Patents

Literature

75results about How to "Play a role in diffusion strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leadless copper base high temperature self lubricating composite material

InactiveCN1718795AImprove toughnessImprove heat resistanceChemical vapor deposition coatingChemical compositionGraphite

A high-temp self-lubricating non-Pb Cu-base composition has a chemical formula: Ni+C+Sn+Zn+MX+Fe+Cu, where MX is chosen from BN, Si3N4, SiC, Al2O3, TiN, TiC and Cr3 C2 and C is graphite and carbon fibres. It has anti-oxidizing, anti-corrosion and high-temp anti-wear characteristics.

Owner:合肥波林新材料股份有限公司

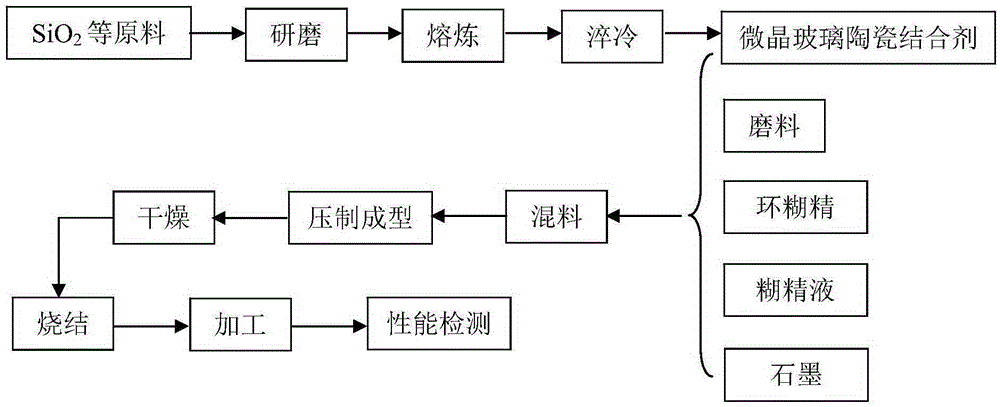

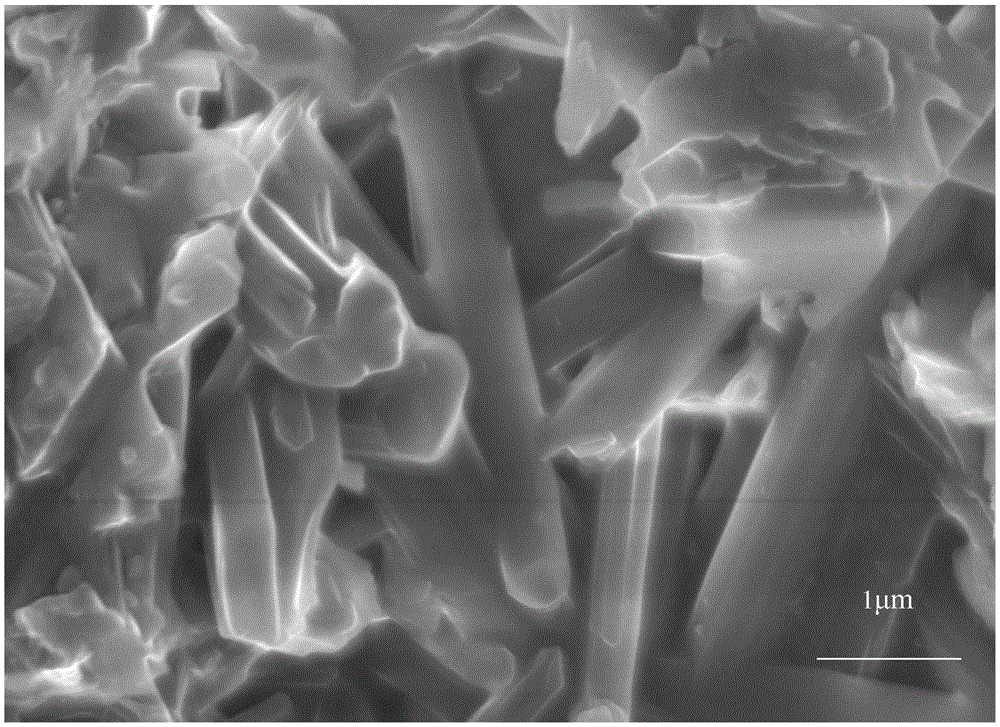

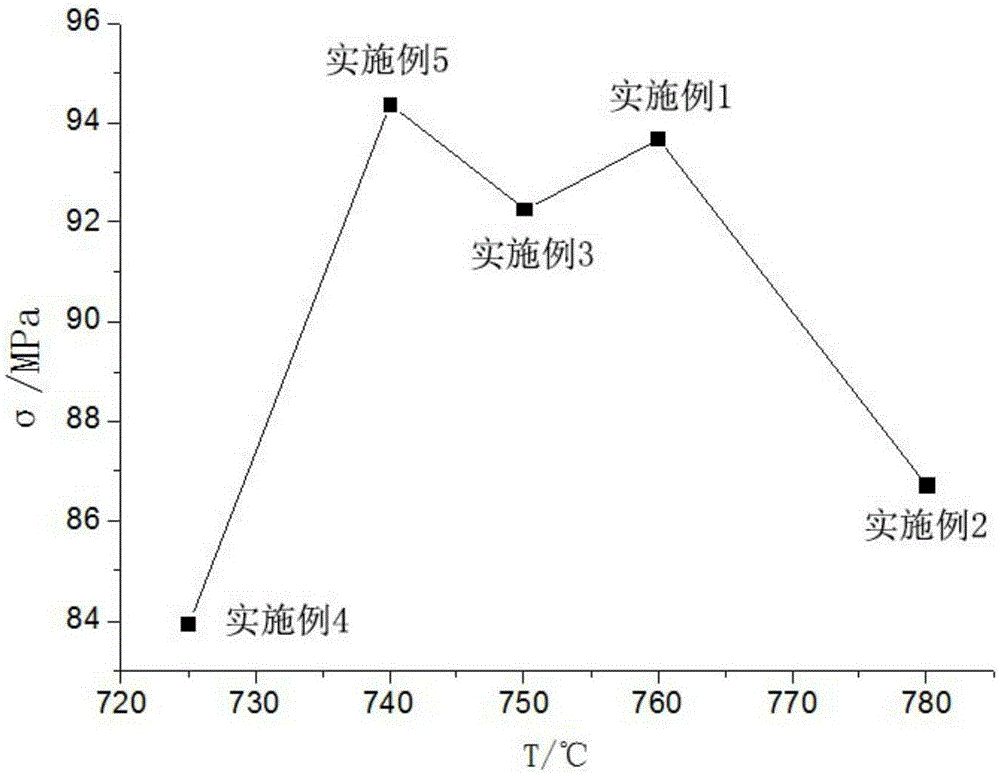

Microcrystalline glass ceramic binding agent, preparing method thereof, SG grinding wheel and preparing method thereof

ActiveCN105252435ASmall coefficient of thermal expansionLow crystallization temperatureAbrasion apparatusGrinding devicesTO-18Materials science

The invention discloses a microcrystalline glass ceramic binding agent, a preparing method thereof, an SG grinding wheel and a preparing method thereof. The binding agent is prepared from, by weight percentage, 40% to 65% of SiO2, 6% to 20% of Al2O3, 5% to 18% of Na2O, 0.5% to 5% of CaO, 3% to 10% of K2O, 8% to 35% of B2O3, 0.5% to 2% of MgO and 2% to 6% of TiO2. The microcrystalline glass ceramic binding agent is formed by reasonably selecting the raw materials, the scientific ratio is adopted, the binding agent has the beneficial effects of being low in thermal expansion coefficient and crystallization temperature and high in strength accordingly, the microcrystalline glass ceramic binding agent is suitable for being used as a binding agent of the SG grinding wheel, the firing temperature of the SG grinding wheel is greatly reduced, and the firing time of the SG grinding wheel is greatly shortened; and meanwhile the work efficiency and the machining accuracy of the SG grinding wheel are improved, grinding heat is reduced, and the service life of the grinding wheel is prolonged.

