Patents

Literature

331results about How to "Lubricious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

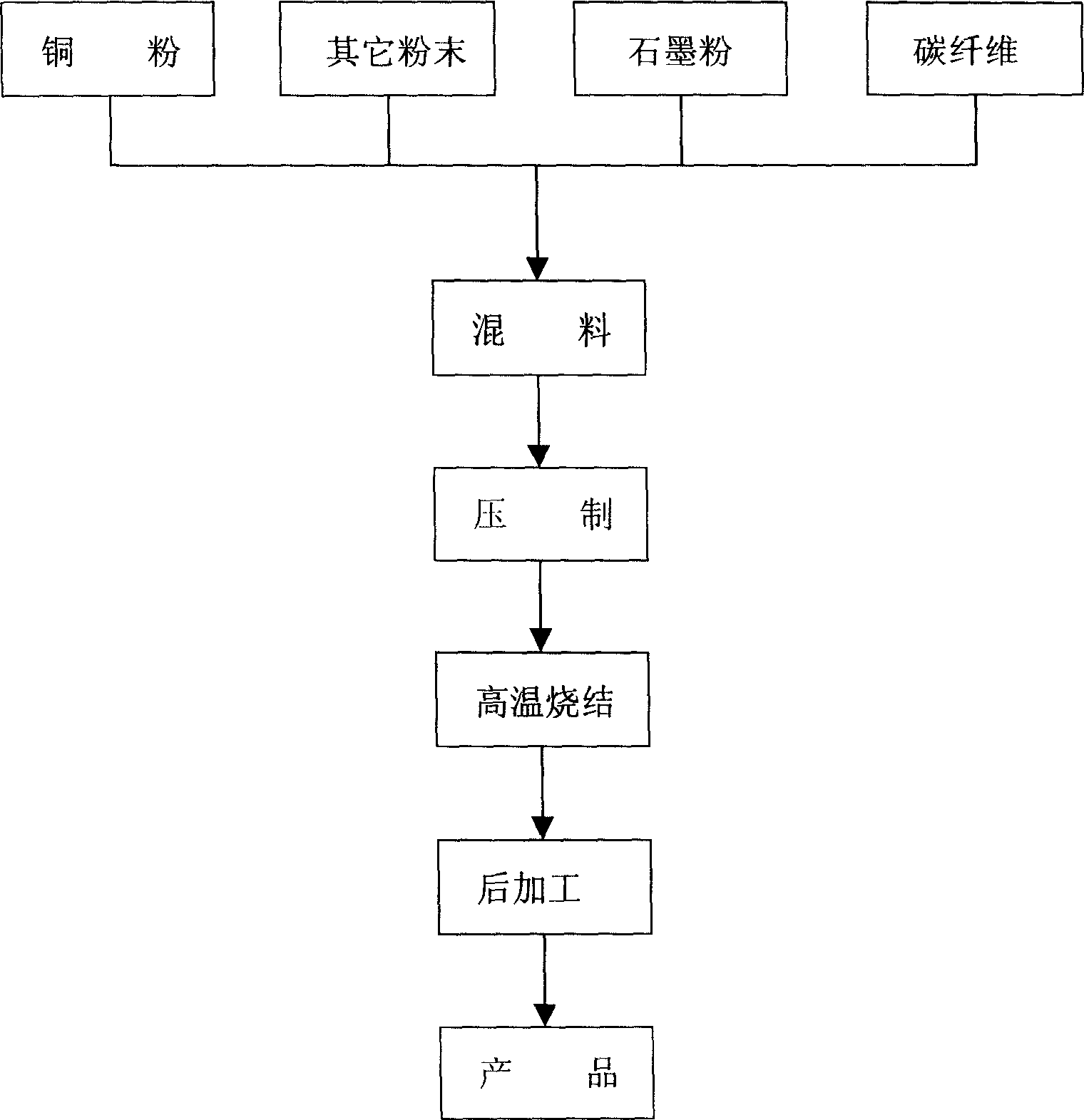

Leadless copper base high temperature self lubricating composite material

InactiveCN1718795AImprove toughnessImprove heat resistanceChemical vapor deposition coatingChemical compositionGraphite

A high-temp self-lubricating non-Pb Cu-base composition has a chemical formula: Ni+C+Sn+Zn+MX+Fe+Cu, where MX is chosen from BN, Si3N4, SiC, Al2O3, TiN, TiC and Cr3 C2 and C is graphite and carbon fibres. It has anti-oxidizing, anti-corrosion and high-temp anti-wear characteristics.

Owner:合肥波林新材料股份有限公司

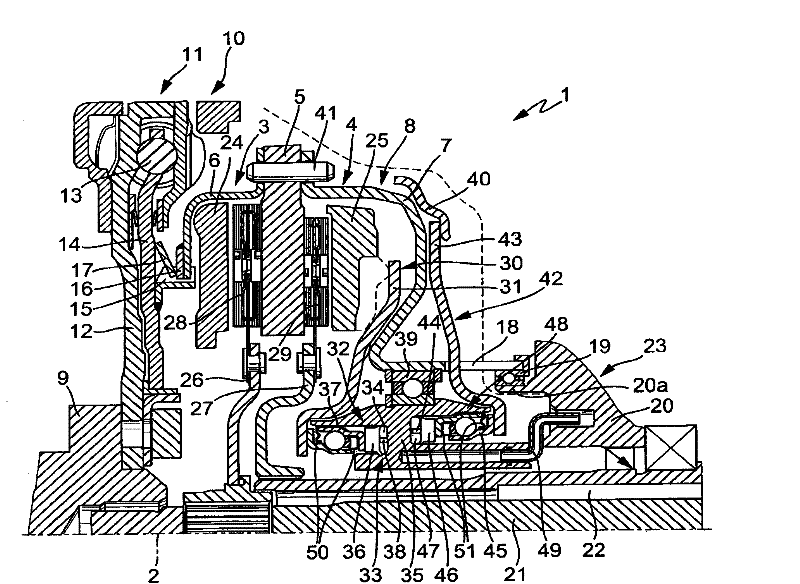

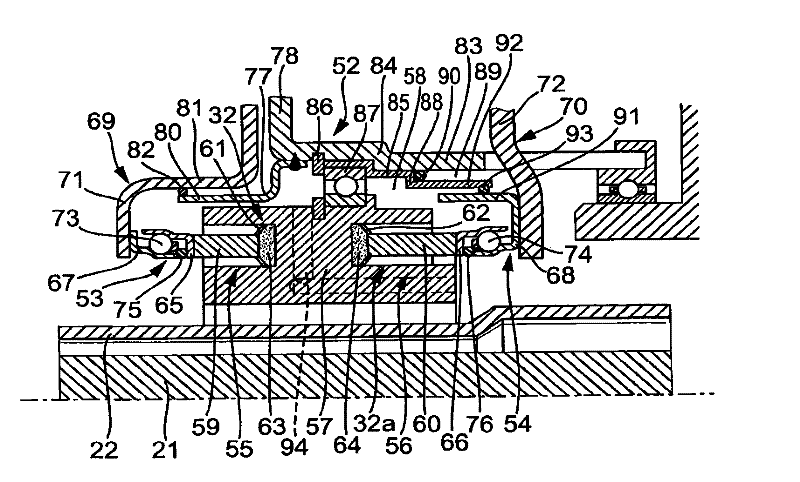

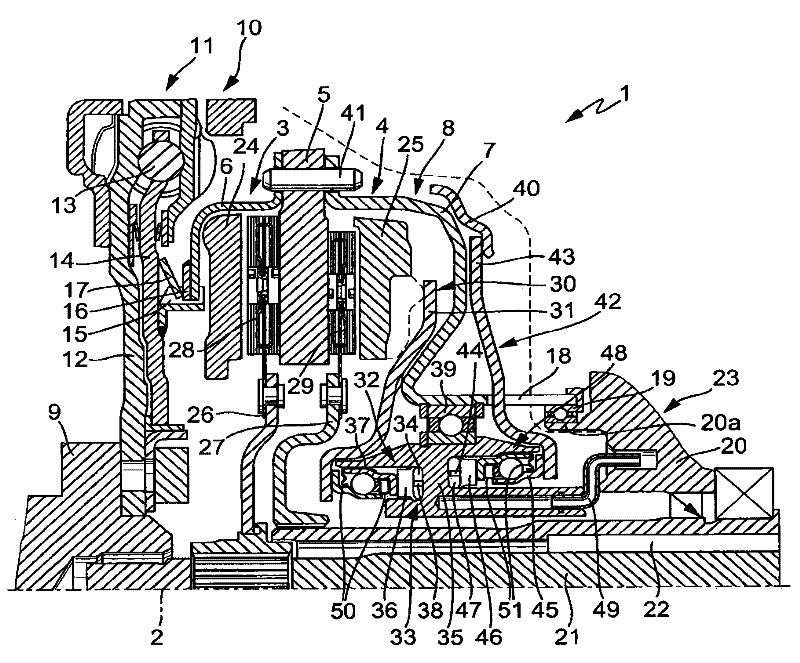

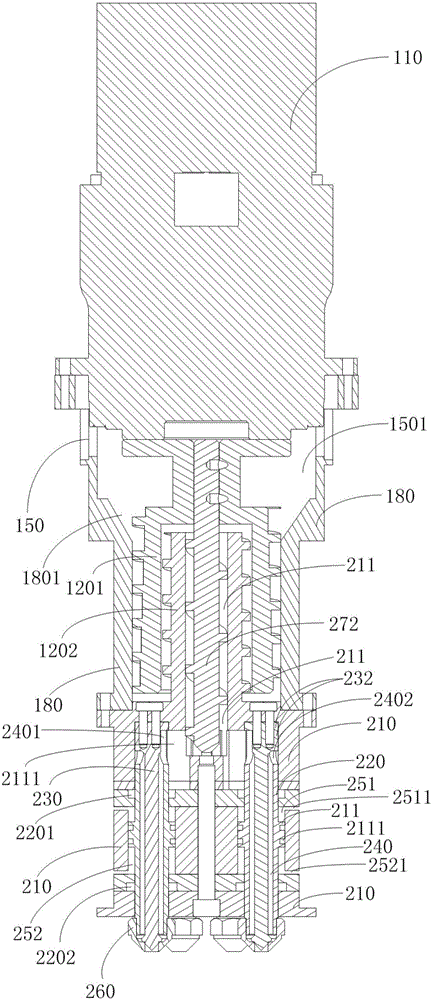

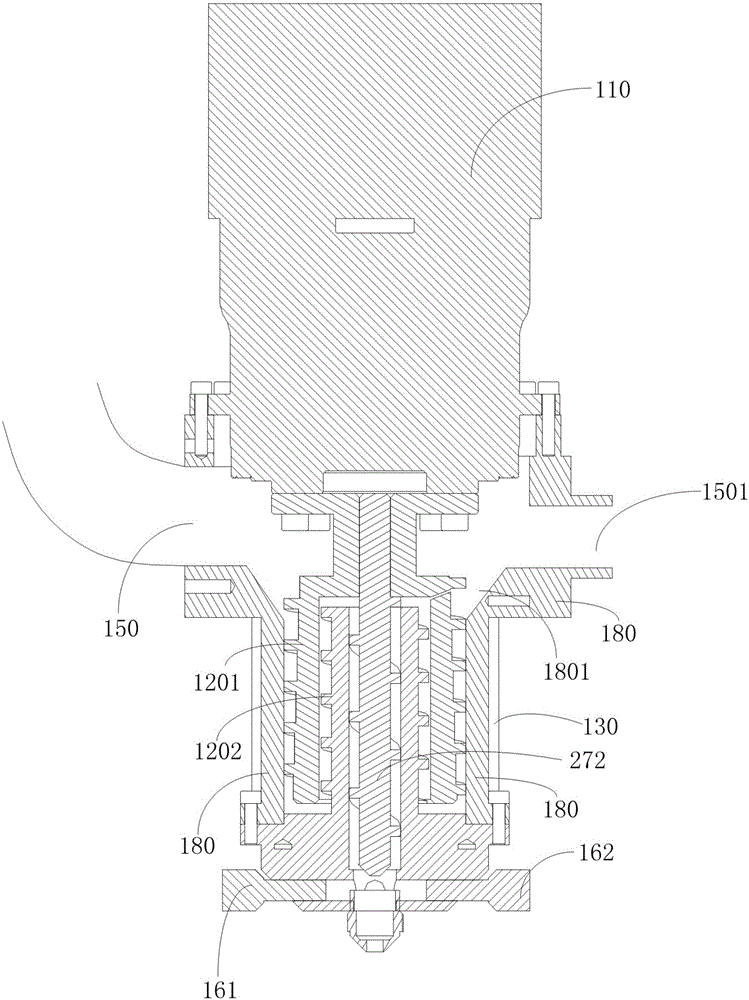

Dual clutch

InactiveCN102099595ACorrectly designedAvoid vibrationRolling contact bearingsMechanical actuated clutchesCentral pressureEngineering

The invention relates to a dual clutch (1) having two friction clutches (3,4), having a central pressure-exerting plate (5) and having two pressure plates (24,25) which are axially movable relative to said pressure-exerting plate (5) with the interposition of the friction linings (28,29) of two clutch disks (26,27), which mesh with in each case one gearbox input shaft (21,22), of actuating devices (32,32a). Here, the pressure plates (24,25) are advantageously acted on by transmission elements (30,42,69,70) by the actuating devices (32,32a) directly without a lever action. Furthermore, for the cooling and lubrication of the actuating devices (32,32a) and the transmission elements (30,42,69,70), an annular chamber (58) can be formed which has an increased fluid volume.

