Hot-pressing preparation method for hexagonal boron nitride-added silicon nitride

A technology of hexagonal boron nitride and silicon nitride, which is applied in the field of ceramic material preparation, can solve the problems of high brittleness and hardness of pure silicon nitride ceramic materials, hidden concerns about quality and safety, and crater wear, etc., and achieve the effect of improving tribological performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

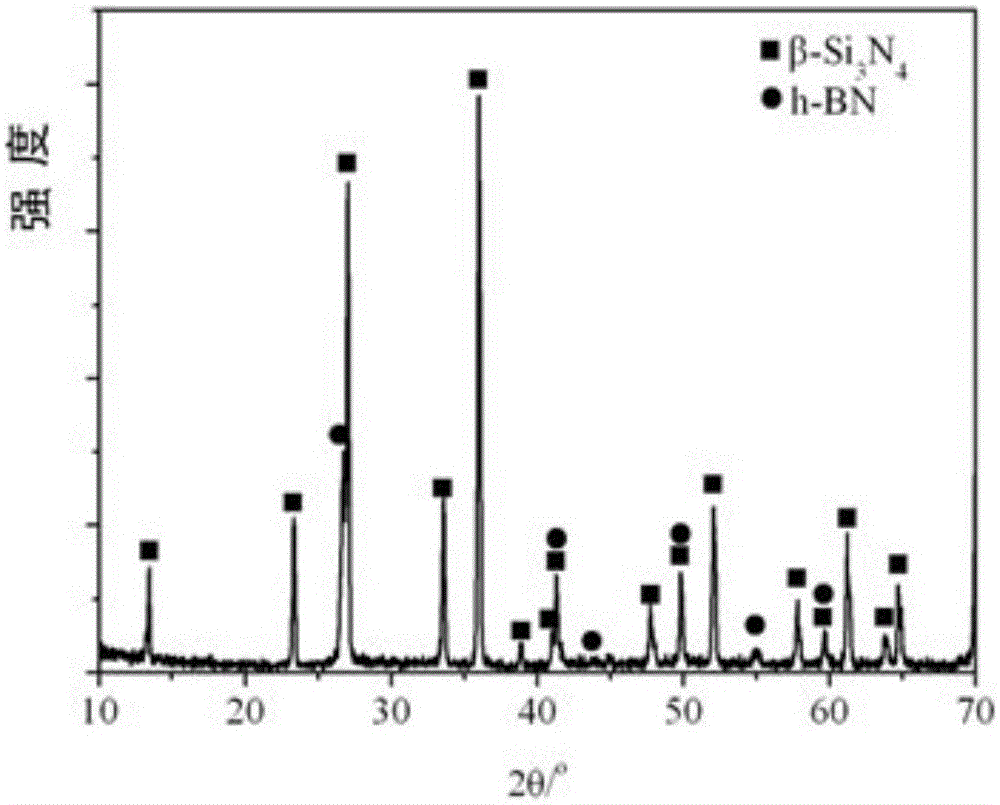

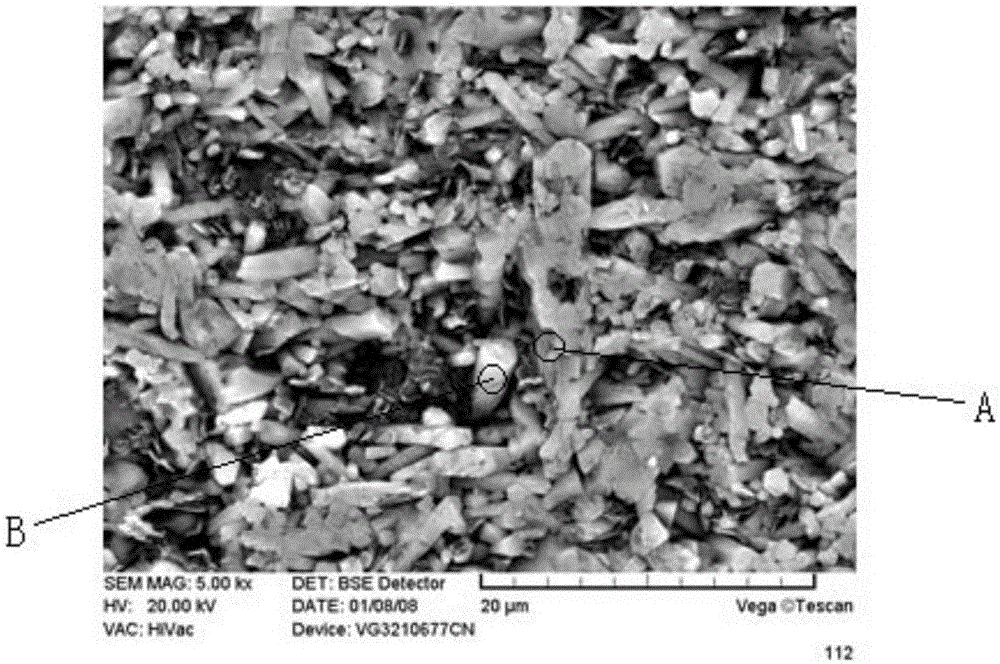

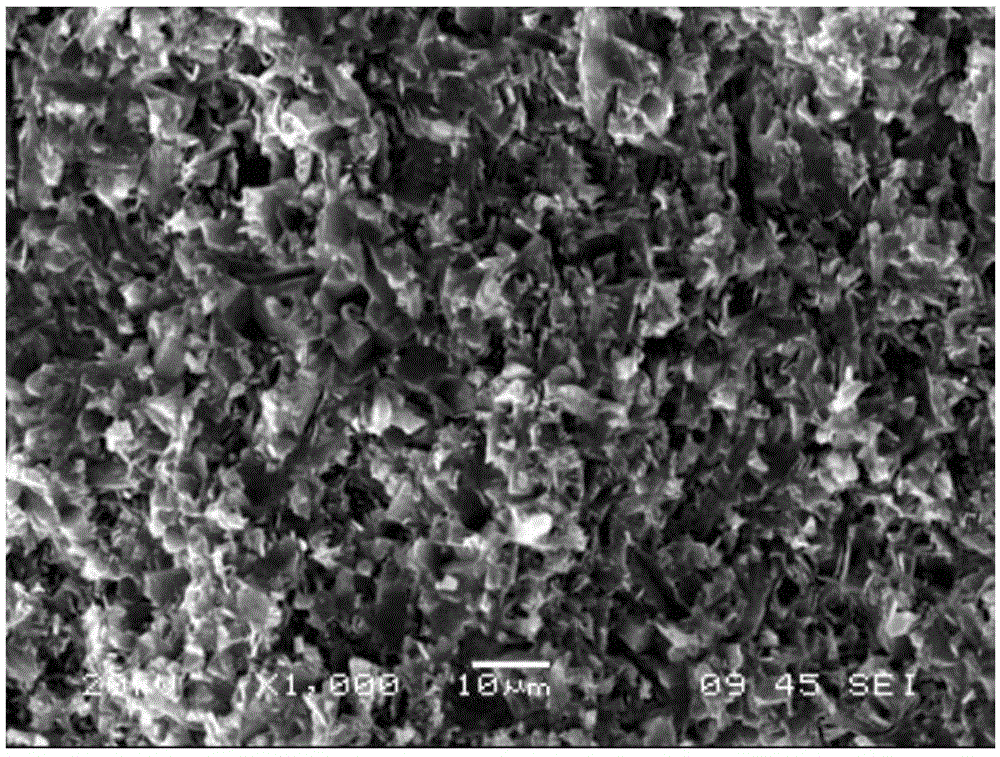

Embodiment 1

[0023] Step 1: Use an electronic balance to weigh 70% of silicon nitride, 20% of hexagonal boron nitride and 10% of sintering aid powder in proportion by volume, and place the weighed powder in a ball mill tank for ball milling, Pour in alcohol, the amount added is 1 / 2 of the weight of the material, adjust the viscosity of the fluid, use a planetary ball mill to make it fully mixed, and the ball milling speed is 150r·min -1 , the ball milling time is about 5h;

[0024] Step 2: Put the ball-milled powder in an oven, heat and evaporate to dryness, stir while evaporating until all the alcohol is lost, and prevent agglomeration at the same time, grind the dried mixture, and sieve it with a 160-mesh sieve ;

[0025] Step 3: Put graphite paper with a thickness of 0.2mm around the mold to facilitate demoulding, put the powder into the mold and pre-press it into a biscuit, place the biscuit in a vacuum carbon tube furnace, and under the protection of nitrogen, in the Under the condi...

Embodiment 2

