Pump with polytetrafluoroethylene or F46 inner coating and method for processing the coating

A technology of polytetrafluoroethylene and a processing method, which is applied to parts of a pumping device for elastic fluids, pumps for special fluids, pumps, etc., can solve problems such as increased manufacturing costs, complicated manufacturing processes, and unsatisfactory use effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

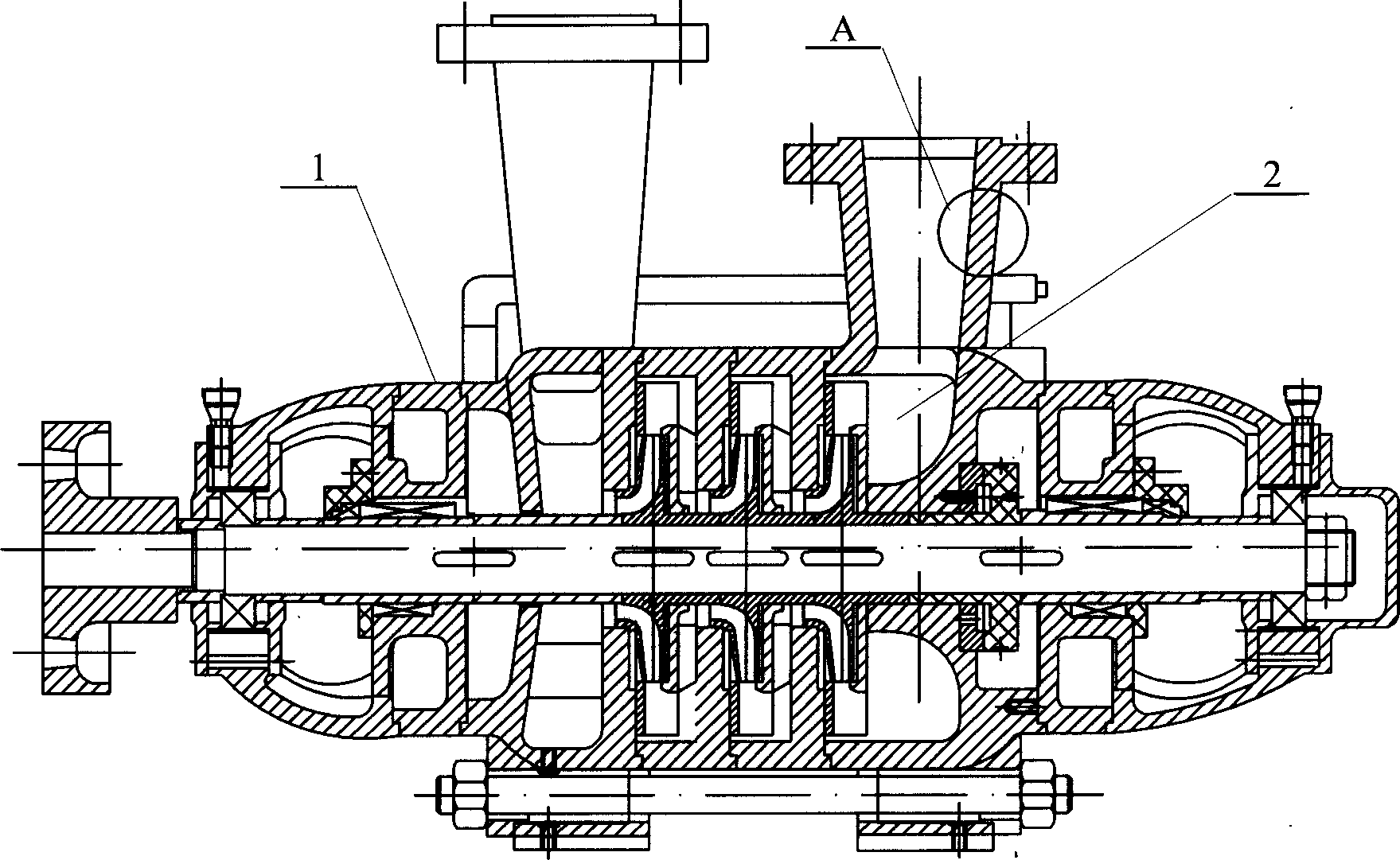

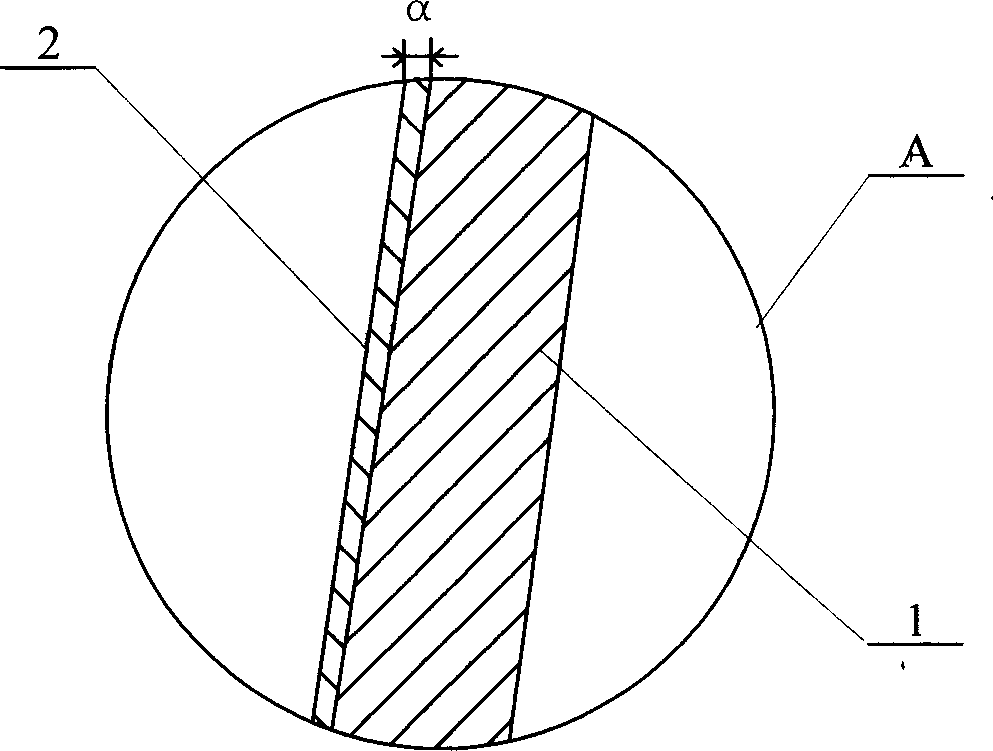

[0005] Specific implementation mode one: (see figure 1 , figure 2 ) The pump with polytetrafluoroethylene or F46 inner coating in this embodiment is composed of a pump body 1 and a polytetrafluoroethylene or F46 inner coating 2, and the polytetrafluoroethylene or F46 inner coating 2 is sprayed and sintered on the pump On the flow surface in the pump of the body 1, the thickness a of the polytetrafluoroethylene or F46 inner coating 2 is 0.1-50um.

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 , figure 2 ) In this embodiment, the thickness a of the polytetrafluoroethylene or F46 inner coating 2 is 0.1-10 um. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific implementation mode three: (see figure 1 , figure 2 ) The thickness a of the polytetrafluoroethylene or F46 inner coating 2 in this embodiment is 11-30 um. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com