Polycondensation vacuum reaction system for flame-retardant slice production and production process

A reaction system and polycondensation technology, applied in pressure vessels/vacuum vessels, chemical/physical/physicochemical fixed reactors, pressure vessels used in chemical processes, etc., can solve the problem of low material reaction rate, low material film forming efficiency, Low heat exchange efficiency and other issues, to achieve the effect of improving the film forming effect, improving the film forming efficiency and increasing the film forming area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

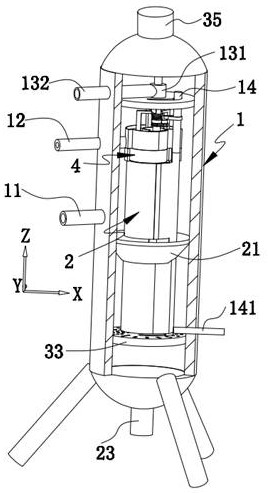

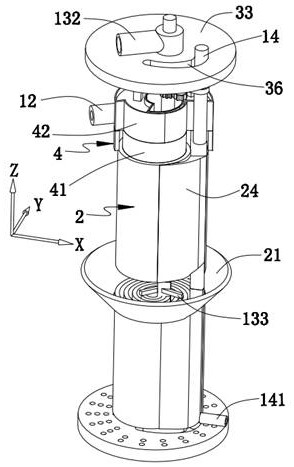

[0073] like Figure 1-2 , 9, the present invention provides a kind of polycondensation vacuum reaction system for flame retardant chip production, comprising:

[0074] The kettle body 1 is provided with a vacuum exhaust pipe 11;

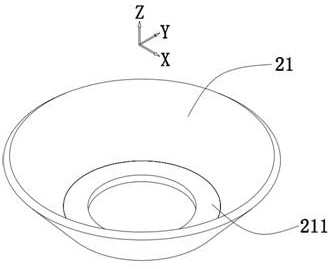

[0075] The hollow coil spring 2 arranged in the kettle body 1;

[0076] A feeding pipe 12 extending into the kettle body 1 and used for feeding material to the upper end of the hollow coil spring 2 so that the material flows down the side wall of the hollow coil spring 2;

[0077] The first tube 13 and the second tube 14 are respectively communicated with both ends of the hollow coil spring 2 and cooperate to drive the hollow coil spring 2 to zoom in and out to promote the heat exchange between the fluid and the material in the hollow coil spring 2 .

[0078] Further, the lower end of the kettle body 1 is provided with a discharge port 15, and the vacuum exhaust pipe 11 is connected to the vacuum pump; the first pipe 13 is located at the center of ...

Embodiment 2

[0095] like Figure 1-11 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is: Figure 4 , 8 , 9, a plurality of the hollow coil springs 2 with different inner diameters are concentrically sleeved, and the plurality of hollow coil springs 2 communicate with the same first tube 13 and the second tube 14.

[0096] It should be noted that a plurality of hollow coil springs 2 are concentrically sleeved, each hollow coil spring 2 has a different inner diameter, and the gaps between adjacent hollow coil springs 2 are the same or close. The same first tube 13 and the second tube 14 are connected to simplify the arrangement structure; compared with the previous embodiment or the prior art, a plurality of hollow...

Embodiment 3

[0129] like Figure 12 As shown, the present embodiment provides a production process for flame retardant chips, comprising the following steps:

[0130] Step 1, the first tube 13 continuously feeds the fluid into the hollow coil spring 2 and causes the fluid to flow out from the second tube 14;

[0131] Step 2. After the fluid is introduced into the hollow coil spring 2, the material is dropped from the top of the hollow coil spring 2. By controlling the amount of material input, the material flows down in the form of a film along the side wall of the hollow coil spring 2. In order to realize the heat exchange with the fluid in the hollow coil spring 2, in order to realize the sufficient overflow of reaction by-products;

[0132] Step 3, while step 2 is being carried out, the by-product overflowing from the side wall of the hollow coil spring 2 in the kettle body 1 is evacuated through the vacuum exhaust pipe 11;

[0133] Step 4. At the same time as step 2, the first tube 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com