Vacuum grouting process

A vacuum and process technology, applied in the field of vacuum grouting technology, can solve the problems of uneven distribution of grout up and down, and achieve uniform treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] refer to Figure 1 ~ Figure 3 , a vacuum grouting process, comprising the following steps:

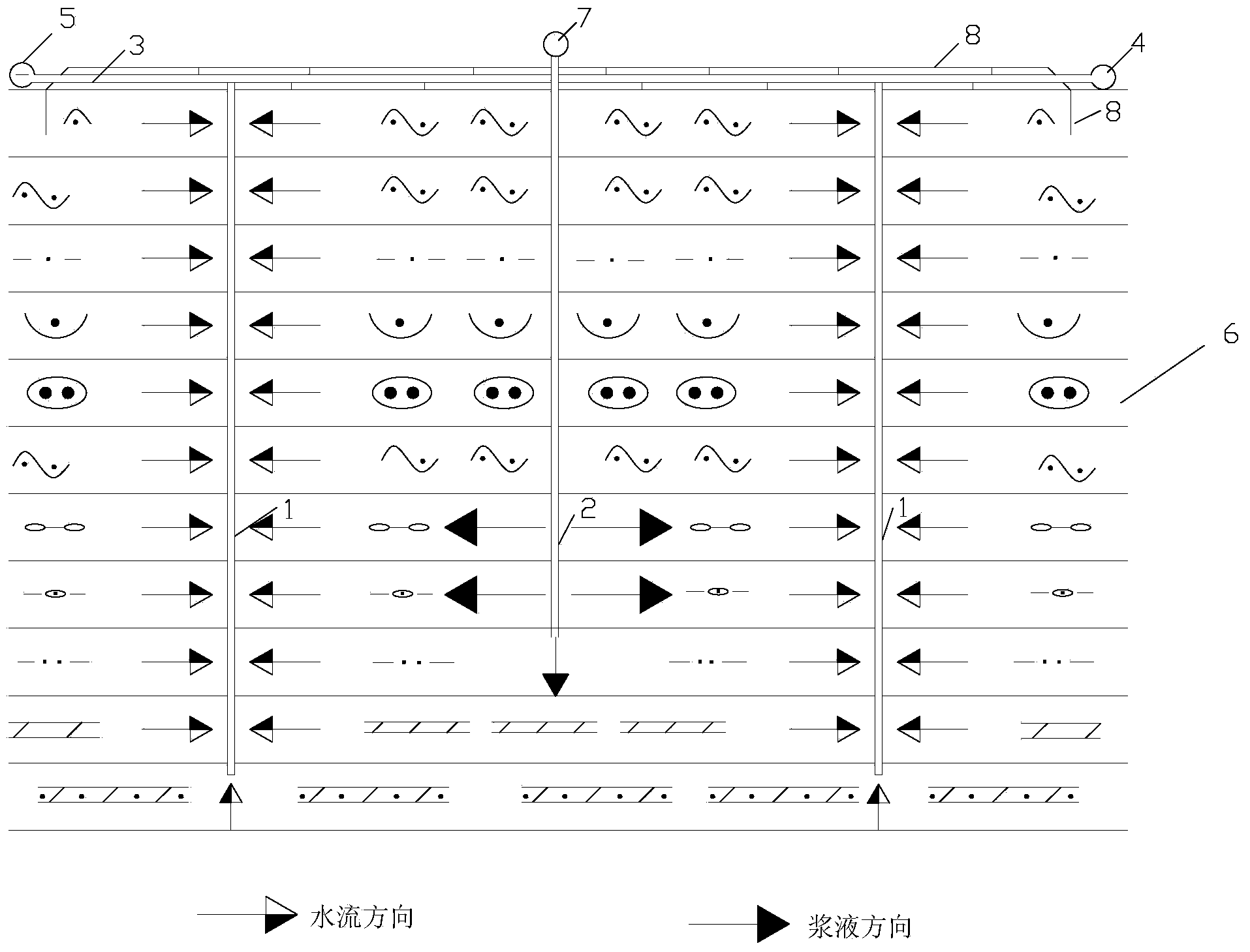

[0034] 1) Arrange vertical drainage boards, horizontal drainage pipes, vacuum pumps, establish a vacuum drainage system according to the ordinary vacuum preloading method, and set up a sealing film embedding ditch, etc. (as attached figure 1 ).

