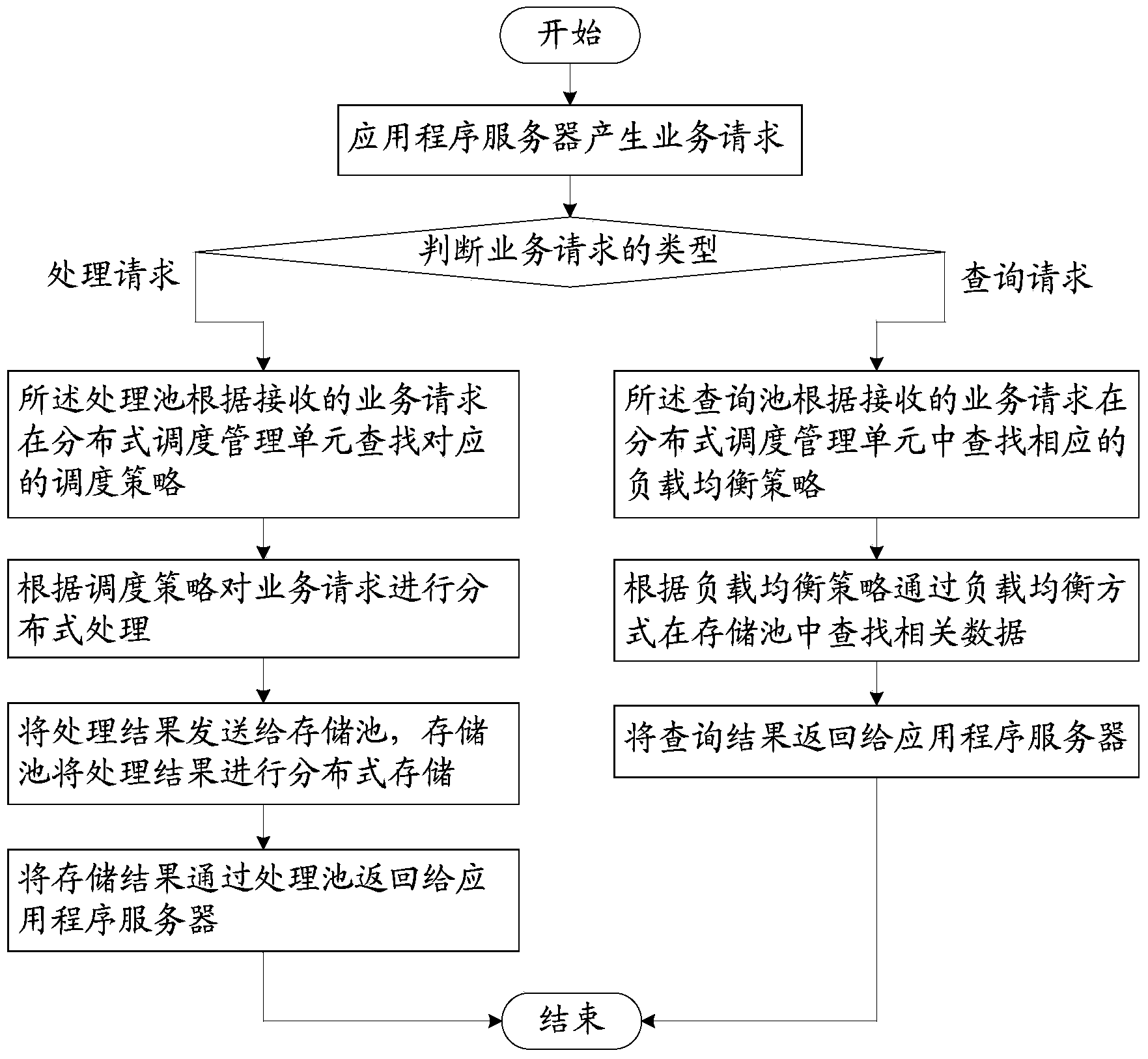

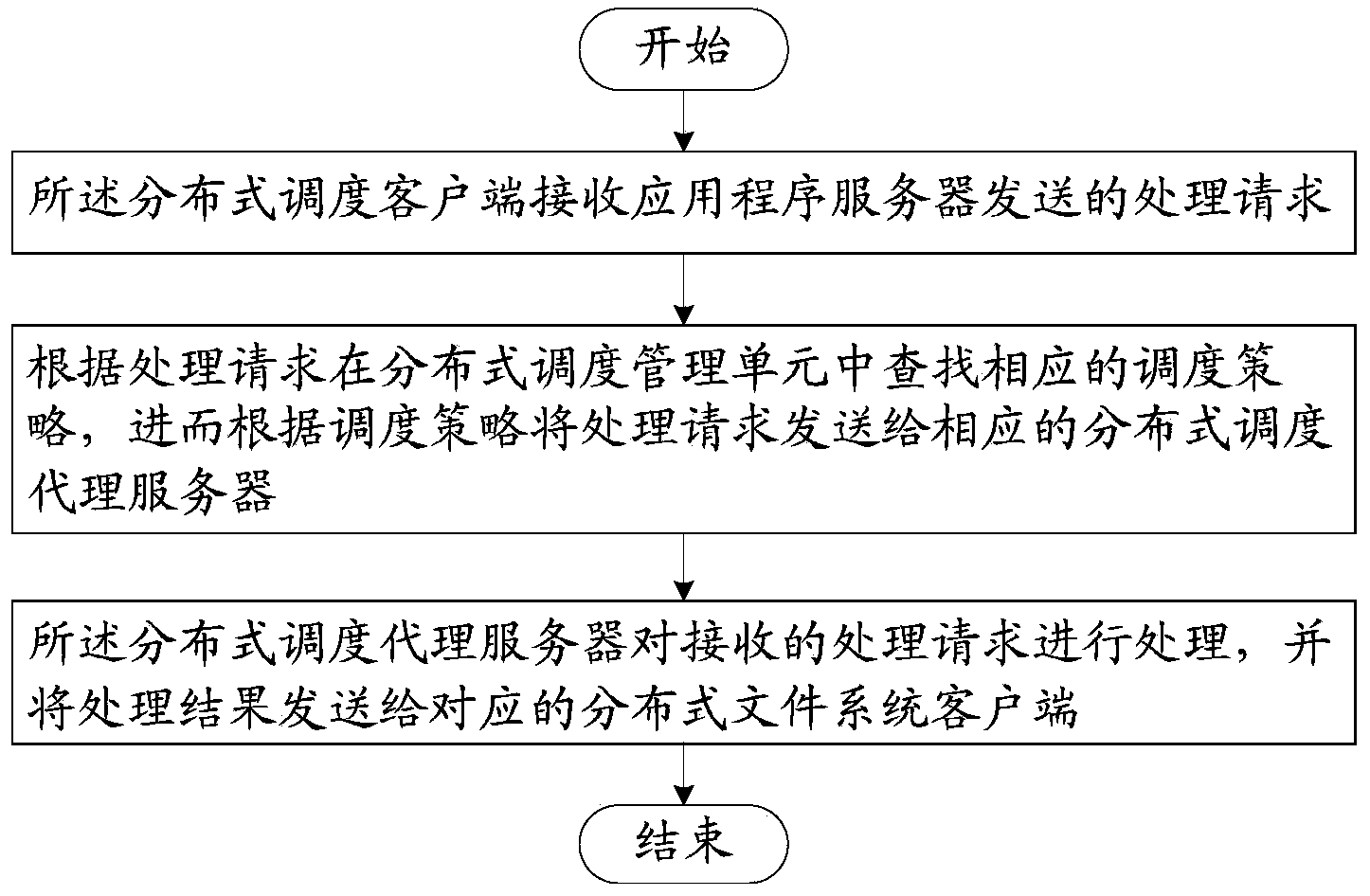

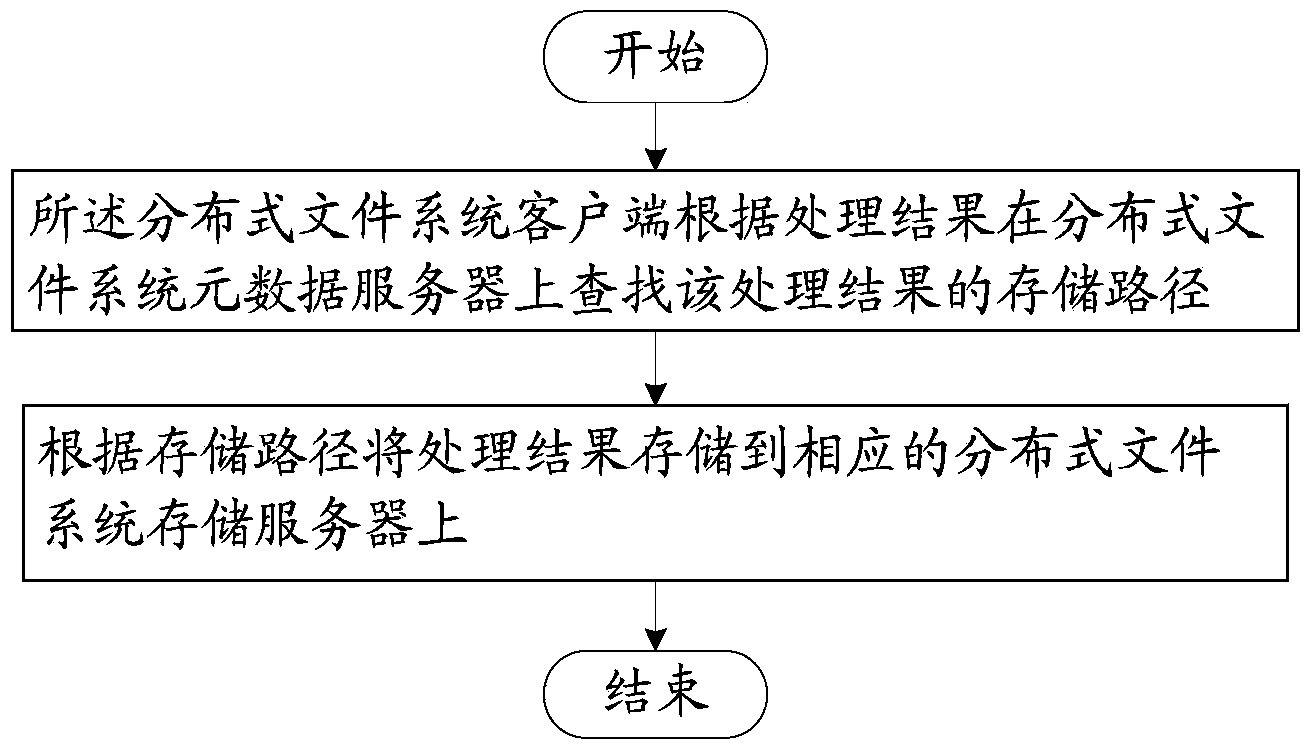

Cloud computing method and system for achieving mobile computing and obtaining mobile data

ActiveCN103491155AReduce hardware costsImprove concurrent processing capabilitiesTransmissionVirtualizationApplication server

The invention relates to a cloud computing method and system for achieving mobile computing and obtaining mobile data. The cloud computing system comprises an application program server, a distributed type dispatching management unit, a processing pool, a query pool, a storage pool and a cloud management platform, the application program server generates service requests and sends the service requests to the processing pool or the query pool, the distributed type dispatching management unit is used for generating dispatching strategies and load balancing strategies, the processing pool is used for carrying out distributed type processing according to the dispatching strategies and storing processing results in the storage pool in a distributed mode, the query pool is used for seeking related data in the storage pool according to the load balancing strategies in a load balancing mode, the storage pool is used for achieving the virtualization of file storage, file sharing and transparent storage, and the cloud management platform is used for monitoring and managing the processing pool, the distributed type dispatching management unit, the storage pool and the query pool. Based on a distributed type dispatching system and a distributed type file system, service application can be clouded, data moving and mobile computing are achieved in a configurable mode, and therefore high-efficiency parallel computing is achieved.

Owner:北京思特奇信息技术股份有限公司

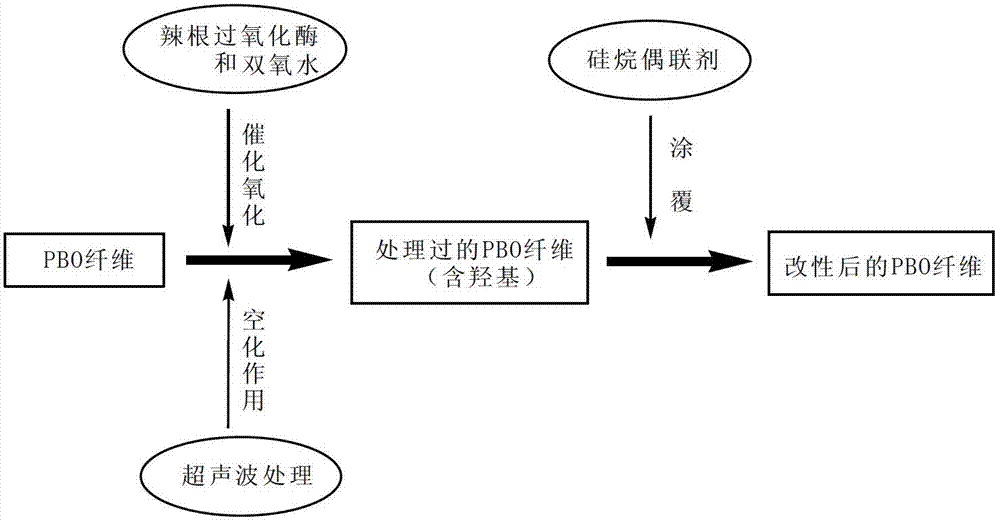

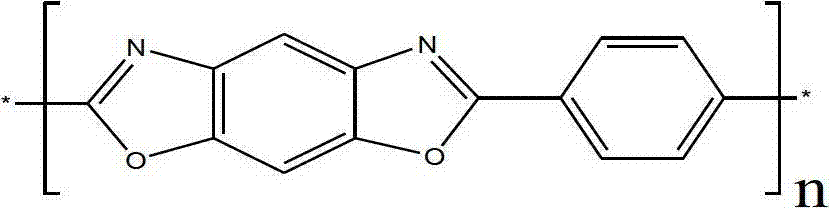

Surface modifying method of PBO (polybenzoxazole) fiber

InactiveCN102808325AAvoid damageEnhanced interface bindingBiochemical fibre treatmentFibre typesFiberActivation method

The invention relates to a surface modifying method of a PBO (polybenzoxazole) fiber. The surface modifying method is technologically characterized in that the PBO fiber is modified by adopting a secondary activation method, so as to reduce the damage to the fiber and improve a modification effect. Namely, the surface modification method comprises the following steps of: first, carrying out pretreatment on PBO by utilizing oxydol and an enzyme, introducing an active hydroxyl on the surface of the PBO, and then, condensing with a coupling agent, and introducing different active functional groups on the surface of the PBO, so as to adapt to the requirement of different thermosetting resins and achieve the purpose of improving an interface combination performance between the fiber and the resins. The surface modifying method has the advantages that the surface of the PBO fiber is first treated by the dilute solution of the oxydol; the oxidation action of the enzyme and the cavitation action of an ultrasound are supplemented; the reaction activity is enhanced; the reaction time is shortened; and further, the effect of treating the fiber is more uniform.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Aluminum alloy substrate for high-cap bottle cap and production method thereof

The invention discloses an aluminum alloy substrate for a high-cap bottle cap. The aluminum alloy substrate comprises, by weight, 0.4 percent to 0.8 percent of Si, 0.6 percent to 0.9 percent of Fe, 0.02 percent to 0.04 percent of Cu, no larger than 0.1 percent of Mn, no larger than 0.05 percent of Mg, no larger than 0.1 percent of Zn, no larger than 0.05 percent of Cr, 0.01 percent to 0.03 percent of Ti, no larger than 0.15 percent of impurities and the balance Al. The invention further discloses a production method of the aluminum alloy substrate for the high-cap bottle cap. The production procedure comprises batching, casting, homogenization treatment, hot continuous rolling, cold rolling, heat treatment, cold rolling, stretching bending and straightening and cropping. In the procedure of homogenization treatment, the temperature of homogenization treatment is 550 DEG C to 600 DEGC, and heat preservation time is 6 h to 10 h; in the procedure of cold rolling, cold rolling is carried out on blanks obtained through the hot continuous rolling procedure till the blanks are 0.4 mm to 0.5 mm, then heat treatment is carried out, the temperature of heat treatment ranges from 300 DEG C to 330 DEG C, heat preservation time ranges from 5 h to 9 h, and discharging cooling is carried out. Finally, cold rolling is carried out the blanks till the designed thickness is achieved.