Owner:白鸽磨料磨具有限公司

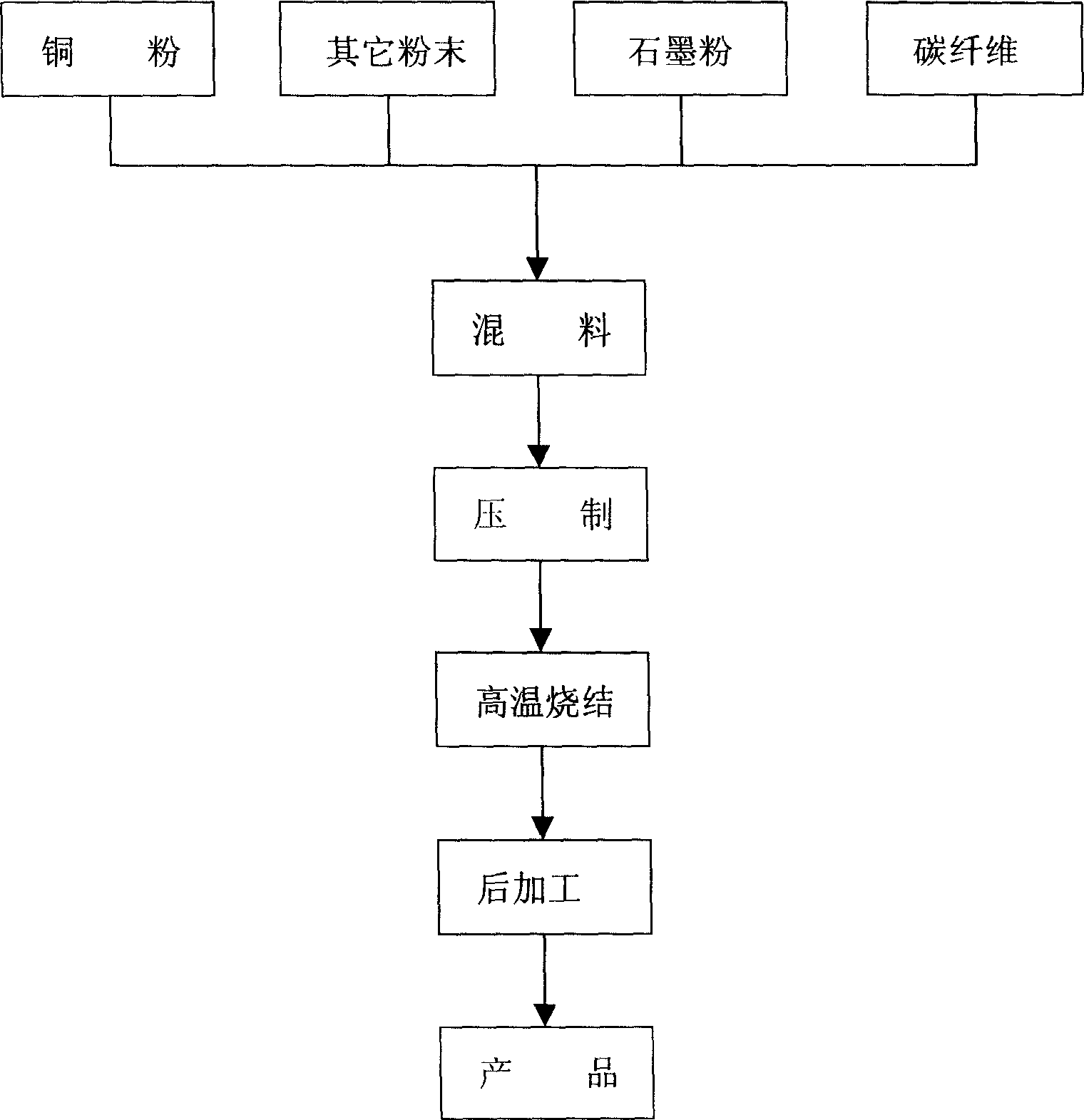

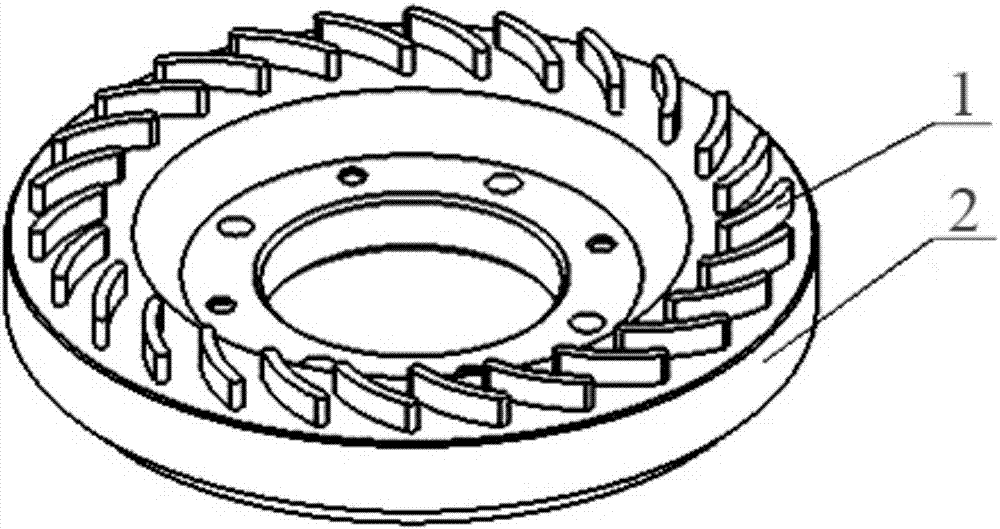

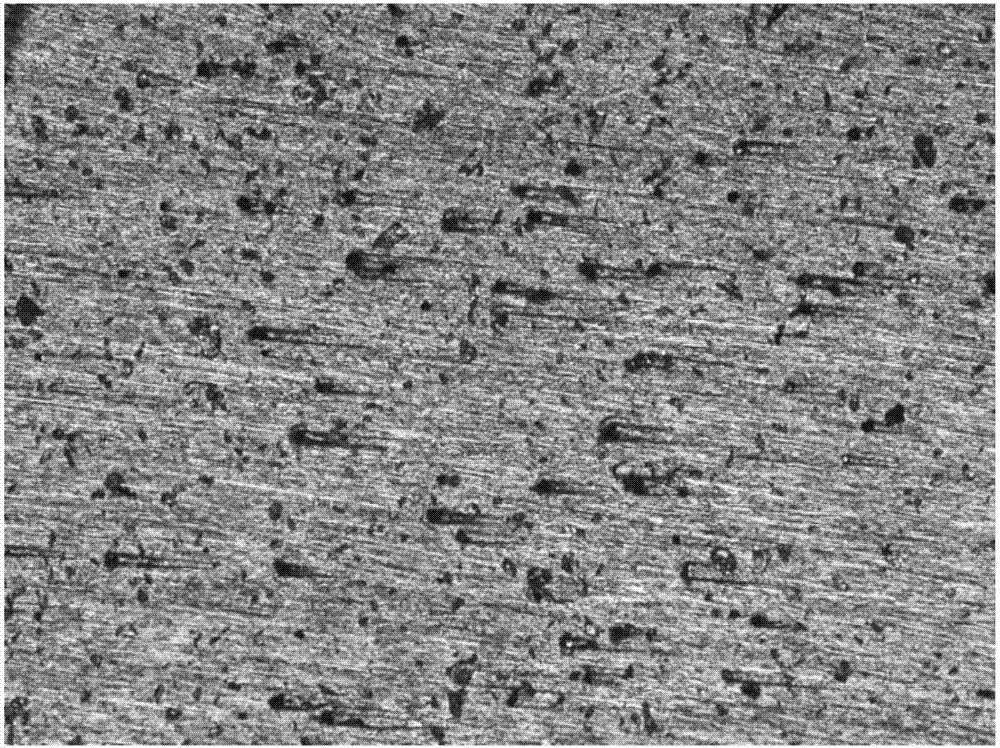

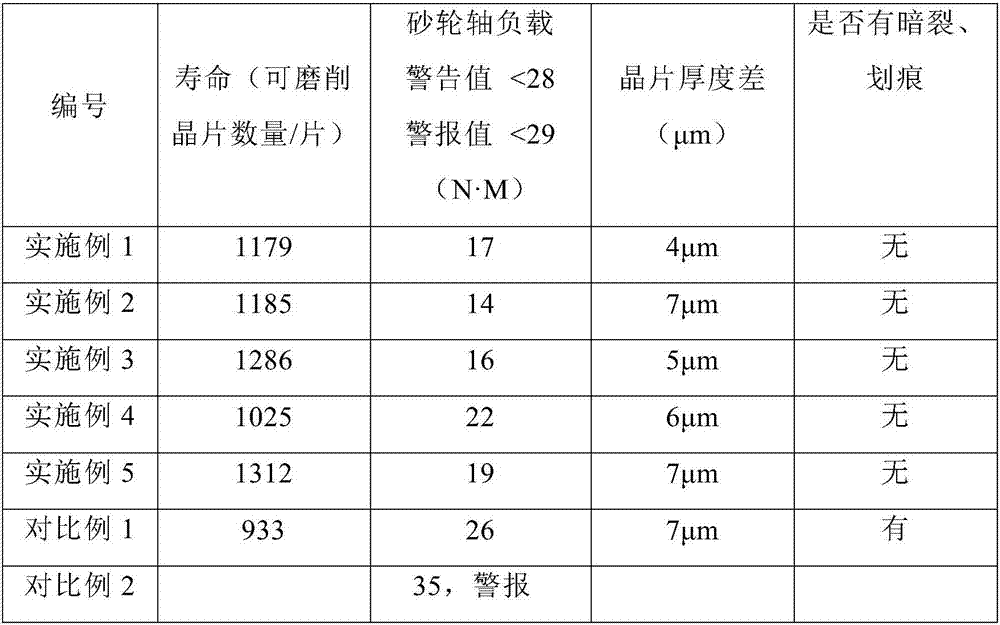

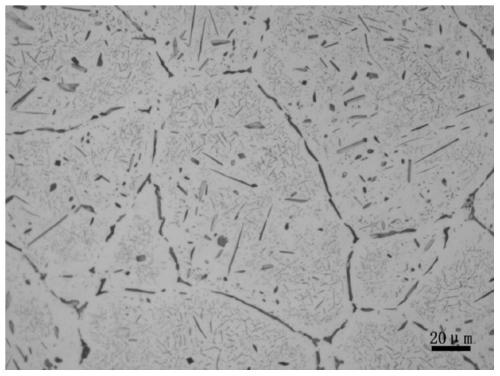

Metallic bond, diamond grinding wheel prepared through bond and preparation method of diamond grinding wheel

The invention relates to a metallic bond, a diamond grinding wheel prepared through the bond and a preparation method of the diamond grinding wheel. The metallic bond comprises, by weight percent, 95%-99% of copper-tin prealloyed powder, 0.5%-3% of graphite powder and 0.5%-2% of nanometer alpha-Al2O3. The copper-tin prealloyed powder, the graphite powder, the nanometer alpha-Al2O3 and diamond are taken according to a certain proportion, procedures of burdening and material mixing, pelletizing, compression, sintering and aftertreatment are carried out in sequence, and tool bits can be prepared. The multiple tool bits are arranged on a matrix at equal distance in the circumferential direction, the cambered surfaces of the tool bits are perpendicular to the matrix, and the diamond grinding wheel is prepared. The above tool bits are uniform in ingredient and good in density, diamond distribution is uniform, and the control effect of the metallic bond on the diamond is good. The grinding wheel has the beneficial effects of being good in ground workpiece surface quality, free of dark cracks and scratches, sharp in grinding and long in service life, facilitating large-scale production and the like and is especially suitable for producing sapphire wafers with the thinning thickness ranging from 100 micrometers to 700 micrometers.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

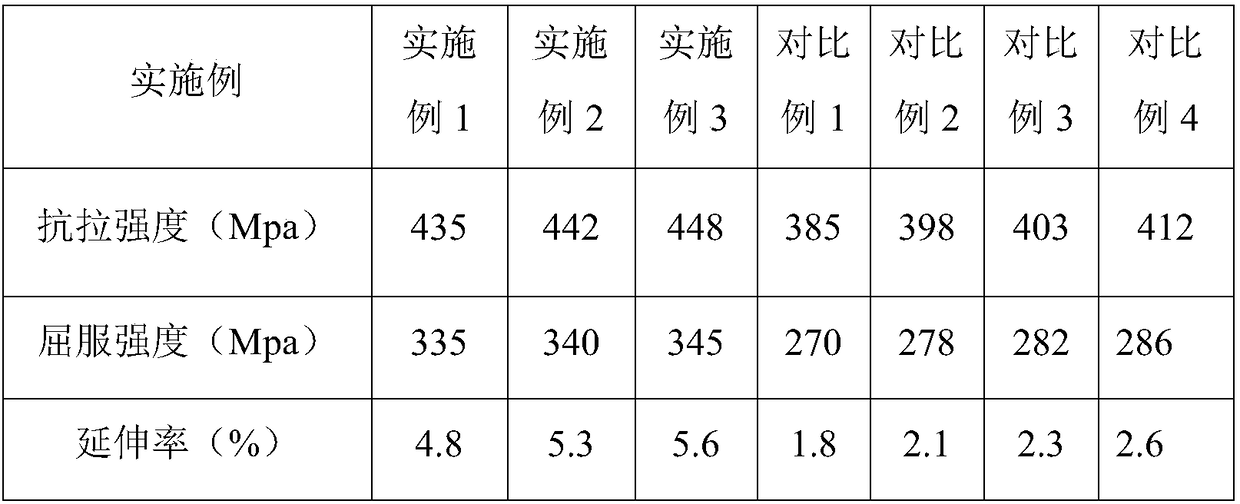

High-strength steel plate for ocean engineering and production method thereof

InactiveCN105586537APlay a role in diffusion strengtheningImprove low temperature toughnessQuenchingMechanical property

The invention discloses a high-strength steel plate for ocean engineering and a production method thereof. The production method comprises the working procedures of smelting, continuous casting, heating, rolling, heat stacking and heat treatment, wherein the molten steel obtained in the smelting procedure comprises the following chemical ingredients with contents in percentage by mass: 0.05-0.09% of C, 0.10-0.30% of Si, 1.1-1.35% of Mn, not greater than 0.010% of P, not greater than 0.003% of S, 0.15-0.4% of Ni, 0.15-0.35% of Cr, 0.10-0.30% of Mo, 0.020-0.050% of Nb, 0.03-0.05% of V, 0.020-0.050% of TAl, and balance Fe and inevitable impurities; a quenching and tempering process is adopted in the heat treatment procedure; during the quenching process, a heating temperature is 880-910 DEG C, and a total heating time is PLC +(20-40) minutes; and during the tempering process, a heating temperature is 580-620 DEG C, a total heating time is 1.5-2 minutes per millimetre, and air cooling is carried out after discharge. According to the method disclosed by the invention, through adjustment and optimization for the proportion of alloy elements in the steel plate, and quenching and low-temperature short-time tempering, good mechanical properties of the steel plate can be guaranteed under a low-carbon-equivalent condition, and the steel plate is enabled to have good structure, comprehensive property and welding property.

