Method for designing multi-pin peening head for ultrasonic peening gun

A technology of ultrasonic impact gun and design method, which is applied in spray guns, metal processing equipment, explosion generating devices, etc., can solve the problems of low efficiency in the shot peening process, reduce the number of round trips and residence time, ensure uniformity, and impact strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

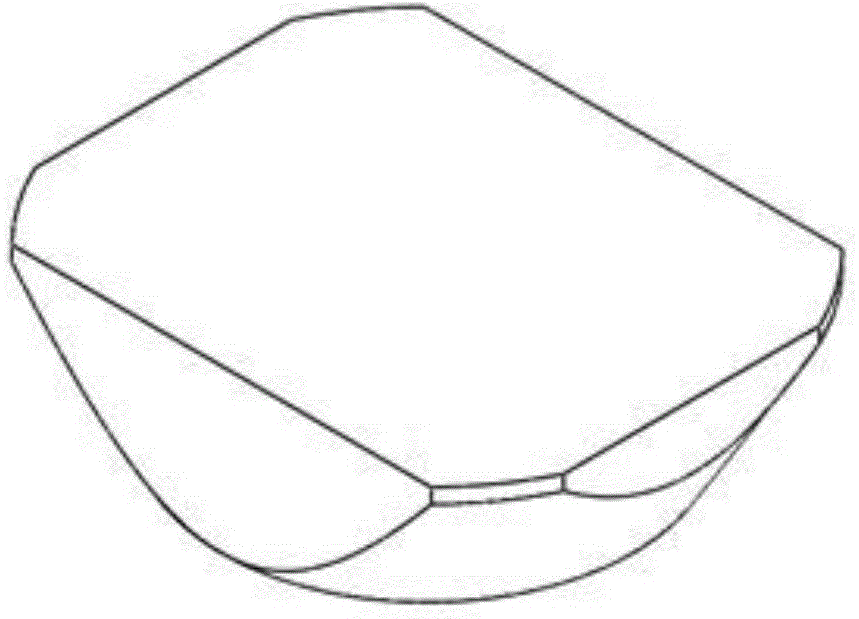

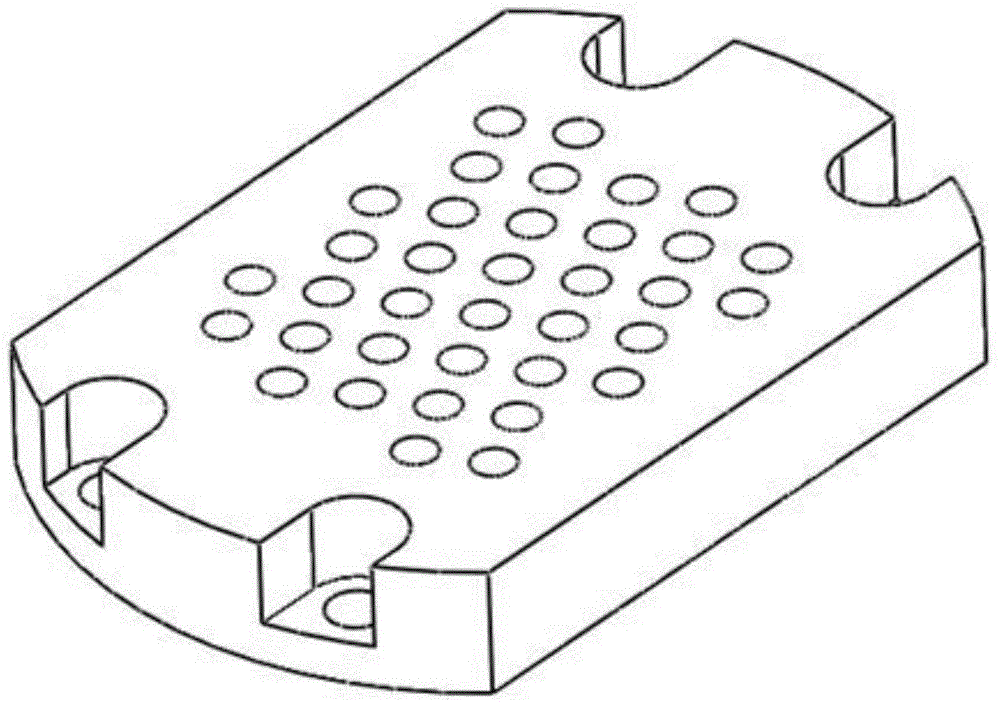

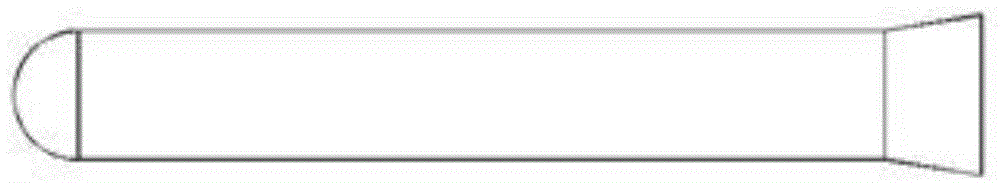

[0031] as attached figure 1 As shown in -6, the multi-needle impact head for the ultrasonic impact gun of the present invention includes an impact needle 1, an impact needle cover plate 2, and a horn end face 3. The end of the end surface of the horn is directly connected with the thread of the horn, and the end surface is provided with an impact needle, and the impact needle passes through the pinhole arranged on the impact needle cover plate, and the impact needle cover plate and the ultrasonic impact gun The gun body is fixedly connected. A moderate movable gap is reserved between the impact needle and the end face of the horn to ensure the normal vibration of the impact needle. The assembled multi-needle impact head is placed on the front end of the ultrasonic impact gun, and the workpiece to be treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com