[0040] Step 1: Use an electronic balance to weigh 60% of silicon nitride, 30% of hexagonal boron nitride and 10% of sintering aid powder in proportion by volume, and place the weighed powder in a ball mill tank for ball milling, Pour in alcohol, the amount added is 1 / 2 of the weight of the material, adjust the viscosity of the fluid, use a planetary ball mill to make it fully mixed, and the ball milling speed is 150r·min -1 , the ball milling time is about 5.5h;

[0041] Step 2: Put the ball-milled powder in an oven, heat and evaporate to dryness, stir while evaporating until all the alcohol is lost, and prevent agglomeration at the same time, grind the dried mixture, and sieve it with a 160-mesh sieve ;

[0042] Step 3: Put graphite paper with a thickness of 0.2mm around the mold to facilitate demoulding, put the powder into the mold and pre-press it into a biscuit, place the biscuit in a vacuum carbon tube furnace, and under the protection of nitrogen, in the Under the con...

Embodiment 3

[0052] Step 1: Use an electronic balance to weigh 80% of silicon nitride, 10% of hexagonal boron nitride and 10% of sintering aid powder in proportion by volume, and place the weighed powder in a ball mill tank for ball milling, Pour in alcohol, the amount added is 1 / 2 of the weight of the material, adjust the viscosity of the fluid, use a planetary ball mill to make it fully mixed, and the ball milling speed is 150r·min -1 , the ball milling time is about 6h;

[0053] Step 2: Put the ball-milled powder in an oven, heat and evaporate to dryness, stir while evaporating until all the alcohol is lost, and prevent agglomeration at the same time, grind the dried mixture, and sieve it with a 160-mesh sieve ;

[0054] Step 3: Put graphite paper with a thickness of 0.2mm around the mold to facilitate demoulding, put the powder into the mold and pre-press it into a biscuit, place the biscuit in a vacuum carbon tube furnace, and under the protection of nitrogen, in the Under the condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com