Owner:CHINALCO SWA COLD ROLLING

Low-compression set silicone rubber and preparation method thereof

The invention discloses a silicone rubber technology, and particularly relates to a low-compression set silicone rubber and a preparation method thereof. The low-compression set silicone rubber comprises the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 30-70 parts of white carbon black, 2-15 parts of a structurized control agent, 0.1-5 parts of a heat-resistant auxiliary agent, 0.2-2 parts of a vulcanizing auxiliary agent, 0.2-1.5 parts of a silane coupling agent and 0.05-1 part of a demoulding agent. After the adoption of the formula and the preparation method, through reasonable cross-linking structure design and addition of the vulcanizing auxiliary agent, the slippage of a molecular chain of a polymer is reduced; through addition of the heat-resistant auxiliary agent, oxidation and degradation of the polymer at high temperature are prevented; moreover, through a multistage heating mixing process, uniform treatment and dispersion of the white carbon black are achieved; the obtained silicone rubber has relatively low compression set and relatively good mechanical properties.

Owner:JIANGSU TIANCHEN NEW MATERIALS

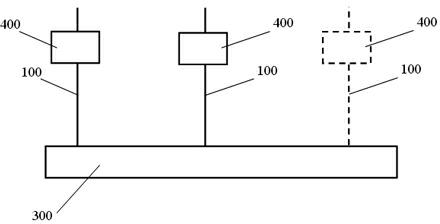

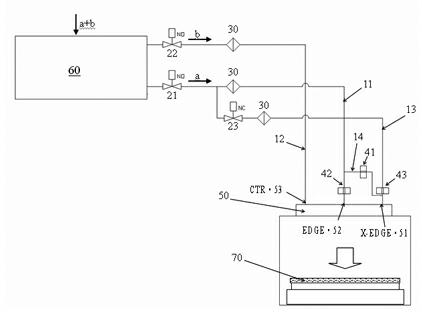

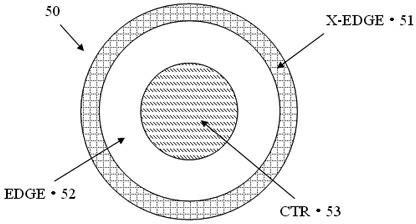

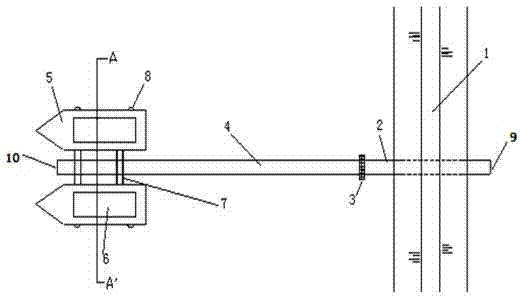

Multi-partition gas conveying apparatus

ActiveCN102522303ASimple controlReduce manufacturing costElectric discharge tubesGas pipelineCurrent limiting

A gas conveying apparatus comprises a reaction gas regulator which outputs controllable flow reaction gas. A first gas pipeline conveys the reaction gas of first flow to a first and a second gas distribution areas through a first and a second current limiting apparatuses respectively. A third gas pipeline is communicated with the first gas pipeline through a controllable valve and is communicated with the first gas distribution area through a third current limiting apparatus. A second gas pipeline conveys the reaction gas of the second flow to a third gas distribution area. According to the invention, distribution control of multipath reaction gases with different flow ratios in a plurality of areas on a spray header can be realized so that uniform plasma processing effects can be obtained on a wafer surface. A selector switch is formed by a valve and the like. Two states: opening and closing should be only possessed. The apparatus is easy to be controlled. And setting cots of the valve and an orifice is lower than the cost of a MFC. A lot of production cost can be saved.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Process for rolling production of decorative drawing aluminum strip by double rollers

The invention discloses a process for rolling production of a decorative drawing aluminum strip by double rollers, belongs to the field of metal surface processing, and comprises the steps of: rolling and drawing: carving a decorative pattern on the surface of the roller by a cutter automatically controlled by a program, and rolling by placing the aluminum strip between the rollers; degreasing: performing chemical clean for the surface of the rolled and drawn aluminum strip to remove greasy dirt and pollutants on the surface; anodizing: through electrolytic oxidation, converting the surface of the aluminum strip into an oxide film; and hole sealing: sealing the hole by deionized water or distilled water. The invention has the beneficial effects that various types of decorative aluminum products on the drawing surface can be produced according to demand, the decorative pattern on the surface of the drawing aluminum plate is better in uniformity, the roller decorative pattern rolled is three-dimensional and layered so that the roller decorative pattern is stronger in metallic texture, the greasy dirt and pollutants on the surface in the degreasing step are removed, so that the surface of the aluminum strip is fully contacted with the treatment solution, so as to obtain uniform treatment effect, and the hole sealing process is performed to stabilize the anodized film.

Owner:江苏鑫皇铝业发展有限公司

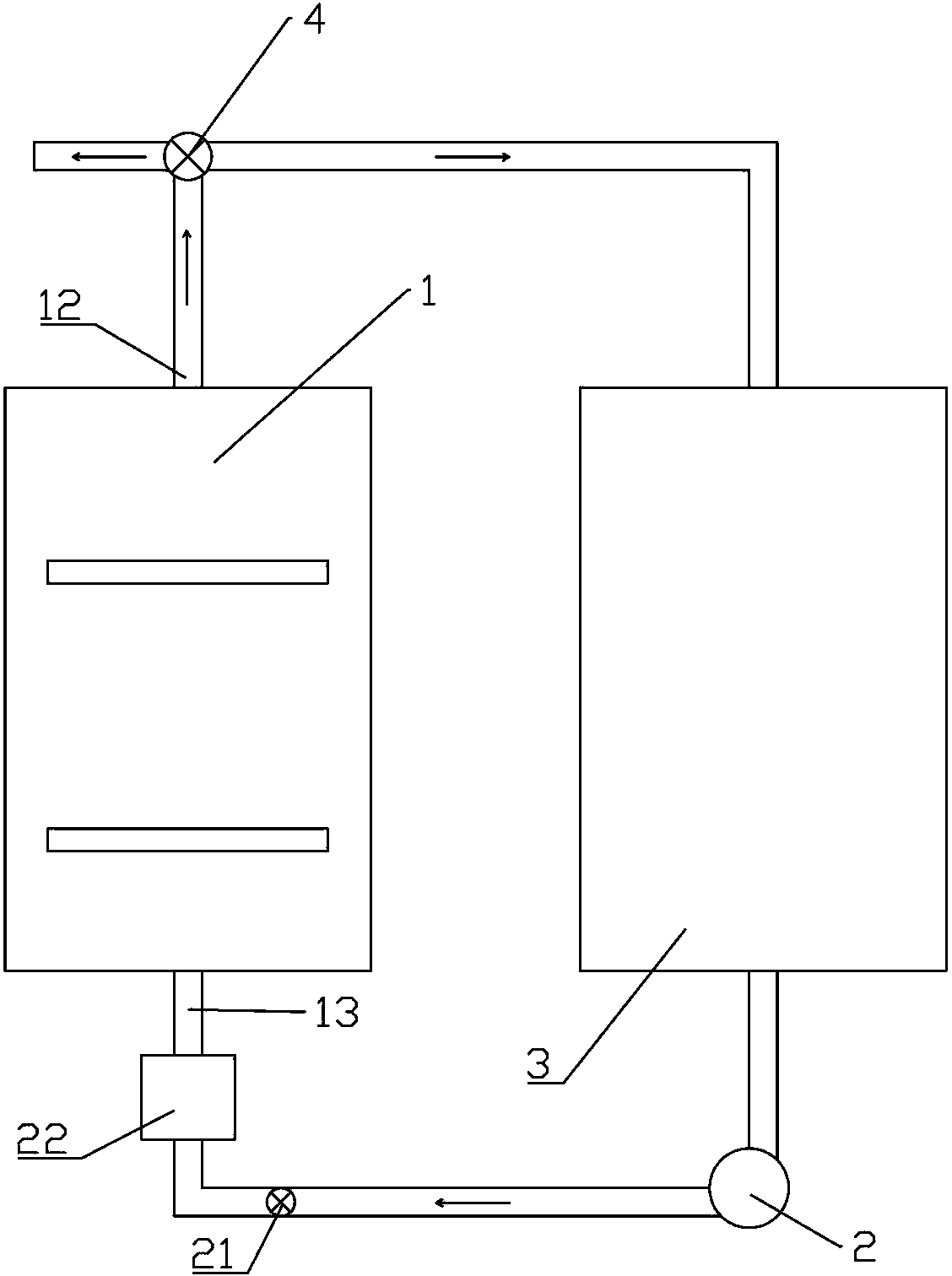

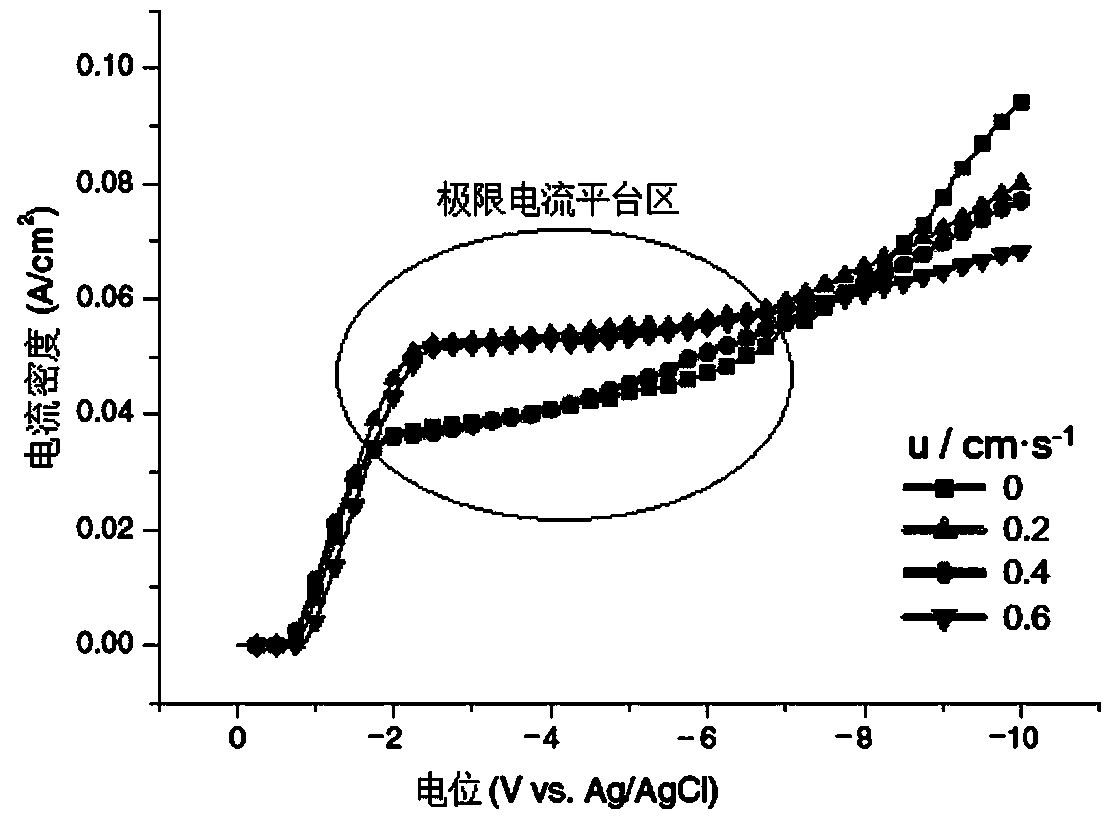

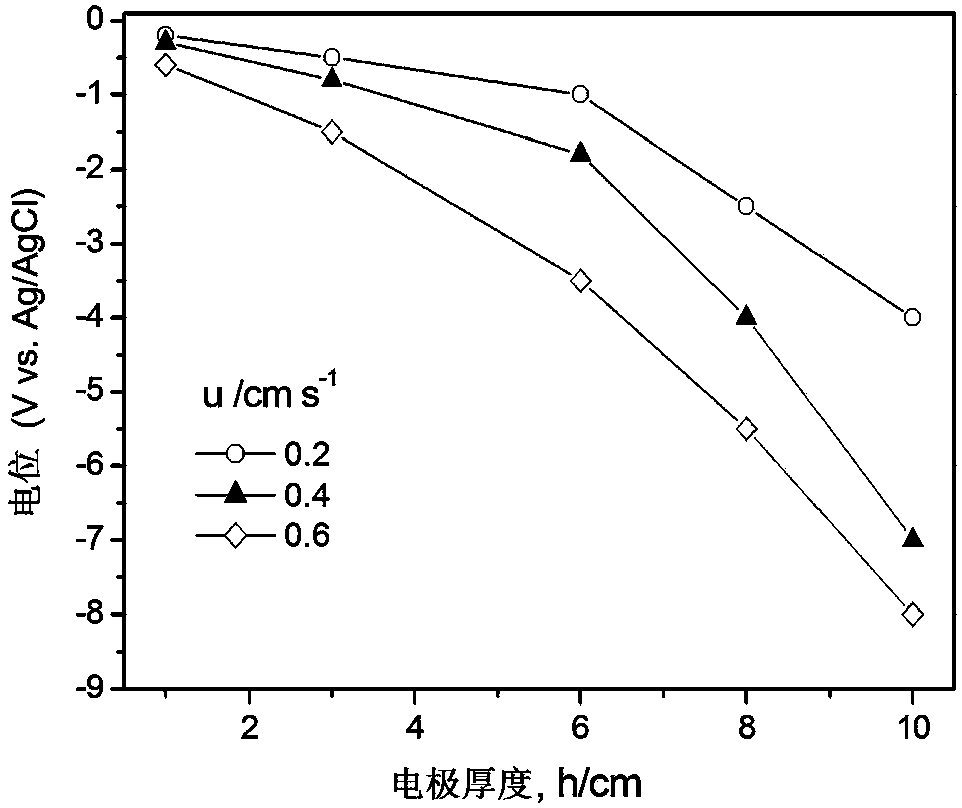

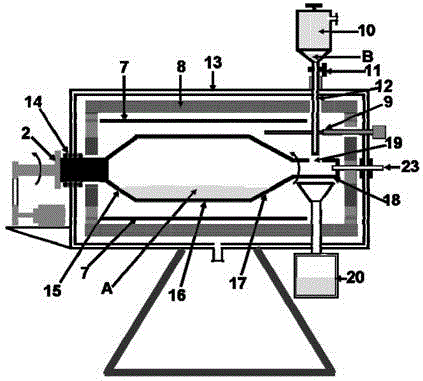

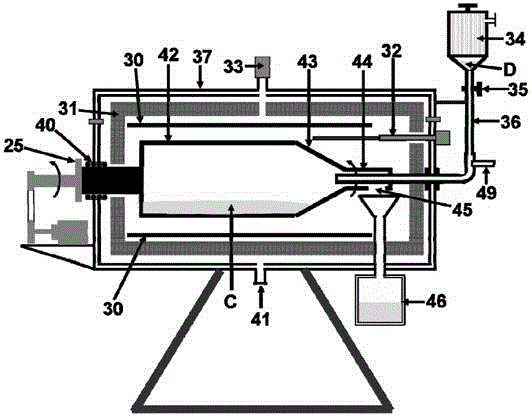

Electrochemical surface treatment method and electrochemical surface treatment device for porous metal material

