Leadless copper base high temperature self lubricating composite material

A high-temperature self-lubricating and composite material technology, applied in metal material coating technology, gaseous chemical plating, coating, etc., can solve the problems of high temperature resistance, improve heat resistance, improve interface bonding strength, and improve resistance Effect of High Temperature Creep Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

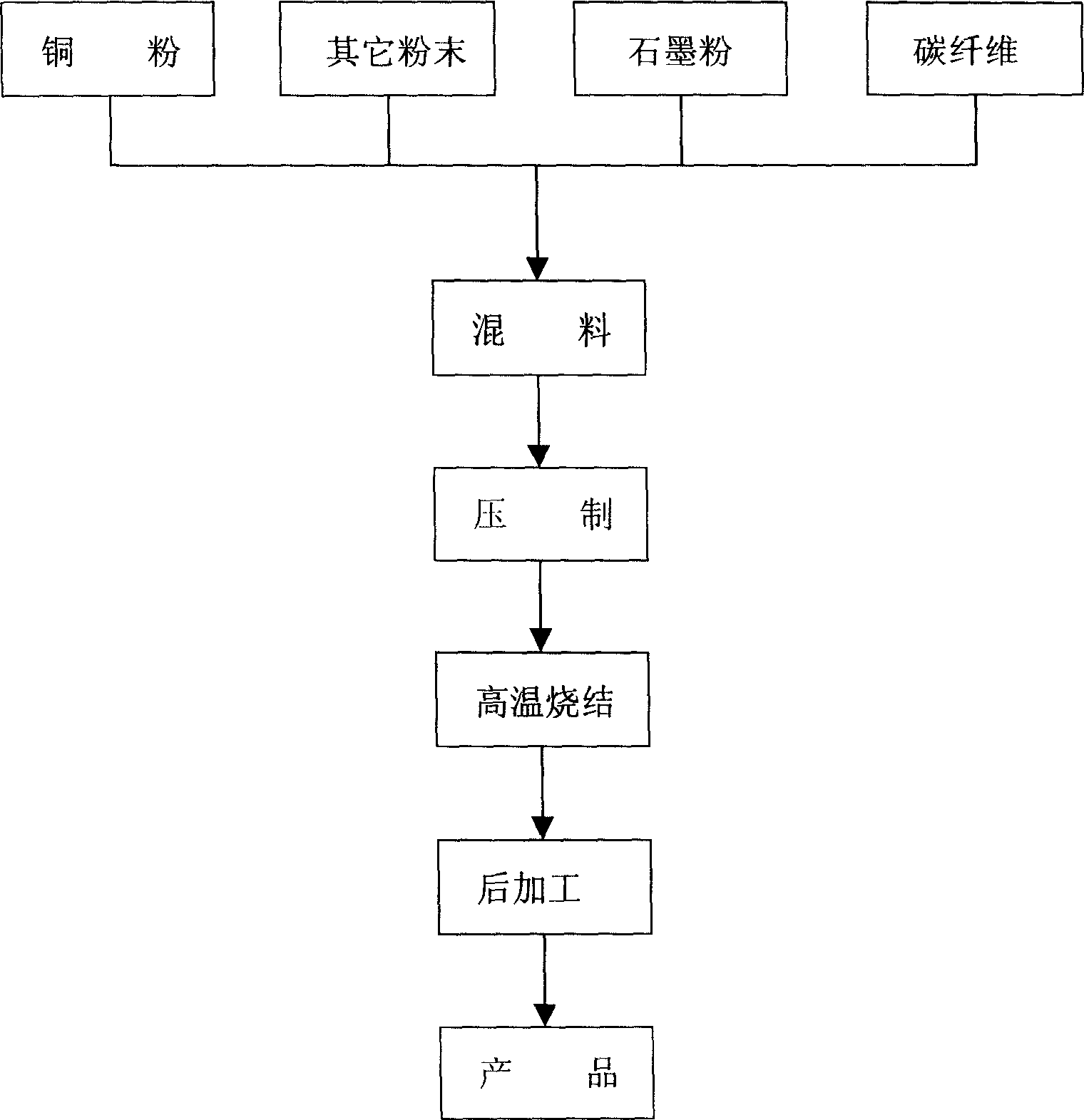

Method used

Image

Examples

Embodiment 1

[0021] Use tin bronze pre-alloyed powder, add -200 mesh nickel powder, iron powder, ultra-fine boron nitride powder and graphite powder and carbon fiber after surface composite plating. The graphite powder is flaky natural graphite powder, the carbon fiber diameter is 5-10 μm, the length is 1-3 mm, and the carbon fiber accounts for 0.5-3% of the total volume of the material. Graphite powder and carbon fiber are respectively electroless plated, first copper plated and then iron plated to form a composite coating of Cu+Fe. The specific chemical composition is shown in Table 1.

[0022] the element

Ni

C

sn

BN

Zn

Fe

Cu

W(%)

10

8

6

0.5

6

1.5

margin

[0023] Put the above raw materials into a "V" type mixer and mix for 2 hours.

[0024] Put the mixed material into a steel mould, and press it into a green compact with a unit pressure of 400MPa on a hydraulic press. Put the green compact i...

Embodiment 2

[0031] Use tin bronze pre-alloyed powder, add -200 mesh nickel powder, iron powder, ultra-fine boron nitride powder and graphite powder and carbon fiber after surface composite plating. The graphite powder is flaky natural graphite powder, the carbon fiber diameter is 5-10 μm, the length is 1-3 mm, and the carbon fiber accounts for 0.5-3% of the total volume of the material. Electroless plating is used for graphite powder and carbon fiber, nickel-phosphorus alloy is first plated and then copper is plated to form a composite coating of Ni-P+Cu. The specific chemical composition is shown in Table 4.

[0032] the element

[0033] Put the above raw materials into a "V" type mixer and mix for 2 hours. Put the mixed material into the graphite mold, and press it into the green compact of the desired shape on the hot press. The mechanical properties of the composite materials are shown in Table 5, and the friction and wear properties are shown in Table 6.

[0034] ...

Embodiment 3

[0037] Use tin bronze pre-alloyed powder, add -200 mesh nickel powder, iron powder, ultra-fine boron nitride and graphite powder and carbon fiber after surface composite plating. The graphite powder is flaky natural graphite powder, the carbon fiber diameter is 5-10 μm, the length is 1-3 mm, and the carbon fiber accounts for 0.5-3% of the total volume of the material. Graphite powder and carbon fiber are electroless plated, copper plated first and then iron plated to form a Cu+Fe composite coating. The specific chemical composition is shown in Table 7.

[0038] the element

[0039] Put the above raw materials into a "V" type mixer and mix for 2 hours. Put the mixed material into a steel mold, press the unit pressure on the hydraulic press to 400MPa, and press it into a green compact of the desired shape, put the green compact into an ammonia decomposition protective atmosphere, sinter at a temperature of 850°C, and keep it warm for 60 minutes. Then repress and rebu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com