Owner:WUYANG IRON & STEEL

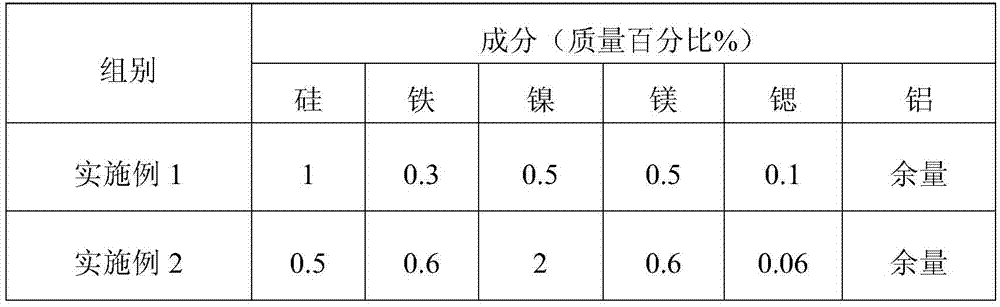

Manufacturing method for aviation 625 MPa grade large-size aluminum alloy pre-stretching plate

The invention discloses a manufacturing method for an aviation 625 MPa grade large-size aluminum alloy pre-stretching plate and relates to the field of manufacturing methods for aluminum alloy pre-stretching plates. Through the manufacturing method, the technical problem that mechanical properties of existing aluminum alloy plates cannot reach the requirements of application to specific wing wallboards is solved. The manufacturing method for the aviation 625 MPa grade large-size aluminum alloy pre-stretching plate comprises the steps that raw materials are weighed according to the mass percentof elements, and the plate is obtained after smelting, casting, homogenizing annealing, hot rolling, solution treatment, pre-stretching and three-level aging treatment. The ultrahigh-strength alloy large-size wide plate prepared with the manufacturing method is the large-size pre-stretching plate which is flat in plate face, uniform in thickness, good in surface and stable in performance. The aviation 625 MPa grade large-size aluminum alloy pre-stretching plate prepared with the manufacturing method is widely applied to the fields of spaceflight, aviation and military and civil large aircrafts.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Novel high-strength corrosion-resistant rare earth aluminum alloy material and preparation method

The invention provides a novel high-strength corrosion-resistant rare earth aluminum alloy material and a preparation method. Based on a high-strength Al-Zn-Mg alloy, a proper amount of elements of Cu, rare earth Ce, rare earth Sc and rare earth Er are added, and the novel Al-Zn-Mg-Cu-Ce-Sc-Er aluminum alloy material is prepared. The material has the beneficial effects of being high in strength, good in plasticity and toughness, resistant to corrosion, good in fatigue resistance and the like. The material is a structural material which can be widely applied to aviation, spaceflight, ships and warships and means of conveyance. The production and preparation method of the material is simple and easy to practice, the processing technology of the material is easy to control, raw materials are sufficient and easy to obtain, the production cost is low, and the material has very wide production and application prospects.

Owner:HEFEI UNIV OF TECH

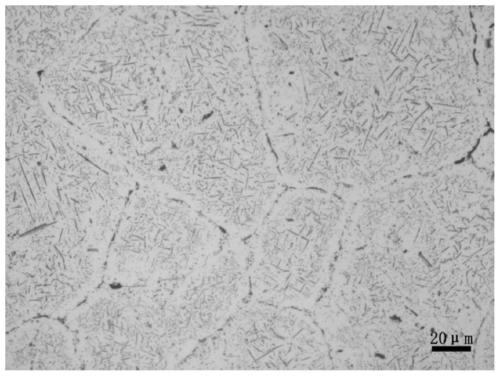

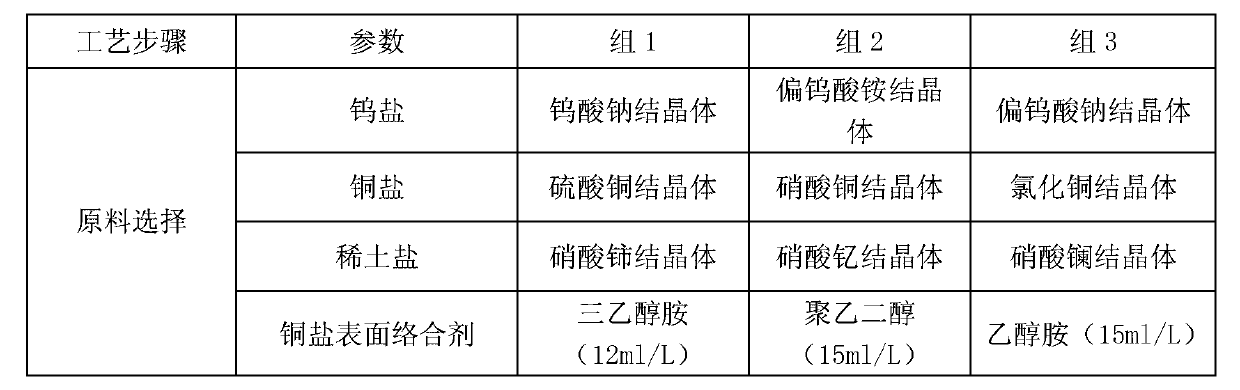

Rare-earth-oxide-doped W-Cu composite material and preparation method thereof

The invention provides a W-Cu composite material which is characterized by comprising the following components in percentage by mass: 5-30 wt% of Cu, 0.5-2 wt% of rare-earth oxide and the balance of W. The invention also provides a preparation method of the W-Cu composite material. The density of the composite material is up to 99.2%, the density uniformized coefficient of different positions is less than 5%, the room temperature tensile strength is greater than 900 MPa, the elongation percentage is greater than 10%, and the fracture toughness K1C is greater than 28 MPa.m<1 / 2>; and thus, the composite material satisfies the performance requirements of electric contact materials and liner materials for complete density, structure uniformity, ablation resistance and the like of the W-Cu alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Special steel for hardware tool and preparation method thereof

The invention discloses a special steel for a hardware tool and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.50-0.60% of C, 0.17-0.37% of Si, 0.20-0.50% of Mn, 0.008-0.020% of P, 0.001-0.005% of S, 0.25-0.60% of Cr, 0.20-0.35% of Ni, 0.07-0.25% of Cu, 0.010-0.030% of Ti, and the rest amount of iron and inevitable impurities. The preparation method is performed by a general clean steel process, and comprises the steps of steel smelting, LF furnace refining, continuous casting, casting blank heating, rolling, cooling and reeling. All alloy element components in the steel are designed to properly increase the carbon content and decrease the content of such noble metals as Ni and Cr; the process of smelting and rolling is controlled to obtain the special steel for the hardware tool with high-hardness surface and low-hardness-toughness heart material matrix; and the steel can satisfy the performance needed by the hardware tool and the target of optical economic benefit.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

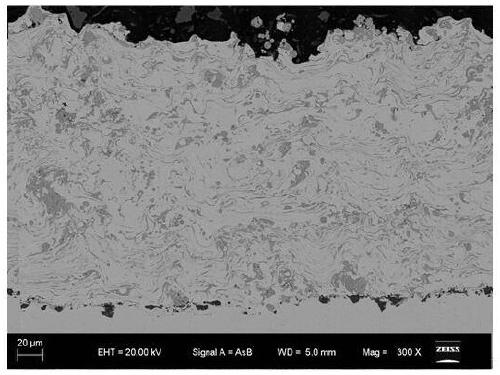

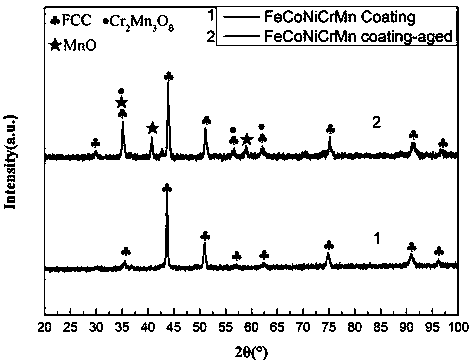

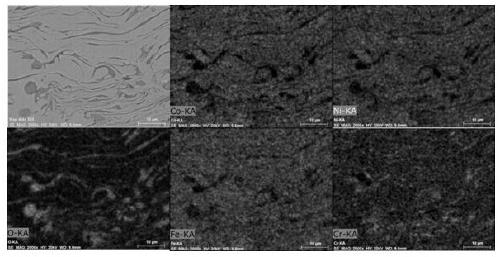

FeCoNiCrMn high-entropy alloy and method for preparing wear-resisting coating through alloy

ActiveCN109930053AImprove solubilityImprove bindingMolten spray coatingHigh entropy alloysWear resistance

The invention discloses a FeCoNiCrMn high-entropy alloy and a method for preparing a wear-resisting coating through the alloy. Elements Fe, Co, Ni, Cr and Mn are adopted as main elements, and an alloysystem is formed according to the equal atomic ratio or the approximate equal atomic ratio. The preparation method of the wear-resisting coating of the FeCoNiCrMn high-entropy alloy is provided. FeCoNiCrMn spherical high-entropy alloy powder is prepared through a gas atomization method, and the wear-resisting coating is prepared on the surface of a stainless steel matrix through an atmosphere plasma spraying process. Spraying parameters are adjusted, the microstructure of the coating is optimized to the largest degree, and the spraying parameters with the optimal coating wear resistance are obtained. The prepared FeCoNiCrMn high-entropy alloy is good in coating combination, compact in structure and extremely good in wear resistance.