ActiveCN103710735AUniform treatment effectEasy to handleElectrolytic inorganic material coatingElectrolytic agentMetallic materials

The invention discloses an electrochemical surface treatment method and an electrochemical surface treatment device for a porous metal material. The method comprises the following steps: on the basis of applying a compact metal material which is the same as a to-be-treated porous metal material as a working electrode, utilizing an electrochemical working station to measure a steady-state cathode polarization curve of the compact metal material in the working electrolyte, determining a platform zone of a current-potential curve, and obtaining limitation diffusion-controlled electrochemical treatment condition of electro-deposition reaction; on the basis of applying to-be-treated porous metal material as a working electrode, enabling the working electrolyte to perform single-direction or circulating flow in an electrolytic cell; applying the determined limitation diffusion-controlled electrochemical treatment condition to carry out electrochemical surface treatment on the porous metal material until a set value is reached. The electrochemical surface treatment method disclosed by the invention can be used for treating the inner surface of the porous metal material more effectively, so that the outer-layer surface and inner-layer surface of the porous structure of the metal material are more uniform in treatment effect, and therefore, a better electro-deposition treatment effect or electro-polishing effect is obtained.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

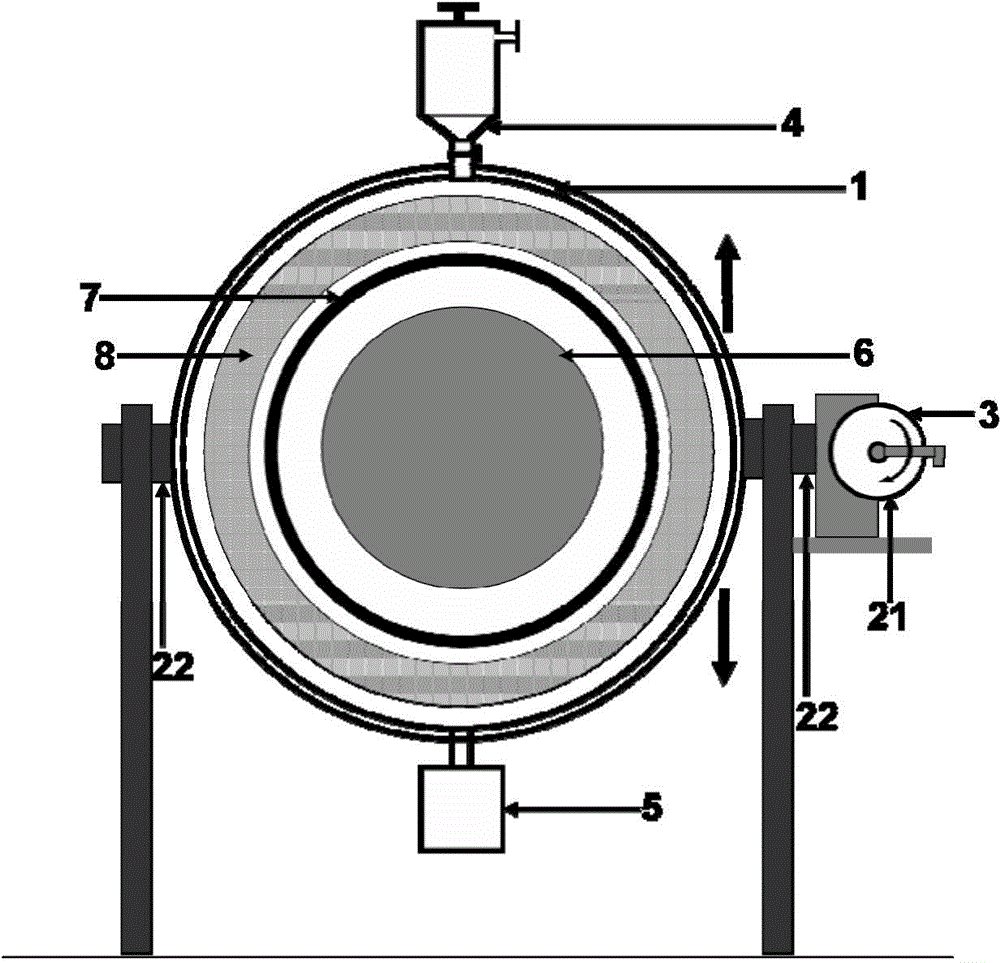

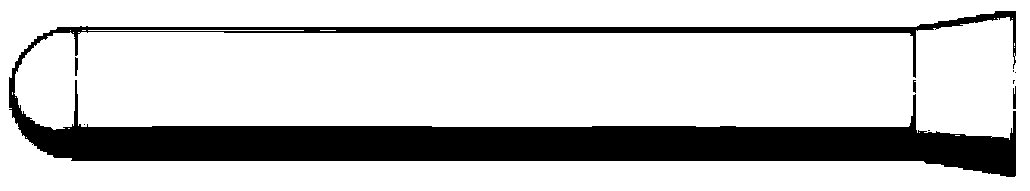

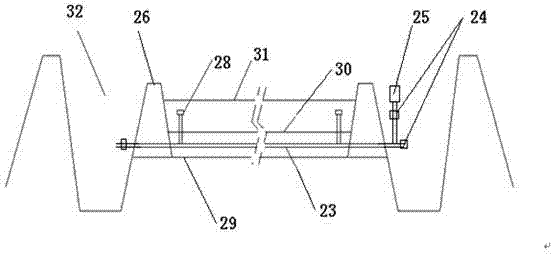

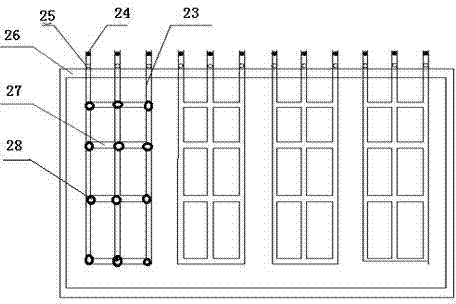

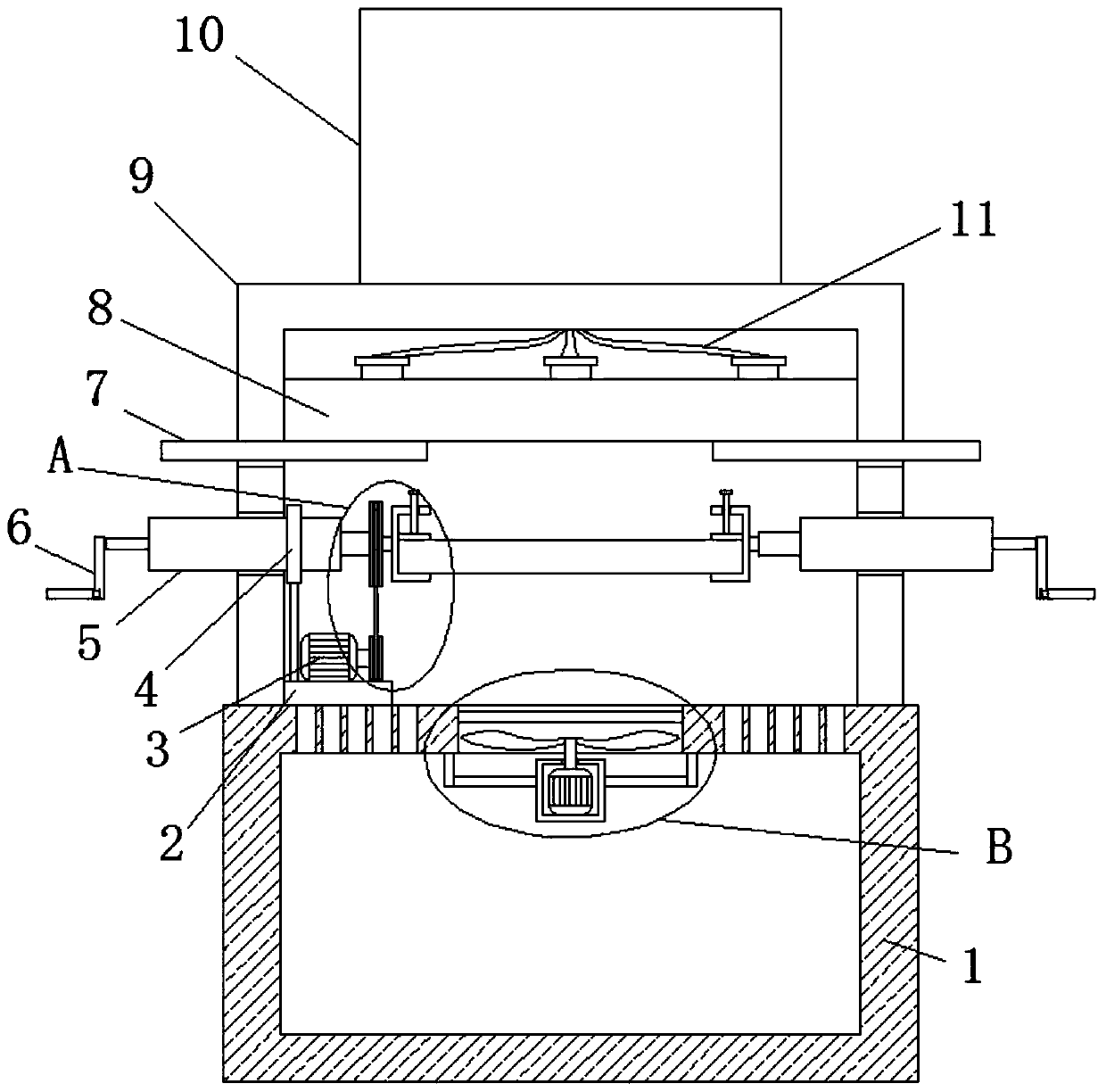

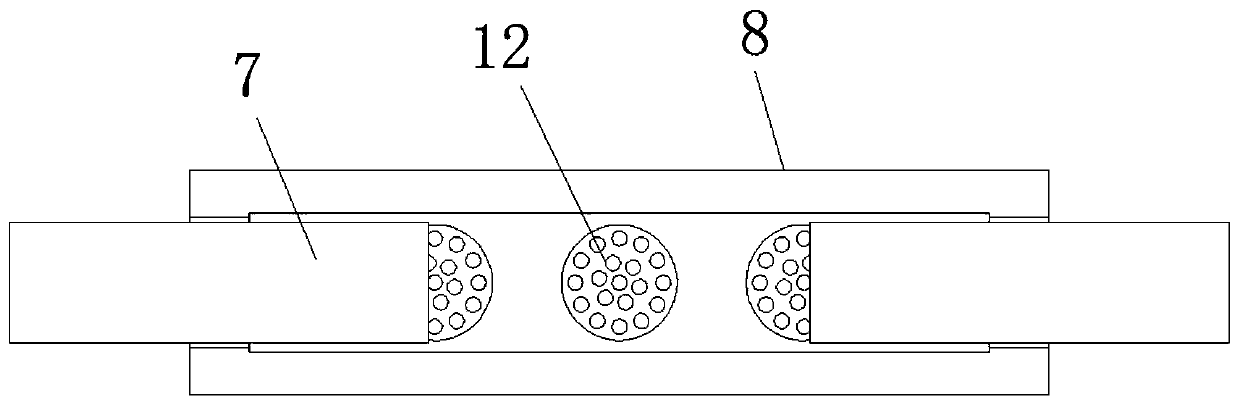

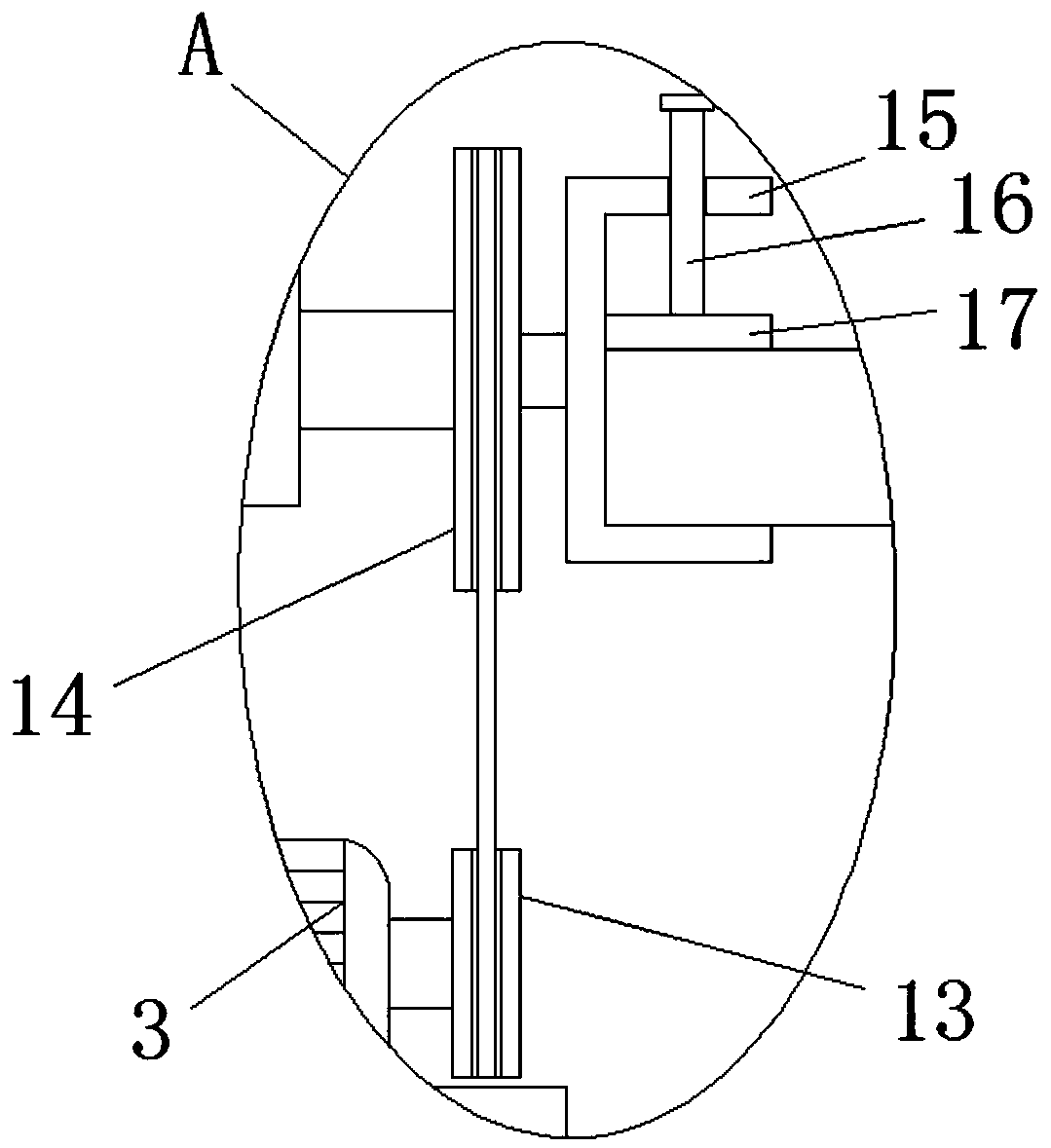

Tilting high-temperature rotary tube furnace for continuous heat treatment

InactiveCN104482757ARealize rapid heating and cooling functionNot easy to residueRotary drum furnacesTube furnaceContinuous operation

The invention belongs to the industry and field of high-temperature heat treatment electric furnaces and particularly relates to a tilting high-temperature rotary tube furnace for continuous heat treatment. The furnace mainly comprises a furnace body, a rotating mechanism and a tilting device. The furnace body is provided with an airtight heart; the upper end of the furnace body is provided with a feeding device; the lower end of the furnace body is provided with a receiving device; the rotating mechanism disposed within the furnace body is connected with a high-temperature-resistant liner and drives the same to rotate, thereby driving material within the high-temperature-resistant liner to move. A heating and insulating device and a temperature measurer are disposed within the furnace body. The feeding device is used for conveying material, to be subjected to heat treatment, into the liner by the aid of the tilting device; after heat treatment at a target temperature is complete, the receiving device delivers out the material by the aid of the tilting device. The furnace allows uniform heat treatment, is capable of heating and cooling the material fast, is available for continuous operation, has high applicable temperature and is low in manufacturing cost.

