Diamond grinding tool of ceramic-metallic bond and preparation method of grinding tool

A metal bond and ceramic bond technology, which is applied in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problem of unsatisfactory service life of diamond abrasive tools, difficulty in meeting market requirements, and inability to use hot-press sintering Process and other issues, to achieve the effect of easy shaping and sharpening, shortening the production cycle, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

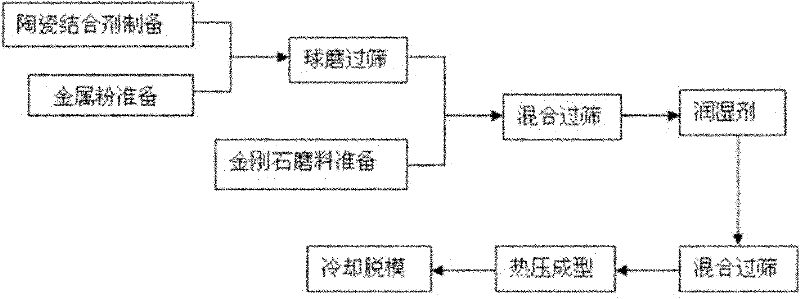

[0030] The specific process of this example is as follows image 3 shown.

[0031] Table 1: Ceramic-metal bond components and proportions

[0032] components

SiO 2

Al 2 o 3

B 2 o 3

Li 2 o

Na 2 o

K 2 o

ZnO

Ti

Al

wt%

44

9

19

6

7

3

5

5

2

[0033] Analytical pure SiO 2 、Al 2 o 3 、HBO 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and ZnO as raw materials, calculated according to the formula in the above table, weighed, mixed evenly, put into a crucible, heated to 1300°C in a high-temperature frit furnace, kept for 2 hours, water quenched after the raw materials were completely melted, and then wet milled on a ball mill ( 1000r / min) for 24h, dry the wet-milled slurry in an oven at 100°C for 12h, dry-grind for 4h, and pass through a 200-mesh sieve to make a basic vitrified bond.

[0034] Add Ti powder (particle size ≤ 20 μm) and Al powder (particle size ...

Embodiment 2

[0038] Table 2: Ceramic-metal bond components and proportions

[0039] components

SiO 2

al 2 o 3

B 2 o 3

Li 2 o

Na 2 o

K 2 o

ZnO

Ti

Al

wt%

48

12

12

3

8

4

2

8

3

[0040] Analytical pure SiO 2 、Al 2 o 3 、HBO 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and ZnO as raw materials, calculated according to the above formula, weighed, mixed evenly, put into a crucible, heated to 1300 °C in a high-temperature frit furnace, kept for 2 hours, water quenched after the raw materials were completely melted, and then wet milled on a ball mill (1000r / min) for 24 hours, dry the wet-milled slurry in an oven at 100°C for 12 hours, then dry-mill it for 4 hours and pass it through a 200-mesh screen to make a basic vitrified bond.

[0041]Add Ti powder (particle size ≤ 20 μm) and Al powder (particle size ≤ 20 μm) designed in the formula to the basic vitrified bond, and...

Embodiment 3

[0046] Table 3: Ceramic-metal bond components and proportions

[0047] components

SiO 2

Al 2 o 3

B 2 o 3

Li 2 o

Na 2 o

K 2 o

ZnO

Ti

Al

wt%

41

8

18

6

9

6

3

6

3

[0048] Analytical pure SiO 2 、Al 2 o 3 、HBO 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and ZnO as raw materials, calculated according to the above formula, weighed, mixed evenly, put into a crucible, heated to 1300 °C in a high-temperature frit furnace, kept for 2 hours, water quenched after the raw materials were completely melted, and then wet milled on a ball mill (1000r / min) for 24 hours, dry the wet-milled slurry in an oven at 100°C for 12 hours, then dry-mill it for 4 hours and pass it through a 200-mesh screen to make a basic vitrified bond.

[0049] Add Ti powder (particle size ≤ 20 μm) and Al powder (particle size ≤ 20 μm) designed in the formula to the basic vitrified bond, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com