Compound finishing agent and preparation method thereof

A technology of finishing agent and application method, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of cumbersome modification process and high cost of industrialization, and achieve the effect of simple compounding process, less environmental pollution and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

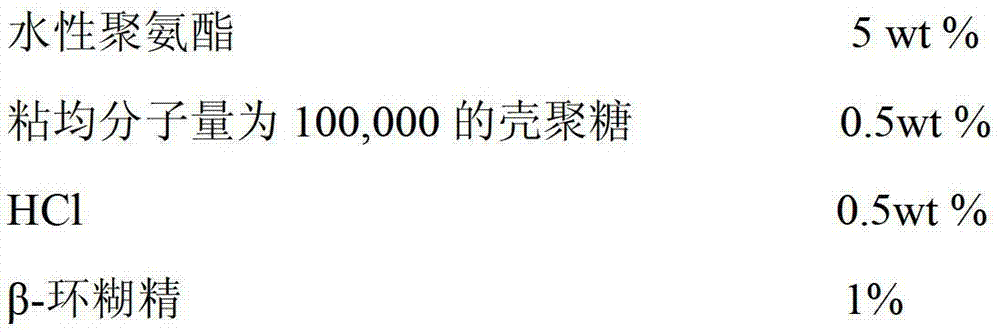

Image

Examples

Embodiment 1

[0035] Composite finishing agent containing 3wt% aqueous polyurethane and 0.1wt% chitosan. The specific content percentage of compound ingredients is as follows:

[0036] Waterborne polyurethane 3wt%

[0037] Chitosan with a viscosity average molecular weight of 100,000 0.1wt%

[0038] Acetic acid 0.1wt%

[0039]First dissolve chitosan with a viscosity average molecular weight of 100,000 in an acetic acid solution with a mass concentration of 1 wt%, and the mass ratio of chitosan to acetic acid is 1:1; then add the acetic acid solution of chitosan to the aqueous polyurethane solution The mass ratio of the acetic acid solution of chitosan to the aqueous polyurethane aqueous solution is 1:9, and the chitosan-waterborne polyurethane composite finishing agent can be obtained by mixing evenly; wherein, the aqueous polyurethane accounts for 3wt% of the composite finishing agent.

Embodiment 2

[0041] Composite finishing agent containing 10wt% aqueous polyurethane and 1wt% chitosan. The specific content percentage of compound ingredients is as follows:

[0042] Waterborne polyurethane 10wt%

[0043] Chitosan with a viscosity average molecular weight of 100,000 1wt%

[0044] Acetic acid 1wt%

[0045] First dissolve chitosan with a viscosity average molecular weight of 100,000 in an acetic acid solution with a mass concentration of 10wt%, and the mass ratio of chitosan to acetic acid is 1:1; then add the chitosan acetic acid solution to the aqueous polyurethane solution The mass ratio of the acetic acid solution of chitosan to the aqueous polyurethane aqueous solution is 1:9, and the chitosan-waterborne polyurethane composite finishing agent can be obtained by mixing evenly; wherein, the aqueous polyurethane accounts for 10wt% of the composite finishing agent.

Embodiment 3

[0047] Composite finishing agent containing 6wt% aqueous polyurethane and 0.5wt% chitosan. The specific content percentage of compound ingredients is as follows:

[0048] Waterborne polyurethane 6wt%

[0049] Chitosan with a viscosity average molecular weight of 120,000 0.5wt%

[0050] Acetic acid 0.5wt%

[0051] First dissolve chitosan with a viscosity average molecular weight of 120,000 in an acetic acid solution with a mass concentration of 5wt%, and the mass ratio of chitosan to acetic acid is 1:1; then add the acetic acid solution of chitosan to the aqueous polyurethane solution The mass ratio of the acetic acid solution of chitosan to the aqueous polyurethane aqueous solution is 1:9, and the chitosan-waterborne polyurethane composite finishing agent can be obtained by mixing evenly; wherein, the aqueous polyurethane accounts for 6wt% of the composite finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com