Binder, preparation method of binder and application of binder used as metallurgical pellet binder

A technology of binder and mixture, applied in the field of binder and preparation, can solve the problems of unstable use, insufficient preheating time, insufficient recrystallization degree of pelletized iron oxide, etc. Small dosage, the effect of promoting internal oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] The main component and index of the iron concentrate raw material used in the embodiment are as follows:

[0029]

[0030]Example Process conditions: the preheating temperature was 950°C, and the preheating time was 10 minutes. The calcination temperature was 1250°C and the calcination time was 10 minutes.

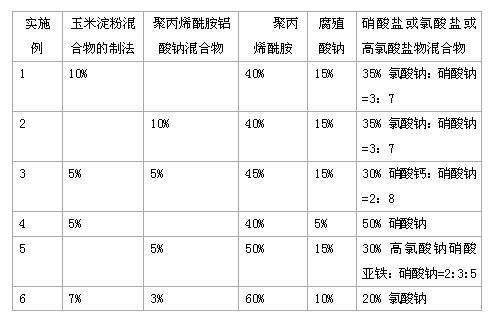

[0031] The mass percentage of binder components in each embodiment:

[0032]

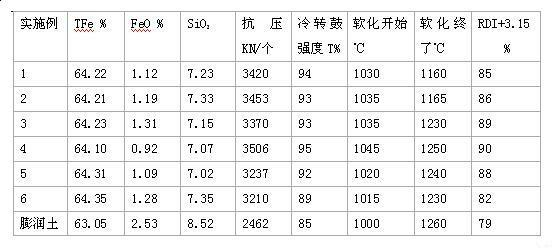

[0033] The application of the binder as a metallurgical pellet binder, the technical indicators of each embodiment are compared with bentonite:

[0034] Raw Ball Indicators:

[0035]

[0036] Finished ball index:

[0037]

[0038] It can be seen by comparison that when the binder of the present invention is used in pellets, only the green ball compression index is slightly lower than that of bentonite, but it can meet industrial production, and other indicators are higher than or equivalent to those of bentonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com