A kind of silicon-modified graphene water-based paint and preparation method thereof

A silicon-modified, vinyl water-based technology, which is applied in polyester coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of limited film-forming resin types, insufficient anti-graffiti penetration and anti-graffiti durability, and low anti-corrosion performance. , to achieve excellent anti-graffiti penetration performance, low cost, and improve anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

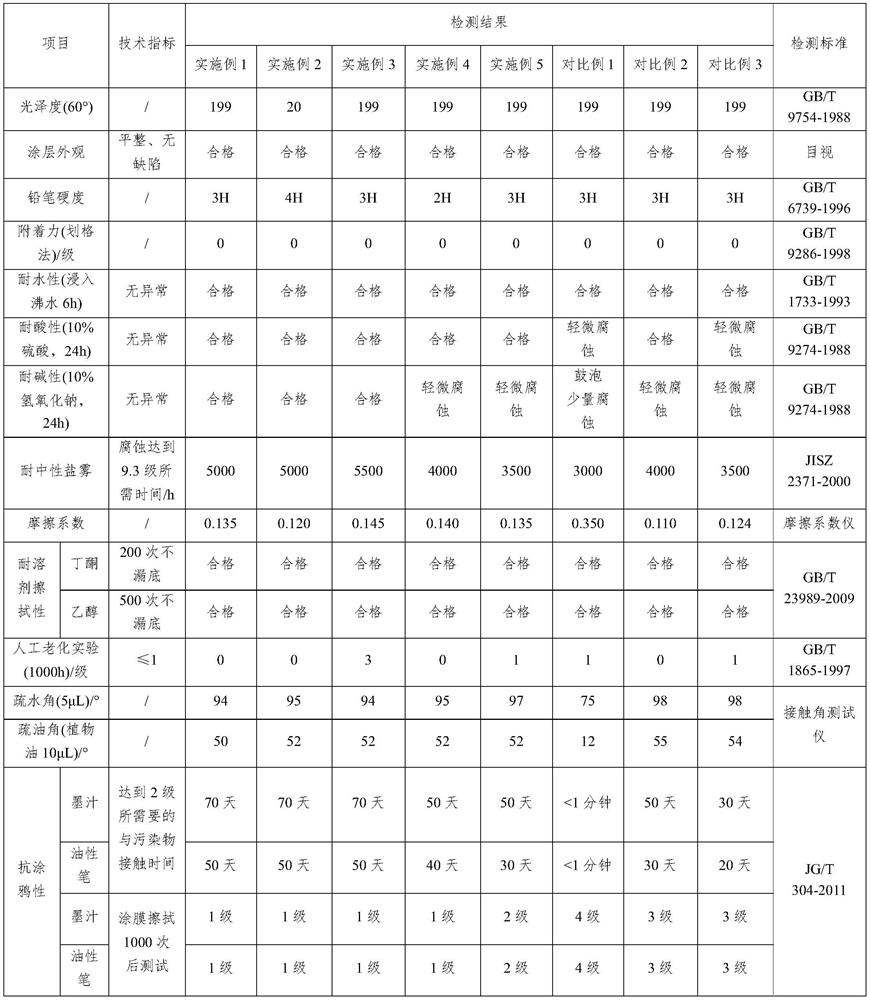

Examples

Embodiment 1

[0055] The present embodiment is used to illustrate the silicon-modified graphene water-based paint disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0056] (1) Weigh the raw materials of the following components according to the mass ratio

[0057] 35 parts of epoxy modified waterborne acrylic resin, 10 parts of waterborne polyurethane resin, 0.8 parts of dimethylethanolamine, 1.5 parts of propylene glycol methyl ether acetate, 1.5 parts of ethylene glycol monobutyl ether, 10 parts of silicon modified graphene slurry, 10.8 parts of partially methyl etherified melamine formaldehyde resin, 0.9 parts of dinonylnaphthalene disulfonic acid, 2 parts of adhesion promoter, 0.5 part of defoamer togo8050, 1.5 parts of water-based color concentrate, 25.5 parts of deionized water;

[0058] The preparation of described silicon-modified graphene slurry:

[0059] The first step: ultrasonically disperse 10 parts of graphene oxi...

Embodiment 2

[0063] The present embodiment is used to illustrate the silicon-modified graphene water-based paint disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0064] (1) Weigh the raw materials of the following components according to the mass ratio

[0065] 35 parts of epoxy modified waterborne acrylic resin, 10 parts of waterborne polyurethane resin, 0.8 parts of dimethylethanolamine, 1.5 parts of propylene glycol methyl ether acetate, 1.5 parts of ethylene glycol monobutyl ether, 10 parts of silicon modified graphene slurry, 10.8 parts of partially methyl etherified melamine formaldehyde resin, 0.9 parts of dinonylnaphthalene disulfonic acid, 2 parts of adhesion promoter, 0.5 part of defoamer togo8050, 1.5 parts of water-based color concentrate, 1.5 parts of matte powder, 24 parts of deionized water ;

[0066] The preparation of described silicon-modified graphene slurry:

[0067] The first step: ultrasonically disper...

Embodiment 3

[0071] The present embodiment is used to illustrate the silicon-modified graphene water-based paint disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0072] (1) Weigh the raw materials of the following components according to the mass ratio

[0073] 50 parts of water-based epoxy resin, 1 part of triethanolamine, 1 part of propylene glycol methyl ether, 2 parts of isopropanol, 10 parts of silicon modified graphene slurry, 2 parts of phenolic resin, 3.5 parts of partially methyl etherified melamine formaldehyde resin, right 0.5 part of toluenesulfonic acid, 0.5 part of dinonylnaphthalene sulfonic acid, 2 parts of adhesion promoter, 0.3 part of defoamer togo8050, 1.5 part of water-based color concentrate, and 25.7 parts of deionized water;

[0074] The preparation of the silicon-modified graphene slurry:

[0075] The first step: ultrasonically disperse 10 parts of graphene oxide in 30 parts of deionized water and 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com