Secondary oiling agent treatment method of heterocyclic aramid

A technology of heterocyclic aramid fiber and processing method, applied in the direction of fiber treatment, heating/cooling fabric, fiber type, etc., can solve the problems of poor weaving performance of heterocyclic fiber and low quality of woven fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

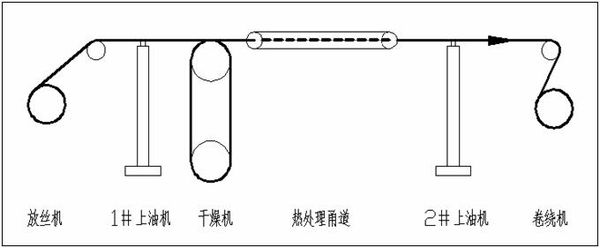

[0046] Such as figure 1 Shown, a kind of secondary oil treatment method of heterocyclic aramid fiber, described method comprises the steps:

[0047] A. Unwinding: Under the condition of a tension of 0.5cN / tex, the heterocyclic aramid raw yarn is unwound from the unwinding machine, so that the raw yarn is evenly unwound from the bobbin at a speed of 35m / min;

[0048] B. First-stage oiling treatment: the raw yarn of heterocyclic aramid fiber is unwound from the unwinding machine and enters the first-stage oiling machine (namely, 1# oiling machine), and the raw silk is immersed in the oiling agent. Carry out continuous and stable oiling treatment at an oil circulation rate of 5L / min;

[0049] C. Drying and heat treatment: the oiled raw silk is dried at 160°C for 0.5min by a dryer and then enters the heat treatment tunnel (temperature 330°C, treatment time 0.6min) for heat setting treatment;

[0050] D. Second-stage oiling treatment: the raw silk becomes finished silk after heat...

Embodiment 2

[0056] Such as figure 1 Shown, a kind of secondary oil treatment method of heterocyclic aramid fiber, described method comprises the steps:

[0057] A. Unwinding: Under the condition of a tension of 0.1cN / tex, the heterocyclic aramid raw yarn is unwound from the unwinding machine, so that the raw yarn is evenly unwound from the bobbin at a speed of 10m / min;

[0058] B. First-stage oiling treatment: the raw yarn of heterocyclic aramid fiber is unwound from the unwinding machine and enters the first-stage oiling machine (namely, 1# oiling machine), and the raw silk is immersed in the oiling agent. Carry out continuous and stable oiling treatment at an oil circulation rate of 2L / min;

[0059] C. Drying and heat treatment: the oiled raw silk is dried at 140°C for 1 minute by the dryer and then enters the heat treatment tunnel (temperature 300°C, treatment time 1 minute) for heat setting treatment;

[0060] D. Second-stage oiling treatment: the raw silk becomes finished silk afte...

Embodiment 3

[0066] Such as figure 1 Shown, a kind of secondary oil treatment method of heterocyclic aramid fiber, described method comprises the steps:

[0067] A. Unwinding: Under the condition of a tension of 0.8cN / tex, the heterocyclic aramid raw yarn is unwound from the unwinding machine, so that the raw yarn is evenly unwound from the bobbin at a speed of 50m / min;

[0068] B. First-stage oiling treatment: the raw yarn of heterocyclic aramid fiber is unwound from the unwinding machine and enters the first-stage oiling machine (namely, 1# oiling machine), and the raw silk is immersed in the oiling agent. Carry out continuous and stable oiling treatment at an oil circulation rate of 10L / min;

[0069] C. Drying and heat treatment: the oiled raw silk is dried at 180°C for 0.2min by a dryer, and then enters the heat treatment tunnel (temperature 350°C, treatment time 0.5min) for heat setting treatment;

[0070] D. Second-stage oiling treatment: the raw silk becomes finished silk after he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com