Owner:SCHAEFFLER TECH AG & CO KG

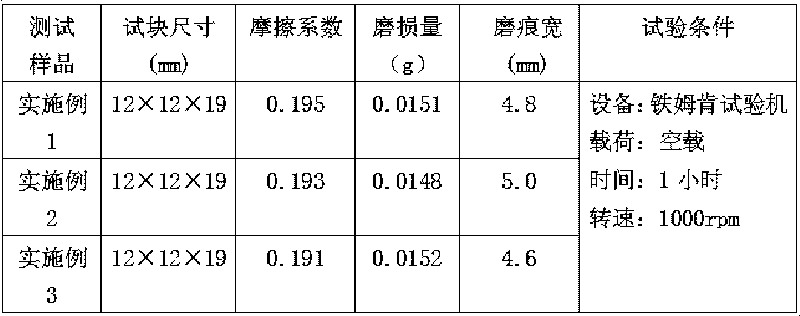

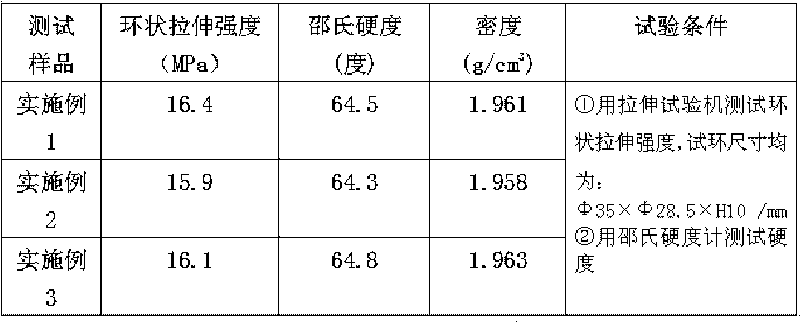

Bearing retainer material and preparation method thereof

ActiveCN101696311AImprove thermal stabilityWide temperature rangeBearing componentsMaterials scienceMetal

The invention discloses a bearing retainer material and a preparation method thereof. The material is prepared from the following raw materials in percentage by weight: 2 to 5 percent of molybdenium disulfide, 8 to 12 percent of polyimide, 9 to 15 percent of polybenzoate, the balance of polytetrafluoroethylene. The preparation method comprises the following steps of: weighting the raw materials; mixing the raw materials; grinding the mixture; loading the mixture into a mould; pressurizing to prepare a blank; sintering the blank; and processing the blank into a finished product. The retainer material has the advantages of high temperature resistance, low temperature resistance, dimension stability, small erosion to metal and rubbed surfaces and good abrasion resistance. A retainer made of the bearing retainer material can be used under harsh conditions of no magnetism, ambient temperature changed between -19 and +55 DEG C, and rotation speed up to 7,200r / min so as to improve the performance of bearings.

Owner:LUOYANG BEARING RES INST CO LTD

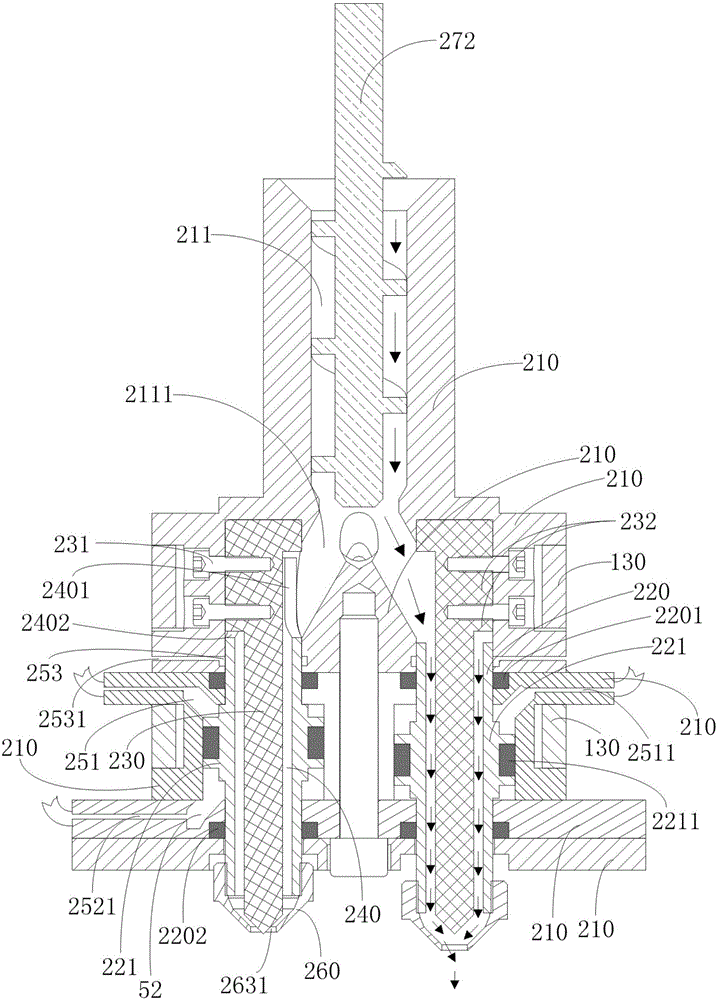

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

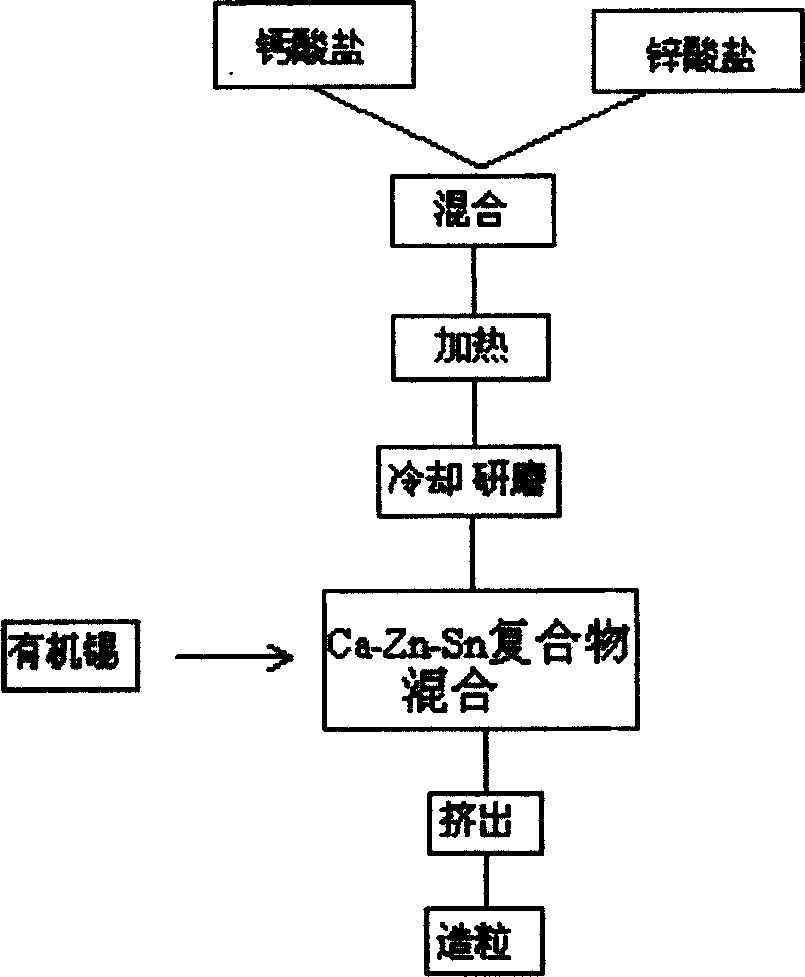

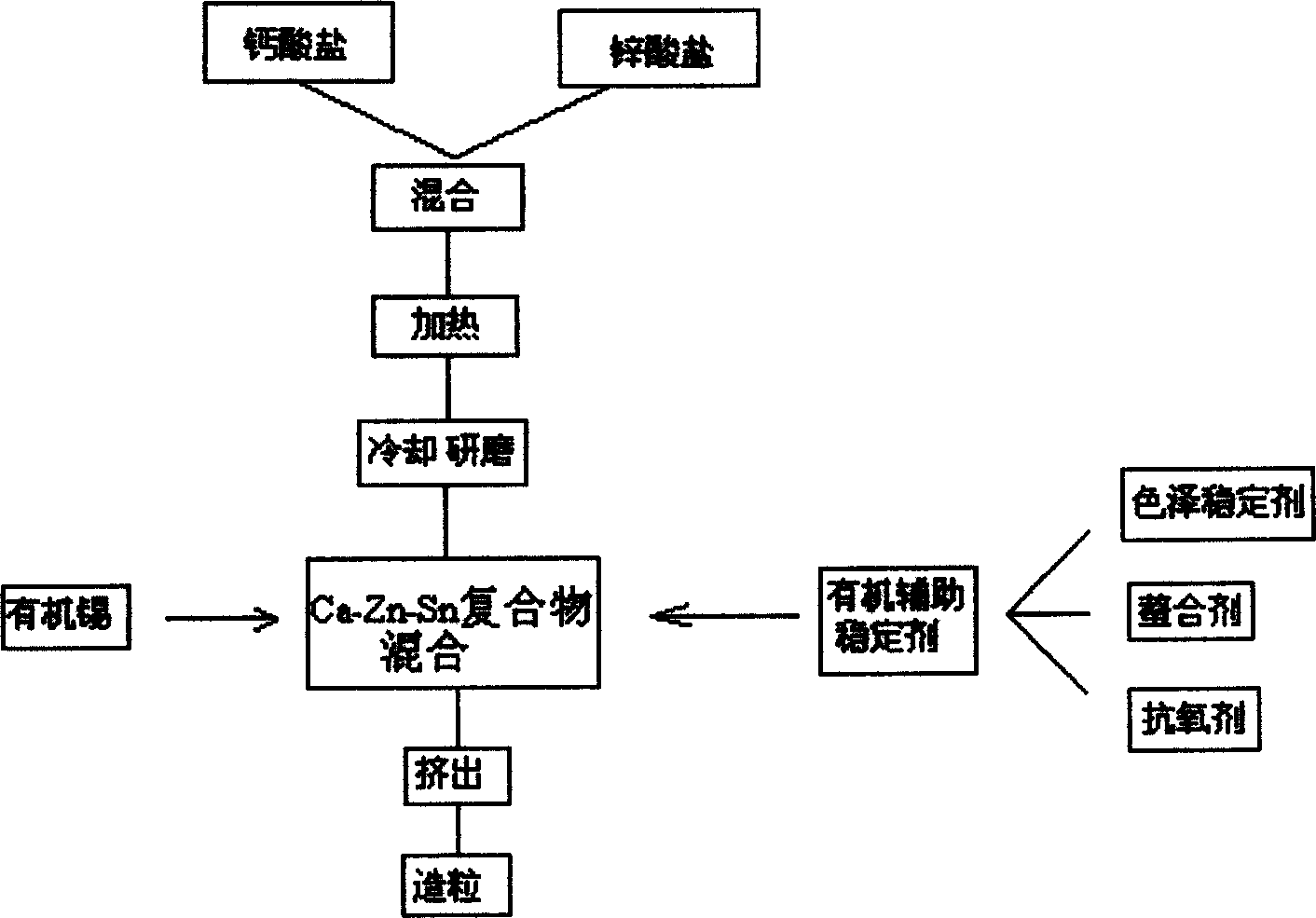

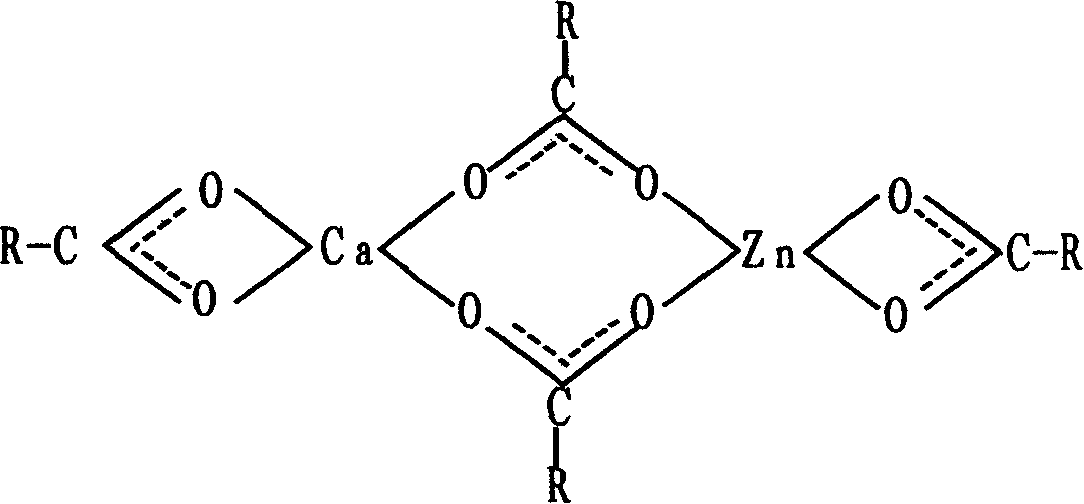

Ca-Zn-Sn composite stabilizer for polyvinyl chloride and method for preparing same