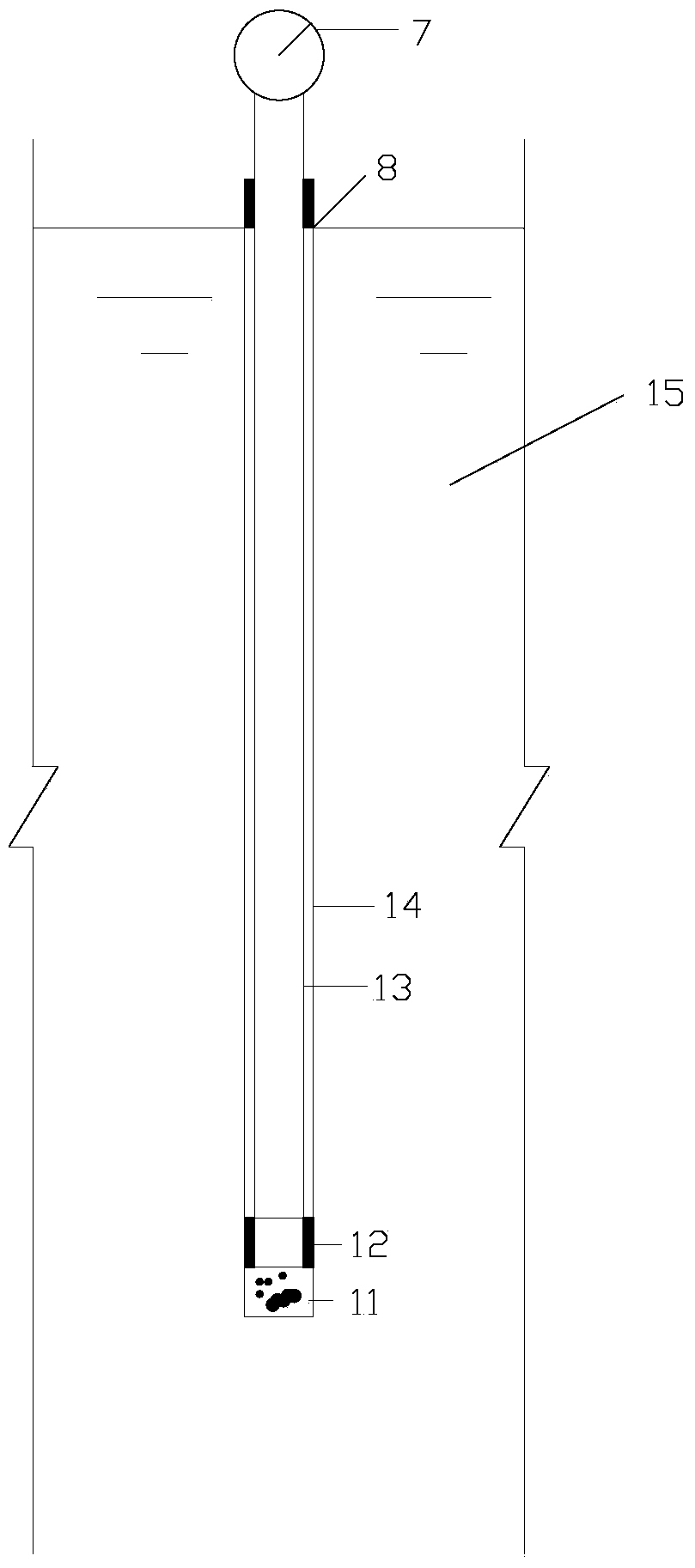

[0035] 2) Set a grouting hole at the center position equidistant from the surrounding vertical drainage board, and arrange a grouting pipe. The grouting pipe can be a plastic pipe or a steel pipe. There are several grouting holes in the middle and lower parts of the grouting pipe, and the upper part passes through the grouting branch pipe and The main pipe is connected with the grout pump.