Owner:扬州睿德石油机械有限公司 +1

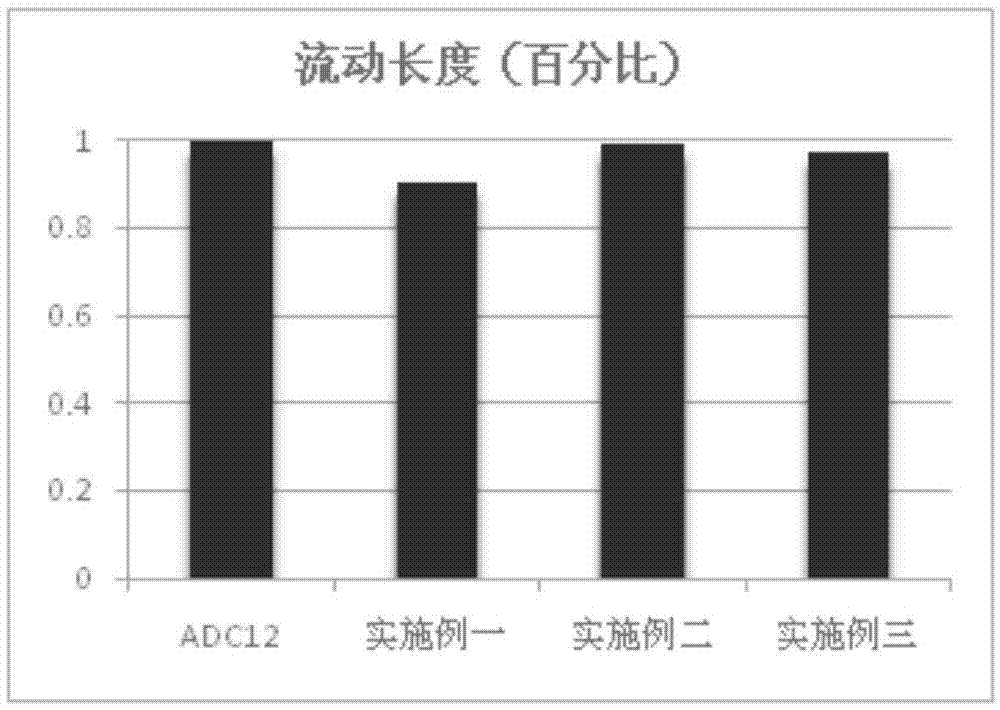

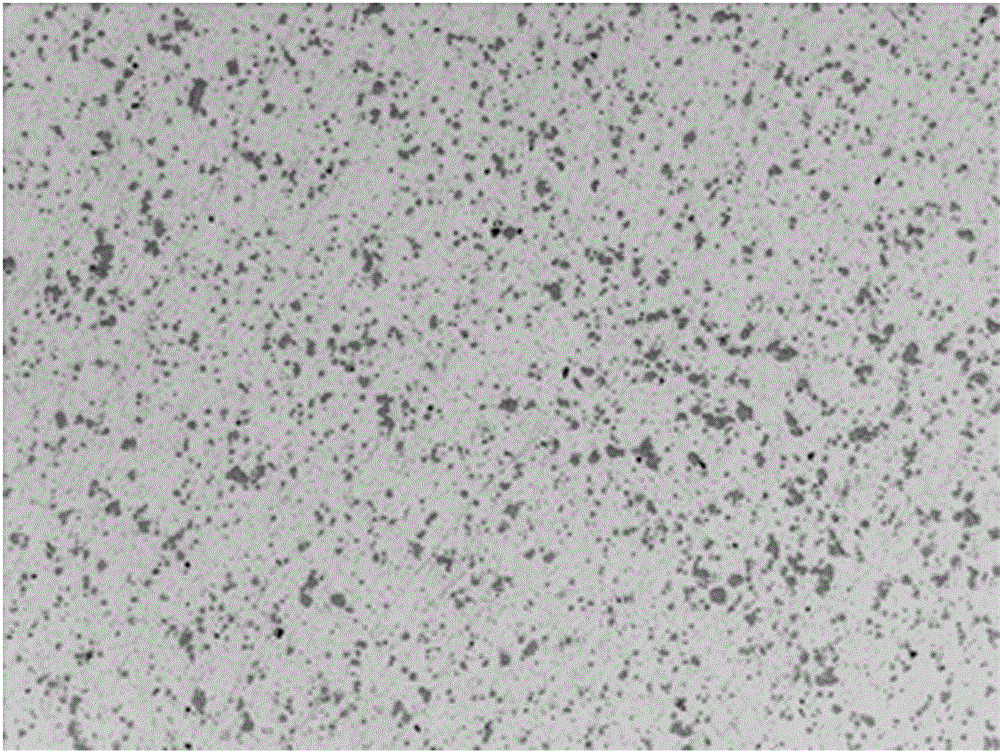

High-thermal-conductivity die-casting aluminum alloy and preparing method thereof

The invention provides a high-thermal-conductivity die-casting aluminum alloy. The high-thermal-conductivity die-casting aluminum alloy comprises, by mass percentage, 0.05%-1.0% of silicon, 0.3%-1. 3% of iron, 0.2%-2.0% of nickel, 0.1%-1.2% of magnesium, 0.001%-0.15% of strontium and the balance aluminum and inevitable impurities, wherein the mass percentage of the impurities is smaller than 0.2%. The invention further provides a preparing method of the high-thermal-conductivity die-casting aluminum alloy. The preparing method comprises the steps that at different heating temperatures, the aluminum and magnesium, an aluminum silicon intermediate alloy, a ferro-aluminium intermediate alloy, a nickel-aluminum intermediate alloy and an aluminum strontium intermediate alloy are sequentially fused to obtain aluminum, silicon, iron, nickel, magnesium and strontium fusion; then refined treatment and slag removal treatment are carried out to obtain an aluminum alloy solution; and the temperature of the aluminum alloy solution is adjusted to be 680 DEG C to 720 DEG C, and then casting can be carried out. The high-thermal-conductivity die-casting aluminum alloy has the excellent casting performance and has the higher heat conductivity coefficient.

Owner:ZTE CORP

Wear-resisting and high-hardness flux core wire

InactiveCN107252994AHigh hardnessHigh strengthWelding/cutting media/materialsSoldering mediaSilicon alloyRare earth

The invention discloses a wear-resisting and high-hardness flux core wire. The wear-resisting and high-hardness flux core wire is composed of a flux core and a low-carbon cold-rolling steel tape sheath wrapped on the outer side of the flux core. The flux core comprises, by weight, 20-25 parts of low-carbon ferrochromium, 1.5-3 parts of titanium powder, 1-2 parts of nickel powder, 5-8 parts of calcium-silicon alloys, 2-4 parts of magnesium-aluminum alloys, 3-5 parts of electrolytic manganese, 1-2 parts of ferromolybdenum, 2.5-4 parts of ferroniobium, 1-2 parts of ferrovanadium, 3-5 parts of rare earth iron alloys, 3-5 parts of carbonate, 3-4 parts of graphite, 120-150 parts of iron powder, 0.5-1.5 parts of tungsten powder and 2-4 parts of calcium fluoride. The wear-resisting and high-hardness flux core wire has good welding performance, deposited metal tissue is compact, air holes and cracks are avoided, combination with base metal is good, performance is stable, and deposited metal has good wear resistance, corrosion resistance, high hardness and other performance.

Owner:天长市通联焊业有限公司

Steel plate for pressure vessel with yield strength being 345 MPa stage and production method

InactiveCN106591703AGood lamellar tear resistanceImprove low temperature toughnessChemical compositionImpurity

The invention discloses a steel plate for a pressure vessel with the yield strength being the 345 MPa stage and a production method. The steel plate comprises chemical components including, by weight, 0.15%-0.18% of C, 0.15%-0.35% of Si, 1.40%-1.50% of Mn, not larger than 0.008% of P, not larger than 0.002% of S, 0.020%-0.040% of Al, 0.020%-0.035% of Nb, not larger than 0.003% of O and the balance Fe and inevitable impurities. The production method includes the heating process, the rolling process and the heat treatment process. According to the steel plate for the pressure vessel with the yield strength being the 345 MPa stage, the clean steel technology idea is adopted; the steel plate has the beneficial effects that the purity degree is high, and -10 DEG C low temperature impact toughness and plasticity mainly show that the extending rate is excellent, and the lamellar tearing resistance is excellent; and the steel for the pressure vessel can meet the requirement for developing to high plasticity and high toughness, and the steel plate can be widely used for the pressure vessel industry.

Owner:WUYANG IRON & STEEL

High-strength and heat-resistant aluminum alloy wire and preparation method thereof

ActiveCN104894437AThe technical difficulty of adding tungsten evenly plays a rolePlay a role in diffusion strengtheningMetal/alloy conductorsHeat resistanceRoom temperature

The invention discloses a high-strength and heat-resistant aluminum alloy wire and a preparation method thereof. The aluminum alloy wire comprises the composition by the mass percentage: 0.6-1.2% of Mg, 0.4-0.8% of Si, 3.0-7.0% of W, and the balance Al. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy liquid, atomizing the aluminum alloy liquid into a powder, screening the aluminum alloy powder, mixing a tungsten powder with the particle size of not more than 3 microns with the aluminum alloy powder, carrying out cold isostatic pressing on the mixed powder into a prefabricated blank, carrying out vacuum degassing, heating, hot-extruding into an aluminum alloy round rod, drawing into an aluminum alloy wire, and carrying out solid solution and aging treatment to obtain the high-strength and heat-resistant aluminum alloy wire. Tungsten is uniformly added into the aluminum alloy wire by adopting a powder hot extrusion method, the strength of the aluminum alloy wire is strengthened, the aluminum alloy wire has excellent room-temperature tensile mechanical properties, electrical conductivity and heat resistance, the room-temperature tensile strength is more than 320 MPa, the elongation rate is more than 9%, the electrical conductivity is more than 56%IACS, and after heat preservation for 1 h at the temperature of 250 DEG C, the tensile strength is more than 290 MPa and the tensile strength survival rate is more than 91%.

