Emulsifying-type linear cutting operating fluid and uses thereof

A wire cutting and working fluid technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problem of short service life of the emulsified wire EDM working fluid, and meet the requirements of high-speed wire EDM processing. , good technical effect, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

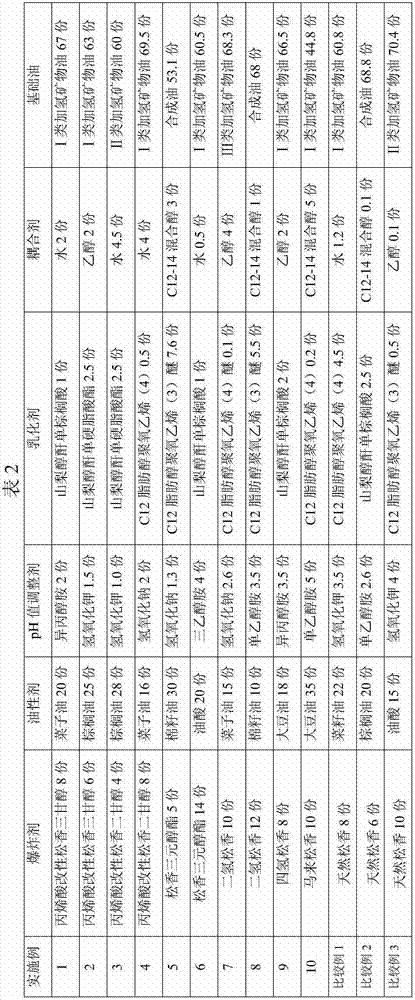

[0032] The components and contents of emulsified wire cutting working fluid are shown in Table 2.

Embodiment 12

[0037] The emulsified wire-cutting working fluids of [Examples 1-10] were configured into oil-in-water emulsions with deionized water to evaluate their performance. The concentration of the emulsion is 5% by weight, the volume of the liquid tank is 200 liters, the processing current is 2A, the processing voltage is 75V, and the electrode wire is molybdenum wire. The properties are shown in Table 3.

[0038] table 3

[0039]

[0040] Note: The chip removal performance is divided into four grades, and the grade description is shown in Table 1, among which grade B is the state recognized in the actual processing of the factory.

[0041] It can be seen from Table 3 that the emulsified wire-cutting working fluid of the present invention can be used to process bearing steel and red copper with different thicknesses, has excellent chip removal performance, lubricating performance and cooling performance, and has a long service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com