Multi-partition gas conveying apparatus

A conveying device and multi-partition technology, which is applied to electrical components, discharge tubes, circuits, etc., can solve the problems of increasing production costs, complicated system layout and control of plasma treatment devices, and achieve the effects of saving production costs and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

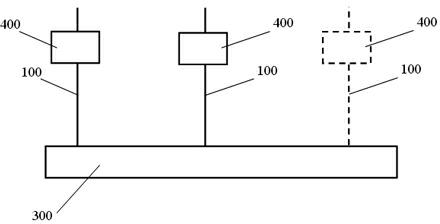

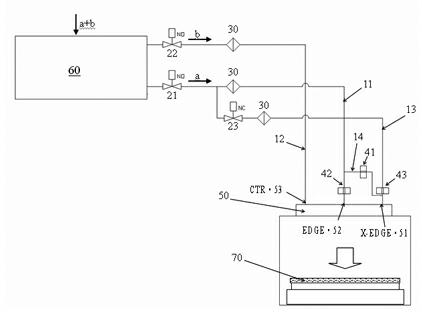

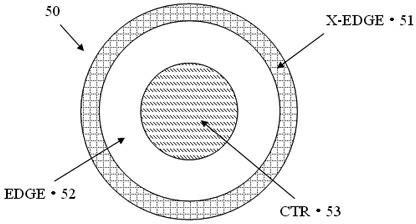

[0024] Such as figure 2 As shown, the multi-zone gas delivery device of the present invention is used to adjust the uniformity of the surface treatment of the wafer 70 . The gas delivery device is connected to the shower head 50 on the top of the reaction chamber in the plasma processing device; Three gas distribution zones 51 , 52 and 53 .

[0025] The two reaction gases conveyed in the device described in the following embodiments are two paths separated from the same reaction gas. After the corresponding adjustment of the provided gas separator and flow controller (MFC), two reaction gases with different flow ratios having the first flow rate and the second flow rate are formed, and then output to the gas delivery device of the present invention. In other embodiments, the two paths of reaction gases used by the gas delivery device may also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com