Owner:THE 3RD ACAD 8358TH RES INST OF CASC

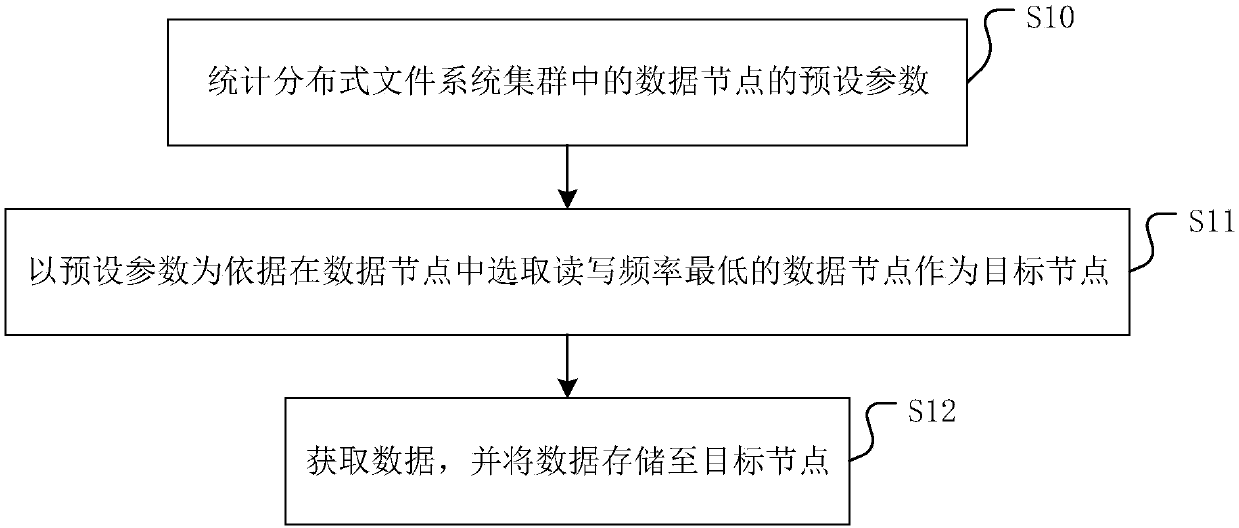

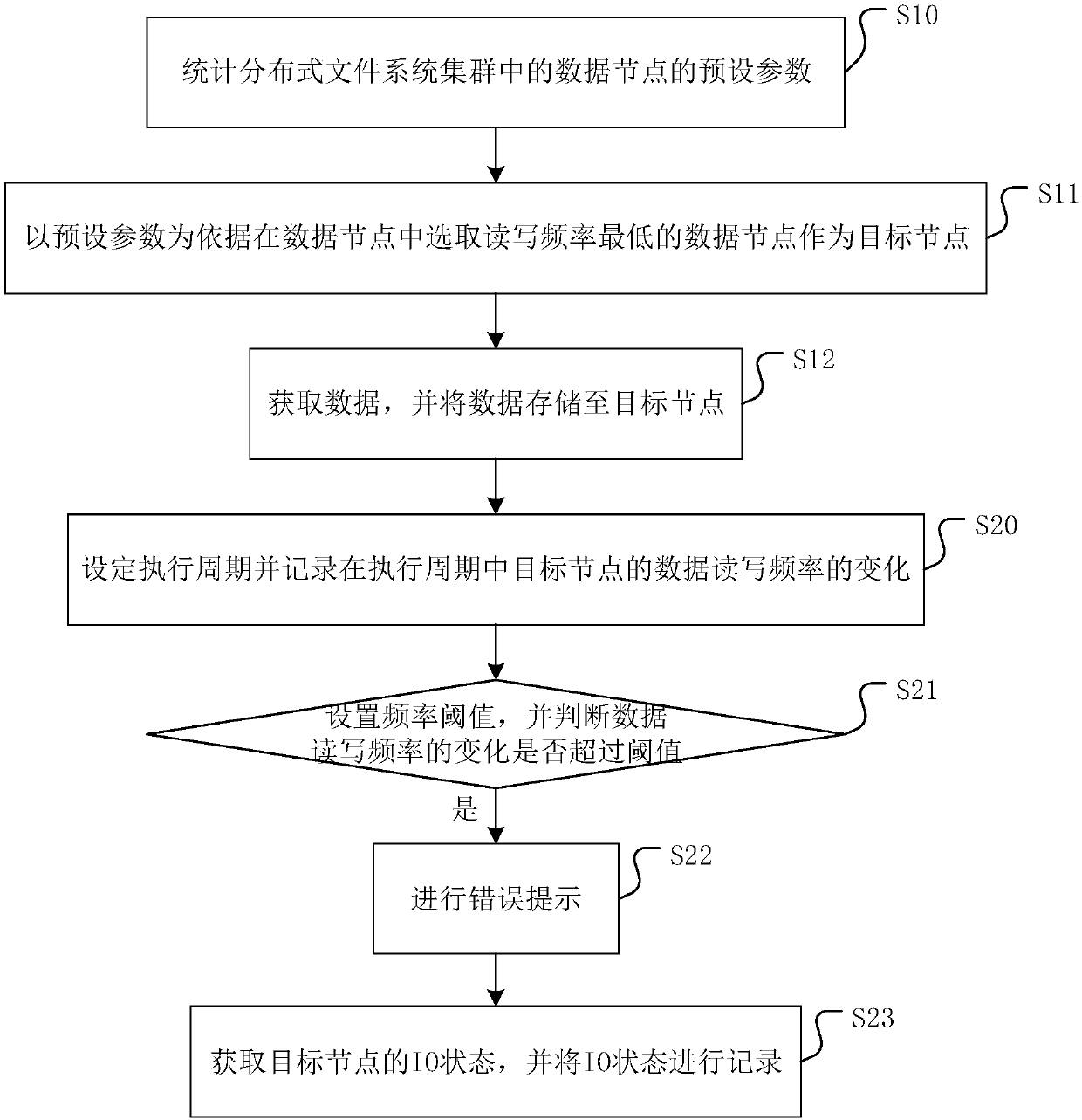

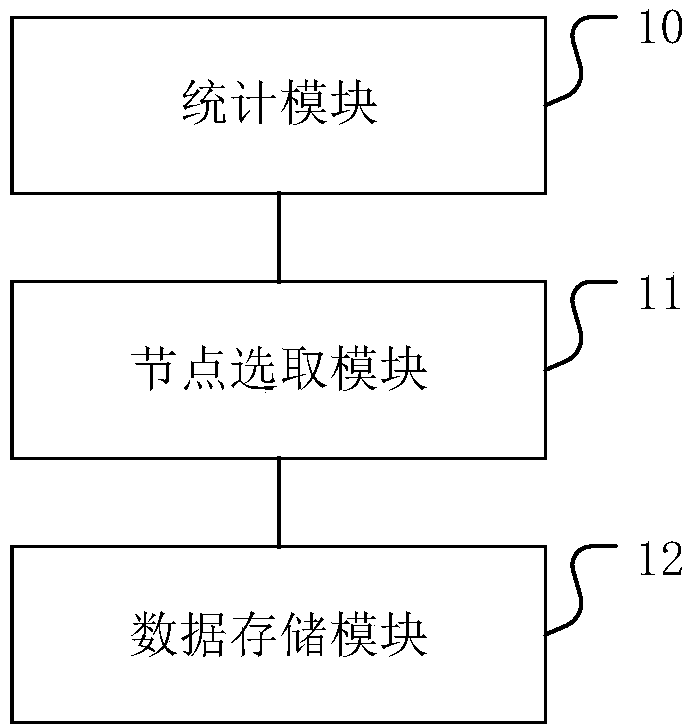

Data storage method and device for distributed file system

InactiveCN107562913AImprove I/O performanceIO performance guaranteeInput/output to record carriersSpecial data processing applicationsDistributed File SystemHigh availability

The invention discloses a data storage method and device for a distributed file system. The method includes the steps that preset parameters of data nodes in a distributed file system cluster are counted; with the preset parameters being a basis, the data node with the lowest read-write frequency is selected from the data nodes and serves as a target node; data is obtained and stored into the target node. Understandably, the data nodes with low read-write frequency are not used frequently in the cluster, in this way, it can be considered that the data node has higher IO performance compared with other data nodes frequently used, and by selecting the data nodes with the low read-write frequency for data storage, the overall processing performance of the cluster can be balanced for the data.In addition, when small files are stored, it is avoided that because the quantity of the small files is large, node IO is busy, the IO performance of the nodes is guaranteed, and then the high availability of the cluster is ensured. In addition, the data storage device has the advantages.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

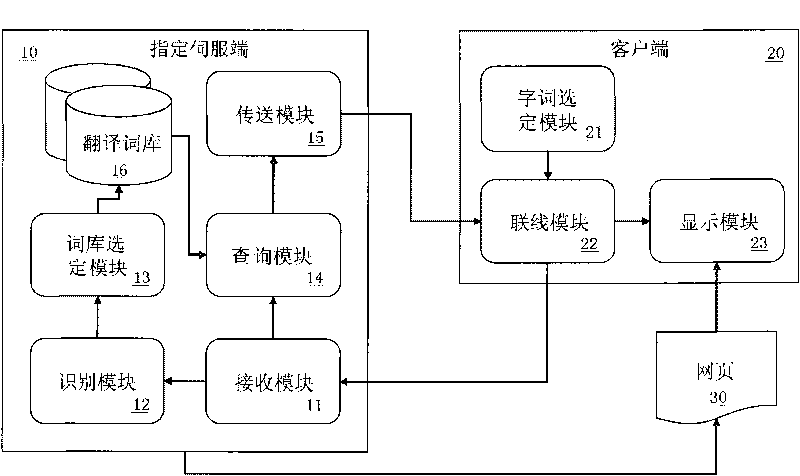

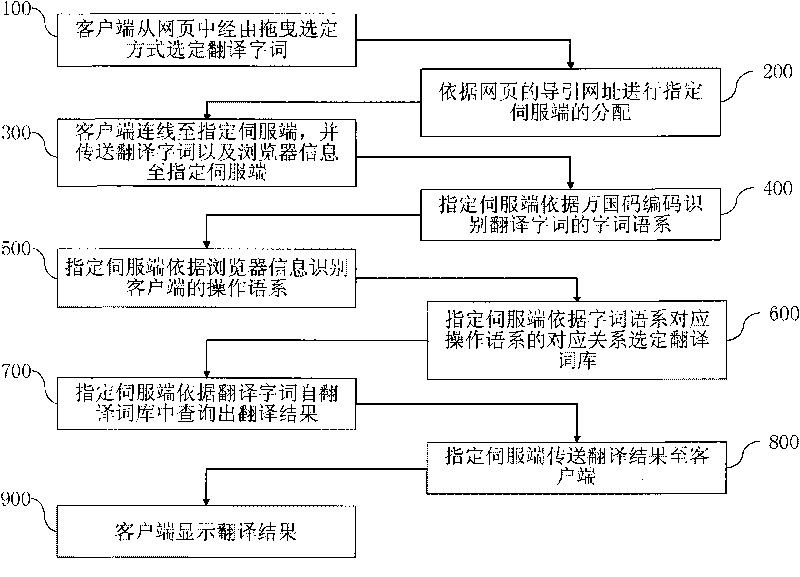

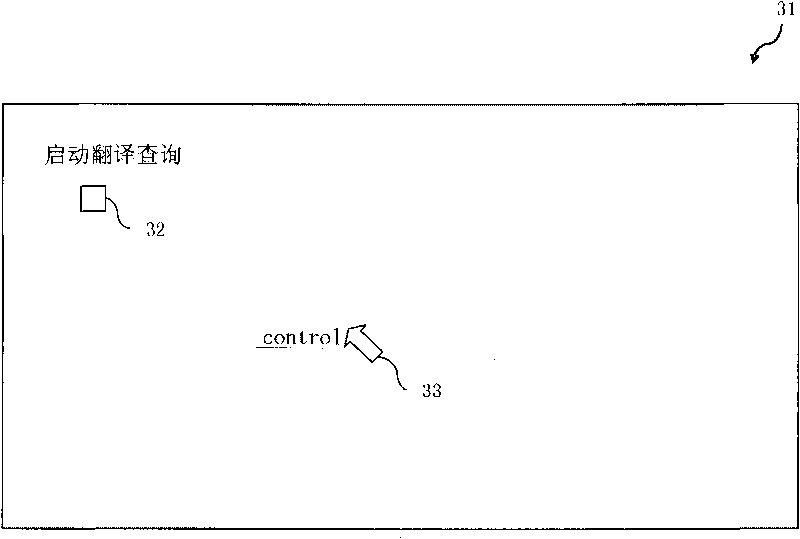

Network translation inquiry system embedded in webpage and method thereof

ActiveCN101739394AUniform treatment effectEasy to operateSpecial data processing applicationsClient-sideWeb page

The invention relates to a network translation inquiry system embedded in a webpage and a method thereof, which can solve the problem of inconvenient operation of translation explanation inquiry on a network inquiry system through the technical means comprising the following steps of: towing a cursor by a user to select a translation word after triggering the webpage in which the system of the invention is embedded, transmitting the translation word selected by the user and browser information to an appointed servo end, recognizing the word language system of the translation word and the operation language system of a network browser on the appointed servo end, translating and converting the translation word into the operation language system according to the word language system to inquire a translation result and returning the translation result to a client end to display, thereby achieving the technical effect of simplifying the network inquiry of translation explanation.