Owner:GUANGDONG SHINE CABLES

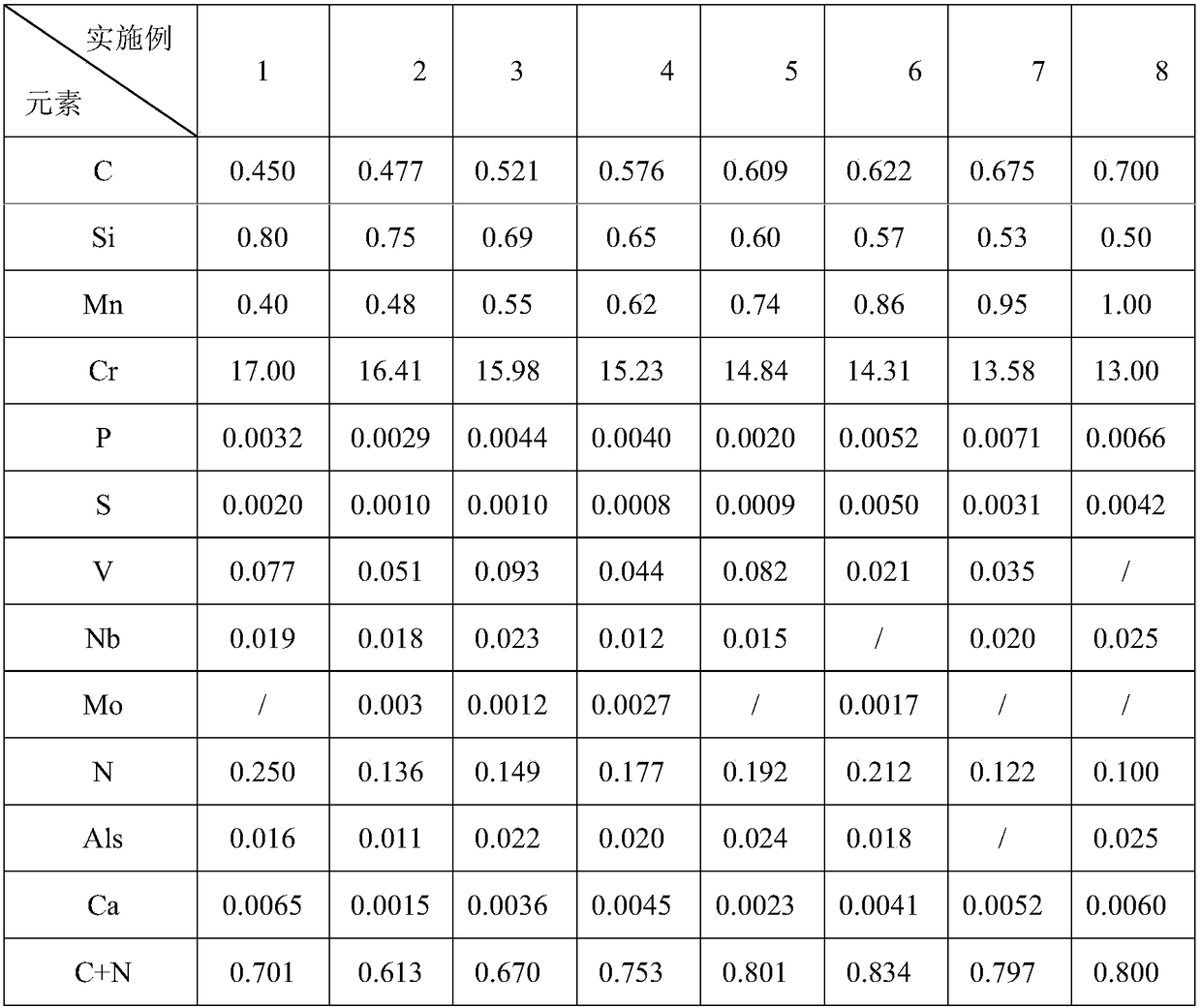

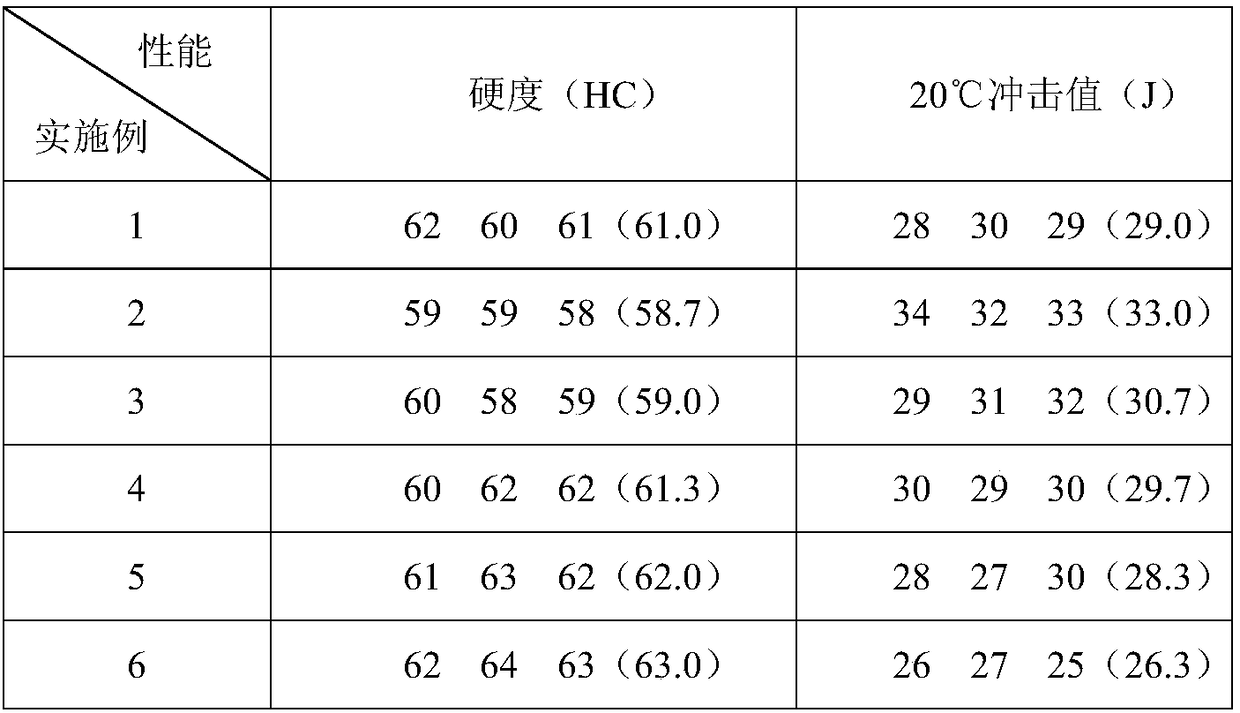

Nitrogen containing martensitic stainless steel for cutting tool and manufacturing method of nitrogen containing martensitic stainless steel

InactiveCN108277432AImprove corrosion resistanceImprove plasticityMartensitic stainless steelNitrogen

The invention relates to nitrogen containing martensitic stainless steel for a cutting tool and a manufacturing method of the nitrogen containing martensitic stainless steel. According to the technical scheme, chemical components of the nitrogen containing martensitic stainless steel for the cutting tool comprise 0.45wt%-0.70wt% of C, 13.0 wt%-17.0wt% of Cr, 0.10wt%-0.25wt% of N, 0.50wt%-0.80wt% of Si, 0.40wt%-1.0wt% of Mn, 0.0015wt%-0.0065wt% of Ca, not larger than 0.20wt% of V, not larger than 0.025wt% of Nb, not larger than 0.025wt% of Als, not larger than 0.03wt% of Mo, not larger than 0.008wt% of P, not larger than 0.005wt% of S and the balance Fe and inevitable elements. Meanwhile, the above chemical components meet the condition that C+N is 0.60-0.85wt%. The manufacturing method ofthe nitrogen containing martensitic stainless steel for the cutting tool comprises the steps of vacuum induction smelting, normal-pressure nitrogen increasing, casting, casting blank heating, rolling,quenching and tempering. The nitrogen containing martensitic stainless steel has the advantages that the alloy components are simple, the process is simple and convenient, the production cost is low,and large-scale production is easy. The manufactured nitrogen containing martensitic stainless steel for the cutting tool is high in hardness and good in toughness.

Owner:WUHAN UNIV OF SCI & TECH

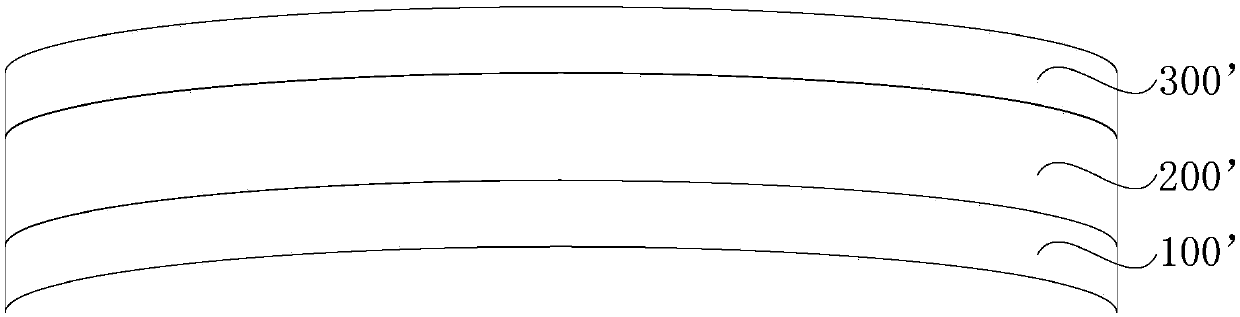

Flexible display panel, manufacturing method thereof and flexible display device

ActiveCN107819004AImprove bendabilityGood compatibilitySolid-state devicesSemiconductor/solid-state device manufacturingNano siliconOrganic light emitting device

The invention provides a flexible display panel, a manufacturing method thereof and a flexible display device. The flexible display panel comprises a first flexible substrate, an organic light emitting device and a second flexible substrate, wherein the organic light emitting device is arranged between the first flexible substrate and the second flexible substrate. The flexible display panel is characterized in that the first flexible substrate and / or the second flexible substrate is prepared from an acrylic material or an epoxy material and a plasticizing copolymerization monomer via copolymerization reaction, and the plasticizing copolymerization monomer is a nano-scale inorganic material. The plasticizing copolymerization monomer such as nano silicon nitride forms certain copolymerization modification with the acrylic material or the epoxy material, so that the abrasion resisting effect is enabled to be more obvious. Meanwhile, the inorganic nano silicon nitride can enhance the hardness of a hard coating film, the thickness of the hard coating film is reduced, and the bending performance of the flexible display panel is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

550MPa grade large-thickness S550Q steel plate, and production method thereof

The invention discloses a 550MPa grade large-thickness low-carbon bainite S550Q steel plate used for hydropower construction, and a production method thereof. The 550MPa grade large-thickness low-carbon bainite S550Q steel plate comprises, by mass, 0.14 to 0.17% of C, 0.20 to 0.40% of Si, 1.00 to 1.20% of Mn, 1.00 to 1.20% of Ni, P<=0.010%, S<=0.005%, 0.020 to 0.040% of Nb, 0.035 to 0.050% of V, 0.30 to 0.50% of Cr, 0.40 to 0.50% of Mo, 0.020 to 0.040% of Al in steel ingot preparation or 0.060 to 0.080% of Al in electro slag ingot preparation, and the balance Fe and inevitable impurities. The production method comprises steps such as heating, rolling, and heat treatment. The 550MPa grade large-thickness low-carbon bainite S550Q steel plate is high in purity, and excellent in mechanical properties; -20 DEG C and Z-direction section shrinkage of the parts at 1 / 4 thickness and 1 / 2 thickness are relatively high; the 550MPa grade large-thickness low-carbon bainite S550Q steel plate possesses excellent single bainite tissue, comprehensive performance, and welding performance.

Owner:WUYANG IRON & STEEL

Preparation method of high-strength and high-toughness high-entropy alloy

The invention discloses a preparation method of a high-strength and high-toughness high-entropy alloy, and relates to the technical field of alloy material production. The preparation method comprises the following specific steps that high-entropy alloy powder prepared from the components in atomic percent: 27%-30% of Mn, 8%-12% of Co, 8%-12% of Cr, 0.4%-1.3% of C and the balance of Fe is prepared; the high-entropy alloy powder is subjected to ball milling treatment and then pre-pressed, the pressure ranges from 300 MPa to 500 MPa, the pressure is maintained for 200 seconds to 300 seconds, and a pre-pressed block of the high-entropy alloy is obtained; the pre-pressing block is subjected to vacuum annealing, vacuum hot pressing sintering and cold rolling deformation; and the high-entropy alloy sheet subjected to cold rolling deformation is subjected to constraint carbon distribution treatment at the temperature of 400-550 DEG C, and free carbon elements are diffused. The C-containing unequal-atom FeMnCoCrC high-entropy alloy prepared through the method has excellent strength and plasticity combination, and meanwhile, the problems that a high-entropy alloy prepared through a traditional technology is uneven in component and unstable in structure are solved.