The invention relates to a Ca-Zn-Sn compound thermal stabilizer for stabalizer and its preparing method, which is based on Ca St2 / ZnSt2, comprised of angxiliary stabalizer and orgnic tin, with the main components: Ca / Zn compound of zincate and polyvinyl chloride-stabalizer portion and orgic tin 0.1-0.3 portion. The invention has outstanding thermal stabalization and processcable performance, increases thermal stabalization effect of thermal stabalizer, anlarge its application range, reduce the quantity of organic tin and decreases the productive cost.

Owner:SICHUAN UNIV

Binder, preparation method of binder and application of binder used as metallurgical pellet binder

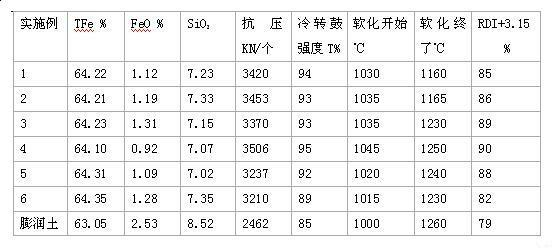

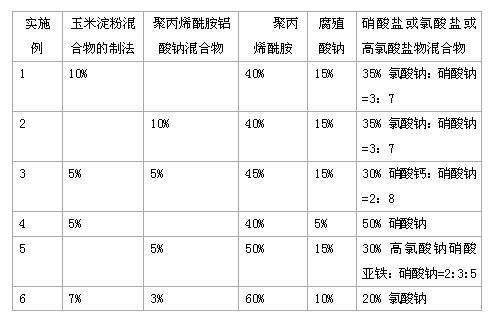

The invention relates to a binder, a preparation method of the binder and an application of the binder used as the metallurgical pellet binder, belonging to the technical field of the production of sintered pellets of the ferrous metallurgy. The technical scheme of the invention is as follows: the binder consists of the following one or two components: the mixture of polyacrylamide, sodium humate and nitrate or chlorate or perchlorate, corn starch mixture and the mixture of polyacrylamide and sodium aluminate. The preparation method comprises the following steps: adding the binder in fine iron powder for pelletizing of which 200-mesh passing rate is no less than 70% to mix evenly and pelletizing, wherein the dosage of the binder is 0.2-0.5% of fine iron powder. The invention has the beneficial effects: the binder has some properties of bentonite such as hygroscopicity and lubricity, the binder does not contain silicon, aluminum, phosphorus and sulfur, the pelletizing dosage of the binder is small, the burning loss is high, the high temperature burning loss of the binder is up to 60%-90%; and the pelletizing process mainly adopts lamellar packing growth, the agglomeration growth is reduced, the internal oxidation of the pellets in the chain grate can be promoted.

Owner:张家口佳一昌科技发展有限公司

Biodiesel drilling fluid lubricant and preparation method thereof

The invention belongs to the field of oilfield chemistry, and in particular relates to a lubricant based on biodiesel and applied to a water-based drilling fluid and a preparation method thereof. The biodiesel drilling fluid lubricant comprises biodiesel; and 80 to 120 milliliters of water, 4 to 10 grams of emulsifier and 2 to 6 grams of defoaming agent are added into every 100 milliliters of biodiesel. The biodiesel is used for substituting white oil and diesel oil and researched into the biodiesel drilling fluid lubricant suitable for the water-based drilling fluid; and the biodiesel drilling fluid lubricant has similar lubricating performance as an oil-based lubricant and can be perfectly dissolved with the water of the drilling fluid, and the whole system has good dispersity.

Owner:山东华阳油业有限公司 +1

Composite insulation material for cable and preparation method thereof

InactiveCN101619148ALittle effect on insulation performanceEffective insulationRubber insulatorsPlasticizerActive agent

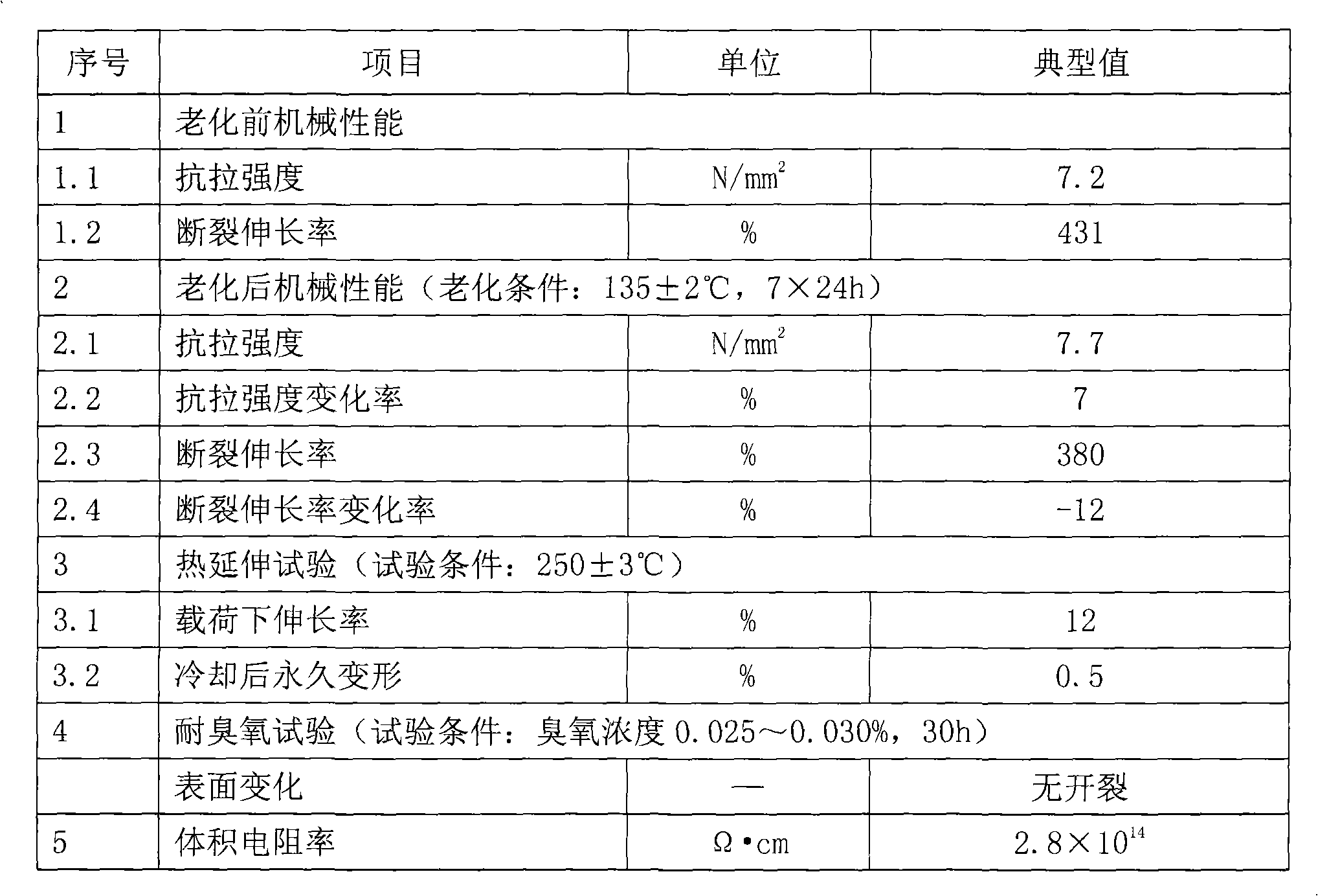

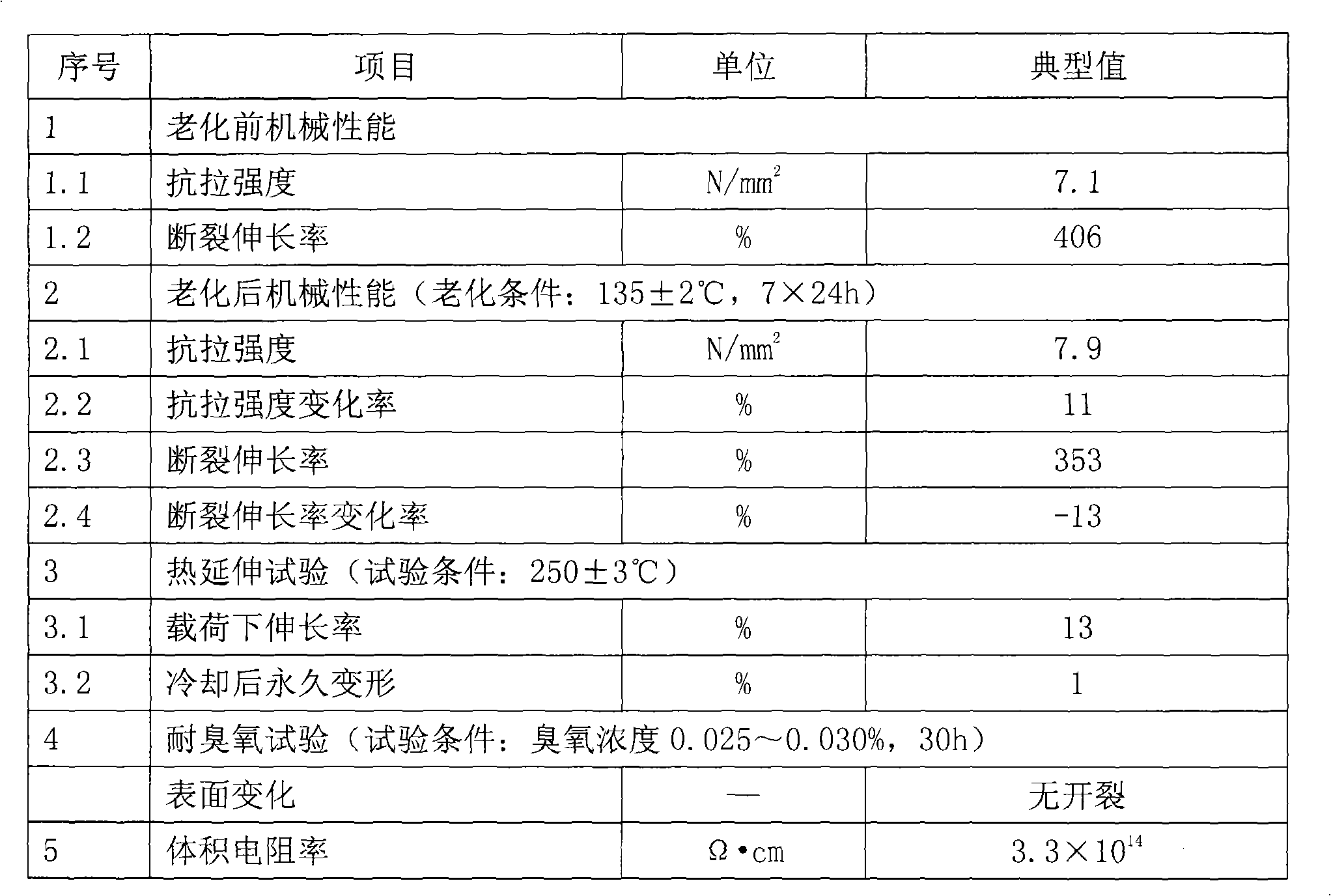

The invention discloses a composite insulation material for a cable and a preparation method thereof. The composite insulation material for a cable comprises the following materials by weight part: 30-60 parts of EPDM rubber, 70-40 parts of styrene-butadiene rubber, 1-4 parts of cross linker, 1-6 parts of cross linker addition agent, 4-16 parts of vulcanizing active agent, 1-4 parts of aging inhibitor, 10-40 parts of plasticizer, 1-3 parts of coupling agent and 100-200 parts of reinforcement filling material. The preparation method comprises the following steps: weighing the materials according to the weight parts; mixing; tabletting; cooling; and collecting. The composite insulation material is used for cable low-voltage insulation, has a temperature resistant level capable of reaching 90 DEG C, can resist heat, ozone and weathers and has high tensile strength, good electrical insulating property and mechanical property and cost being far lower than the cost of ethylene propylene rubber, and the preparation method is simple, applicable and easy to operate.

