Ultrathin glass single-side thinning method

An ultra-thin glass, single-sided technology, used in machine tools, grinders, grinding/polishing equipment suitable for grinding workpiece planes, etc., can solve the problem of polishing and repairing the bumps and scratches on the surface of the glass, and the effective area of the glass is prone to glue residue. Contamination, the difficulty of tearing off the acid-proof film, etc., to achieve the effect of improving the performance yield, reducing the risk of fragmentation, and being convenient and quick to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

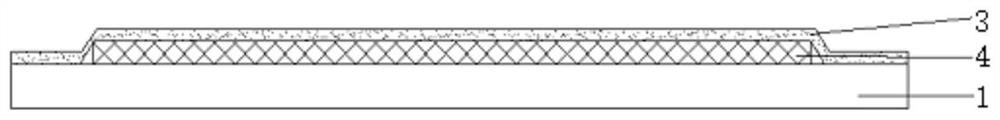

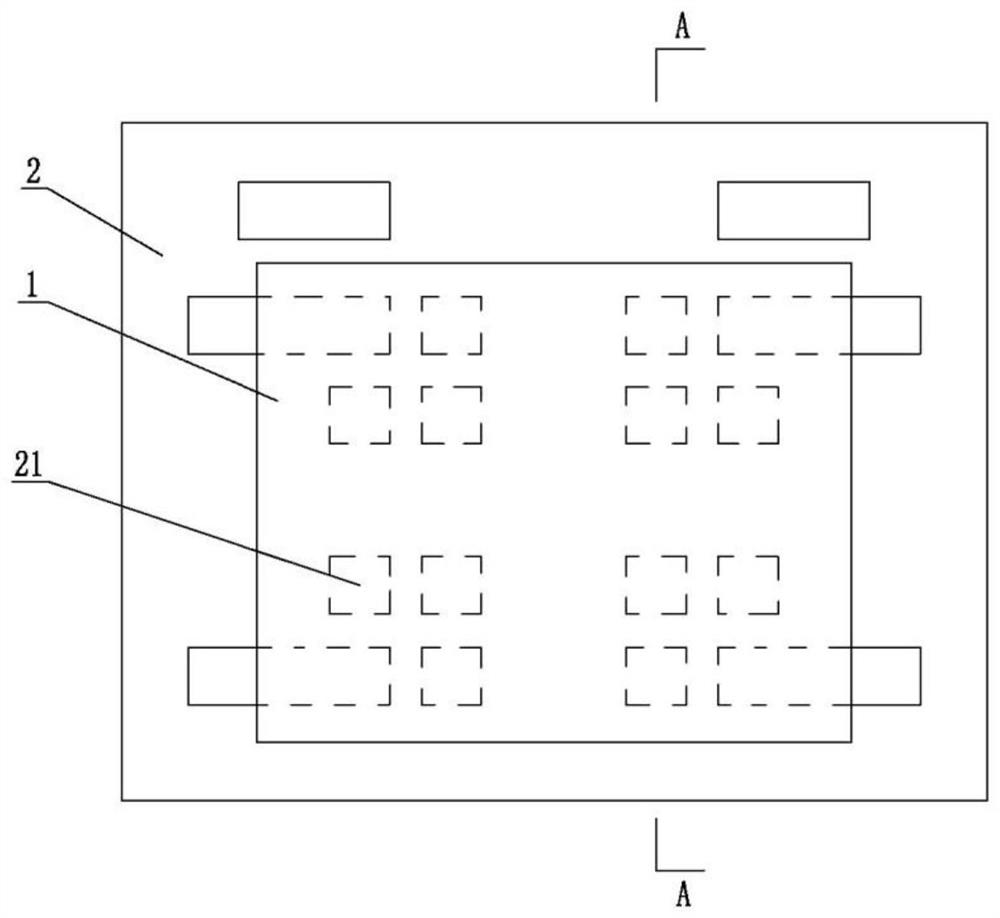

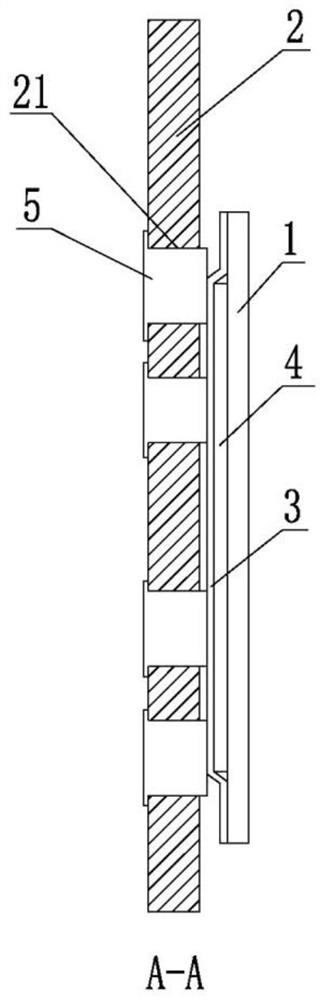

[0038] like Figure 1 ~ Figure 3 As shown, the present invention provides a method for thinning one side of ultra-thin glass, comprising the following steps:

[0039] Step 1: Paste the attached film on the non-thinning surface of the glass substrate 1: the attached film includes a photodissociation film 3 and an isolation layer 4, the isolation layer 4 covers the effective circuit area of the glass substrate 1, and the isolation layer 4 It can be set as a release paper or an electrostatic film, the release paper can be recycled and reused, and the electrostatic film has a better attachment effect. The size is the same as that of the non-thinned surface of the glass substrate 1 , and the photodissociation film 3 is attached on the isolation layer 4 and covers the non-thinned surface of the glass substrate 1 . The isolation layer 4 protects the effective circuit area of the glass substrate 1 from being polluted by the residual glue of the photodissociation film 3, further e...

Embodiment 2

