Independent-type multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber

A technology of ultrasonic atomization and reaction chamber, applied in spray booths, coatings, spraying devices, etc., can solve the problems of single atomization source, easy cross contamination, poor repeatability of process parameters, uncontrollable film composition, etc., to improve film formation Efficiency, facilitates deposition and formation, and prevents the effect of polluting droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

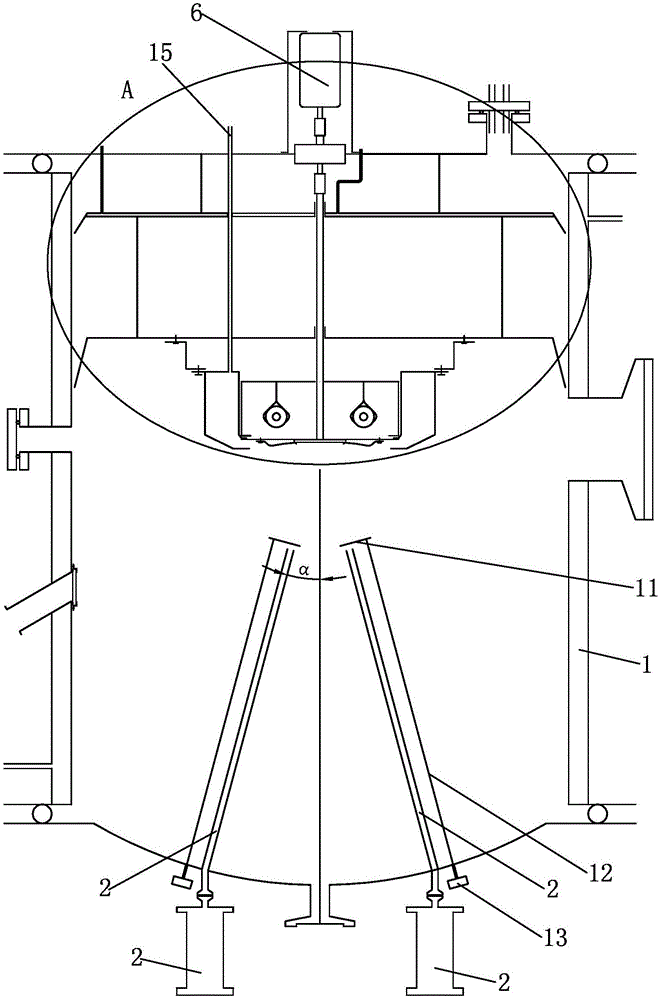

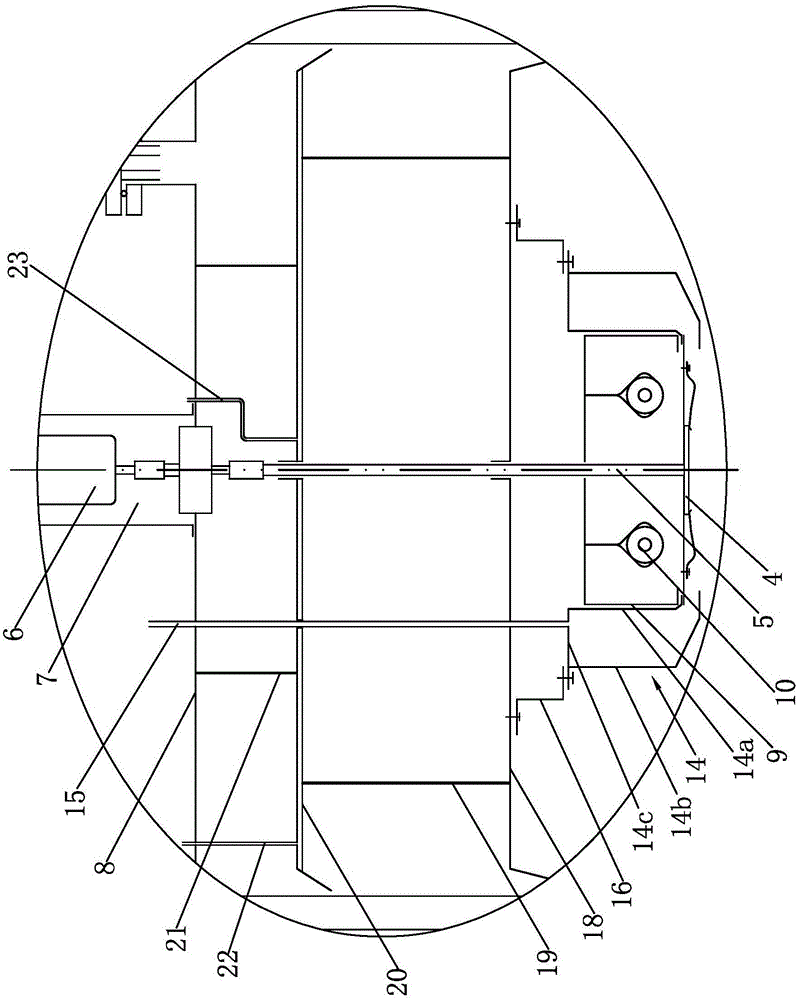

[0029] Such as figure 1 , 2 As shown, an independent multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber is mainly composed of a reaction chamber 1, an atomization source 2, a spray tube 3, a sample carrier 4, a rotating rod 5, a motor 6, and a motor bracket 7 , upper cover 8, heating body shell 9, heating body 10, drive assembly, exhaust gas cover 14, exhaust gas extraction pipe 15, mounting bracket 16, fixing frame 17, heat reflection cover 18, lower fixing column 19, water cooling heat shielding plate 20, the upper fixed column 21, the water inlet pipe 22 and the water outlet pipe 23 constitute. Wherein, a group of atomization sources 2 is provided under the reaction chamber 1 , the number of the atomization sources 2 is at least two, and these atomization sources 2 are independent from each other and arranged along the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com