Electrochemical surface treatment method and electrochemical surface treatment device for porous metal material

A surface treatment device and porous metal technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of effective overpotential and reactant concentration drop, and achieve good electrodeposition treatment effect or electropolishing effect, and uniform treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

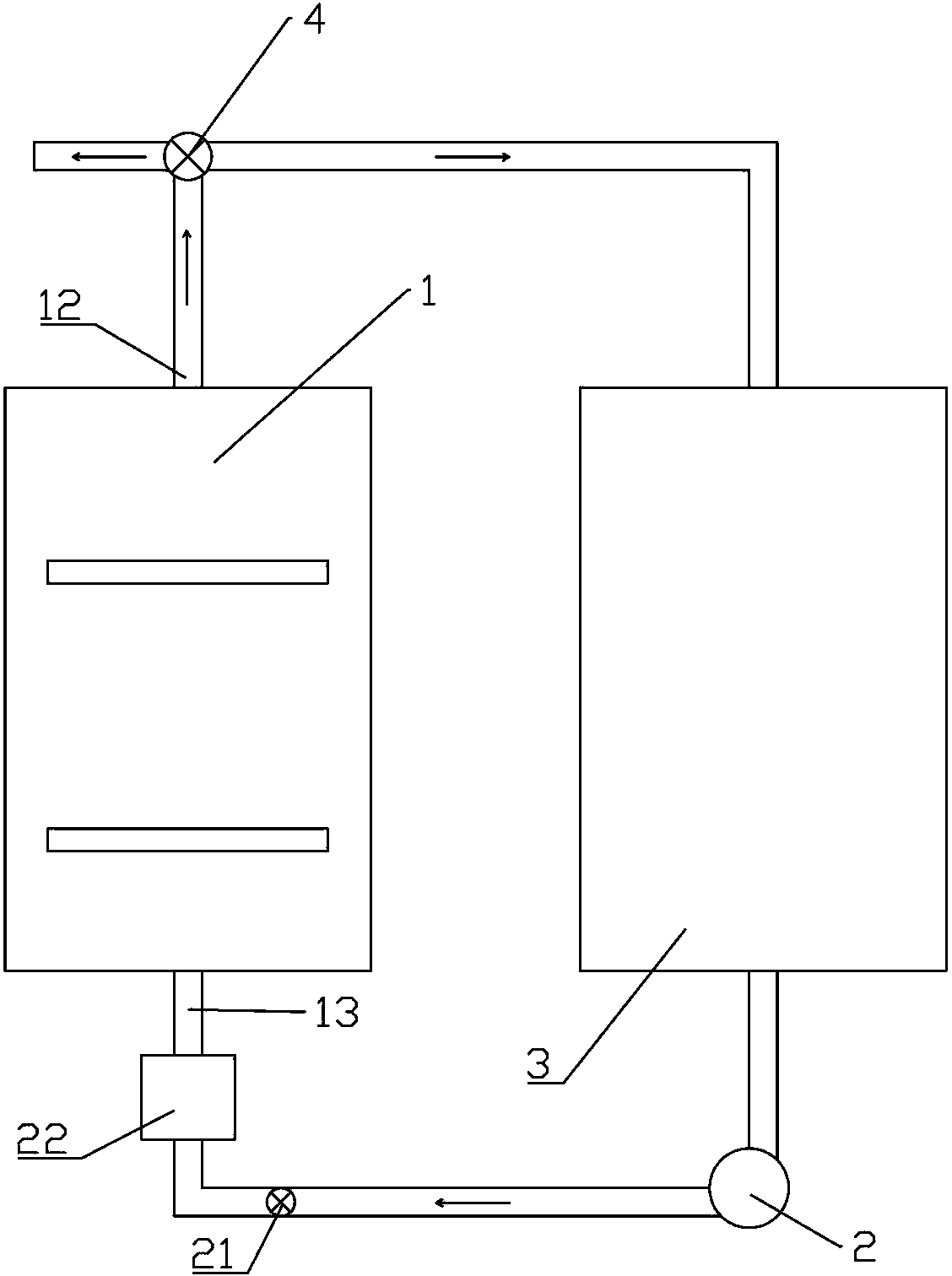

[0025] Below in conjunction with accompanying drawing, further illustrate the device of the present invention.

[0026] refer to figure 1 , an electrochemical surface treatment device for porous metal materials, comprising an electrolytic cell 1, the electrolytic cell 1 is provided with an electrode holder, the lower part of the electrolytic cell 1 is provided with a working electrolyte inlet 11, and the upper part is provided with a working electrolyte outlet 12, and the working electrolytic The liquid inlet 11 is connected to the pump 2 that drives the working liquid, and the liquid inlet end of the pump 2 is connected to the working electrolyte outlet 12 or the working electrolyte storage tank 3 .

[0027] As a further improvement of the present invention, in the above electrochemical surface treatment device, a flow regulating valve 21 is provided between the working electrolyte inlet 11 and the pump 2 .

[0028] As a further improvement of the present invention, in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com