Magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and welding method

A technology of pulsed laser and dissimilar metals, applied in laser welding equipment, welding/welding/cutting items, welding media, etc., can solve the problems of low efficiency, low mutual solubility, loss of intermediate layer materials, etc., achieve low cost and avoid welding The effect of stomata

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

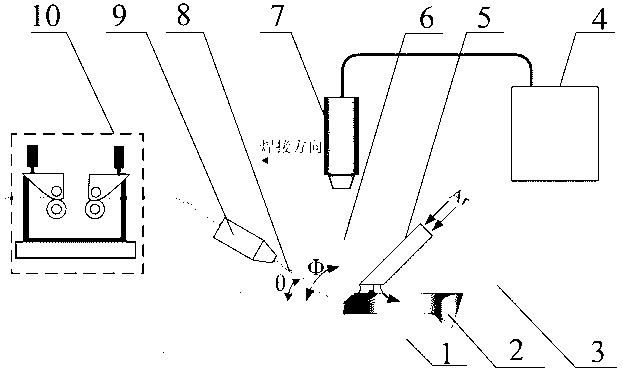

[0041] combine figure 1 , which is an implementation of super-audio frequency pulse laser welding of magnesium-steel butt joints, and the steps of the welding method are as follows:

[0042]Step 1: In order to effectively promote the wettability and spreadability of the liquid magnesium alloy on the steel plate 1, the part to be welded of the workpiece is processed into a V-shaped or Y-shaped groove, and the surface and both sides of the groove are polished and cleaned to remove the workpiece Oil stains and oxide films on the surface.

[0043] Step 2: Before welding, fix the steel plate 1 and magnesium plate 3 on the welding fixture, adjust the position and angle of the wire feeding nozzle 9 to ensure that the welding wire 8 is automatically fed from the front of the laser beam 6 at a certain angle θ, and use the argon nozzle 5 Protect the weld 2.

[0044] Step 3: During the welding process, the laser beam 6 is slightly biased on the side of the magnesium alloy 3 by 0.2mm-0....

specific Embodiment approach 2

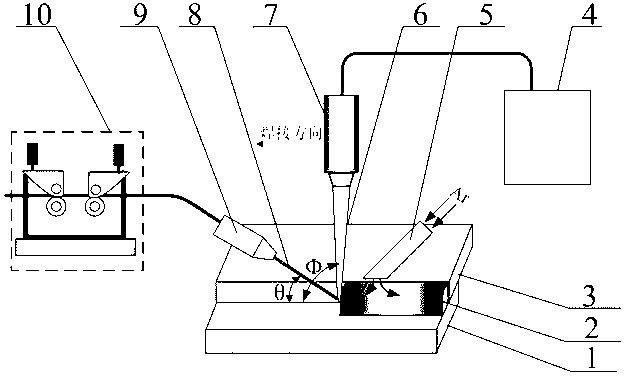

[0047] combine figure 2 , it is an embodiment of the super-audio frequency pulse laser welding magnesium-steel lap joint. The welding method steps are as follows:

[0048] Step 1: The workpiece to be welded is not grooved or a single-sided Y-shaped groove is made on the magnesium alloy 3 side, and the surface and both sides of the workpiece are polished and cleaned with sandpaper and acetone to remove oil and oxide film on the surface of the workpiece.

[0049] Step 2: Combine the workpieces with clean surface treatment into a lap joint (magnesium alloy plate 3 is on the top, steel plate 1 is on the bottom), adjust the position and angle of the wire feeding nozzle 9, so that the welding wire 8 is automatically moved from the front of the laser beam 6 at a certain angle θ The welding seam 2 is protected by an argon nozzle 5 .

[0050] Step 3: During the welding process, the precise control of the welding heat input is realized by adjusting the power density of the fiber laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com