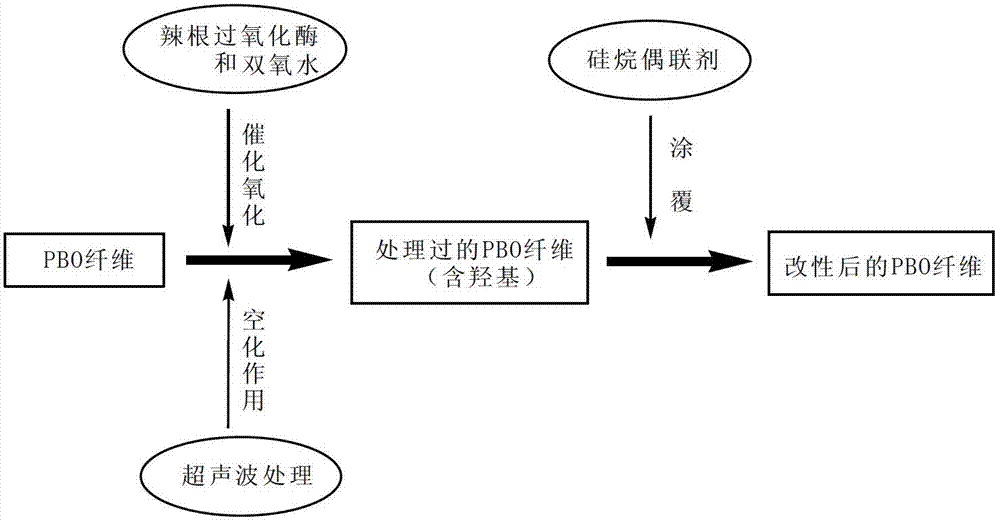

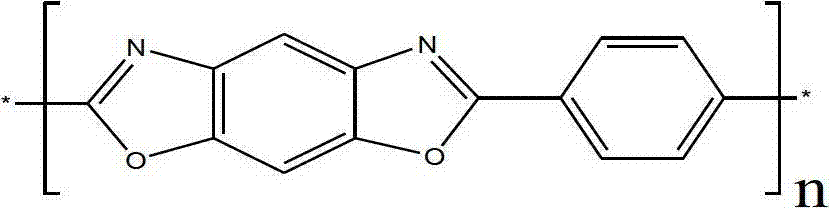

Surface modifying method of PBO (polybenzoxazole) fiber

A surface modification and fiber technology, which is applied in the field of polymer fiber surface modification, can solve the problems of fiber strength reduction, PBO fiber strength reduction, and environmental pollution, and achieve uniform effects, shortened reaction time, and enhanced reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, add 10g of PBO fiber and 20mg of horseradish peroxidase to a three-necked flask filled with 200ml of phosphate buffer solution and 100ml of dioxane mixture, feed nitrogen, ultrasonically vibrate, and drop 4wt. The aqueous solution of % hydrogen peroxide is 1~50mL in total. After the dropwise addition, react for 2h, take out the fiber, wash it with distilled water, and dry it. Then, dissolve the coupling agent KH-560 in acetone at a concentration of 1.0%, adjust the pH value to 5, soak the PBO fiber at room temperature for 24 hours, wash and dry it with distilled water, and measure the tensile strength of its monofilament It is 4.15GPa, and the pull-out strength of monofilament made of cyanate resin is 8.50MPa.

Embodiment 2

[0025] First, add 10g of PBO fiber and 20mg of horseradish peroxidase to a three-necked flask filled with 200ml of phosphate buffer solution and 100ml of dioxane mixture, feed nitrogen, ultrasonically vibrate, and drop 4wt. The aqueous solution of % hydrogen peroxide is 1~50mL in total. After the dropwise addition, react for 2h, take out the fiber, wash it with distilled water, and dry it. Then, dissolve the coupling agent KH-560 in acetone at a concentration of 1.0%, adjust the pH value to 5, soak the PBO fiber at room temperature for 24 hours, wash and dry it with distilled water, and measure the tensile strength of its monofilament The pull-out strength of monofilament made of bismaleimide resin is 8.81MPa.

Embodiment 3

[0027] First, add 10g of PBO fiber and 20mg of horseradish peroxidase to a three-necked flask filled with 200ml of phosphate buffer solution and 100ml of dioxane mixture, feed nitrogen, ultrasonically vibrate, and drop 4wt. The aqueous solution of % hydrogen peroxide is 1~50mL in total. After the dropwise addition, react for 2h, take out the fiber, wash it with distilled water, and dry it. Then, dissolve the coupling agent KH-550 in acetone at a concentration of 3.0%, adjust the pH value to 5, soak the PBO fiber at room temperature for 24 hours, wash and dry it with distilled water, and measure the tensile strength of its monofilament It is 4.21GPa, and the pull-out strength of monofilament made of epoxy resin is 8.93MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com