Paint-brushing and dust-removing device for wood boards

A dust removal device and painting technology, which is applied in the field of wood processing, can solve the problems of easy peeling of paint and poor painting effect, and achieve the effect of easy painting and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

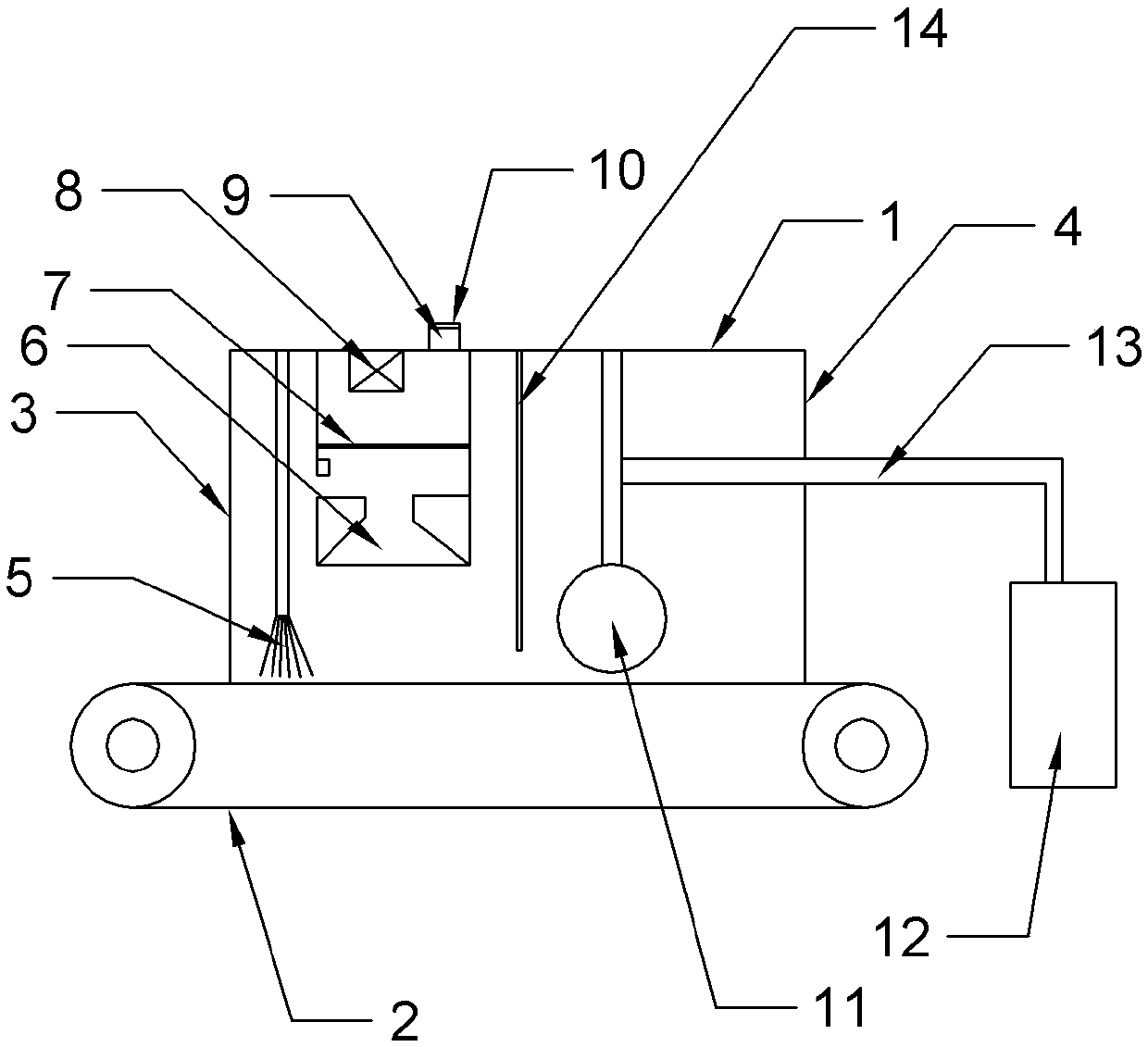

[0015] The marks in the accompanying drawings of the present invention are: casing 1, transmission mechanism 2, inlet 3, outlet 4, brush 5, dust collecting place 6, cloth bag 7, fan 8, explosion-proof opening 9, film 10, roller 11, paint Bucket 12, feed pipe 13, sticky plate 14.

[0016] like figure 1 As shown, the painting and dust removal device for wooden boards includes a casing 1, and a transmission mechanism 2 is fixed below the casing 1. The transmission mechanism 2 is driven by a belt, with a stable structure and stable transmission. The two sides of the casing 1 are respectively provided with an inlet 3 and an outlet 4. There are also a dust removal part and a paint brushing part inside the casing. end, it is convenient to dust the board first, and then paint it. The dust removal part includes a brush 5 and a dust suction mechanism, the brush 5 is slidably connected with the casing 1, and the dust suction mechanism includes a dust collection place 6, a cloth bag 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com