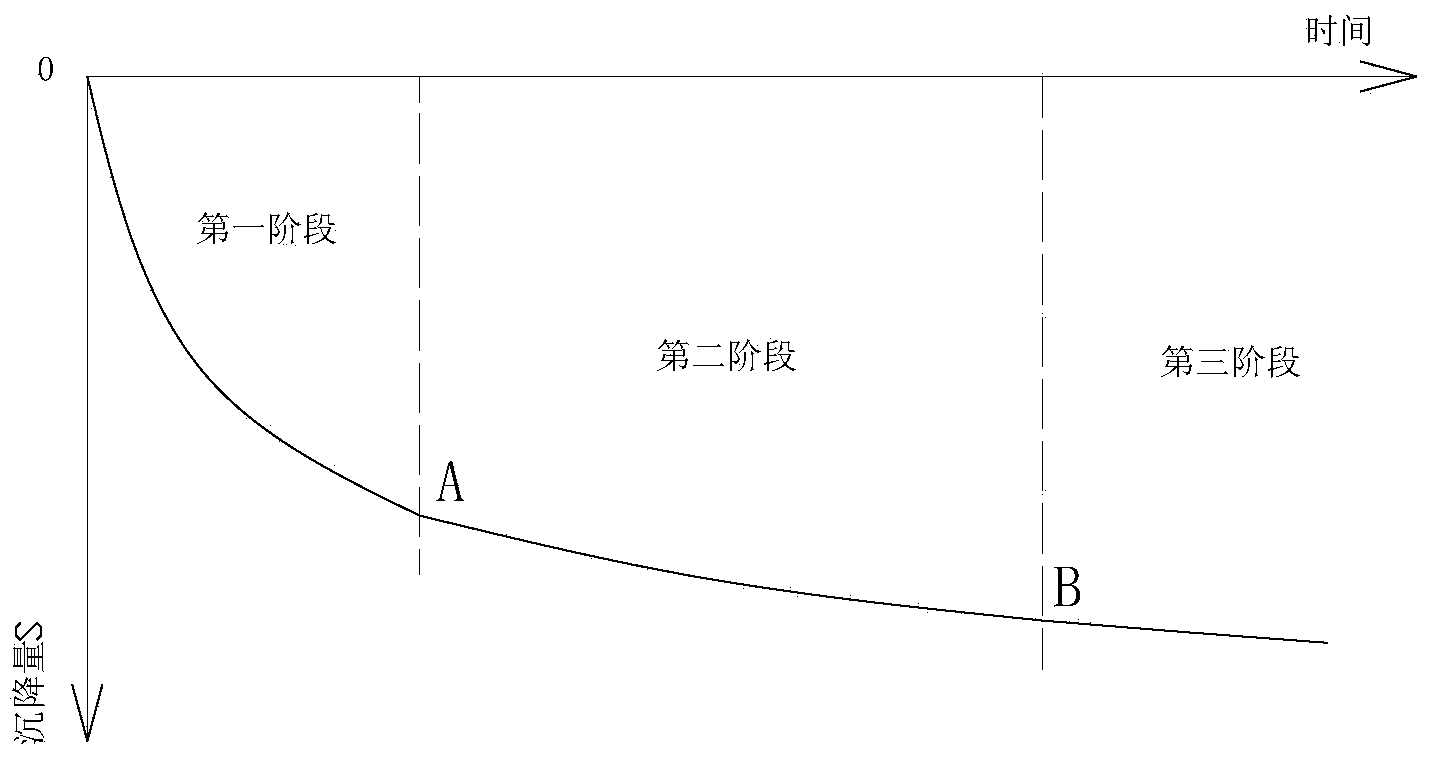

[0036] 3) Set up a vacuum pressure observation hole near the grouting hole, and establish a settlement observation point on the surface....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com