Rare-earth-oxide-doped W-Cu composite material and preparation method thereof

A technology of rare earth oxides and composite materials, which is applied in the field of nanomaterial technology and powder metallurgy, can solve problems such as splashing of copper liquid and failure to meet the requirements of ultra-high voltage for the use of contact materials, so as to improve sintering activity and suppress W-W phase Agglomeration, effect of improving sintering formability and forging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

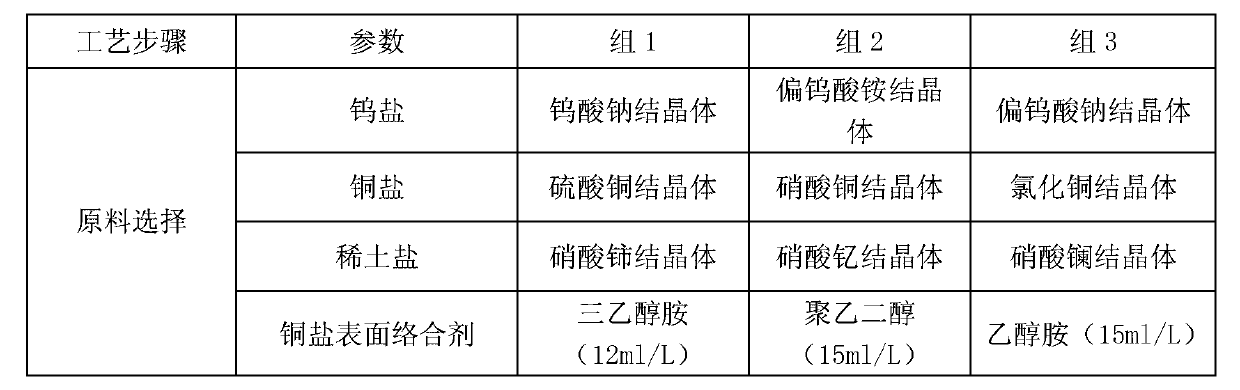

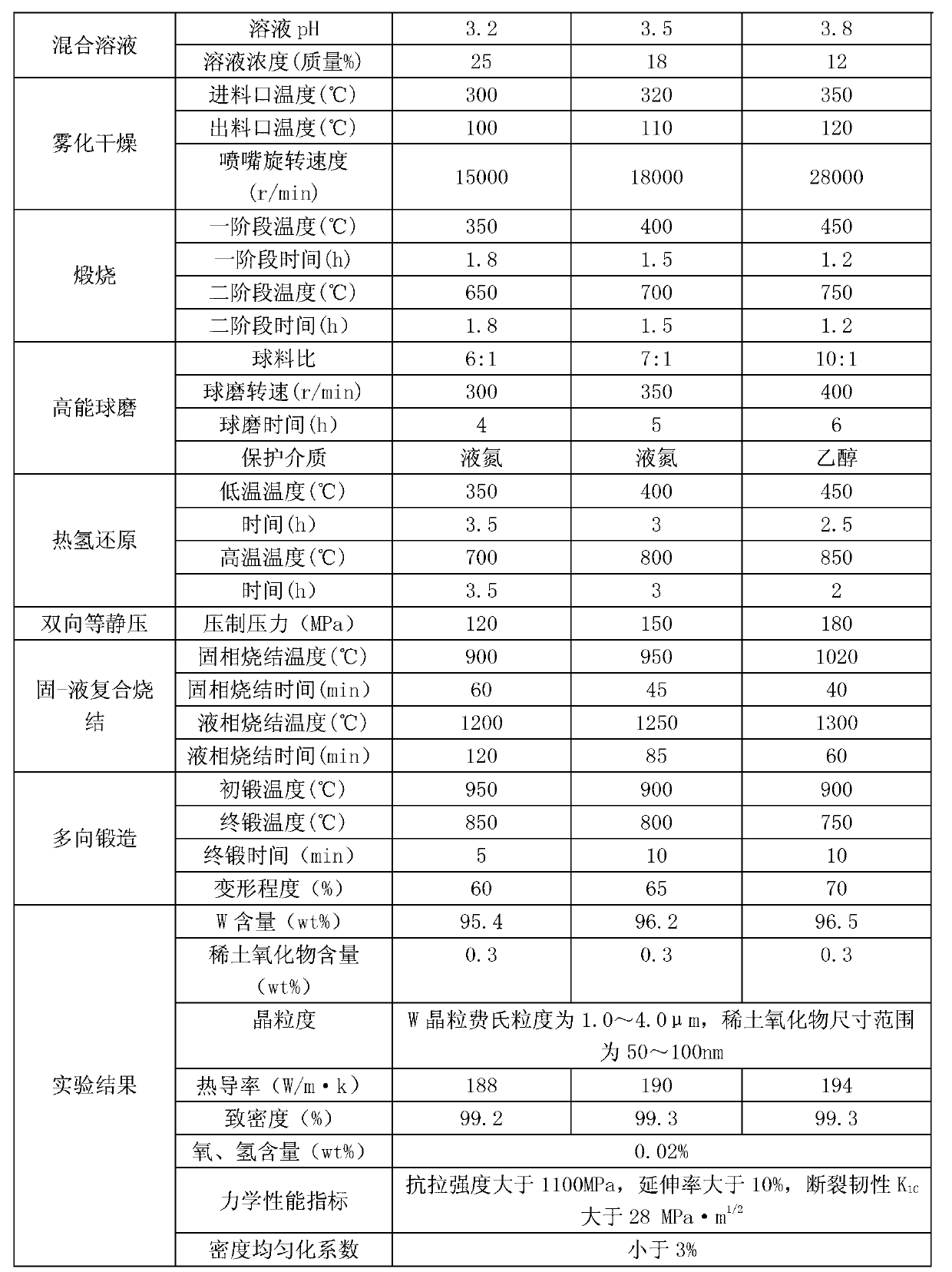

Examples

Embodiment 1

[0028] (1) Prepare W-5Cu composite powder containing rare earth oxides by using mixed solution-atomization drying-calcination-high energy ball milling-(low temperature + high temperature) two-step hot hydrogen reduction method; weigh 31.8g copper chloride crystals, 271.9g Ammonium metatungstate crystals, 2g yttrium nitrate crystals, and 3g polyethylene glycol were dissolved in 660ml deionized water to prepare a solution with a concentration of 10%, and adding a 10% nitric acid solution to adjust the pH of the solution to 4, And let it stand for 30 minutes to obtain a stable mixed dissolved salt solution;

[0029] The mixed dissolved salt solution is atomized and dried, the temperature of the feed port is 250°C, the temperature of the discharge port is 80°C, and the rotation speed of the nozzle is 20000r / min to obtain the oxide mixed powder precursor, and then the oxide powder precursor is mixed in the air Calcined the body, kept at 300°C for 2 hours to remove water and part of...

Embodiment 2