Owner:ZHONGBEI UNIV

6061 aluminum alloy and processing method thereof

The invention relates to a 6061 aluminum alloy and a processing method thereof, and belongs to the field of metal materials. The processing method comprises the following steps of smelting and refining raw materials of the 6061 aluminum alloy, casting, homogenizing and extruding. The 6061 aluminum alloy is prepared from the raw materials in percentage by weight 0.65 to 0.7 percent of Si, 0.25 to 0.35 percent of Fe, 0.18 to 0.23 percent of Cu, 0.1 to 0.15 percent of Mn, 0.85 to 0.9 percent of Mg, 0.15 to 0.25 percent of Cr, 0.08 to 0.12 percent of Ti, 0.15 to 0.2 percent of rare earth cerium tin, and the balance Al. The processing method is simple and easy to operate, and extrusion cracks of the 6061 aluminum alloy can be effectively reduced. The obtained 6061 aluminum alloy is good in quality and cannot produce cracks at the extrusion speed of 6m / min.

Owner:SHANDONG NANSHAN ALUMINUM +1

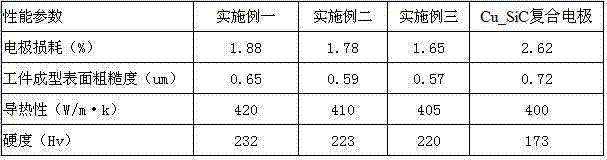

Composite material tool electrode for electrolytic deposition and electric spark and preparation method thereof

ActiveCN103878455AHigh specific heat capacityHigh hardnessElectrical-based machining electrodesMachined surfaceHardness

The invention discloses a composite material tool electrode for electrolytic deposition and electric spark and a preparation method of the composite material tool electrode, and belongs to the technical field of electrical discharge machining of electric spark. The composite material tool electrode for electrolytic deposition and electric spark is characterized by comprising, by weight, 16-18% of SiC particles, 14-16% of TiB2 particles, and the balance copper as a base body, and the SiC particles and the TiB2 particles are embedded in the base body. Due to the fact that the SiC particles and the TiB2 particles are added to the copper base body, compared with the method that only the SiC particles are added in the initial research stage, on the premise of not changing the total adding amount, the specific heat capacity of the tool electrode is improved by 10%, the coefficient of thermal expansion is lowered by 3%, the hardness is improved by 5%, and therefore the loss of the electrode under same electrical discharge machining parameters is lowered by 7%, and the roughness of a machined surface is lowered by 2%.

Owner:SHANDONG UNIV OF TECH

A New Type of High Scandium Aluminum Alloy Welding Wire

ActiveCN103286471BGood electrical conductivityHigh strengthWelding/cutting media/materialsSoldering mediaManganeseWeld strength

The invention relates to the field of welding materials, in particular to a novel high-scandium aluminum alloy welding wire. The novel high-scandium aluminum alloy welding wire chemically comprises, by mass, 4.5-6.0% of Mg, 0.10-0.20% of Mn, 0.20-0.30% of Ti, 0.30-0.50% of Zn, 0.10-0.20% of Cr, 0.25-0.35% of Zr, 1.20-1.60% of Sc, not more than 0.20% of Fe, not more than 0.20% of Si, not more than 0.05% of Cu, not more than 0.0005% of Be, not more than 0.1% of other single impurity elements, not more than 0.15% of other impurity elements and the balance Al. The novel high-scandium aluminum alloy welding wire has the advantages of uniformity in texture, tiny grains, good electrical conductivity, excellent welding performance, high weld strength, good ductility and toughness, excellent mechanical property, low hot-cracking susceptibility and excellent corrosion resistance.

Owner:NORTHEASTERN UNIV LIAONING +1

Process of producing high quality carbon steel ingot with aluminium and RE added for high grade forging

The present invention is the technological process of adding aluminum and RE to produce high quality carbon steel ingot for high grade forging. During producing high quality carbon steel ingot, final deoxidizing agent of aluminum and RE is adopted and aluminum in 0.5-0.9 Kg and RE in 0.5-0.8 Kg for each ton of steel are added successively while smelting, and the steel ingot is demolded after 7-9 times the setting time. The high quality carbon steel ingot of the present invention may be used in producing high grade forging.

Owner:RUI STEEL INDAL OF PANZHIHUA GANGCHENG GROUP

Aluminum alloy mobile telephone shell

InactiveCN107974594AHigh strengthImprove plasticityVacuum evaporation coatingSputtering coatingComposite filmMobile phone

The invention discloses an aluminum alloy mobile telephone shell comprising a shell body; the surface of the shell body is coated with a nanoscale composite film layer in a vacuum mode. The thicknessof the shell body is 0.1-0.3 mm. The thickness of the nanoscale composite film layer is 200-300 nm. The thickness of shell body is 0.2 mm, and the thickness of the nanoscale composite film layer is 250 nm. The nanoscale composite film layer is a nano-sliver layer. The shell body is aluminum alloy sections. The aluminum alloy sections using in the shell body has good high tensile strength, high yield strength, high extending rate, anti-corrosion property, and high-temperature stability, and the performance of the aluminum alloy sections is higher than iron pipe.

Owner:JIANGSU SAIBO YUHUA TECH CO LTD

High-strength magnesium alloy and die-casting method thereof

The invention provides a high-strength magnesium alloy. The high-strength magnesium alloy comprises Zn, Al, Cr, Mn, La, Ce, Nd, Yb, Y, VC, ZrC, WC, TiC, TiB2, ZrB2 and Mg. The invention further provides a die-pressing method of the high-strength magnesium alloy. According to the high-strength magnesium alloy, rare earth elements like La are added in the alloy and have high solubility in the magnesium alloy, the dispersion strengthening effect and the great solution strengthening can both be achieved, besides, the rare earth elements can also have a high bonding effect with impurities elements,such as oxygen, hydrogen, nitrogen, sulfur and iron in a raw material alloy, gas and inclusions in the alloy can be reduced, the form of the inclusions is improved, the inclusions tend to be spheroidized, the inclusions and gas can be removed advantageously, and a melt purifying effect is also achieved; and in addition, the added rare earth elements differ in content, and the synergistic effect of the different rare earth elements greatly improves the strength and corrosion resistance of the magnesium alloy.

Owner:仝仲盛

High-performance wrought magnesium alloy which can be extruded quickly and preparation method thereof

The invention provides a high-performance wrought magnesium alloy which can be extruded quickly and a preparation method thereof. The high-performance wrought magnesium alloy is prepared from, by mass, 1.0-3.0% of Al, 0.5-2.0% of Ca, 0.5-3.0% of Nd and / or Y, 0.1-1.0% of Ce and the balance magnesium and unavoidable impurities. Industrial pure Mg, industrial pure Al and middle alloys Mg-Ca, Mg-Nd, Mg-Y and Mg-Ce are adopted as raw materials and smelted to obtain an ingot casting; then, uniform thermal treatment, mechanical machining and plastic-deformation thermal machining are carried out to obtain a magnesium alloy material. The magnesium alloy material can be subjected to high-speed extrusion at the speed not lower than 15m / min. Moreover, the obtained material is excellent in mechanical performance, the yield strength and the tensile strength can reach 260 MPa and 290 MPa or above respectively, the specific elongation reaches 16% or above, and the application range of the magnesium alloy is further expanded.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Manufacturing method of large-scale high-purity molybdenum alloy rotating target material

ActiveCN106567048AGood composition uniformityImprove tissue uniformityVacuum evaporation coatingSputtering coatingSmall particleVolumetric Mass Density

The invention discloses a manufacturing method of a large-scale high-purity molybdenum alloy rotating target material. The manufacturing method comprises the following steps of: preparing molybdenum trioxide powder; pouring a tube blank by utilizing the molybdenum trioxide powder and hafnium, and carrying out isostatic cool pressing on the tube blank; and carrying out sintering, extrusion and machining. According to the manufacturing method, a trace of hafnium powder is added in molybdenum trioxide to play a role of refining the particles, so that small-particle size molybdenum powder can be obtained and the density and breaking tenacity of the sintered blank can be improved; and the density of the prepared rotating target material is greater than 10.18g / cm3 and the purity is greater than 99.9%.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

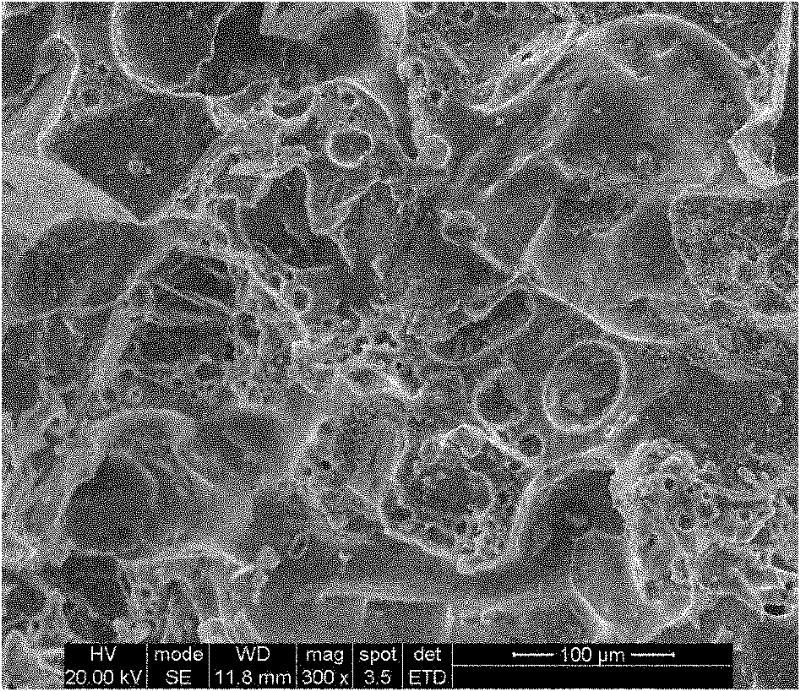

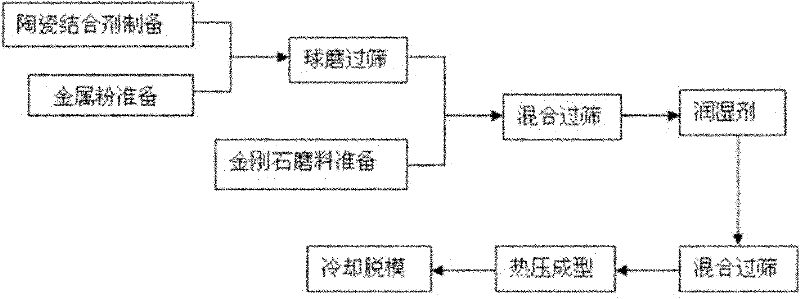

Diamond grinding tool of ceramic-metallic bond and preparation method of grinding tool

ActiveCN102152248BImprove toughnessHigh strengthAbrasion apparatusGrinding devicesLithium oxideMixed materials

The invention discloses a diamond grinding tool of a ceramic-metallic bond and a preparation method of the grinding tool. The preparation method comprises the following steps of: firstly, preparing the ceramic-metallic bond by ball milling the following components in percentage by weight: 40 to 50 percent of silicon dioxide (SiO2), 8 to 15 percent of aluminium oxide (Al2O3), 12 to 20 percent of diboron trioxide (B2O3), 3 to 6 percent of lithium oxide (Li2O), 6 to 12 percent of sodium oxide (Na2O), 3 to 6 percent of potassium oxide (K2O), 2 to 8 percent of zinc oxide (ZnO), 1 to 10 percent of titanium (Ti) and 1 to 5 percent of aluminium (Al); secondly, mixing the ceramic-metallic bond with a diamond abrasive to obtain a mixed material, and then adding 3 to 5 mass percent of wetting agent into the mixed material to obtain a raw material of the grinding tool; and finally, carrying out hot-forming and cooling de-moulding on the raw material of the grinding tool respectively to obtain thediamond grinding tool of the ceramic-metallic bond. The diamond grinding tool of the ceramic-metallic bond provided by the invention has the advantages of the diamond grinding tool of a metallic bondand the grinding tool of a ceramic bond.

