Bearing retainer material and preparation method thereof

A bearing cage and polyimide technology, applied in the field of materials, can solve the problems of large abrasion effect of metal on friction surface, large deformation of cage size, large friction torque, etc., and achieve good thermal conductivity and compression creep resistance. performance, excellent friction and wear resistance, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

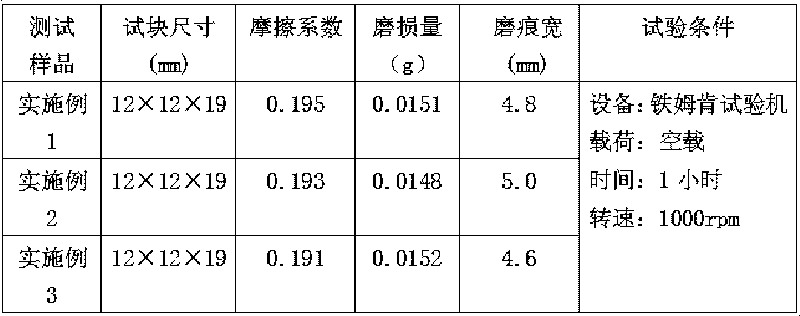

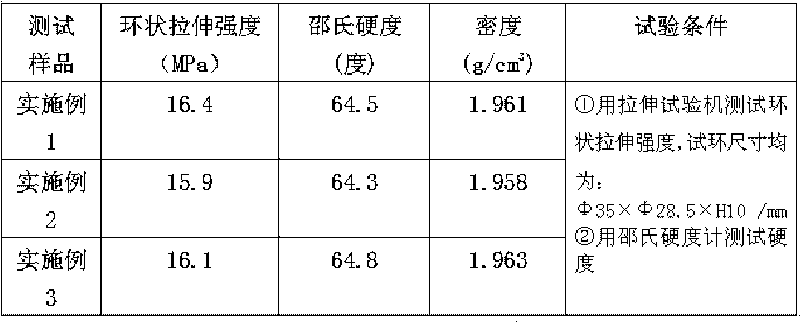

Embodiment 1

[0025] The composition of the bearing cage material by weight percentage is:

[0026] Molybdenum disulfide 2%, polyimide 12%, polyphenylene 12%, polytetrafluoroethylene 74%.

[0027] Among them, the logarithmic viscosity of polyimide is 115ml / g, and the apparent density is 0.40g / cm 3 .

[0028] The preparation method of the bearing cage material comprises the following steps:

[0029] (1) Accurately weigh molybdenum disulfide, polyimide, polyphenylene ester and polytetrafluoroethylene by weight percentage, wherein the particle diameter of molybdenum disulfide is 100-150 mesh, and the particle diameter of polyimide is 100-300 mesh, the particle size of polyphenylene is 100-300 mesh, the particle size of polytetrafluoroethylene is 100-150 mesh, put it into the mixer with a rotation speed of 10000r / min and stir and mix 5 times, each time for 20 seconds , and then grind it with a mortar for 5 minutes, and use a 20-fold microscope to observe that there is no obvious uneven pheno...

Embodiment 2

[0035] The composition of the bearing cage material by weight percentage is:

[0036] Molybdenum disulfide 5%, polyimide 8%, polyphenylene 9%, polytetrafluoroethylene 78%.

[0037] Among them, the logarithmic viscosity of polyimide is 150ml / g, and the apparent density is 0.35g / cm 3 .

[0038] The preparation method of the bearing cage material comprises the following steps:

[0039] (1) Accurately weigh molybdenum disulfide, polyimide, polyphenylene ester and polytetrafluoroethylene by weight percentage, wherein the particle diameter of molybdenum disulfide is 100-150 mesh, and the particle diameter of polyimide is 100-300 mesh, the particle size of polyphenylene is 100-300 mesh, the particle size of polytetrafluoroethylene is 100-150 mesh, put it into the mixer with a rotation speed of 12000r / min and stir and mix 5 times, each time for 10 seconds , and then grind it with a mortar for 10 minutes, and use a 20-fold microscope to observe that there is no obvious unevenness, w...

Embodiment 3

[0045] The composition of the bearing cage material by weight percentage is:

[0046] Molybdenum disulfide 5%, polyimide 10%, polyphenylene 15%, polytetrafluoroethylene 70%.

[0047] Among them, the logarithmic viscosity of polyimide is 130ml / g, and the apparent density is 0.45g / cm 3 .

[0048] The preparation method of the bearing cage material comprises the following steps:

[0049] (1) Accurately weigh molybdenum disulfide, polyimide, polyphenylene ester and polytetrafluoroethylene by weight percentage, wherein the particle diameter of molybdenum disulfide is 100-150 mesh, and the particle diameter of polyimide is 100-300 mesh, the particle size of polyphenylene is 100-300 mesh, the particle size of polytetrafluoroethylene is 100-150 mesh, put it into the mixer with a rotation speed of 12000r / min and stir and mix 3 times, each time for 15 seconds , and then grind it with a mortar for 8 minutes, and use a 20-fold microscope to observe that there is no obvious unevenness, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com