[0034] (1) Prepare W-20Cu composite powder containing rare earth oxides by using mixed solution-atomization drying-calcination-high energy ball milling-(low temperature + high temperature) two-step hot hydrogen reduction method; weigh 97g of copper sulfate crystals, 128g of metatungstic acid Sodium crystals, 3g cerium nitrate crystals, and 3g triethanolamine were dissolved in 740ml deionized water to prepare a solution with a concentration of 30%, and a 10% nitric acid solution was added to adjust the pH value of the above solution to 3, and allowed to stand for 30 minutes. A stable mixed dissolved salt solution is obtained; the mixed dissolved salt solution is atomized and dried, the inlet temperature is 400°C, the outlet temperature is 150°C, the nozzle rotation speed is 30000r / min, and the oxide mixed powder precursor is obtained, and then The oxide powder precursor was calcined in the air, kept at 500°C for 1h to remove water and part of the complexing agent in the molten s...

Embodiment 3

[0039] (1) Prepare W-30Cu composite powder containing rare earth oxides by using mixed solution-atomization drying-calcination-high energy ball milling-(low temperature + high temperature) two-step hot hydrogen reduction method; weigh 125g copper nitrate crystals, 103g ammonium paratungstate crystals, 2g of lanthanum nitrate crystals and 3g of ethanolamine were dissolved in 770ml of deionized water to prepare a solution with a concentration of 20%, and a solution of nitric acid with a concentration of 10% was added to adjust the pH of the above solution to 3.5, and stood for 30 minutes to obtain a stable mixture. Dissolved salt solution: Atomize and dry the mixed dissolved salt solution, the temperature of the feed port is 300°C, the temperature of the discharge port is 100°C, and the rotation speed of the nozzle is 15000r / min to obtain the oxide mixed powder precursor, which is then mixed in the air The oxide powder precursor was calcined, kept at 400°C for 1.5h to remove wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com