[0047] Different from Example 1, the composition and proportioning of the etching pretreatment solution in step 5 are different, and the used pretreatment solution of etching pretreatment includes hydrofluoric acid and sulfuric acid, accounting for 2.3-3% of the total mass of the pretreatment solution respectively. 2.7%, 45.0-50.0%, the remaining components are water, the soaking time is 40-50min, and the thickness removed by etching is 30-50μm.

[0048] After the etching pretreatment with the above composition and proportioning etching pretreatment liquid, the glass substrate 1 with a thickness of 0.3-0.5mm is thinned to 0.05mm. The time required for the whole process is 3-4 hours, and the glass substrate 1 is thin. After melting, the performance yield rate reaches 85.0±2.0%, the proportion of surface defects such as pits and scratches is 15.0±2.0%, the plate thickness CPK=1.28 (CPK≥1.33 is the best), and the single plate thickness difference is ≤8μm.

Embodiment 3

[0050] Different from Example 1 and Example 2, the composition and proportioning of the etching pretreatment liquid in step 5 are different, and the pretreatment liquid used for etching pretreatment includes hydrofluoric acid, hydrochloric acid, sulfuric acid, respectively accounting for the pretreatment liquid The total mass is 2.3-2.7%, 2.0-3.0%, 45.0-50.0%, the rest is water, the soaking time is 40-50min, and the thickness removed by etching is 30-50μm.

[0051] After the etching pretreatment with the above composition and proportioning etching pretreatment liquid, the glass substrate 1 with a thickness of 0.3-0.5mm is thinned to 0.05mm. The time required for the whole process is 3-4 hours, and the glass substrate 1 is thin. After melting, the performance yield rate reaches 88.0±2.0%, the raw material defect ratio such as pits and scratches is 12.0±2.0%, the board thickness CPK=1.31 (CPK≥1.33 is the best), and the single-piece board thickness difference is ≤7μm .

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com