Novel powder plasma processing device

A plasma and processing device technology, applied in the field of ion plasma processing devices, can solve the problems of incomplete processing, poor processing effect, unevenness, etc., and achieve the effects of improving work efficiency, uniform processing effect, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

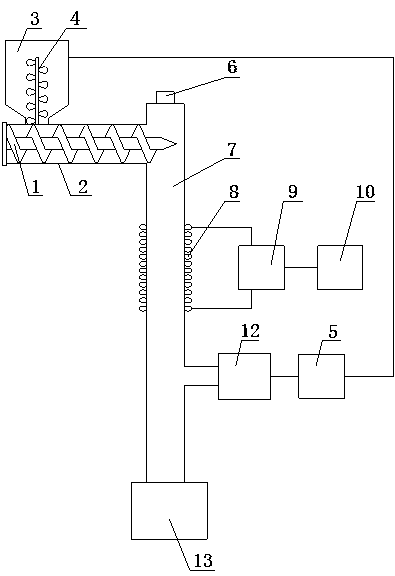

Embodiment 1

[0020] Such as figure 1 As shown, as the first preferred embodiment, this embodiment provides a novel powder plasma treatment device, including a feed chamber 3, a screw feeding mechanism, a reaction chamber 7, an electrode assembly 8, a plasma generator, and a collection chamber 13 And the negative pressure device 5, the top of the reaction chamber 7 is provided with a gas inlet 6 for the introduction of the reaction gas, the upper part of the reaction chamber 7 is provided with a feed port (not shown in the figure), and the bottom of the reaction chamber 7 is provided with a discharge port (Fig. not shown in ), the feeding chamber 3 is connected to the feeding port, the screw feeding mechanism is arranged between the feeding chamber 3 and the feeding port, the electrode assembly 8 is arranged on the outer surface of the reaction chamber 7 and is located below the feeding port, the plasma The bulk generator is electrically connected to the electrode assembly 8, the collection...

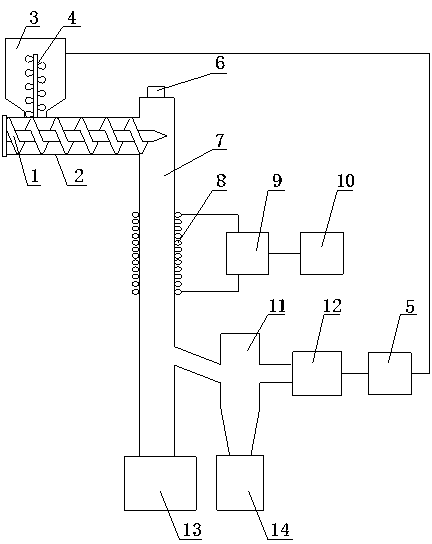

Embodiment 2

[0024] Such as figure 2 As shown, the rest are the same as in Embodiment 1, the difference is that this embodiment also includes a cyclone separator 11, and the cyclone separator 11 is arranged between the negative pressure device 5 and the reaction chamber 7, and the bottom of the cyclone separator 11 is connected with the first Two collection chambers 14 .

[0025] In this embodiment, a cyclone separator 11 is added to separate the powder material brought out by the reaction gas from the reaction gas. The powder material is collected by the second collection chamber 14, and the reaction gas is extracted by the negative pressure device 5, and the powder is collected for the second time. materials, effectively avoiding the extraction of powder materials with the reaction gas, saving raw materials and being more environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com