Owner:SICHUAN MINGXING CABLE

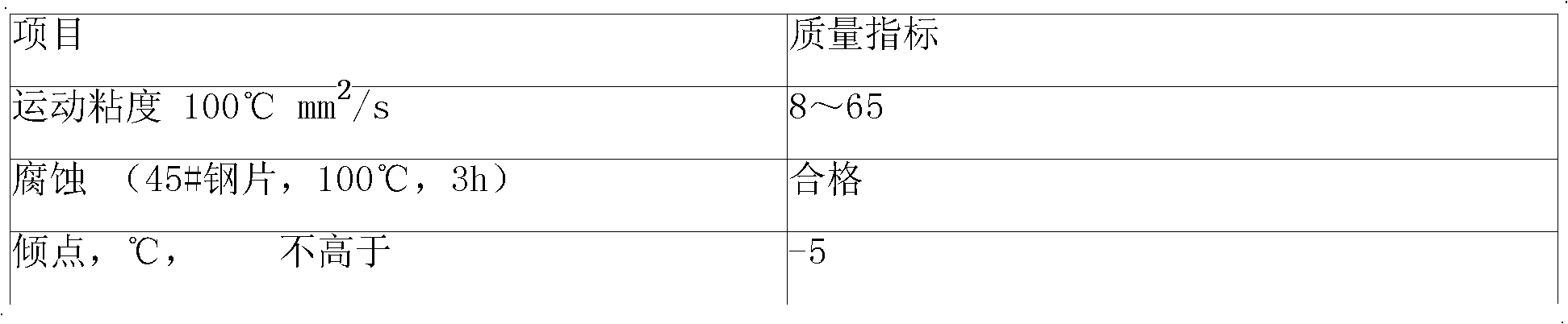

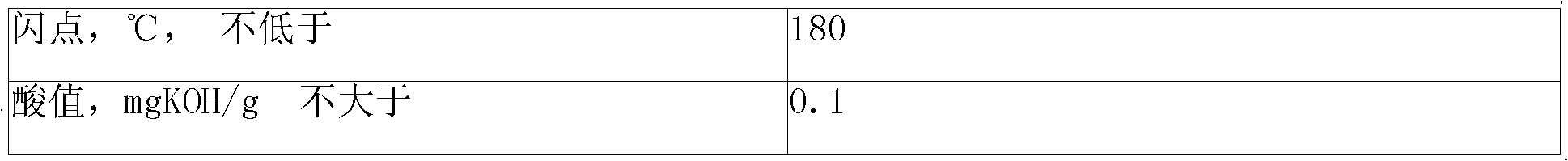

Efficient lubrication type anti-rust oil and preparation method thereof

InactiveCN102533404AReduce coefficient of frictionImprove anti-wear performanceAdditivesHigh resistanceBase oil

The invention relates to efficient lubrication type anti-rust oil and a preparation method thereof. The anti-rust oil comprises: (A) 5-20 percent of oil-soluble corrosion inhibitor by weight; (B) 5-20 percent of anti-rust additive by weight; (C) 0.1-5 percent of lubricating additive by weight; (D) 0.01-5 percent of antioxidant by weight; and (E) 50-90 percent of refined mineral base oil by weight. The preparation method comprises: 1, adding 20-25 percent of refined mineral base oil (E) into a reactor according to the proportion; 2, heating in the reactor, adding the oil-soluble corrosion inhibitor (A) and the anti-rust additive (B) according to the proportion, and mixing; 3, cooling in the reactor, adding the lubricating additive (C) and the antioxidant (D) according to the proportion, and mixing; 4, adding the residual refined mineral base oil into the reactor according to the proportion, continuously mixing, keeping the temperature, and fully mixing; and 5, sampling, inspecting, filtering when the sample is acceptable, discharging, and packaging, thereby completing preparation of the efficient lubrication type anti-rust oil. The anti-rust oil has high rust resistance, good lubricating performance and good resistance against wear under the extreme pressure.

Owner:布兰诺工业包装材料(上海)有限公司

Preparation method for cassava starch modified by combining three kinds of modification processes

ActiveCN104031295AImprove reaction efficiencyImprove the uniformity of the reactionFibre treatmentPaper coatingWater contentChemistry

A disclosed preparation method for cassava starch modified by combining three kinds of modification processes is characterized by comprising: taking starch as a raw material, employing a wet-process crosslinking-oxidation-esterification chemical modification technological route, specifically, performing a crosslinking reaction and an oxidation reaction on an active starch slurry at the same time, then adding a pretreated composite esterification reagent to perform esterification reaction, and adjusting the pH value of the starch slurry to 5.0-6.5, so as to finish combined modification of cassava starch, filtering to obtain wet starch with the water content of 35% or less, then adding polyethylene glycol, mixing uniformly, and performing drying, cooling, crushing and sieving, so as to obtain the cassava starch modified by combining three kinds of modification processes. Only one time of post-processing process comprising washing, centrifugation, drying and the like is performed, the technological process is continuous and automatic, energy and reaction time are saved; and the product is low in gelatinization temperature, good in formability, improved in permeability, caking property, film forming ability and anti-ageing property, and is suitable for being used as a coating adhesive and a surface sizing agent in papermaking industry, a sizing agent in weaving industry, an industrial binder and the like.

Owner:广西农垦明阳生化有限公司

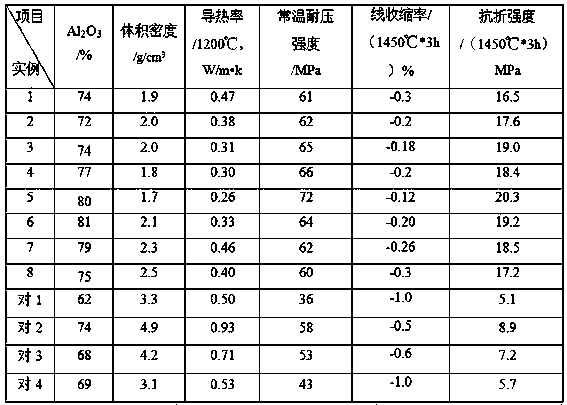

High-alumina refractory castable and preparation method thereof

The invention belongs to the technical field of refractory materials, in particular to a high-alumina refractory castable and a preparation method thereof. The high-alumina refractory castable is prepared from the following raw materials in parts by weight: 50-70 parts of high bauxite, 8-13 parts of andalusite, 11-23 parts of floating bead, 15-20 parts of silicon carbide, 10-15 parts of silicon nitride, 7-12 parts of alpha-Al2O3 micro powder, 3-9 parts of silica-alumina colloid powder, 1-5 parts of attapulgite clay, 10-25 parts of calcium aluminate cement, water reducer and aluminium silicatefiber, wherein the water reducer occupies 0.1-0.3% of total mass of the above raw materials, and the aluminium silicate fiber occupies 0.05-0.12% of total mass of the above raw materials. The high-alumina refractory castable has the advantages of high Al2O3 content, light weight, low heat conductivity and high castable strength.

Owner:黎文泰

Environment-friendly thixotropic anti-rust oil

ActiveCN103992858AImprove performanceImprove washing resistanceLubricant compositionBobbinPhenyl Ethers

The invention discloses an environment-friendly thixotropic anti-rust oil. The anti-rust oil comprises the following raw materials by weight: 81 to 90 parts of bobbin oil, 0.1 to 0.3 part of hydroxyethylpyrrolidone, 1 to 2 parts of 1-hydroxyethyl-2-oleic imidazoline, 5 to 7 parts of dinonyl-naphthalene sulfonic acid calcium salt, 1 to 2 parts of organic bentonite, 0.7 to 1 part of polyoxyethylene nonyl phenyl ether, 3 to 4 parts of epoxidized soybean oil, 0.6 to 2 parts of decyl primary amine, 0.6 to 2 parts of Span-80 and 5 to 6 parts of an anti-rust auxiliary agent. The anti-rust oil provided by the invention has excellent performance and cleaning performance, certain lubricity and good thixotropy, so the anti-rust oil can form a stable oil film on the surface of metal, hardly flows and can maintain the stable oil film when a steel plate is rolled up, thereby reducing the application amount of the oil.

Owner:诺土(上海)新材料技术有限公司

Grease used for metal fastener

InactiveCN101805656AImprove adhesionImprove antioxidant capacityAdditivesPreservativeFilm-forming agent

The invention discloses grease used for a metal fastener, which is prepared from the following components in percentage by weight ( in percentage by total weight of the grease): 50.0 to 90.0 percent of basic grease, 1.5 to 20.0 percent of film-forming agent, 0.1 to 1.0 percent of anti-oxidation preservative, 5.1 to 8.3 percent of anti-rust agent and 2.5 to 26.0 percent of solid stuffing. The grease has higher oxidation resistance, higher corrosion and rust resistance, better water resistance, more excellent sealing property, better pressure resistance, better adhesivity, more environment-friendly suitability, convenient brushing and injection and stable structure and is not easy to generate swelling action on protected nonmetal assorted components. The grease can be largely applied to thespeed acceleration of the trunk line of the railway ballastless track.

Owner:成都蜀光石油化学有限公司

Hyaluronic acid and silica gel composition for scar prevention and early repair and preparation method of hyaluronic acid and silica gel composition

ActiveCN105012228AGood chemical stabilityImprove breathabilityAerosol deliveryOintment deliveryDimethyl siloxaneHyaluronic acid

The invention provides a hyaluronic acid and silica gel composition for scar prevention and early repair and a preparation method of the hyaluronic acid and silica gel composition. The method includes the steps of adding purified water to hyaluronic acid to be evenly stirred to prepare a hyaluronic acid solution, adding purified water to onion extract to prepare an onion extract solution, adding carbomer and purified water to glycerol to be evenly stirred to prepare a carbomer solution, sequentially adding the hyaluronic acid solution and the onion extract solution to the carbomer solution to be stirred, adding polydimethylsiloxane and dimethyl siloxane cross-linked polymers to be evenly stirred, making the mixture pass through a colloid mill, and obtaining the hyaluronic acid and silica gel composition. By adding natural plant extract for promoting skin wound healing, natural moisturizing factors, namely, hyaluronic acid, and siloxane polymers, the good effect of preventing scars from being formed is achieved, the effect of rapidly repairing scars in the early stage is achieved, and good effects are achieved for prevention and early repair of scars caused by general operations, traumas and burns.