Owner:ZHIGU HLDG

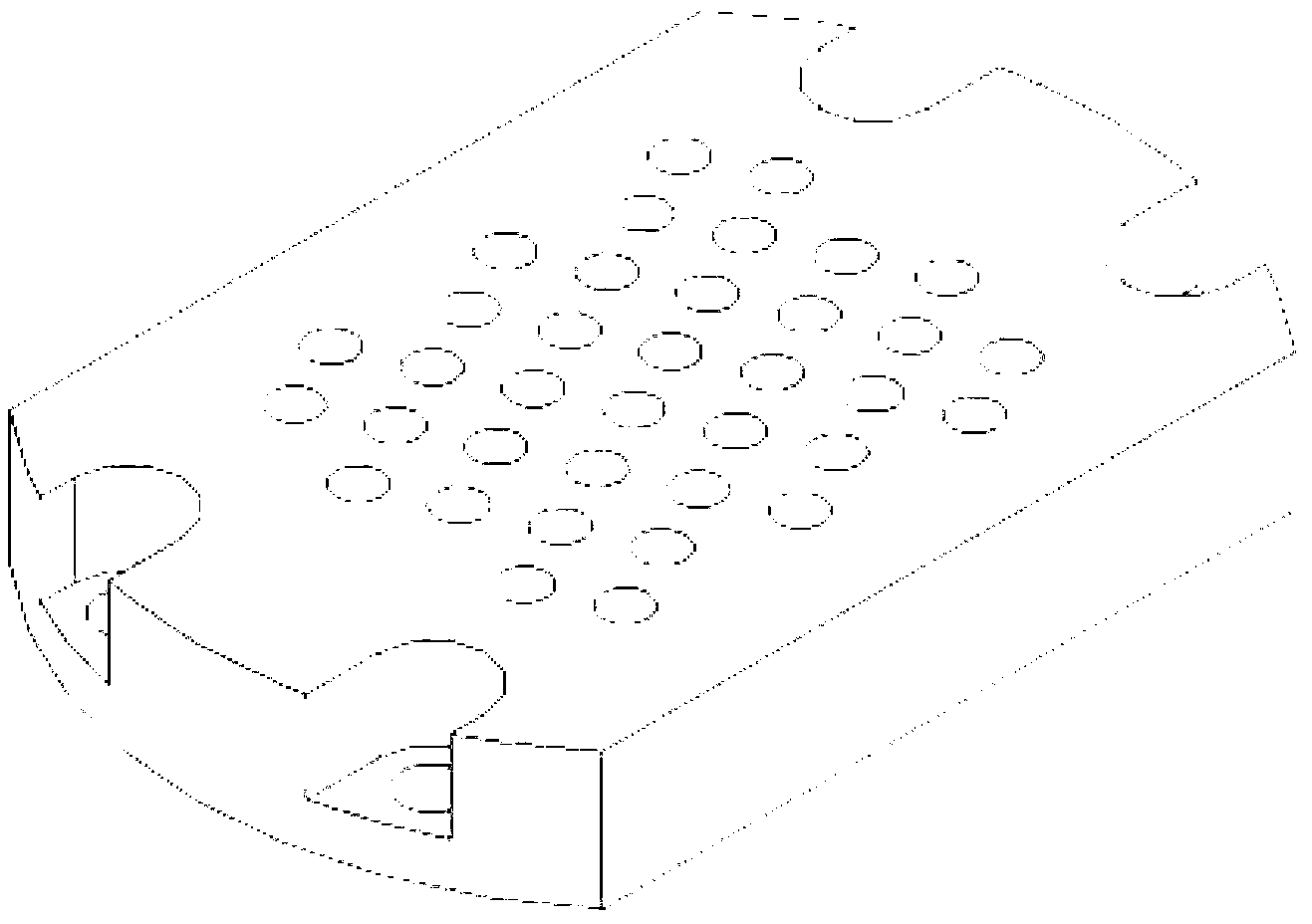

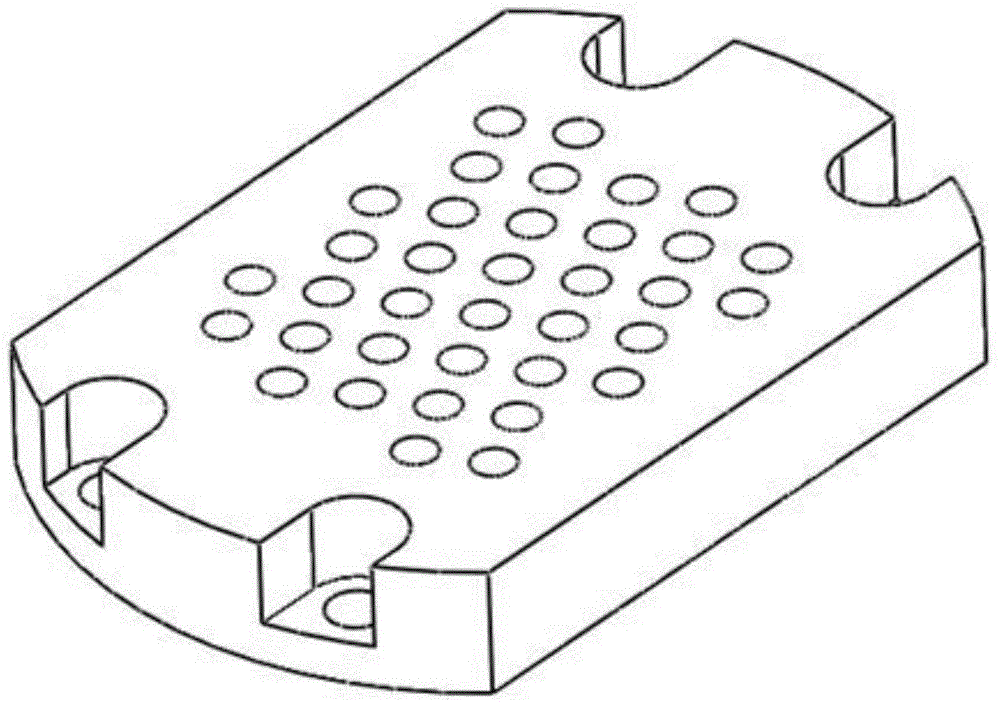

Multi-needle type impacting head for ultrasonic impacting gun and design method of impacting head

ActiveCN103264356AReduce the number of round tripsReduce dwell timeBlast gunsEngineeringStress corrosion cracking

The invention discloses a multi-needle type impacting head for an ultrasonic impacting gun and a design method of the impacting head. The multi-needle type impacting head is composed of an amplitude-changing rod end surface, an impacting needle cover plate and impacting needles, wherein hole arrays in rows are filled in effective regions of the amplitude-changing rod end surface and an impacting needle cover. The multi-needle type impacting head and the design method thereof provided by the invention have the advantages that by virtue of the multiple impacting needles, compared with an existing impacting head, the work efficiency is improved by 300%-400%, the impact strength is improved by about 5%, and the problems that a welding structure cracks due to stress corrosion, is unstable and deforms, the fatigue service life of the welding structure is shortened and the like are effectively alleviated.

Owner:天津益普科技发展有限公司

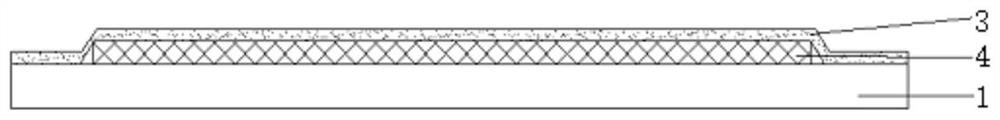

Ultrathin glass single-side thinning method

PendingCN113336447AReduce plate thickness differenceImprove uniformityGrinding work supportsPlane surface grinding machinesEtchingSi substrate

The invention relates to an ultrathin glass single-side thinning method, which belongs to the technical field of glass substrate thinning process. The method comprises the following steps: attaching an attaching film on a non-thinning surface of a glass substrate; polishing the thinned surface of the glass substrate; subjecting the polished glass substrate to cleaning and drying and removing the attached film; pasting a back plate after the non-thinned surface of the glass substrate is coated with the attaching film; moving the glass substrate fixed with the back plate into an etching tank, etching firstly, and then performing single-face thinning treatment; after the glass substrate is separated from the back plate, cleaning and drying the thinned glass substrate, removing the attached film, and inspecting. The method has the beneficial effects that the polishing and pretreatment processes are added before single-side etching, and enough supporting force is provided for the polished glass substrate, so that the plate thickness difference of glass incoming materials is reduced, the uniformity of the thickness of the glass plate is improved, the expression yield of products can be improved, and the risk of fragment is reduced.

Owner:重庆永信科技有限公司

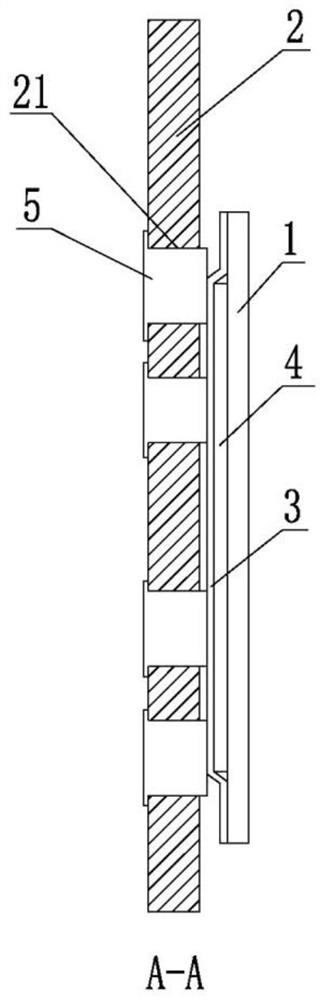

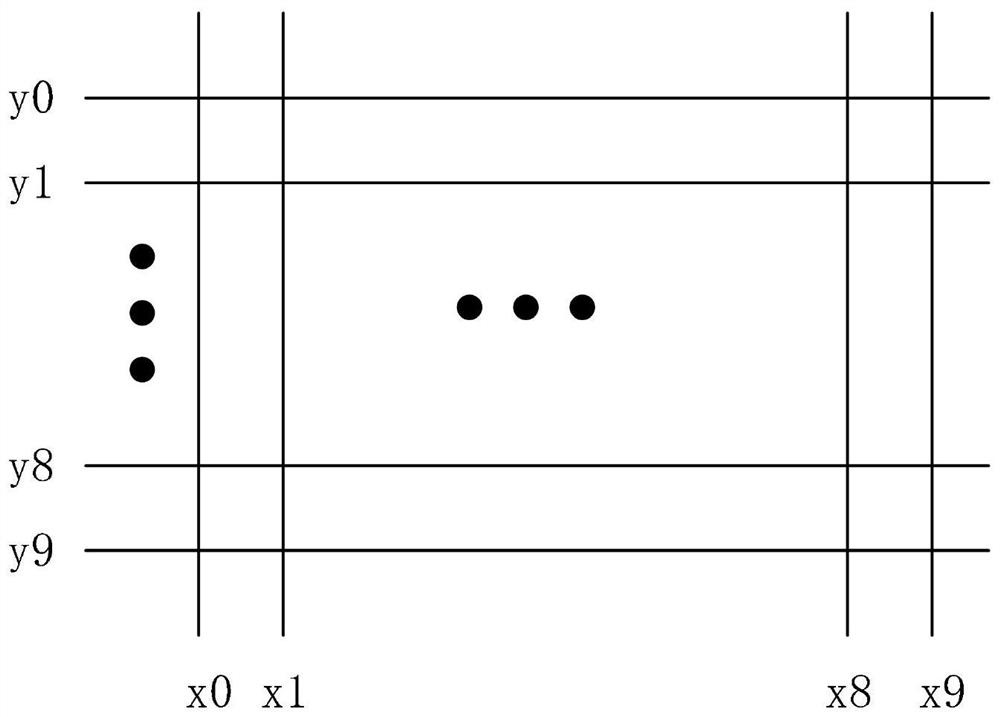

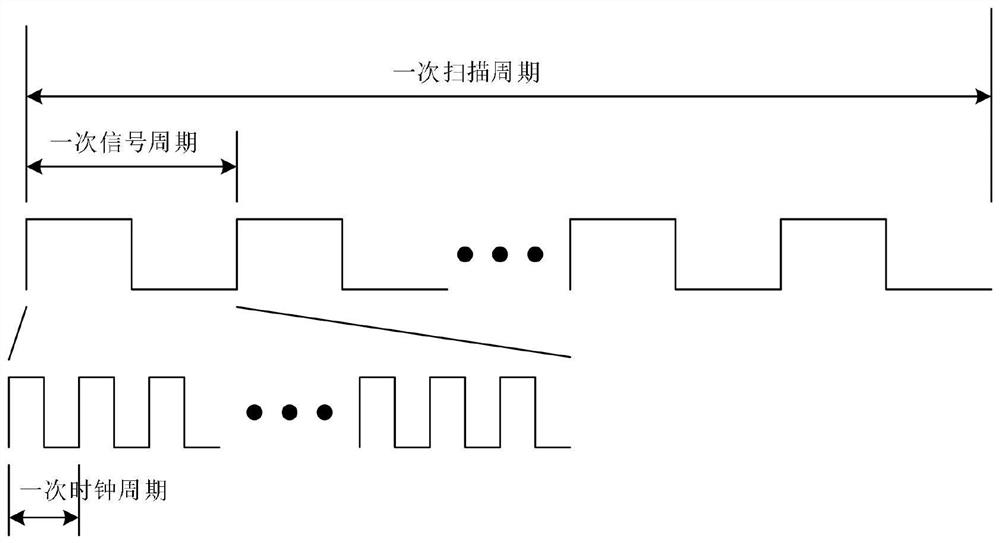

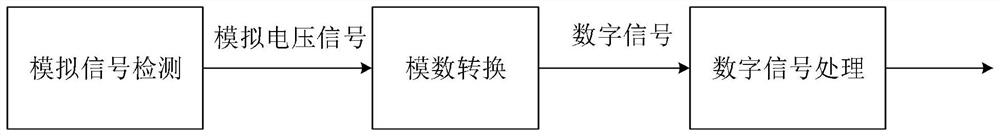

Touch screen scanning data self-adaptive noise control method and touch screen scanning data self-adaptive noise control system

ActiveCN112684938AReduce noise interferenceImprove reporting rateInput/output processes for data processingComputer graphics (images)Original data

The invention discloses a touch screen scanning data self-adaptive noise control method, which comprises the following steps: S1, completing one-frame scanning on a touch screen, and calculating according to scanning data to obtain original data; s2, performing difference calculation on the original data and pre-stored reference data to obtain difference data; s3, searching a peak value in the difference data and calculating a touch screen coordinate corresponding to the peak value; s4, reporting the touch screen coordinates corresponding to the peak values, and meanwhile, obtaining a peak value distribution diagram and performing feature analysis; s5, judging whether scanning parameters need to be adjusted or not according to feature analysis result; if yes, executing the step S6, and if not, returning to the step S1, and starting the scanning of the next frame; and S6, calculating a new scanning parameter, and starting the scanning of the next frame. According to the invention, scanning parameters can be dynamically modulated according to the noise intensity, and effective balance can be carried out between noise processing and a point reporting rate.