Owner:长沙百通新材料科技有限公司

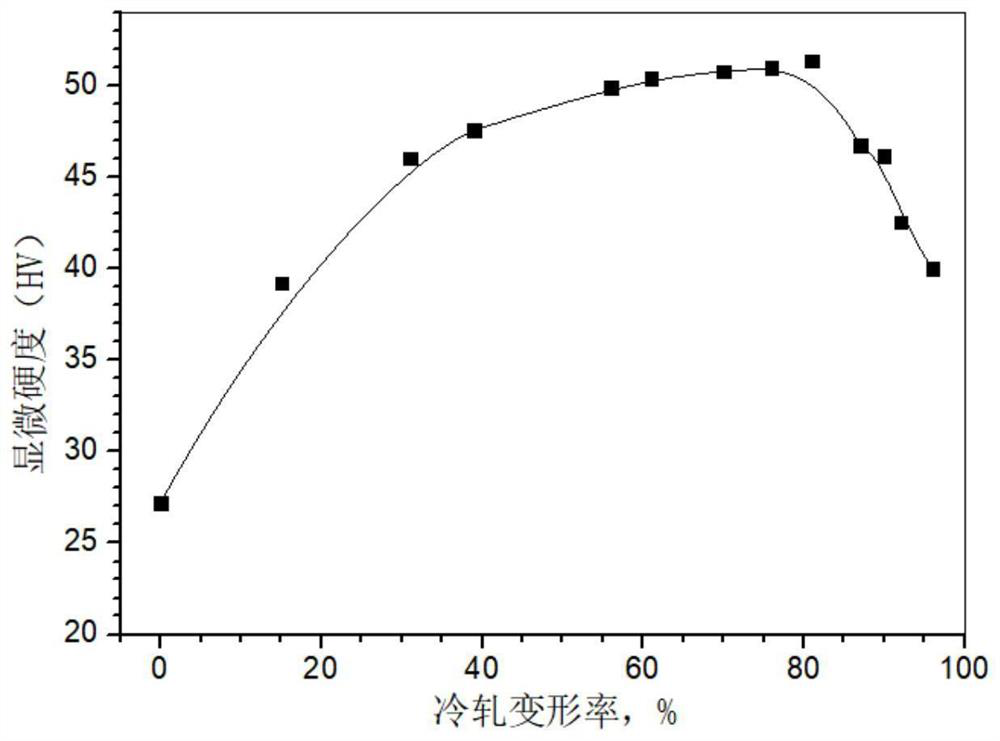

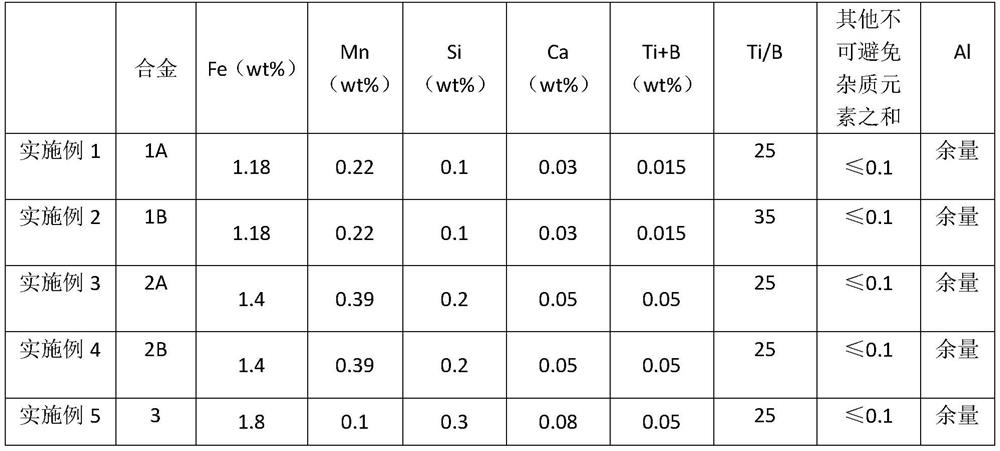

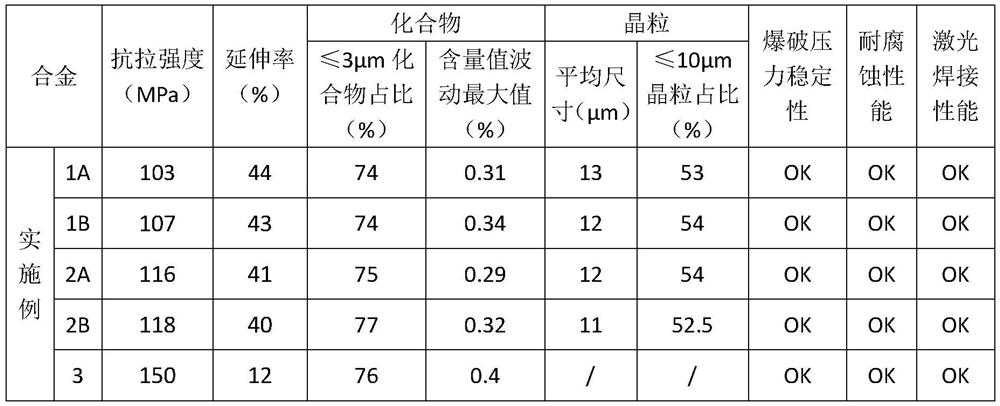

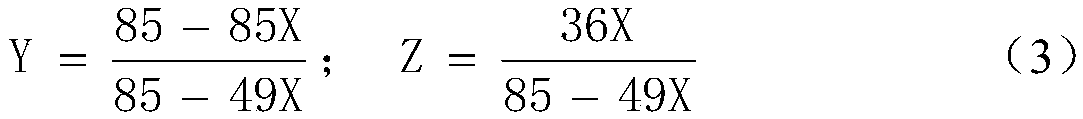

Aluminum alloy plate strip for lithium battery cover plate and preparation method of aluminum alloy plate strip

InactiveCN113088764AGuaranteed process softeningHigh strengthCell component detailsMaterials scienceLaser soldering

The invention discloses an aluminum alloy plate strip for a lithium battery cover plate and a preparation method of the aluminum alloy plate strip. The aluminum alloy plate strip comprises the following components of, in percentage by mass, 1.18 wt%-1.8 wt% of Fe, Mn less than or equal to 0.395 wt% 0.03 wt%-0.08 wt% of Ca, 0.1 wt%-0.3 wt% of Si and the balance Al and inevitable impurities, wherein Fe + Mn is less than 2 wt%, Fe / Mn is more than or equal to 2.5, Mn + Si is less than 0.6 wt%, and (Fe + Mn + Ca) / Si is more than or equal to 2.5. According to the aluminum alloy plate strip for the lithium battery cover plate and the preparation method of the aluminum alloy plate strip, the alloy has good mechanical performance, forming performance and laser welding performance at the same time, especially the performance stability of a material can be improved, and a prepared explosion-proof valve has stable explosion pressure.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

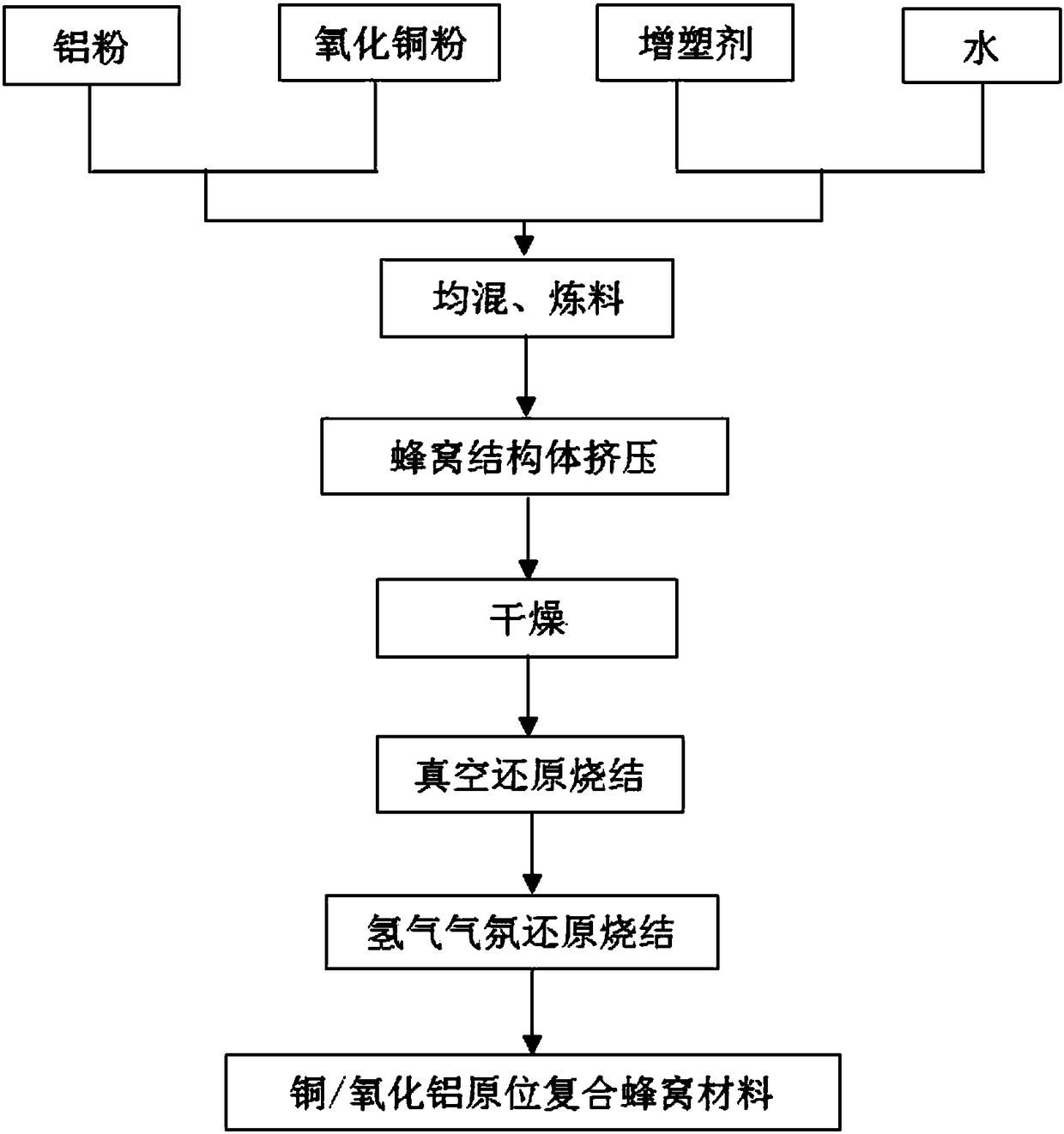

Preparation method of copper/alumina in-situ composite honeycomb material

ActiveCN108526459APlay a role in diffusion strengtheningEnhanced interface bindingTransportation and packagingMetal-working apparatusPlasticizerCopper oxide