Owner:郑州和济生物科技股份有限公司

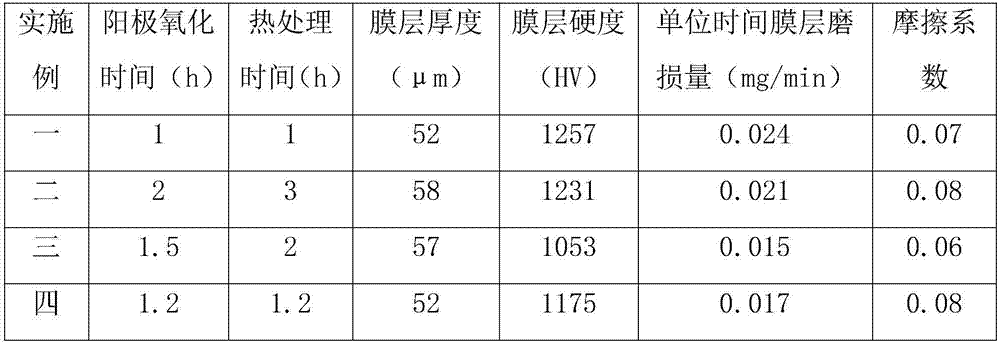

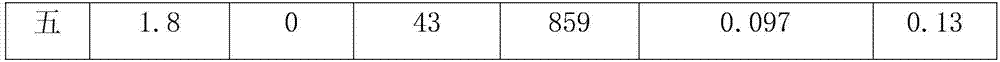

Aluminum alloy template with self-lubricating film layer and processing method of aluminum alloy template

ActiveCN107475763AReduce wearEasy to separateAnodisationForming/stuttering elementsCarbon nanotubePolytetrafluoroethylene

The invention discloses an aluminum alloy template with a self-lubricating film layer and a processing method of the aluminum alloy template. The aluminum alloy template comprises an aluminum alloy template base material and the self-lubricating film layer formed on the surface of the aluminum alloy template base material. The self-lubricating film layer includes a carbon nano tube, nano polytetrafluoroethylene and nano SiO2, and the thickness of the self-lubricating film layer ranges from 40 micrometers to 60 micrometers. According to the aluminum alloy template, the Al2O3 / polytetrafluoroethylene composite oxidation film layer is formed on the surface of the aluminum alloy template through anodic oxidation, the self-lubricating function is achieved under the action of nano polytetrafluoroethylene, and the film layer is uniform and compact; corrosion resistance and friction hardness are high, and the friction coefficient is low; corrosion of cement can be borne, wear of concrete to the template in the pouring process can be reduced, the adhesion of the concrete on the surface of the template is weak, and the aluminum alloy template can be easily separated from a pouring object; and the flatness of a pouring wall body is high, after use, the building aluminum alloy template only needs to be cleaned with water, and the situation that a large quantity of manpower and releasing agents are put to remove cement attached to the building aluminum alloy template is not needed.

Owner:重庆新久融科技有限公司

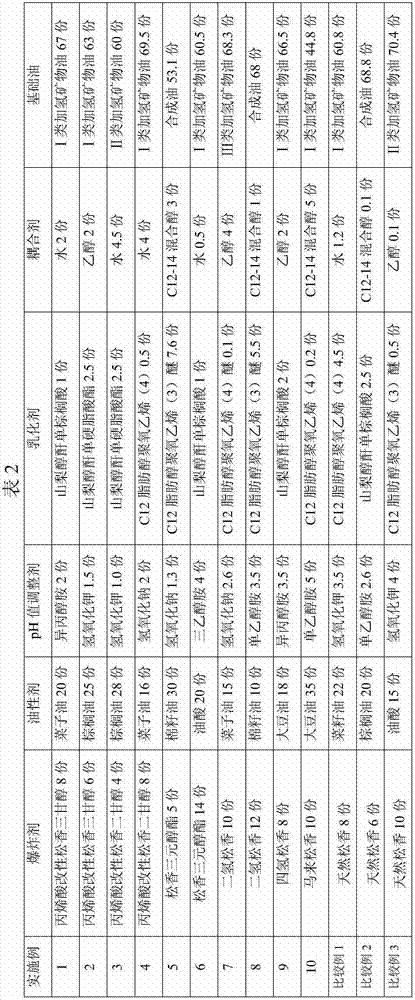

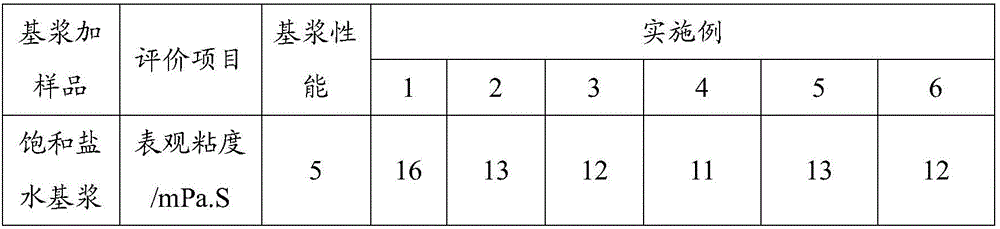

Emulsifying-type linear cutting operating fluid and uses thereof

ActiveCN103710075AImprove stabilityImprove antioxidant propertiesAdditivesHydrogenation reactionDouble bond

The invention relates to an emulsifying-type linear cutting operating fluid and uses thereof, and mainly solves the problem of short service life of the emulsifying-type electric-spark linear cutting operating fluid in the prior art. The emulsifying-type linear cutting operating fluid comprises the following components: by weight, a) 1-20 parts of a modified rosin blasting agent; b) 2-40 parts of a vegetable oilness agent; c) 0.2-5 parts of a pH adjustment agent; d) 0.1-10 parts of a coupling agent; e) 0.1-8 parts of an emulsifier; and f) 25-80 parts of base oil; the modified rosin blasting agent is selected from at least one from modified rosin prepared by esterification reaction or neutralization reaction of carboxyl in a molecular structure of rosin, or by addition reaction, hydrogenation reaction, disproportionation reaction or polymerization of double bonds of the molecular structure of the rosin, and the technical scheme solves the problem well, and can be used in the industrial production of the emulsifying-type electric-spark linear cutting operating fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel sealing washer

InactiveCN102032344AImprove aging resistanceImprove radiation resistanceProductsEngine sealsAging resistanceSulfur

The invention discloses a novel sealing washer, which comprises a body and an inner ring, wherein the body is made from chloroprene rubber (CR), nylon, clay powder and mica-feldspar particulates; the inner ring is made of low-sulfur graphite rubber; and the body is connected with the inner ring in a bonding way. The novel sealing washer disclosed by the invention has reasonable component preparation, simple and convenient processing technology and high high-temperature resistance, corrosion resistance, solvent resistance, aging resistance and radiation resistance; simultaneously, the washer has self-lubricating property, gas tightness, low manufacturing cost and long service life, can effectively prevent leakage of gas and liquid and can be widely applied to various types of electronic devices / pieces of equipment.

Owner:常熟市双华电子有限公司

Cleaning fluid composition for contact lens, its use and method

ActiveCN1818048APromote exchangeQuick washNon-ionic surface-active compoundsDetergent compounding agentsOphthalmologyActive agent

The invention provided a washing liquid compound for the contact lens. The batch formula is: at least one active agent, at least one antiseptic, the water, not or containing nonionic osmotic regulation agent, not or containing the non-ionic surface active agent, not or containing the non-ionic refrigerant. It can slake the disinfectant or the deproteinized agent of the contact lens, so it can avoid the illness of the eyes caused by the disinfectant or the deproteinized agent.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Anti-static woven bag and manufacturing method thereof

InactiveCN104609010AReduce coefficient of frictionImprove anti-static effectElectroconductive/antistatic filament manufactureBagsLinear low-density polyethyleneEngineering

The invention discloses an anti-static woven bag and a manufacturing method thereof. The anti-static woven bag comprises, by weight, 2-3.5% of dispersing agent, 1.5-3% of cross-linking agent, 0.8-1.5% of coupling agent, 0.8-2.0% of nano calcium carbonate, 1-2% of antioxidant, 9-11% of linear low density polyethylene, 2.0-4.0% of anti-static agent and the balance polypropylene. According to the anti-static woven bag and the manufacturing method of the anti-static woven bag, due to the fact that the 2-4% of anti-static agent is added in ingredients of the woven bag, the surface of the woven bag can have lubricity, the friction coefficient of the woven bag is obviously lowered, meanwhile, static charges generated on the surface of the woven bag are restrained and reduced, and thus the woven bag has the excellent anti-static performance. In addition, in the process of manufacturing the anti-static woven bag, the anti-static performance of the woven bag can be effectively achieved by adjusting the specific parameters of drawing, weaving and other links, and the anti-static effect of the woven bag is finally achieved.

Owner:LIAONING TENGHUA PLASTIC

Double polar plate used for phosphoric acid type fuel cell and method for producing the same

InactiveCN101174695AHigh heat resistanceImprove thermal stabilityCell electrodesCollectors/separatorsFiberNew energy

The present invention pertains to the field of new energy materials, in particular to a phosphate fuel cell bipolar plate and a preparation method. The phosphate fuel cell bipolar plate takes graphite as a conductive filler, carbon fiber as a reinforcer, the mixture of polyphenylene ether resin and fluorin resin as a binder; the quality percentage of each component is respectively 45-55 percents of graphite, 5-10 percents of carbon fiber, 30-40% of polyphenylene ether resin and 5-10 percents of fluorin resin. The preparation method adopts the one-time hot forming of die casting method with the pressure of 15-25MPa and the insulation time of 20-30min. The bipolar plate provided by the present invention has the advantages of high-temperature resistance, high thermal stability and good corrosion resistance. In addition, the present invention is somewhat hydrophobic, thus omitting hydrophobic materials and drainage in the battery; and has lubrication performance, which is conducive to demolding in the molding process and makes the waste bipolar plate material used repeatedly.

Owner:SHANDONG UNIV

Hydrocarbon-resistant thick fireproof coating

The invention relates to a hydrocarbon-resistant thick fireproof coating in order to solve the technical problems that the fireproof coating can not well achieve a fireproof function and protect a steel structure and a concrete supporting part. The adopted technical scheme is as follows: the fireproof coating is prepared from the following raw materials in parts by weight: 20-25 parts of brucite, 10-12 parts of calcined kaolin, 29-30 parts of aluminum refractory cement, 10-16 parts of sodium silicate, 1-3 parts of polymerized aluminum phosphate, 1-2 parts of zinc oxide, 1-2 parts of bentonite, 10-20 parts of polymer powder, 20-23 parts of active powder, 8-10 parts of complex fiber, 9-10 parts of antimonous oxide, 10-15 parts of aluminum oxide, 12-15 parts of light calcium carbonate, 5-7 parts of mica powder, 15-20 parts of expanded vermiculite, 18-23 parts of expanded perlite, and 10-12 parts of hollow float beads. The hydrocarbon-resistant thick fireproof coating has the technical effects that the hydrocarbon-resistant thick fireproof coating can bear the instantly rising lasting high temperature of 1100 DEG C, has the characteristics of high bonding strength and compressive strength, strong adhesive force, good water tolerance, good solvent erosion resistance, thermocycling resistance, low heat conductivity coefficient and excellent fireproof performance and antiseptic performance, and can well achieve the fireproof function and achieve the purpose of protecting the steel structure and the concrete supporting part.

Owner:石家庄雅致化工有限公司

Filtrate loss reducer for drilling fluid and preparation method thereof

InactiveCN106256870AShorten the production cycleReduce workloadDrilling compositionCross-linkEmulsion polymerization

The invention provides a filtrate loss reducer for a drilling fluid and a preparation method thereof. The filtrate loss reducer is an inverse emulsion polymer prepared from a water phase and an oil phase through emulsification. The water phase comprises, by weight, 45-56 parts of a sulfonic monomer, 25-38 parts of an amide group monomer, 5-10 parts of a rigid structure monomer and 100-120 parts of water. The water phase also comprises a cross-linking agent and an initiator, a mass ratio of the cross-linking agent to the sulfonic monomer, the amide group monomer and the rigid structure monomer is 0.008-0.015%, and a mass ratio of the initiator to the sulfonic monomer, the amide group monomer and the rigid structure monomer is 0.05-0.15%. The oil phase comprises 80-110 parts by weight of base oil and 4-10% by mass of an emulsifier. The preparation method has simple processes, a fast dissolution rate and excellent filtrate loss reduction performances.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Preparation method for colorful polyurethane plastic and construction process for colorful polyurethane plastic track

ActiveCN104710593AHigh hardnessIncrease reaction rateWax coatingsGround pavingsAcrylic resinSports facility

The invention discloses a preparation method and a construction process for a colorful polyurethane plastic track, and belongs to the technical field of sports facilities. The preparation method for colorful polyurethane plastic comprises the following steps: uniformly stirring 10 to 15 parts of polyether polyol, 10 to 30 parts of hydroxylated acrylic resin, 10 to 30 parts of paraffin, 2 to 4 parts of a chain extender and 0.1 to 0.5 part of an age resistor, and raising temperature to 90 to 100 DEG C; adding 30 to 50 parts of a filler, 2 to 9 parts of a pigment and 0.1 to 0.5 parts of an age resistor, and performing uniform stirring; starting a colloid grinder to grind the materials into particle sizes of smaller than 400 meshes; continuing heating, and performing dehydration for 2 to 3 hours under the conditions of temperature of 90 to 100 DEG C and vacuum degree of lower than 0.095Mpa. According to the preparation method and the construction process, with the adoption of the high-functionality polyether polyol, reaction is accelerated, the hardness of a formed film is increased, and construction time is shortened; by the hydroxylated acrylic resin, high glossiness and higher weather resistance and color retention are achieved, and the service life is prolonged.