Owner:SHENZHEN BETTERLIFE ELECTRONICS SCI & TECH

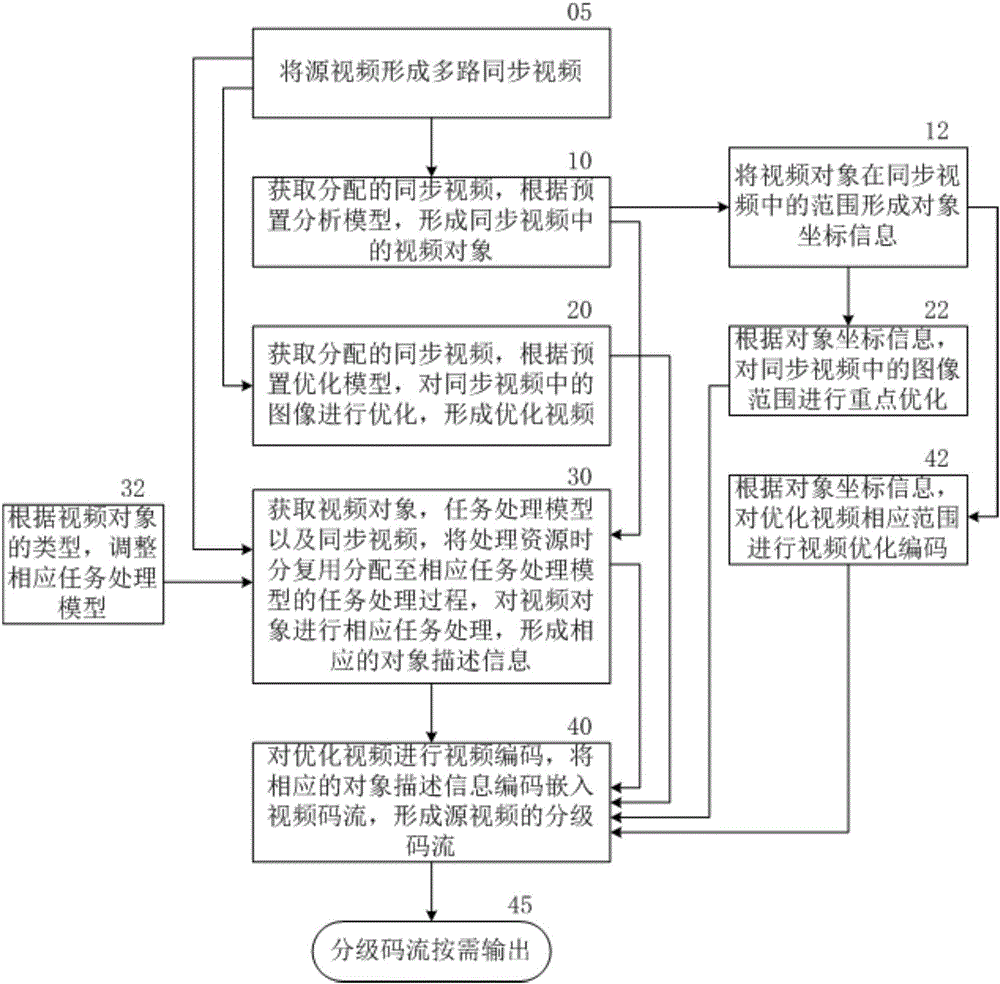

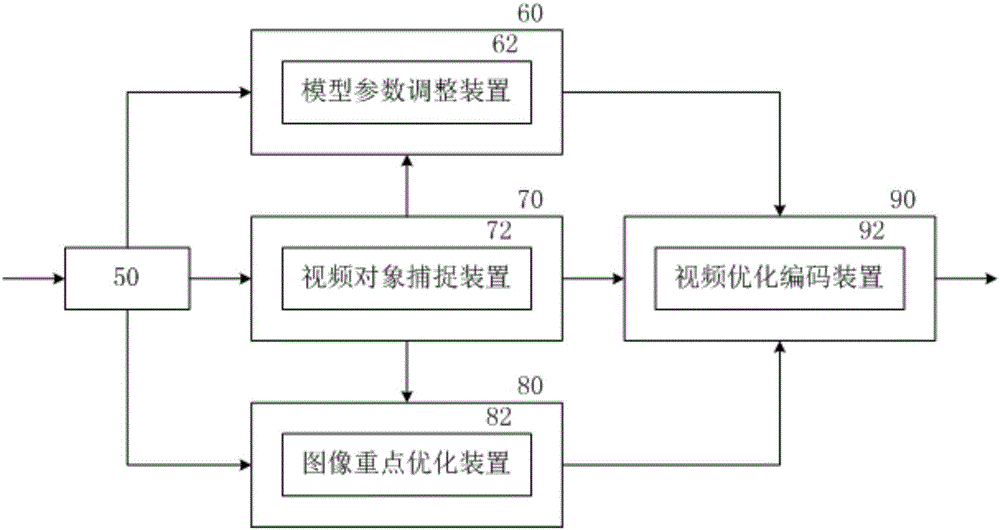

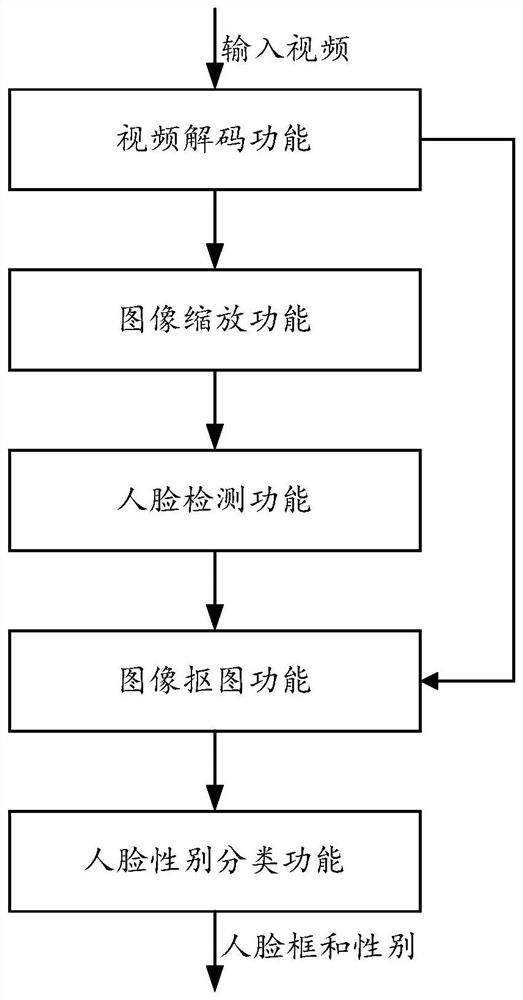

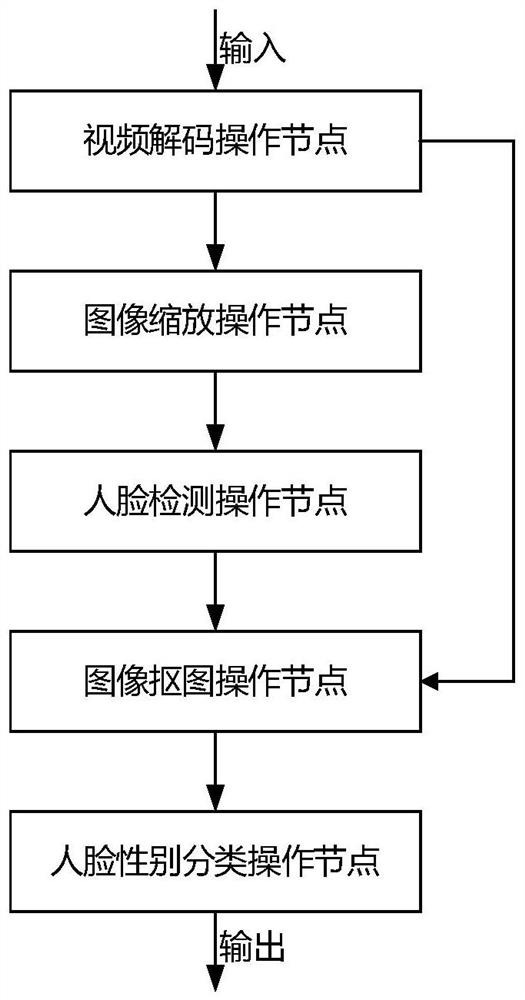

Hierarchical video code stream coding method and architecture for time division multiplexing neural network processor

ActiveCN106303527ARealize time division multiplexingAvoid task bursts or data processing loads that cannot be sharedDigital video signal modificationTime-division multiplexingAnalysis models

The invention provides a hierarchical video code stream coding method for a time division multiplexing neural network processor. The hierarchical video code stream coding method comprises the following steps: obtaining a synchronous video, and forming a video object in the synchronous video according to a preset analysis model; obtaining the synchronous video, and optimizing the image in the synchronous video according to a preset optimization model to form an optimized video; obtaining the video object, a task processing model and the synchronous video, allocating processing resources to a task processing process of the task processing model by time division multiplexing, and carrying out corresponding task processing on the video object to form corresponding object description information; and carrying out video coding on the optimized video, coding the corresponding object description information, and embedding video code stream to form hierarchical code stream of a source video. The optimized video and the analysis and processing result information of the video objects are synchronously combined in a coding mode, so that the source video forms the hierarchical code stream containing video contents and related information of the video objects. The invention further provides hierarchical video code stream coding architecture for the time division multiplexing neural network processor.