The invention discloses a preparation method of a copper / alumina in-situ composite honeycomb material, and belongs to the field of porous composite materials. The preparation method comprises the steps that aluminum powder and copper oxide powder are adopted to be uniformly mixed, a plasticizer and water are then added and mixed, the mixed material is extruded into a honeycomb structure, the extruded honeycomb structure is dried and then reduced and sintered through two steps of vacuum and reducing atmosphere to prepare the copper / alumina in-situ composite honeycomb material. According to thecopper / alumina in-situ composite honeycomb material, the alumina prepared in-situ and a copper matrix are good in interface bonding, the copper / alumina in-situ composite honeycomb material has the characteristics of high-temperature resistance, high strength, high heat conductivity and the like, the production cost is low, and industrial production can be realized.

Owner:KUNMING UNIV OF SCI & TECH

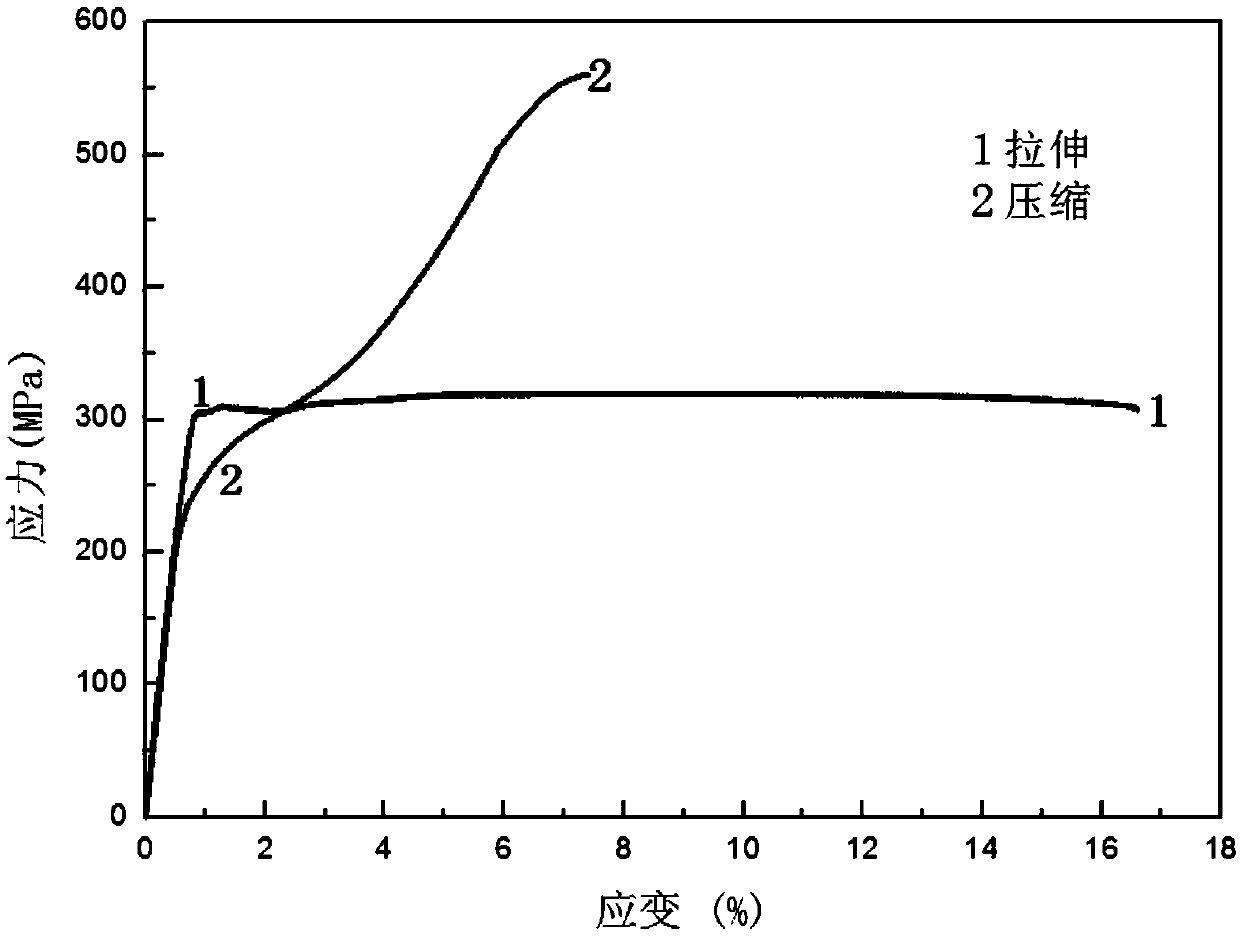

A Mg-Al-Ca-Ce-based magnesium alloy and preparation method thereof

The invention discloses a Mg-Al-Ca-Ce-based magnesium alloy and a preparation method thereof, which is composed of the following components ordered in percentage by mass: 2.0-6.0 percent of Al, 1.0-4.0 percent of Ca, 0.2-2.0 percent of Ce, magnesium and some inevitable impurities. The magnesium alloy is obtained by melting and extrusion molding process, using an industrial pure magnesium ingot, anindustrial pure Al, and a Mg-Ce intermediate alloy as raw materials. The magnesium alloy of the invention can obtain extremely fine crystal grains and a dispersed second phase under the extruded condition. The tensile yield strength can reach 300 MPa, the compressive yield strength is 260 MPa, and the yield strength tensile compression ratio exceeds 85%. The tensile pressure is asymmetric and hasa high elongation, reaching over 14%, hereby has excellent extrusion deformation performance. It is a wrought magnesium alloy with excellent comprehensive mechanical properties.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

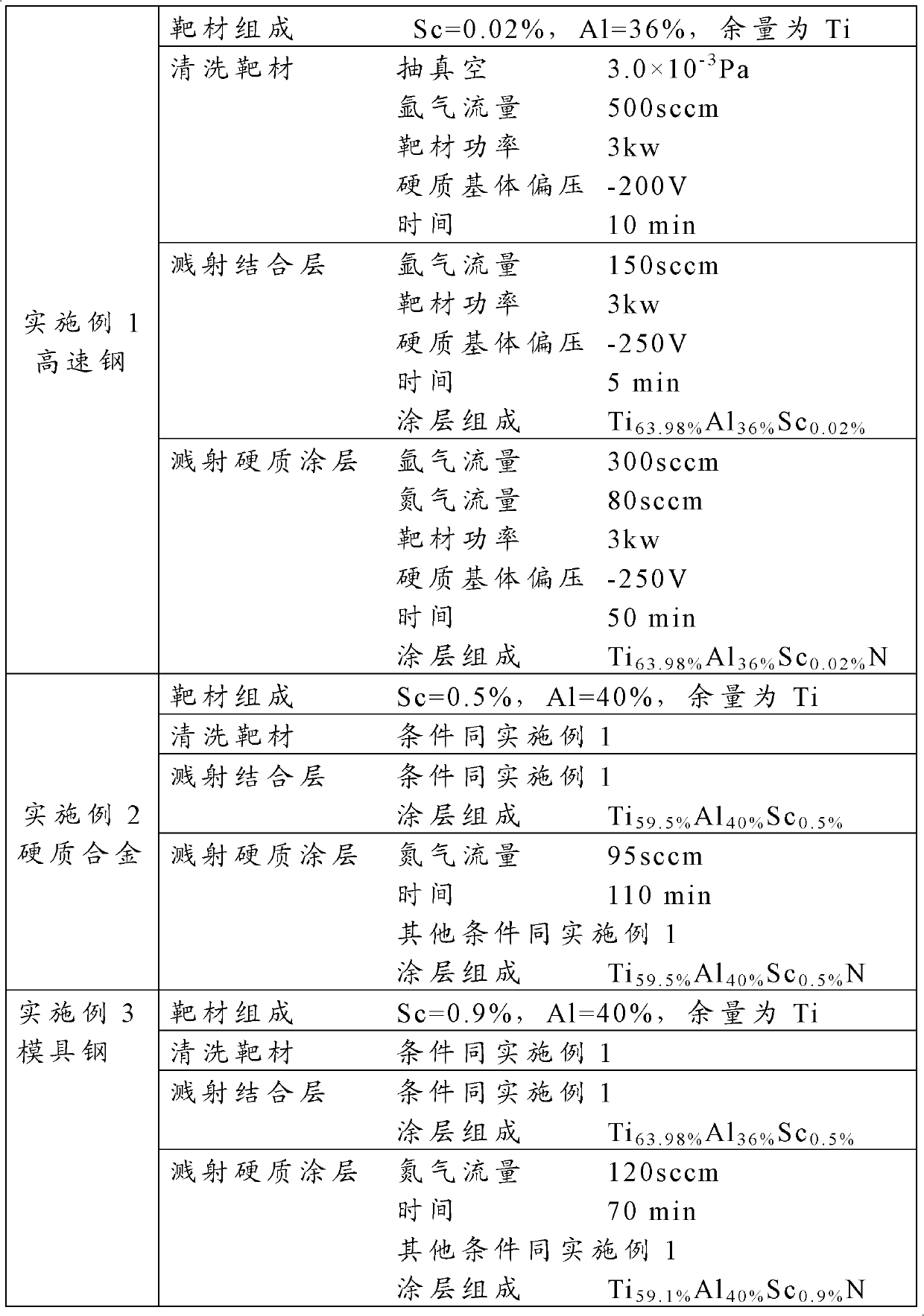

Laminated member with hard coating and preparation method of laminated member

InactiveCN102560347AImprove wear resistancePlay a role in diffusion strengtheningVacuum evaporation coatingSputtering coatingHardnessOxidation resistant

The invention provides a laminated member with a hard coating, which comprises a hard matrix, a bonding layer formed on the hard matrix, and a hard coating formed on the bonding layer, wherein the hard coating comprises TiXAlYMZN, wherein X, Y and Z respectively express percentages of atoms of Ti, Al and M, M is Sc or Dy, X+Y+Z=1, X is not less than 35 percent and not more than 45 percent, and Z is not less than 0.01 percent and not more than 1 percent. The invention also provides a method for preparing the laminated member by adopting a magnetron sputtering method. The laminated member with the hard coating has high hardness, better abrasion performance and high temperature oxidization resistance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com