Owner:山东世纪联合新材料科技有限公司

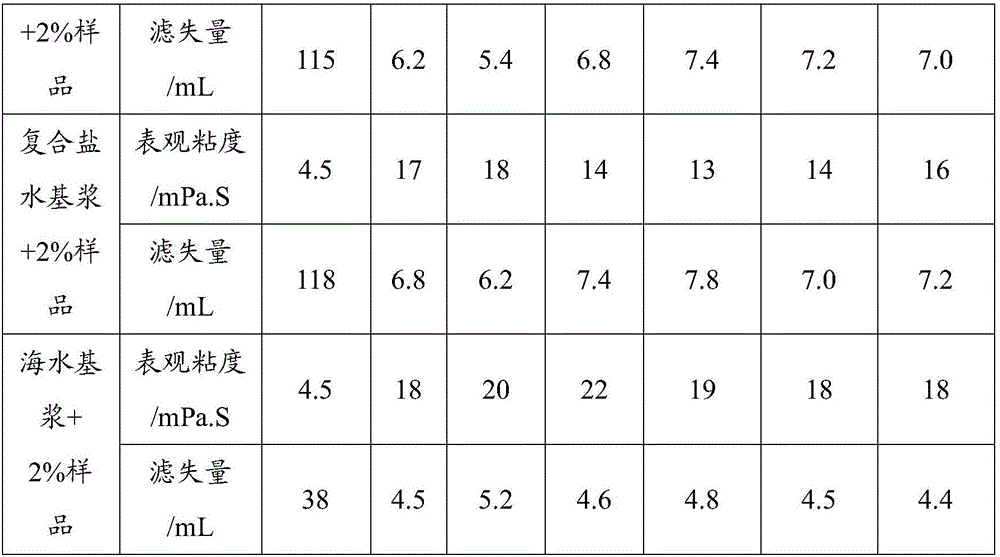

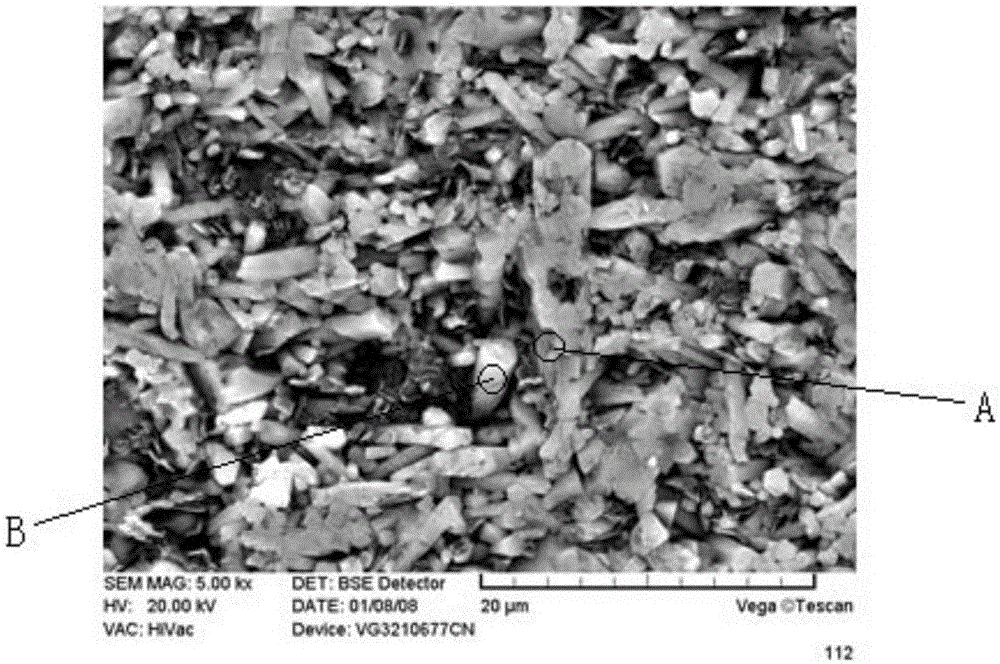

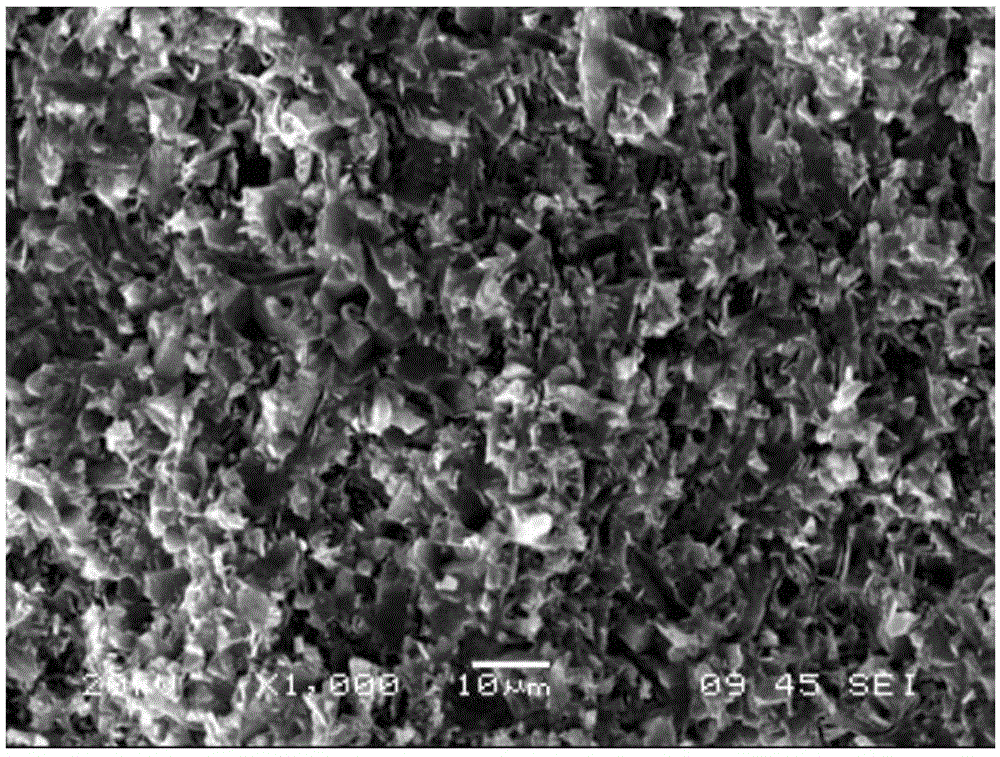

Hot-pressing preparation method for hexagonal boron nitride-added silicon nitride

InactiveCN105036749ALubriciousImprove tribological performanceChemical reactionHexagonal boron nitride

The invention relates to a hot-pressing preparation method for hexagonal boron nitride-added silicon nitride. The preparation method comprises the following steps: adding hexagonal boron nitride having a laminar structure as a solid lubricating agent to silicon nitride, and mixing; meanwhile, adding a sintering aid and carrying out ball grinding; pouring alcohol to adjust the viscosity of fluid; then putting the ball-ground powder to a drying oven, heating, drying by steaming and sieving; then loading the powder to a die, and pre-pressing to form a biscuit; carrying out temperature preservation and pressure preservation in a vacuum carbon tube furnace; finally, reducing the temperature of the vacuum carbon tube furnace to room temperature, and taking sintered silicon nitride composite ceramic out. According to the preparation method disclosed by the invention, boron-containing oxides and hydroxides are generated by means of a chemical reaction between the hexagonal boron nitride and water molecules, so that the siding surface of a material has a lubricating property per se, and thus the tribological property of the silicon nitride ceramic material is remarkably improved, namely the friction factor of the silicon nitride ceramic material is remarkably reduced; the silicon nitride composite ceramic produced by hot-pressing sintering has the characteristics of good self-lubricating and tribological properties and can meet the using demands in actual engineering.

Owner:SHAANXI UNIV OF SCI & TECH

Skin-care sunblock product for infants

InactiveCN105055249AHigh affinityImprove microcirculationCosmetic preparationsToilet preparations1,3-PropanediolDimethyl siloxane

The invention provides a skin-care sunblock product for infants. The skin-care sunblock product comprises an A phase, a B phase, a C phase and a D phase. The A phase is composed of cetostearyl alcohol olive oil acid ester, cetostearyl alcohol, glyceryl stearate, squalane, simmondsia chinensis seed oil, isohexadecane, nano-zinc oxide, ethylhexyl methoxycinnamate and polydimethylsiloxane. The B phase is composed of water, glycerol, 1,3-propylene glycol, butanediol and EDTA disodium. The C phase is emulgator polyacrylate-13, polyisobutene and polysorbate-20. The D phase is composed of vitamin E, phenoxyethanol, 1,2-octylene glycol and plant desensitizer. The skin-care sunblock product for infants is capable of protecting the delicate skin of the infants and protecting the infants against sunburn, good in moisturizing effect, safer and healthier.

Owner:YANGZHOU ZHONGHUI BIOTECH

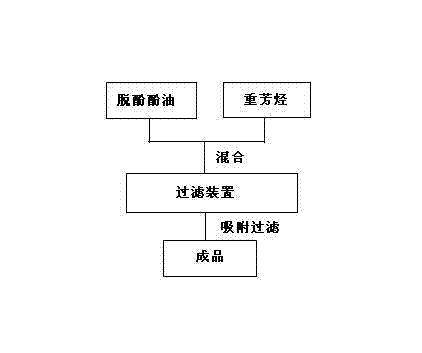

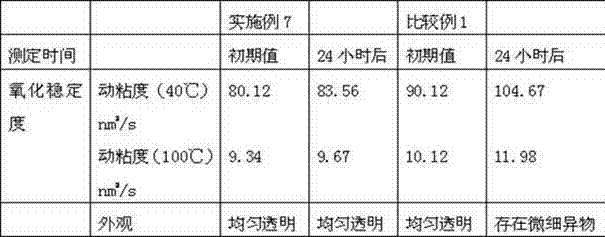

Fuel oil

InactiveCN103589466AGuaranteed not to cokeNo dustLiquid carbonaceous fuelsFuel oilOxidation stability

The invention discloses a fuel oil, which comprises dephenolized phenol oil and heavy aromatics. The invention applies dephenolized phenol oil in the field of coal chemical industry to fuel oil and utilizes the characteristic of high blending performance of the dephenolized phenol oil to prepare fuel oil with low production cost, high oxidation stability, low benzene content and standard viscosity. As the dephenolized phenol oil has wide and adequate source, the obtained fuel oil is easy to prepare, so as to solve the existing condition of the lack of fuel oil.

