Vacuum flour mixer

A dough mixer and vacuum technology, applied in the direction of mixing/kneading with vertical installation tools, can solve problems such as product quality decline, vacuum tube blockage, affecting the effect of vacuuming, etc., and achieve the effect of solving air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

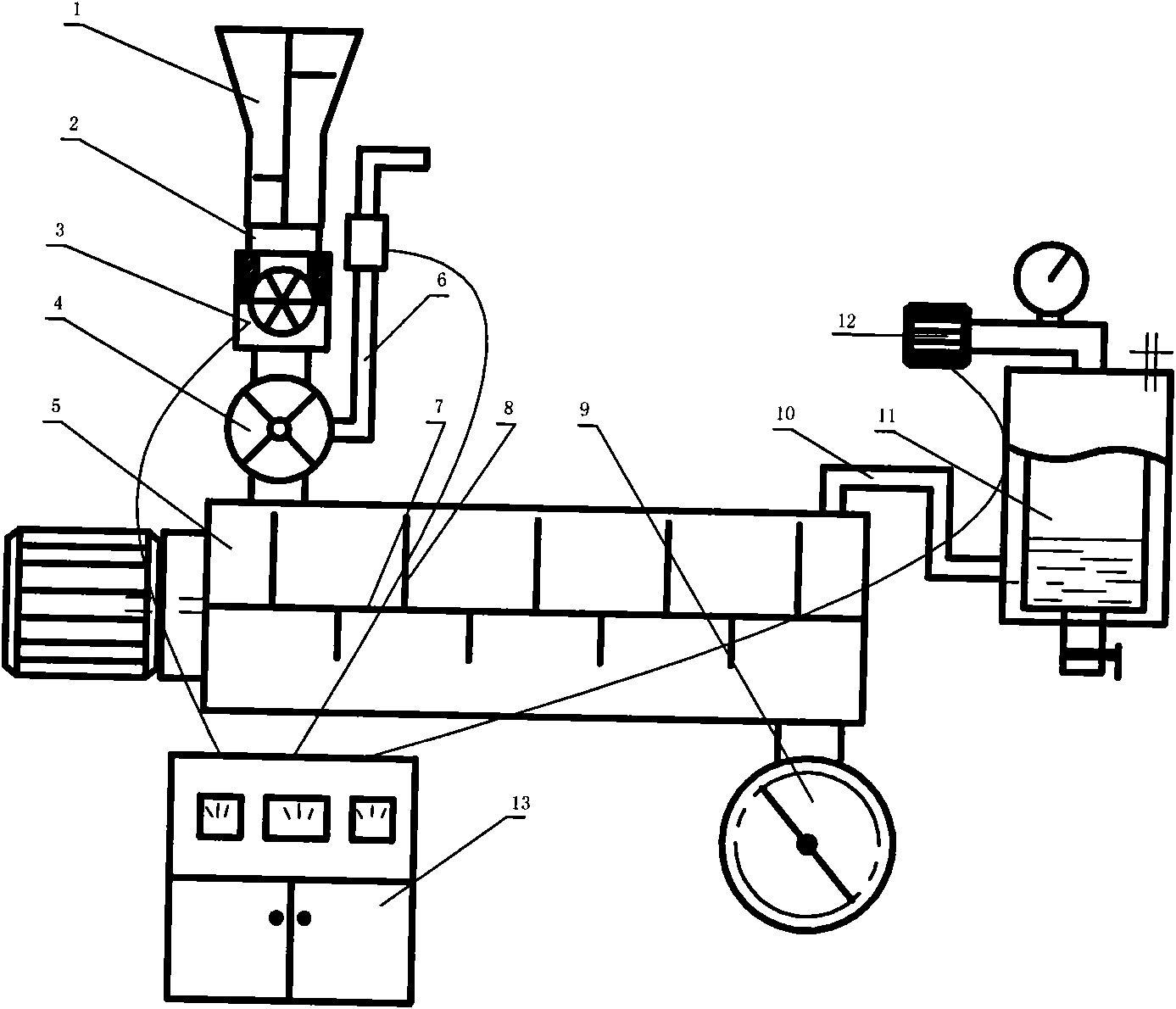

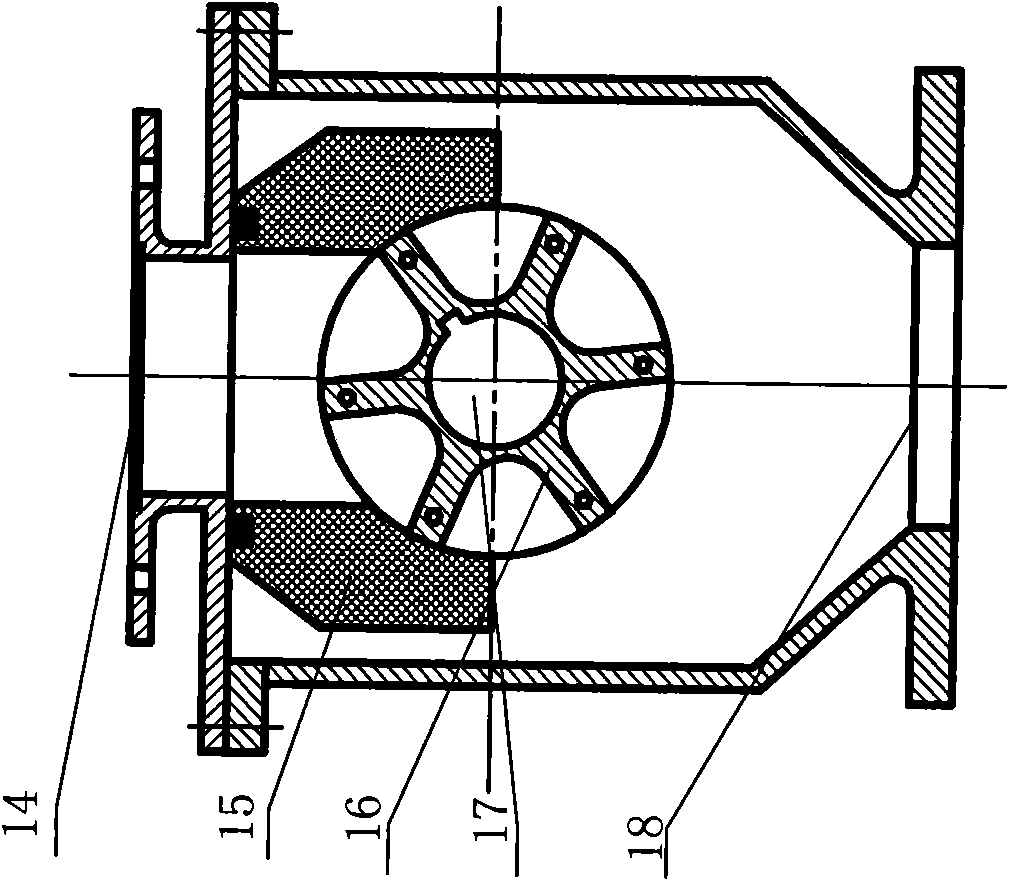

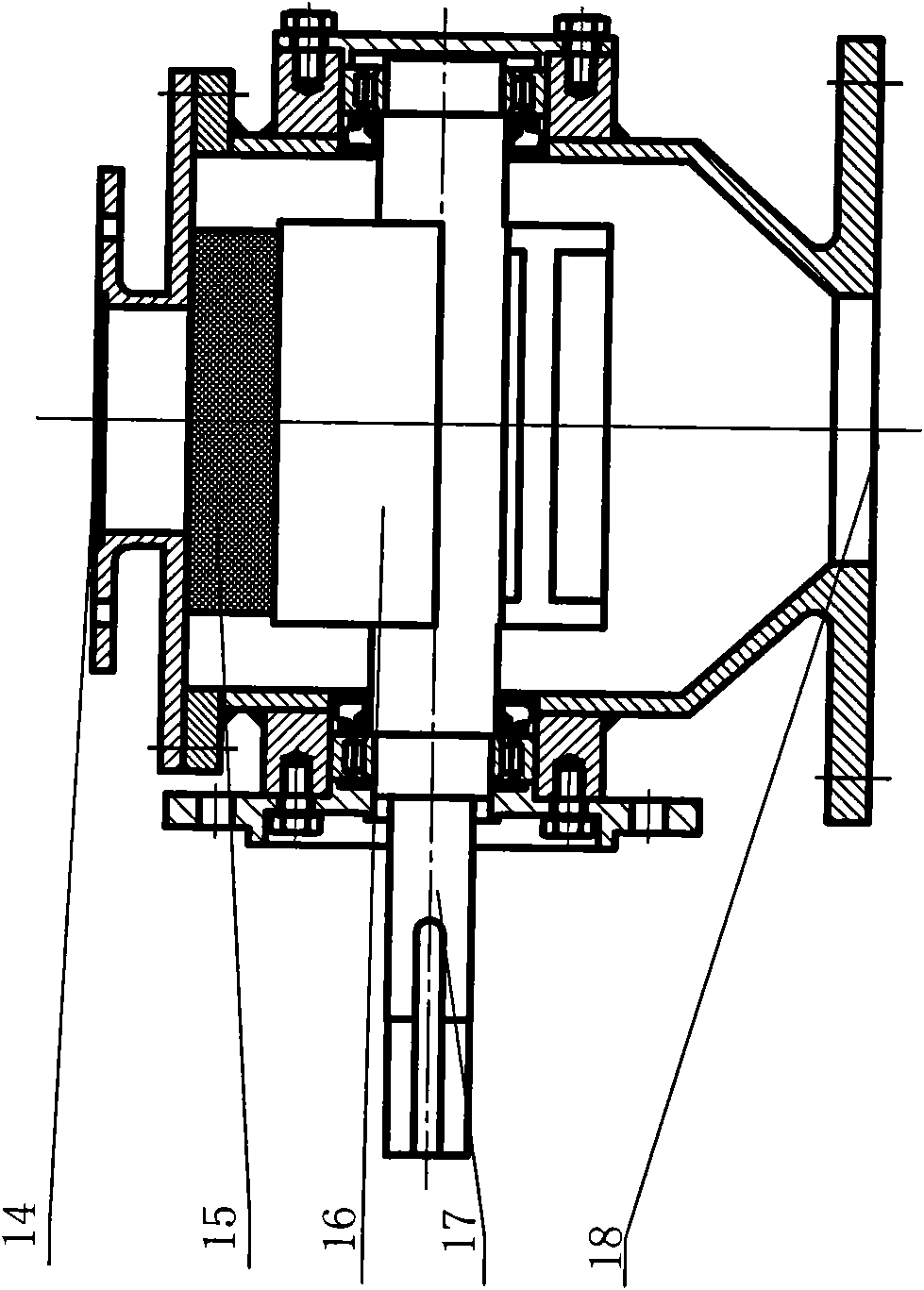

[0023] The flour of the present invention is fed through the powder feeding device 1 and supplied with water by the water feeding device 6 . The powder feeding device 1 and the water feeding device 6 are arranged on the frame, communicated with the stirring container, both of which are connected with a control device 13, and the control device 13 controls the amount of powder feeding and water feeding according to actual needs, so as to produce different products , there is a buffer plate inside the powder feeding device 1, so that the powder can be fed more smoothly. The lower part of the powder feeding device 1 is provided with a visible feeding tube 2 made of glass, which can be seen through the screw thread Connected to the powder feeding device 1, the feeding situation of the fabric can be clearly observed. In case of feeding blockage, the fault can be cleared in time. A rotary feeder connected to the stirring container is installed directly below the powder feeding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com