Aluminum alloy template with self-lubricating film layer and processing method of aluminum alloy template

A technology of aluminum alloy formwork and self-lubricating film, which is applied in the direction of formwork/formwork components, coatings, surface reaction electrolytic coatings, etc., can solve the problems of variable, non-recyclable, low reuse rate, etc., and achieve mutual repulsion Reinforcement, weakening of mutual entanglement, dense and uniform filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

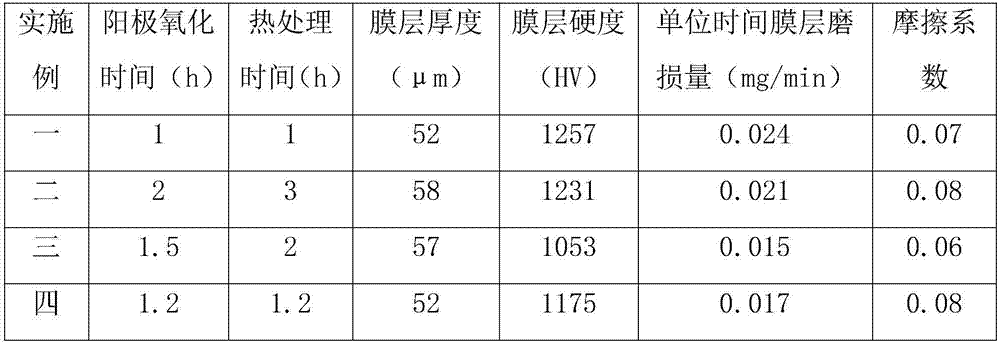

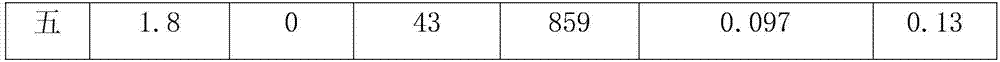

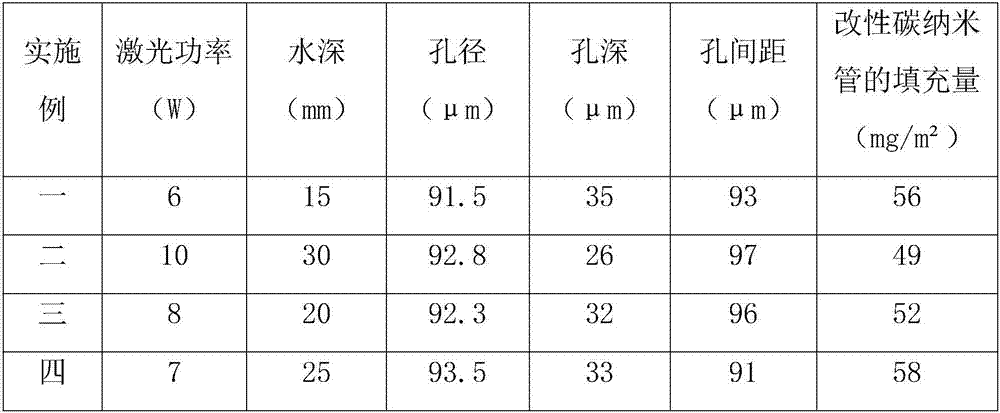

Examples

Embodiment 1

[0029] First use fine sandpaper to polish the surface of the aluminum alloy formwork base material. After grinding, rinse off the impurities on the surface of the aluminum alloy formwork base material with deionized water, and then immerse the polished aluminum alloy formwork base material in NaOH with a molar ratio of 5:1. and Na 3 PO 4 Soak in the mixed solution of 80-85°C for 5-10 minutes. After soaking, first rinse the aluminum alloy template substrate with deionized water for 3-5 minutes, then rinse with ethanol solution for 5-10 minutes and then dry it; The dry aluminum alloy template substrate is immersed in a polishing solution at 100-120°C and polished for 10 seconds, and then the aluminum alloy template substrate is repeatedly rinsed with deionized water, wherein the polishing solution includes 400g / L NaOH, 150g / L NaNO 2 , 30g / L NaF, 20g / L Na 3 PO 4 ;Immerse the polished aluminum alloy template substrate in the mixed acid electrolyte, linearly adjust it to a prese...

Embodiment 2

[0031] First use fine sandpaper to polish the surface of the aluminum alloy formwork base material, and then rinse off the impurities on the surface of the aluminum alloy formwork base material with deionized water, and then immerse the polished aluminum alloy formwork base material in NaOH with a molar ratio of 3:1 and Na 3 PO 4 Soak in the mixed solution of 80-85°C for 5-10 minutes. After soaking, first rinse the aluminum alloy template substrate with deionized water for 3-5 minutes, then rinse with ethanol solution for 5-10 minutes and then dry it; The dry aluminum alloy template substrate is immersed in a polishing solution at 100-120°C for 10 seconds, and then the aluminum alloy template substrate is rinsed repeatedly with deionized water, wherein the polishing solution includes 500g / L NaOH, 180g / L NaNO 2 , 40g / L NaF, 30g / L Na 3 PO 4 ;Immerse the polished aluminum alloy template substrate in the mixed acid electrolyte, linearly adjust it to a preset value of 120V withi...

Embodiment 3

[0033] First use fine sandpaper to polish the surface of the aluminum alloy formwork base material, after the grinding is completed, rinse off the impurities on the surface of the aluminum alloy formwork base material with deionized water, and then immerse the polished aluminum alloy formwork base material in NaOH with a molar ratio of 4:1 and Na 3 PO 4 Soak in the mixed solution of 80-85°C for 5-10 minutes. After soaking, first rinse the aluminum alloy template substrate with deionized water for 3-5 minutes, then rinse with ethanol solution for 5-10 minutes and then dry it; The dry aluminum alloy template substrate is immersed in a polishing solution at 100-120°C and polished for 10 seconds, and then the aluminum alloy template substrate is repeatedly rinsed with deionized water, wherein the polishing solution includes 450g / L NaOH, 165g / L NaNO 2 , 35g / L NaF, 25g / L Na 3 PO 4 ;Immerse the polished aluminum alloy template substrate in the mixed acid electrolyte, linearly adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com