Owner:上海烨燃石油化工有限公司

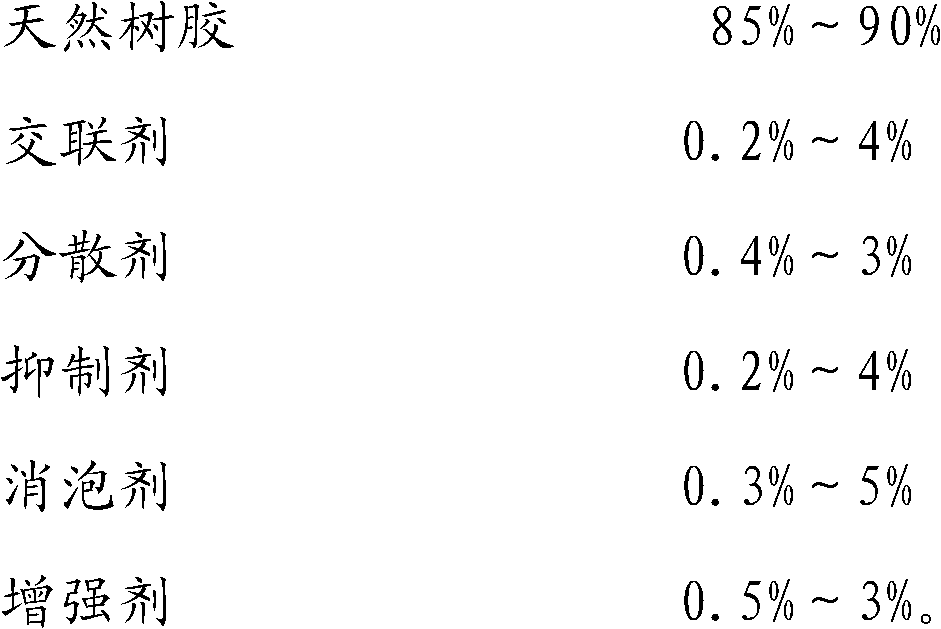

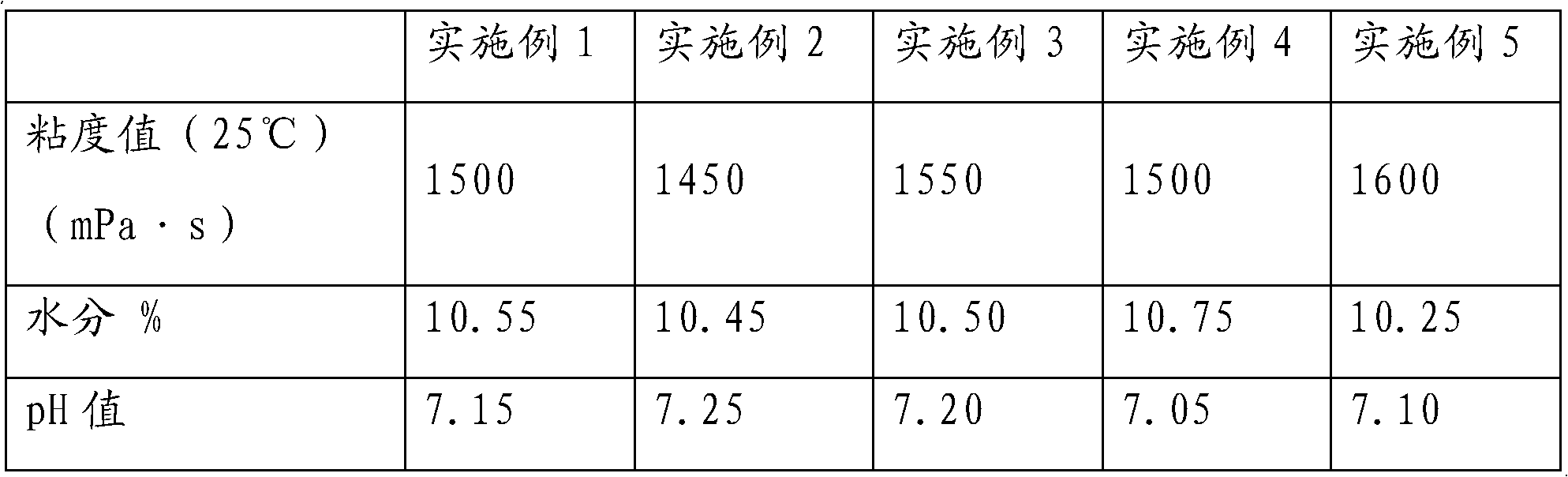

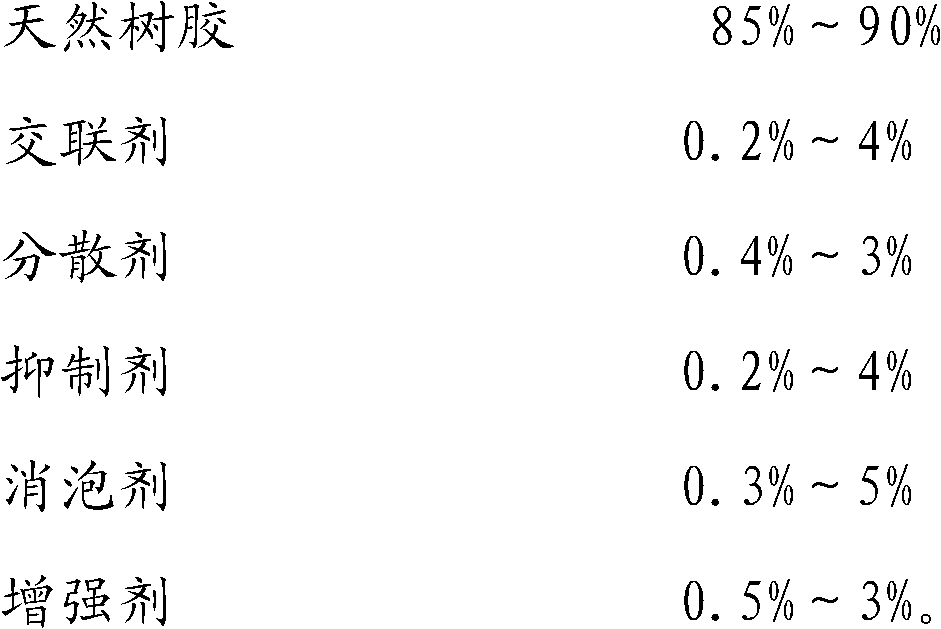

Natural gum adhesive for ecological restoration and application thereof

ActiveCN102533275AStrong environmental affinityGood water solubilityAgriculture tools and machinesOther chemical processesDefoamerChemistry

The invention discloses a natural gum adhesive for ecological restoration and an application thereof. The natural gum adhesive comprises components of the following mass percentage: 85-90 percent of natural gum, 0.2-4 percent of cross-linking agent, 0.4-3 percent of dispersing agent, 0.2-4 percent of inhibitor, 0.3-5 percent of defoamer and 0.5-3 percent of reinforcing agent. The main component adopts the natural gum material which can be degraded completely has strong affinity to the environment; the adhesive can be used safely, and no impact can be caused on the working environment and the human health; and the adhesive also has high bonding strength, and the materials has high affinity. The bonding strength can be gradually enhanced along with reduction of the moisture, is lasting after dehydration, and is conducive to adhesion of slurry to a slope.

Owner:北京中盛益世环保科技有限公司

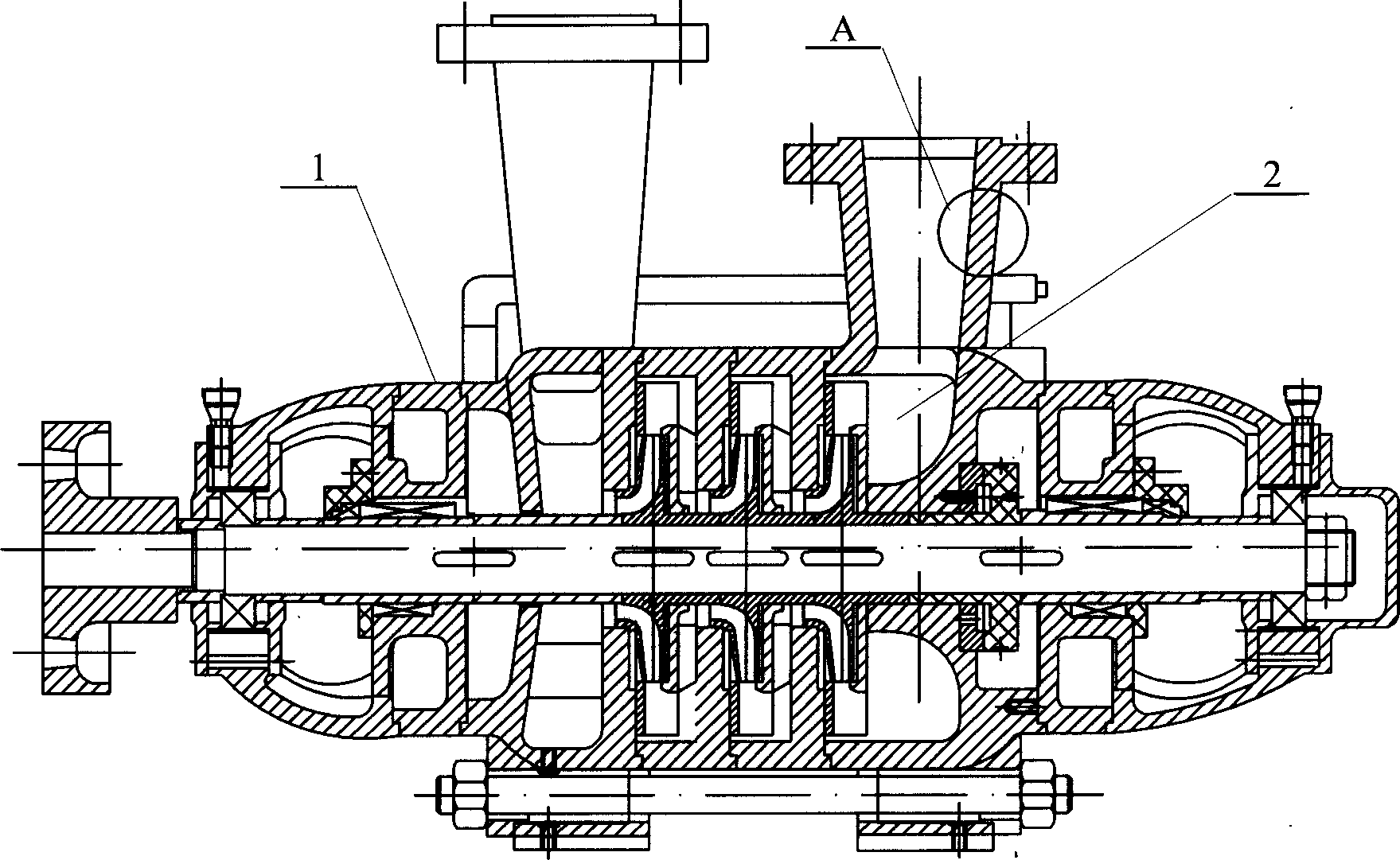

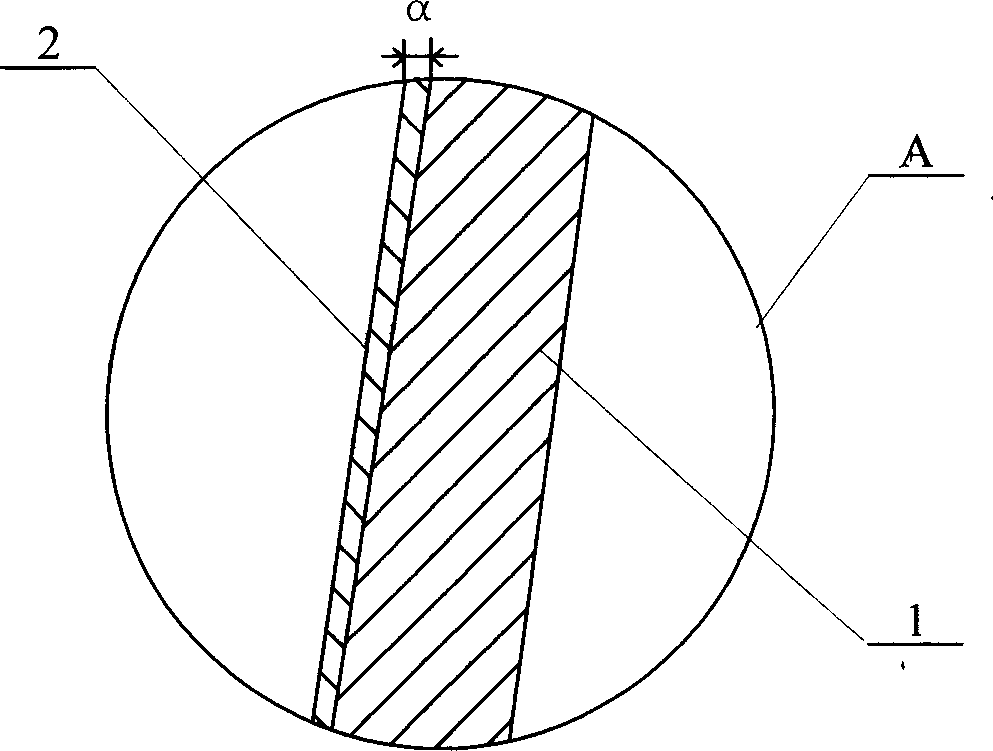

Pump with polytetrafluoroethylene or F46 inner coating and method for processing the coating

InactiveCN1828062ANon-stickLubriciousSpecific fluid pumpsPump componentsCoated surfaceMaterials science

The invention relates to a pump with politef or F46 coat and relative producing method, which solve the problem for plating politef inside the pump, with high producing cost. The thickness of politef or F46 inner coat (2) of pump flow section (a) is 0.1-50um. The producing method comprises: sintering the pump plated with politef or F46 coat in 280-350Deg. C for 2-4 hours. The invention has the advantages as thin coat and better resistance. It has simple process, smooth surface and small friction parameter.