Owner:GUANGDONG VIMICRO

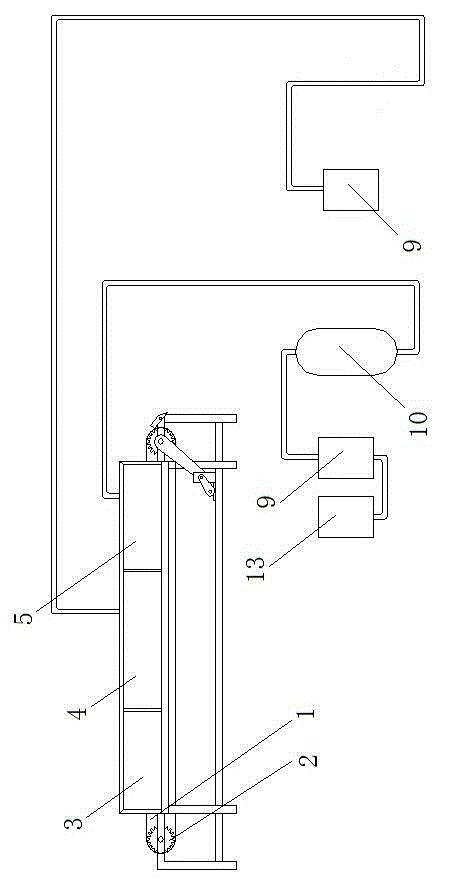

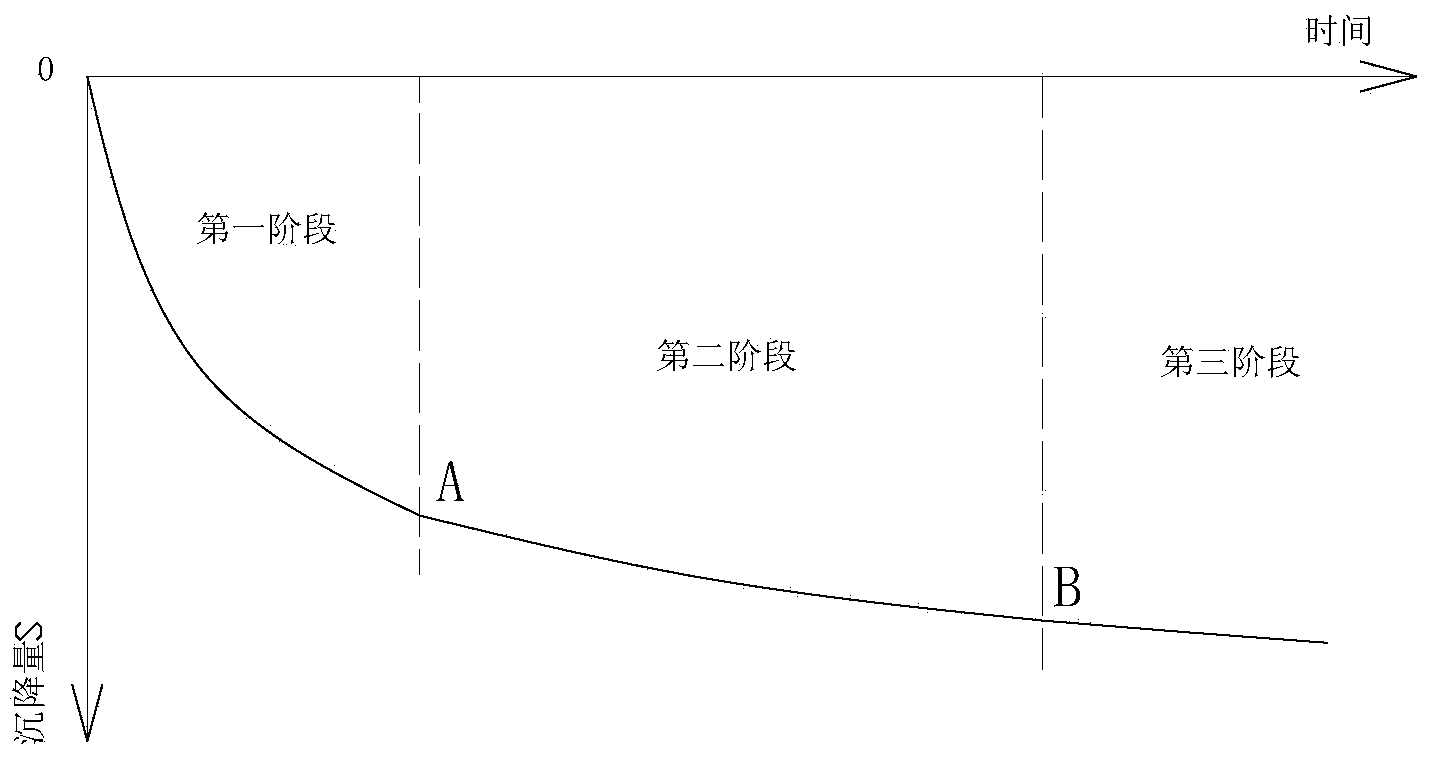

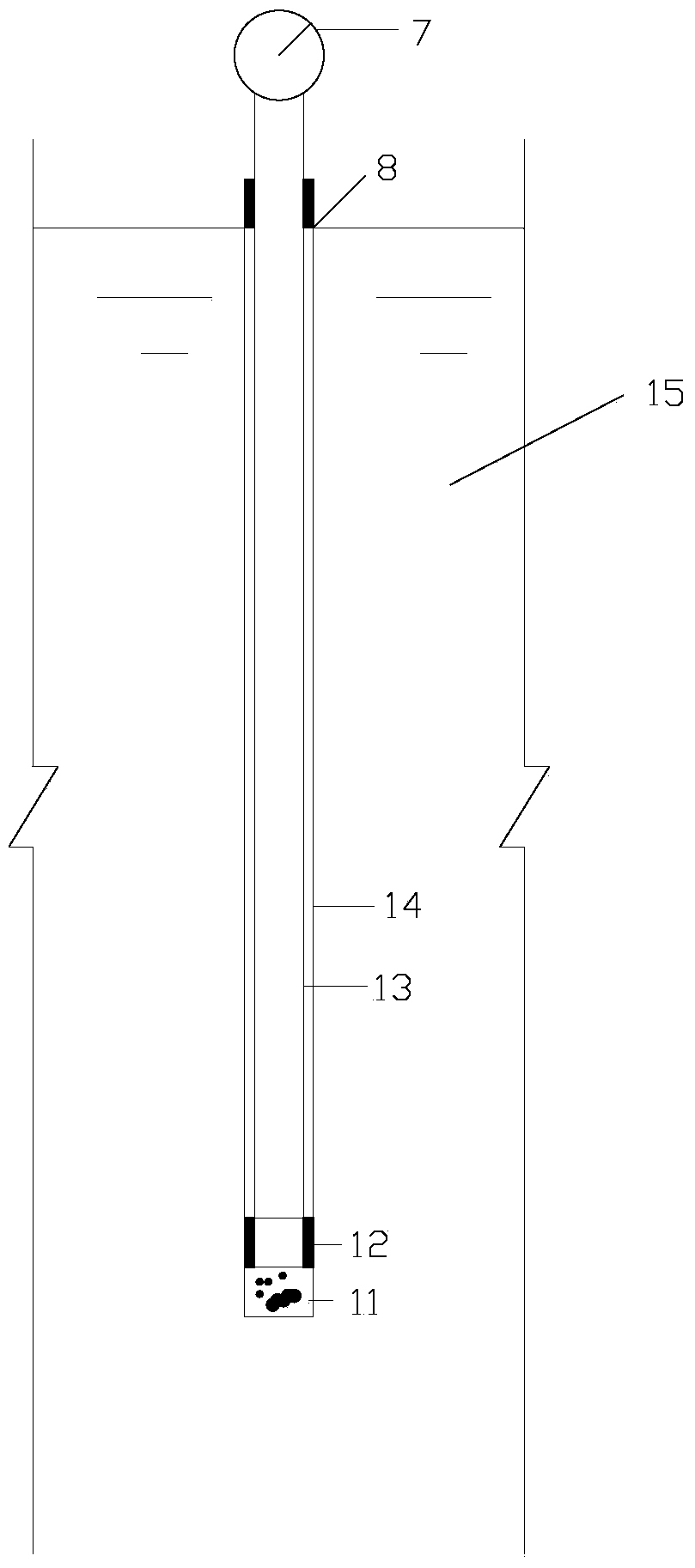

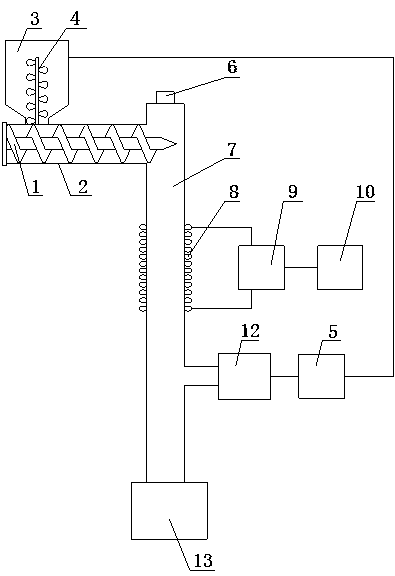

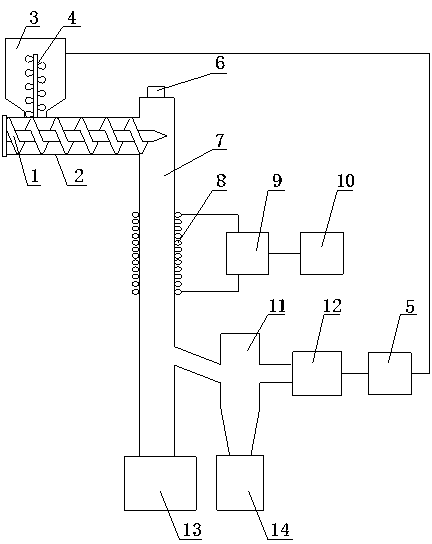

Negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method

The invention discloses a negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method. The negative-pressure three-dimensional flow-guiding disturbance impact solidification dredger filling method mainly comprises the steps that a dredger fill area is cleaned and flattened; a ditch is horizontally formed in the dredger area or a horizontal water seepage pipe is arranged by inclining by 0.5-5 degrees, and backfilling is conducted through medium and rough sand-gravel aggregate; a dam and a drainage canal are constructed on the periphery of the dredger fill area, and a water diversion pipe and an automatic-flowing drainage pipe are pre-buried; a dredger fill pipeline is led into the dredger fill area in the dam; slurry is guided into the surface layer of the dredger fill area and underground water is guided into the drainage canal after silt deposits; a water suction pump is connected to the outer port of the drainage pipe, and then forced drainage is conducted. Meanwhile, the invention creatively provides a suspension controllable dredger fill area drainage device, a movable multifunctional integrated well tube draining and vibrating-flushing device and technologies matched with the suspension controllable dredger fill area drainage device and the movable multifunctional integrated well tube draining and vibrating-flushing device. Compared with the prior art, the reinforcing period can be shorted by about 50% and the comprehensive unit cost can be reduced by about 45% under the same condition, and the bearing capacity of a fill stratum within the overall depth range can reach 60-80 kPa after treatment.

Owner:江苏楚匠建设工程有限公司

Spraying support for building decorative plates

PendingCN111229500ASolve the decorativeSolve processingPretreated surfacesLiquid spraying apparatusArchitectural engineeringStructural engineering

The invention discloses a spraying support for building decorative plates, and relates to the field of decorative plate spraying. Aiming at the problem that an existing spraying support cannot carry out spraying and drying treatment on building decorative plates of different sizes at the same time, the following scheme is proposed. The spraying support comprises a waste collecting box, a U-shapedmounting frame is fixedly mounted at the top end of the waste collecting box, a material collecting box is welded to the top end of the mounting frame, and fixing plates are fixedly mounted on the upper sections of the inner walls of the two sides of the mounting frame; and open cavity structures are arranged at the bottom ends of the fixing plates, and spray heads are evenly mounted in the fixingplates, movable plates are mounted at the opening positions of the bottom ends of the fixing plates in a sealed and sliding mode, and the movable plates penetrate through the mounting frame. The spraying support is novel in structure, can effectively fix plates of different sizes, can carry out drying treatment in the spraying process, improves the machining efficiency of the building decorativeplates, and is suitable for popularization.

Owner:广东菲力绿色板业有限公司

Pretreatment equipment for mechanical component rust prevention technology

ActiveCN104550089AAvoid defectsGood effectDrying gas arrangementsDrying machines with progressive movementsMechanical componentsProcess engineering

The invention discloses pretreatment equipment for a mechanical component rust prevention technology. The pretreatment equipment comprises a conveying device, a cleaning device and a drying device, wherein the cleaning device comprises a cleaning chamber; a plurality of cleaning spraying heads are arranged in the cleaning chamber and are communicated to a cleanser tank arranged outside the cleaning chamber; the drying device comprises two drying chambers; a plurality of drying spraying openings are respectively formed in each drying chamber and are communicated to an air compressor arranged outside the corresponding drying chamber; hot dry air tanks are respectively arranged between the air compressor and the drying spraying openings in the drying chamber, positioned in the conveying forwarding direction, of the multiple drying chambers. The pretreatment equipment disclosed by the utility model can be used for cleaning and drying the surface of a mechanical component more uniformly, so that the surface of the mechanical component can be kept clean and dry before the mechanical component enters the rust prevention working procedure.

Owner:JIANGSU HONGBAO FORGING

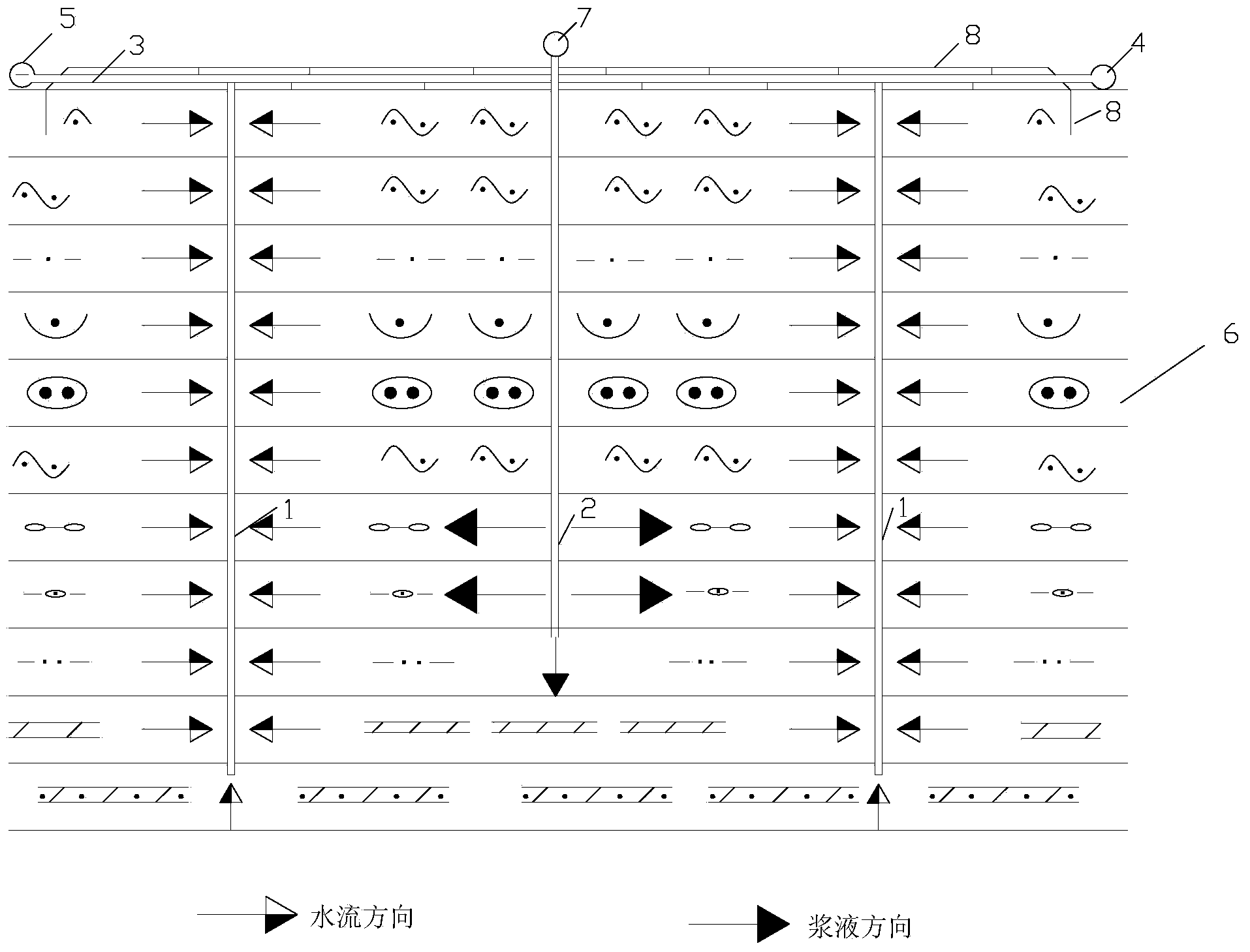

Vacuum grouting process

ActiveCN104032728AUniform treatment effectEvenly distributedIn situ soil foundationSoil preservationVacuum pressureFormation water

The invention discloses a vacuum grouting process. The vacuum grouting process includes steps of 1), creating a vacuum drainage system according to a vacuum prepressing method; 2), forming grouting holes in center positions with equal distances to peripheral vertical drainage plates and arranging grouting pipes; 3), forming vacuum pressure observation holes in positions close to the grouting holes and setting settlement observation points on ground surfaces; 4), laying sealing films; 5), starting vacuum pumps to pump formation water and gas, observing vacuum pressures of various positions in formations and ground surface settlement, and drawing vacuum pressure changing curves of depths of the various formations and ground surface settlement curves; 6), determining first grouting time; 7), continuing to perform vacuum pumping, stopping the vacuum pumps and tracking and observing change of the ground surface settlement and change of the vacuum pressures; 8), restarting machines to perform vacuum pumping; 9), determining re-grouting time; 10), repeating the steps 7), 8) and 9) until grout can no longer be grouted into the formations or requirements on designed grouting quantities are met. The vacuum grouting process has the advantages that factors due to post-construction softening can be eliminated, and vacuum grouting soft-soil foundation treating effects and the vacuum grouting soft-soil foundation treating efficiency can be improved.

Owner:浙江工业大学工程设计集团有限公司 +1

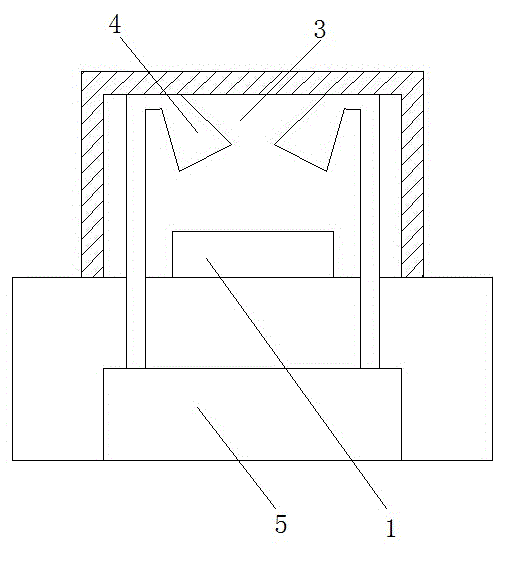

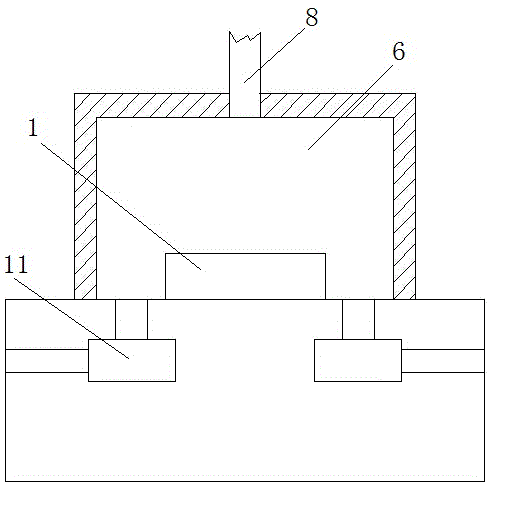

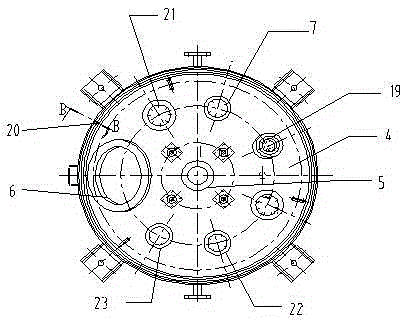

Novel powder plasma processing device

InactiveCN103730319AGuaranteed vacuumUniform treatment effectElectric discharge tubesBiochemical engineeringPlasma generator

The invention relates to a novel powder plasma processing device which comprises a feeding cavity, a reaction cavity, an electrode assembly, a plasma generator, a collecting cavity and a negative pressure device. A gas inlet where reaction gas is led is formed in the top of the reaction cavity, a feeding opening is formed in the upper portion of the reaction cavity, a discharging opening is formed in the bottom of the reaction cavity, the feeding cavity is connected with the feeding opening, the electrode assembly is arranged on the outer surface of the reaction cavity and located below the feeding opening, the plasma generator is electrically connected with the electrode assembly, the collecting cavity is connected with the discharging opening, and the negative pressure device is respectively connected with the feeding cavity and the reaction cavity. According to the novel powder plasma processing device, powder materials are blown by the reaction gas in the process of entering the reaction cavity so that the processing effect can be even, the vacuum degree of the reaction cavity is kept in the feeding process of the feeding cavity, feeding can be carried out without stopping processing, time is saved, and the work efficiency is improved.

