A kind of nano-sponge composite sound-absorbing board and its application

A technology of nano-sponge and sound-absorbing board, which is applied in the field of sound-absorbing materials, can solve the problem of low noise absorption effect, achieve the effect of reducing dosage, light weight and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

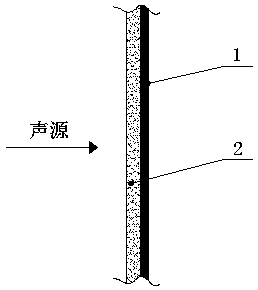

[0039] as attached figure 1 As shown, a nano-sponge composite sound-absorbing panel of the present invention includes at least two layers, the bottom layer is a main board body 1, the main board body 1 adopts a closed-cell structure, and the outer layer is a nano-sponge layer 2. Compared with the main board body 1, the configuration On the side close to the sound source, the main body 1 and the nano-sponge layer 2 are combined to form a nano-sponge composite sound-absorbing panel.

Embodiment 2

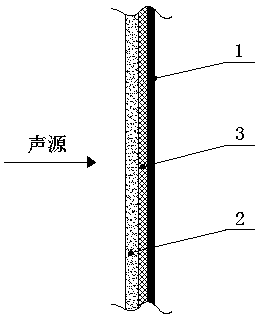

[0041] as attached figure 2 As shown, on the basis of embodiment one, an intermediate layer is additionally set between the main body 1 and the nano-sponge layer 2 of embodiment two, and the intermediate layer adopts a semi-open memory foam 3, and its aperture is between the main body 1 and the nano-sponge layer. 2, and form a buffer transition between the main body 1 and the nanosponge layer 2.

Embodiment 3

[0043] On the basis of Examples 1 and 2, Example 3 uses the nano-sponge as the carrier, utilizes the porous structure of the nano-sponge, loads the photocatalyst, and uses it as the outer layer of the nano-sponge composite sound-absorbing board.

[0044] When using nano-sponge as a carrier to load photocatalyst, the steps are as follows:

[0045] 1) Soaking: Put the nano-sponge in an organic solvent and take it out after fully soaking. The organic solvent is a mixture of ether and ethanol at a volume ratio of 1:1;

[0046] 2) Drying: Dry the soaked nano-sponge at 50°C;

[0047] 3) Flattening: Place the dried nano-sponge under a briquetting block with a force of 2500 Newton for flattening treatment, and the flattening time is controlled at 20 minutes;

[0048] 4) Use a watering can to spray 200 mL of the pre-configured photocatalyst solution evenly on the outer surface of the nano-sponge;

[0049] The raw materials of each L photocatalyst solution include: 300 mL ether, 500 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com