Owner:康庆刚

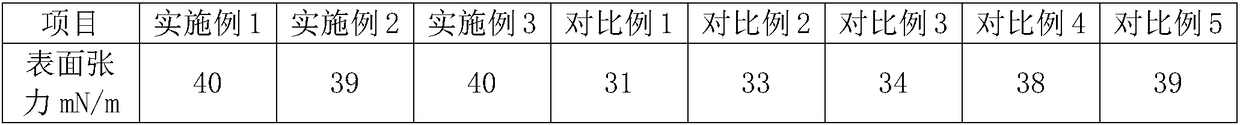

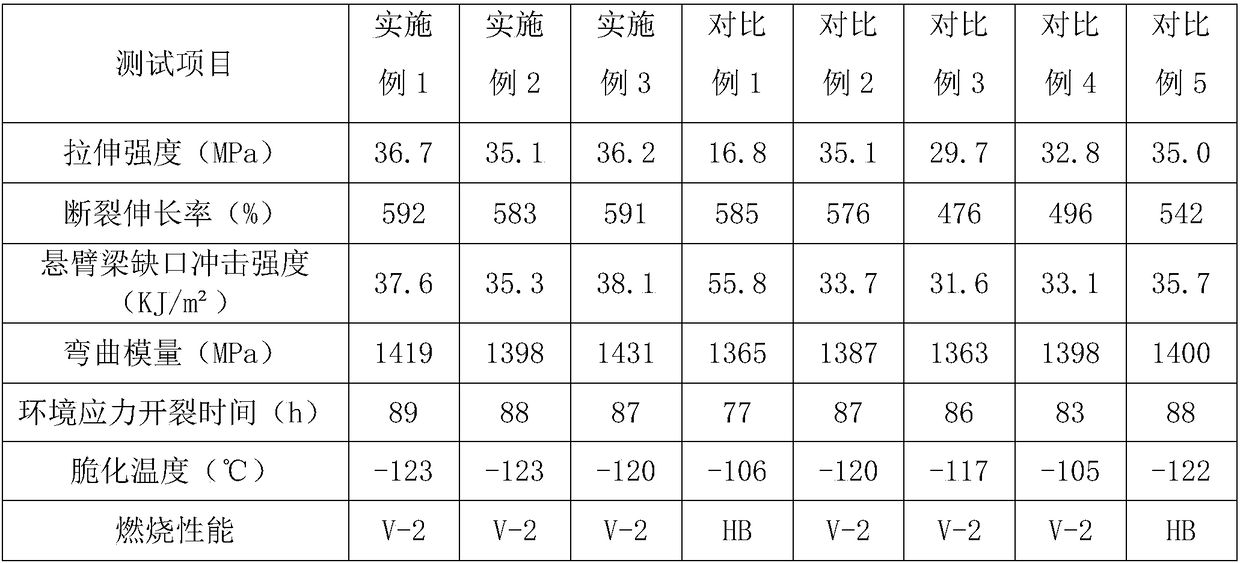

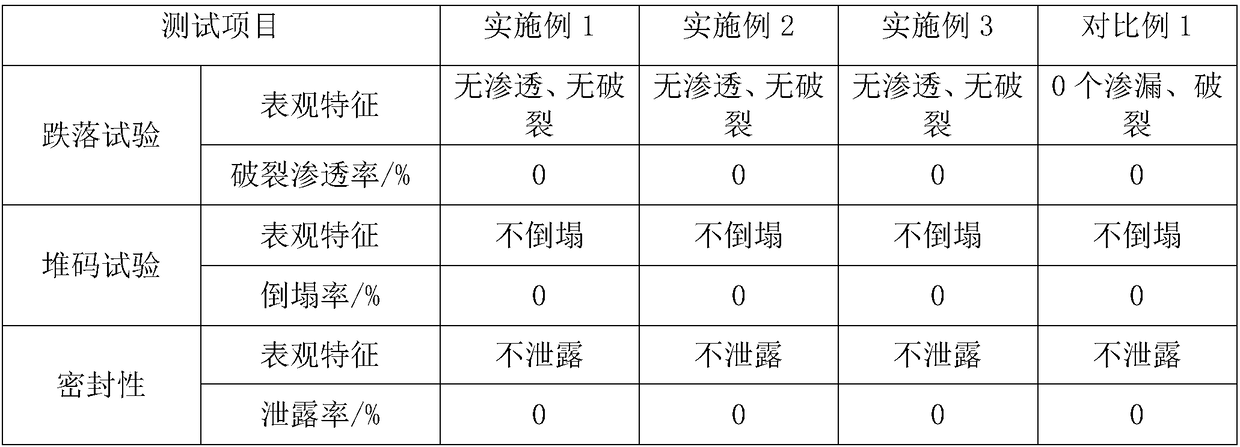

Cold-resistant plastic bucket and preparation method thereof

ActiveCN108822385AImprove cold resistanceImprove heat resistanceLinear low-density polyethylenePolymer science

The invention discloses a cold-resistant plastic bucket and a preparation method thereof, and belongs to the technical field of a plastic packaging container. The cold-resistant plastic bucket is characterized in that the cold-resistant plastic bucket is prepared from the components in parts by weight: 60 to 80 parts of high-density polyethylene, 15 to 25 parts of linear low-density polyethylene,10 to 20 parts of maleic anhydride grafted high-density polyethylene, 5 to 7 parts of high-polymerization-degree polyvinyl chloride, 6 to 8 parts of ethylene-vinyl acetate copolymer, 0.5 to 1.0 part of ultraviolet absorption agent, 1 to 1.5 parts of antioxidant, 2 to 3 parts of plasticizer and 5 to 7 parts of silica power; the high-density polyethylene has a density of 0.936 g / cm<3> and a melt index of 1.4 g / 10 min; the linear low-density polyethylene has a density of 0.920 g / cm<3> and a melt index of 1.0 g / 10 min. The invention reaches the technical effect of enabling the polyethylene plasticbucket to also have excellent printing performance when having cold resistance.

Owner:青岛邦德化工有限公司

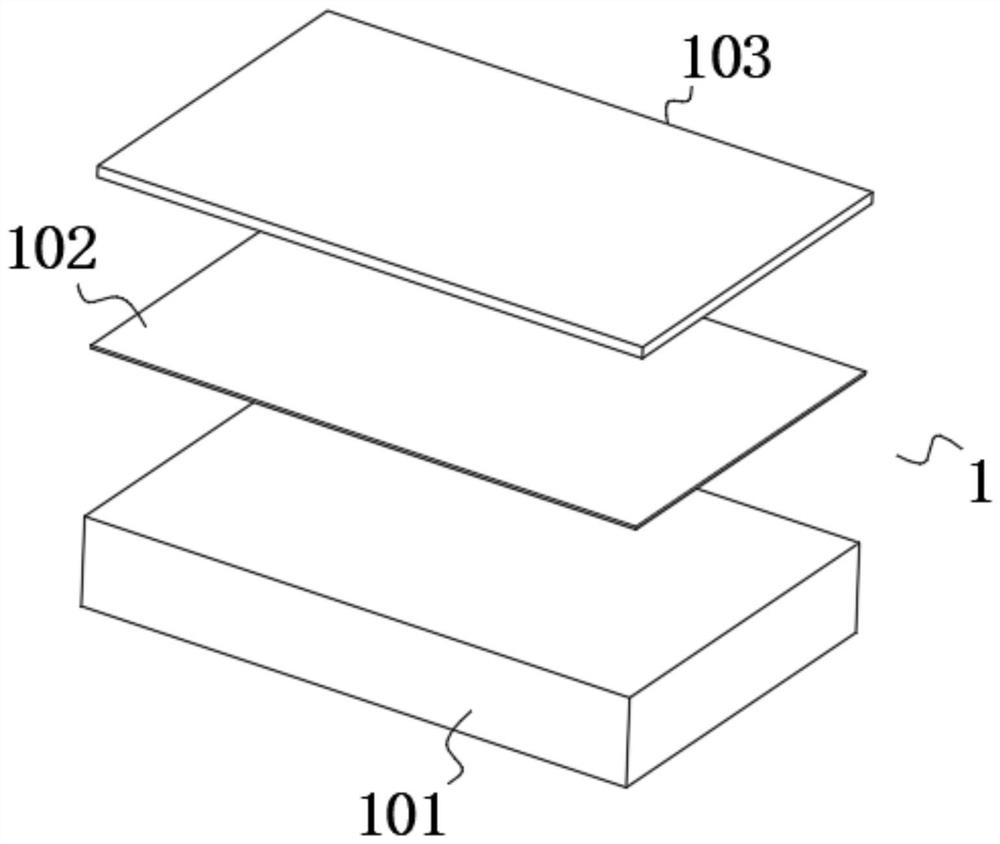

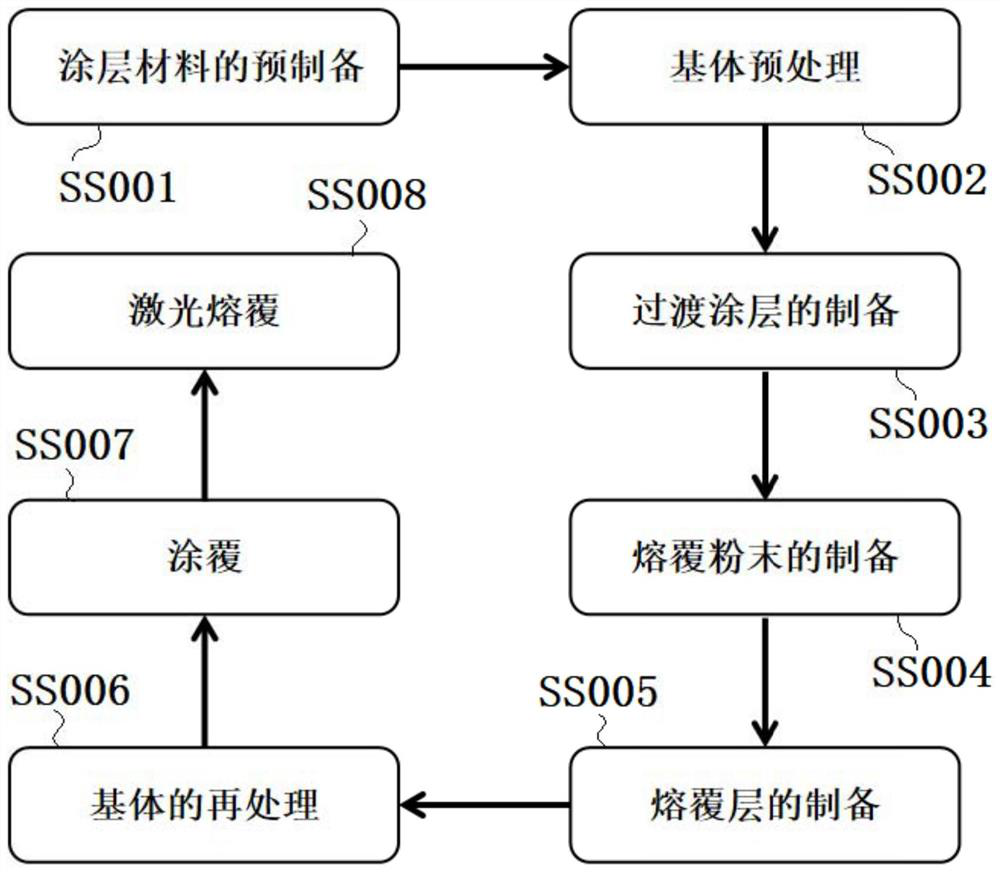

Magnesium-aluminum alloy surface laser cladding self-lubricating coating and construction method thereof

PendingCN112063951AReduce thermal stressEnhance strain coordinationMolten spray coatingSuperimposed coating processThermal conductivityAlloy surface

The invention discloses a magnesium-aluminum alloy surface laser cladding self-lubricating coating and a construction method thereof, and relates to the technical field of magnesium-aluminum alloy processing. The magnesium-aluminum alloy surface laser cladding self-lubricating coating comprises a coated body, the coated body comprises a base body; and a transition coating and a cladding layer arecorrespondingly arranged on the surface of the base body from bottom to top. The construction method of the magnesium-aluminum alloy surface laser cladding self-lubricating coating comprises the following steps of SS001, prefabrication of coating materials and preparation of Ni-based alloy powder, TiB2 alloy powder and MoS2 alloy powder, and the weight percentage of the Ni-based alloy powder to the TiB2 alloy powder is 90% to 95%. Through the design of the transition coating, direct laser coating of a traditional magnesium-aluminum alloy is changed into indirect laser coating, during processing, through the design of the transition layer, the stress difference between a cladding layer and the base body can be effectively reduced, the heat conductivity and the thermal expansion coefficientof the cladding layer and the base body are close, and therefore thermal stress caused by the temperature gradient is reduced.

Owner:ZHANGJIAGANG RUNSHENG SCI & TECH MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com