Owner:SUZHOU OPS PLASMA TECH

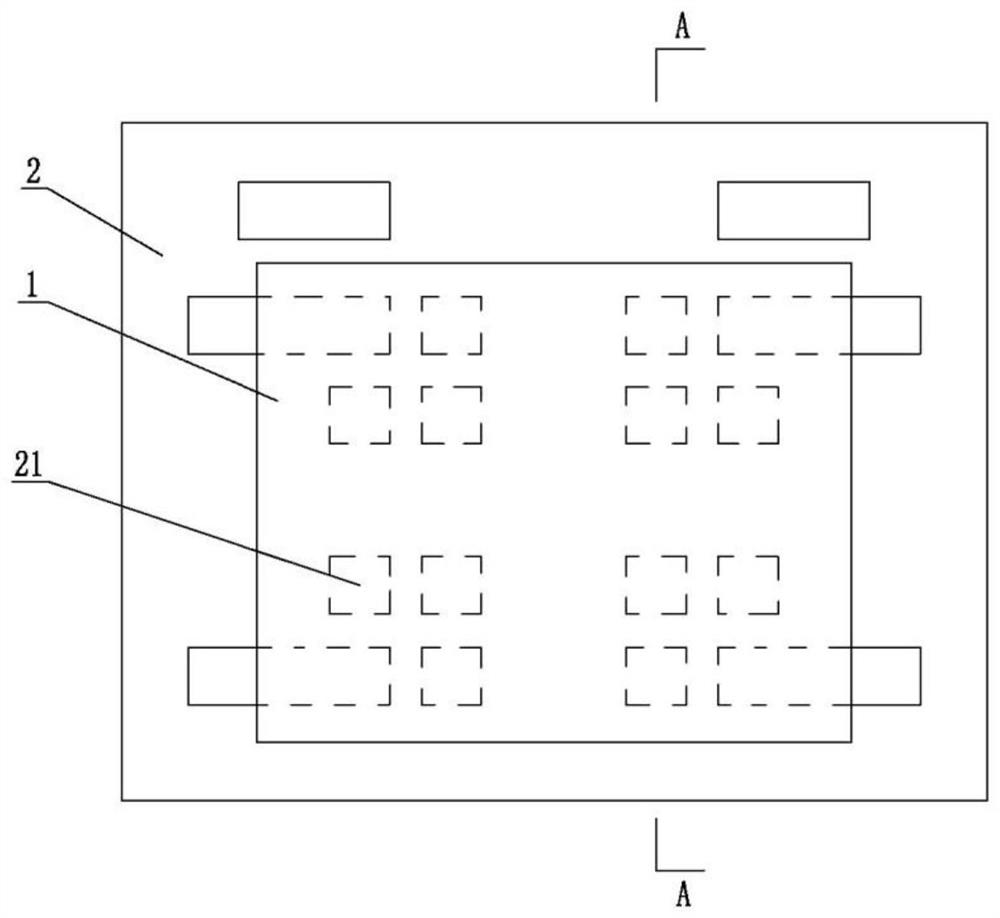

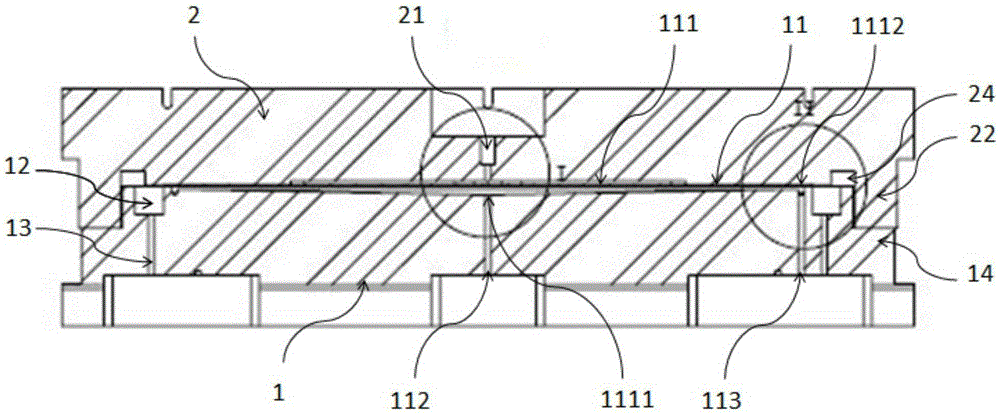

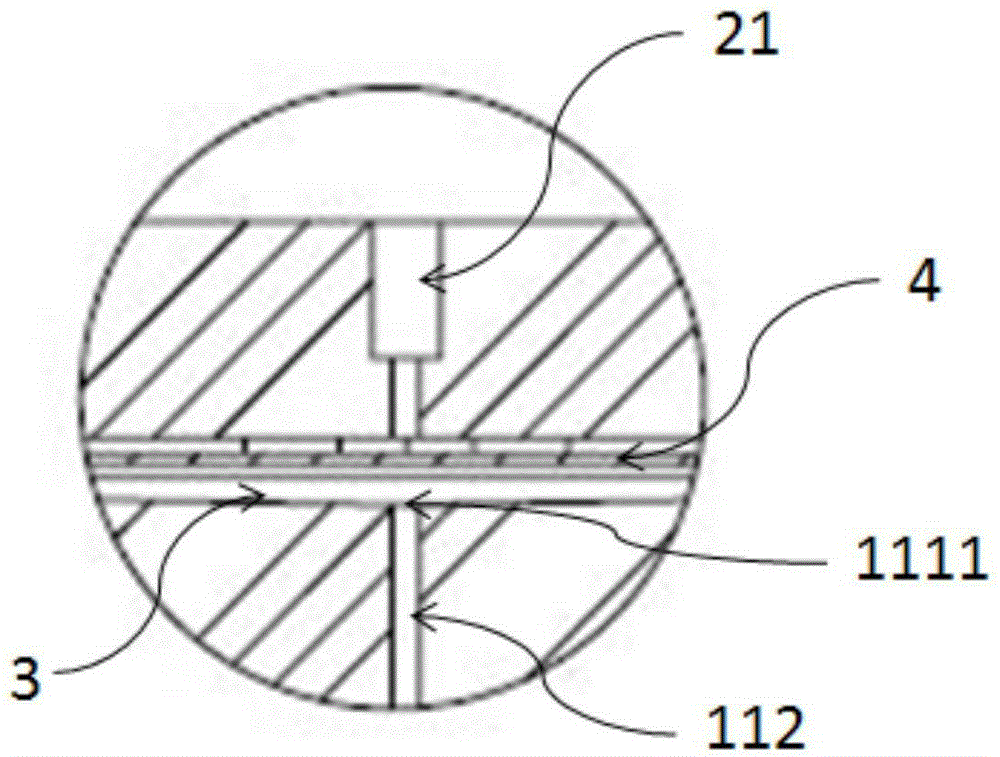

Semiconductor processing device and method thereof

ActiveCN106803477AControl liquidityControl flow speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical reactionEngineering

The invention discloses a semiconductor processing device and a method thereof, which relate to the technical field of semiconductors. The semiconductor processing device comprises a body and at least one semiconductor processing unit formed on the body, wherein each semiconductor processing unit comprises a recessed part formed on the upper end surface of the body, a first channel and a second channel, the bottom wall of the recessed part is provided with at least position, a fall trend is presented from the position to the edge of the bottom wall along a gravity direction or a rise trend is presented from the position to the edge of the bottom wall along a direction opposite to the gravity direction, the first channel is opened in each position of the bottom wall and communicated with the recessed part, the second channel is opened in the body at the edge of the bottom wall of the recessed part and communicated with the recessed part, and the first channel and the second channel can be used as outlets and / or inlets of fluid. Through controlling the flowing direction of the fluid on the surface of a substrate, the fluid is contacted with the surface of the substrate during a process of flowing the recessed part and a physical and / or chemical reaction happens, and process processing is carried out on the surface of the substrate.

Owner:WUXI HUAYING MICROELECTRONICS TECH CO LTD

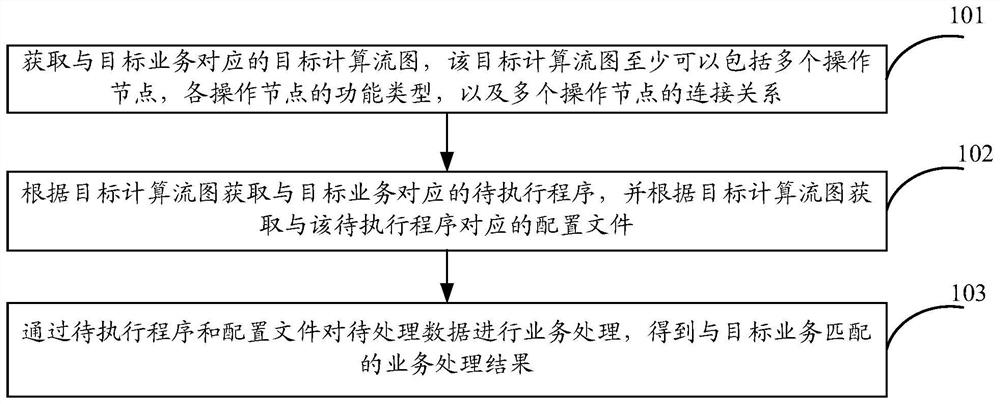

Service processing method, device and equipment

The invention provides a service processing method, apparatus and device. The method comprises the steps of obtaining a target calculation flow graph corresponding to a target service; obtaining a to-be-executed program corresponding to a target service according to the target calculation flow graph, and obtaining a configuration file corresponding to the to-be-executed program according to the target calculation flow graph; and performing service processing on to-be-processed data through the to-be-executed program and the configuration file to obtain a service processing result matched withthe target service. Through the technical scheme of the invention, various types of service processing can be realized by using a machine learning technology, and an application development frameworkbased on the calculation flow graph can be realized.

Owner:HANGZHOU HIKVISION DIGITAL TECH

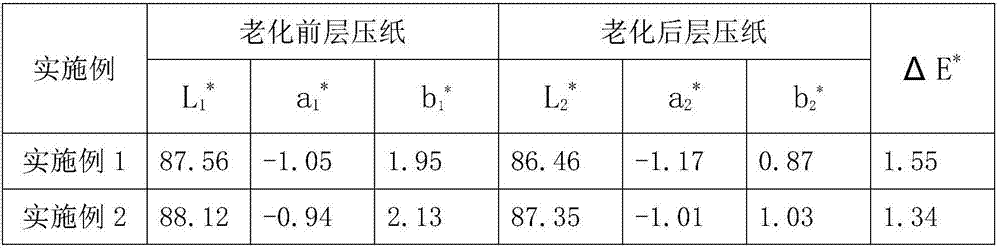

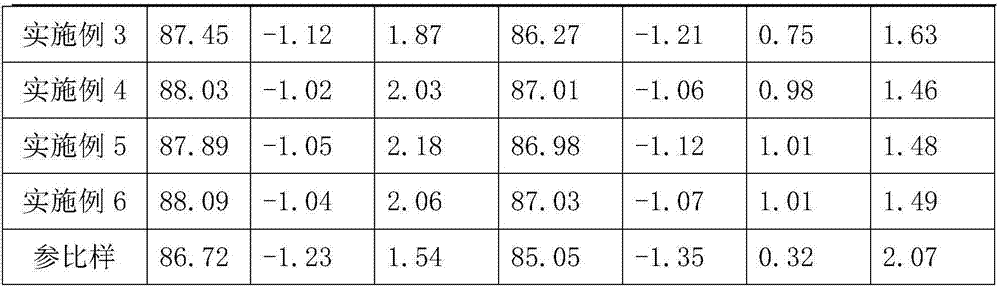

Method for improving weather resistance of decorative base paper titanium dioxide

ActiveCN107500348AReduce concentrationIncrease concentrationTitanium dioxideWeather resistancePotassium

The invention provides a method for improving weather resistance of decorative base paper titanium dioxide, and belongs to the technical field of decorative base paper titanium dioxide. The control is performed through salt treatment and calcination. The method comprises the following steps of A, using bleached slurry as raw materials; adding titanium dioxide sol into the raw materials; controlling the addition to meet the requirement that the proportion of TiO2 in the titanium dioxide sol to TiO2 in metatitanic acid is 2 to 6 percent; performing water washing; diluting the slurry subjected to water washing into 300 to 400g / L TiO2 slurry; B, adding potassium and phosphorus solution with the K2O / P2O5 ratio being 1.3 to 4.0 into the diluted slurry; performing stirring; adding aluminum-containing compound solution according to the Al2O3 to TiO2 proportion being 0.3 to 0.9 percent; performing stirring; C, performing pressurized filtering on the slurry material treated by the step B until the filter cake solid content is 45 to 55 percent; C, roasting the filter cake in the step C for 8 to 10h at the roasting temperature of 200 to 950 DEG C. Through the control on the salt treatment and roasting processes, the primary product weather resistance of the decorative base paper titanium dioxide is improved; the weather resistance of the decorative base paper titanium dioxide is further improved.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Method for designing multi-pin peening head for ultrasonic peening gun

ActiveCN104802096AReduce the number of round tripsReduce dwell timeBlast gunsEngineeringStress corrosion cracking

The invention discloses a multi-needle type impacting head for an ultrasonic impacting gun and a design method of the impacting head. The multi-needle type impacting head is composed of an amplitude-changing rod end surface, an impacting needle cover plate and impacting needles, wherein hole arrays in rows are filled in effective regions of the amplitude-changing rod end surface and an impacting needle cover. The multi-needle type impacting head and the design method thereof provided by the invention have the advantages that by virtue of the multiple impacting needles, compared with an existing impacting head, the work efficiency is improved by 300%-400%, the impact strength is improved by about 5%, and the problems that a welding structure cracks due to stress corrosion, is unstable and deforms, the fatigue service life of the welding structure is shortened and the like are effectively alleviated.

Owner:天津益普科技发展有限公司

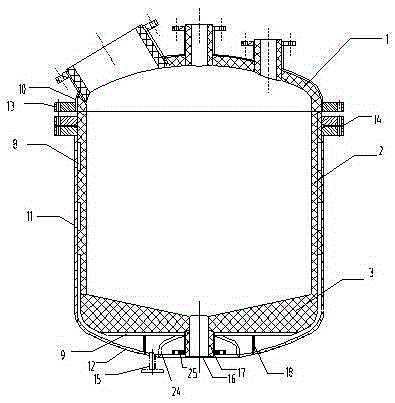

Graphite reaction kettle

ActiveCN105344298AAvoid residueEvenly distributedChemical/physical/physico-chemical processesFeed devicesGraphiteCooling fluid

The invention relates to a graphite reaction kettle which comprises an upper graphite shell cover, a graphite barrel body, a lower graphite shell cover and metal protective layers; the graphite reaction kettle is characterized in that cooling liquid or steam is introduced into a circular-ring-shaped groove 8 and a circular-ring-shaped groove 9, and the cooling liquid or steam circulates through a gap reserved between the barrel body metal protective layer and the graphite barrel body as well as a gap reserved between the lower shell cover metal protective layer and the lower graphite shell cover, so that the graphite reaction kettle can be cooled or heated, heating or cooling of the reaction kettle can be more uniform, the production efficiency can be improved, and finally the cooling liquid or steam can be discharged through a drain outlet formed in the bottom end, the cooling liquid is prevented from remaining in the graphite reaction kettle; a man hole adopts an ellipsoidal structure, therefore pipelines and batching holes on the upper graphite shell cover can be distributed more uniformly and reasonably.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com