Patents

Literature

170results about How to "Prevent full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

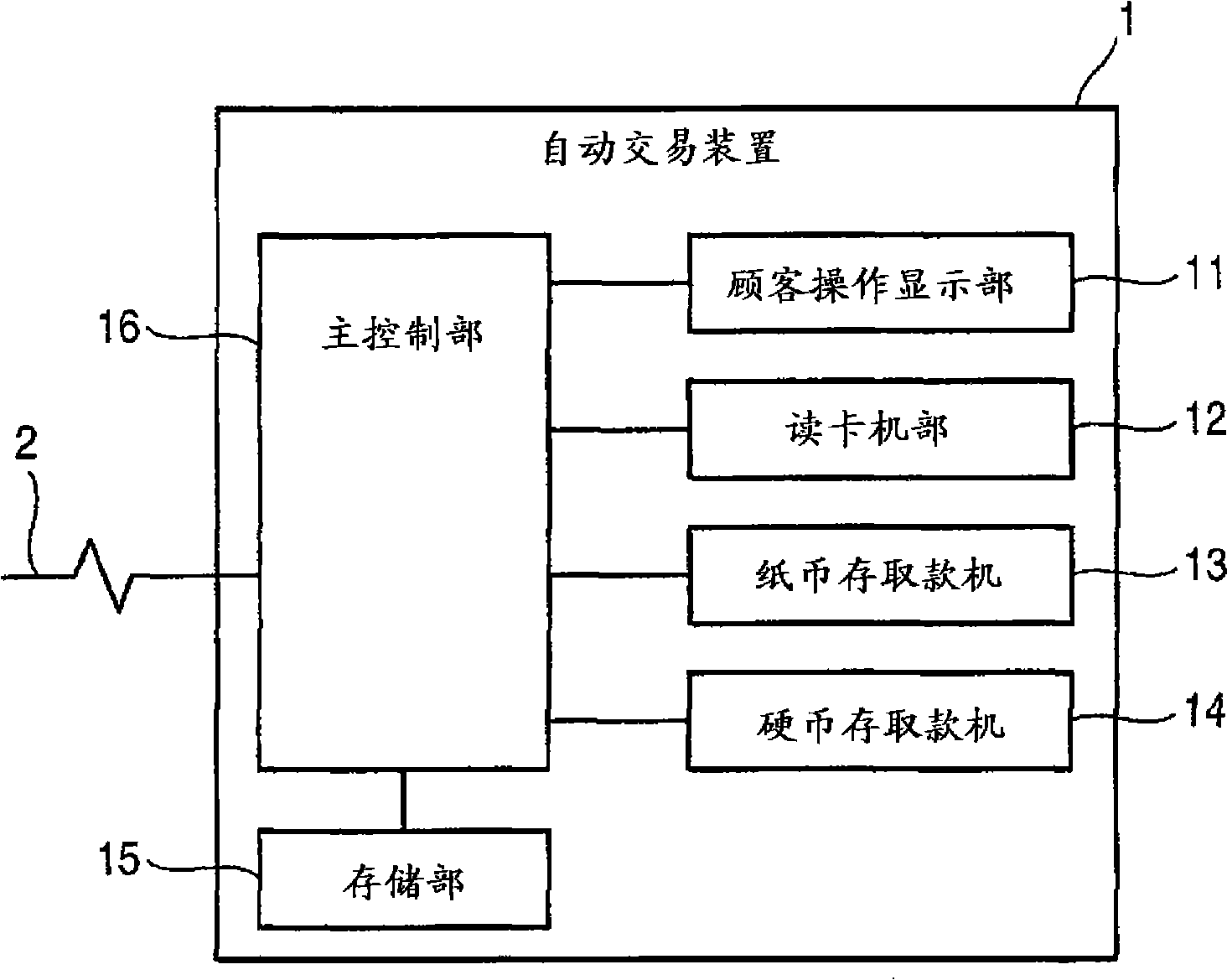

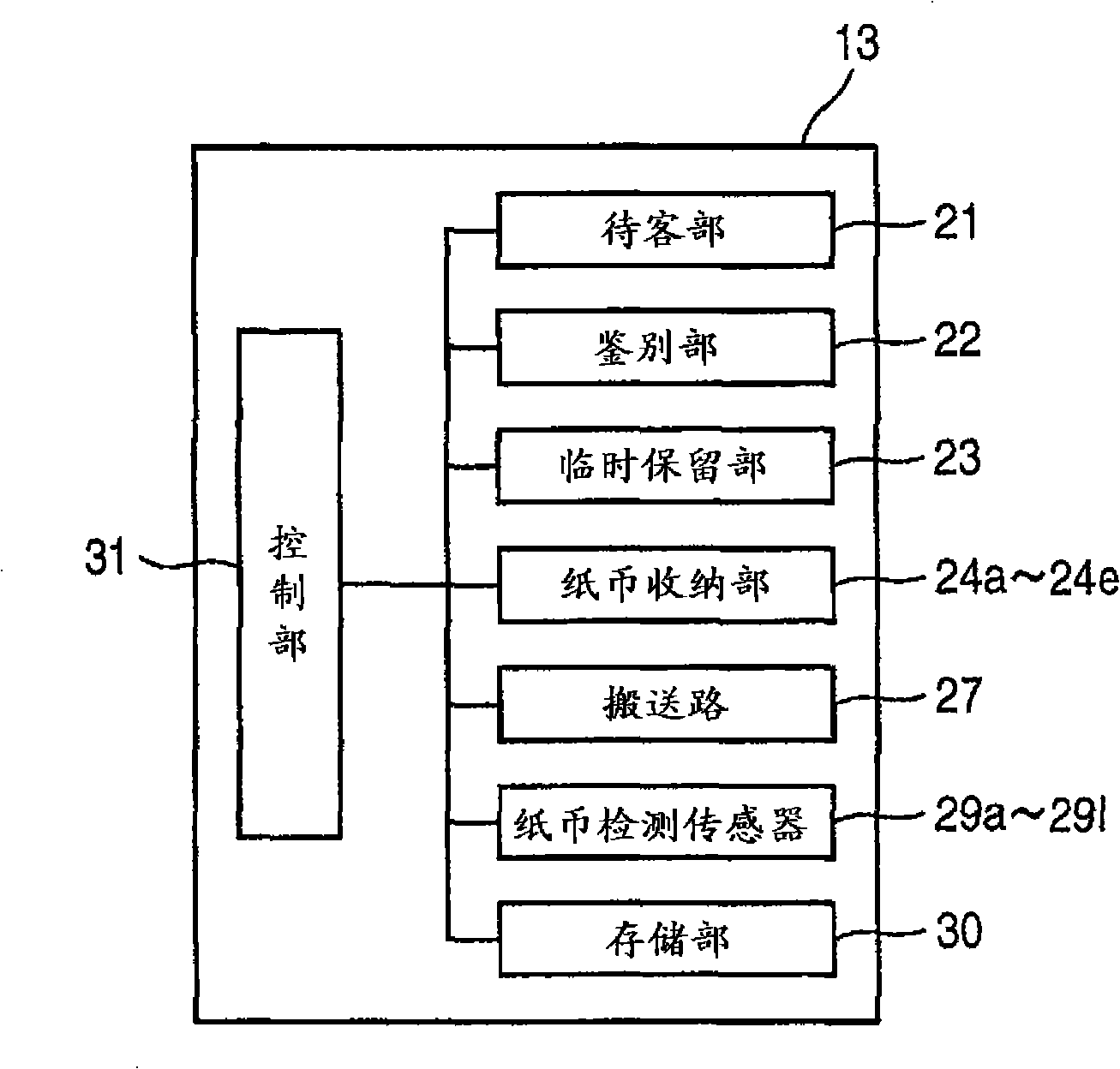

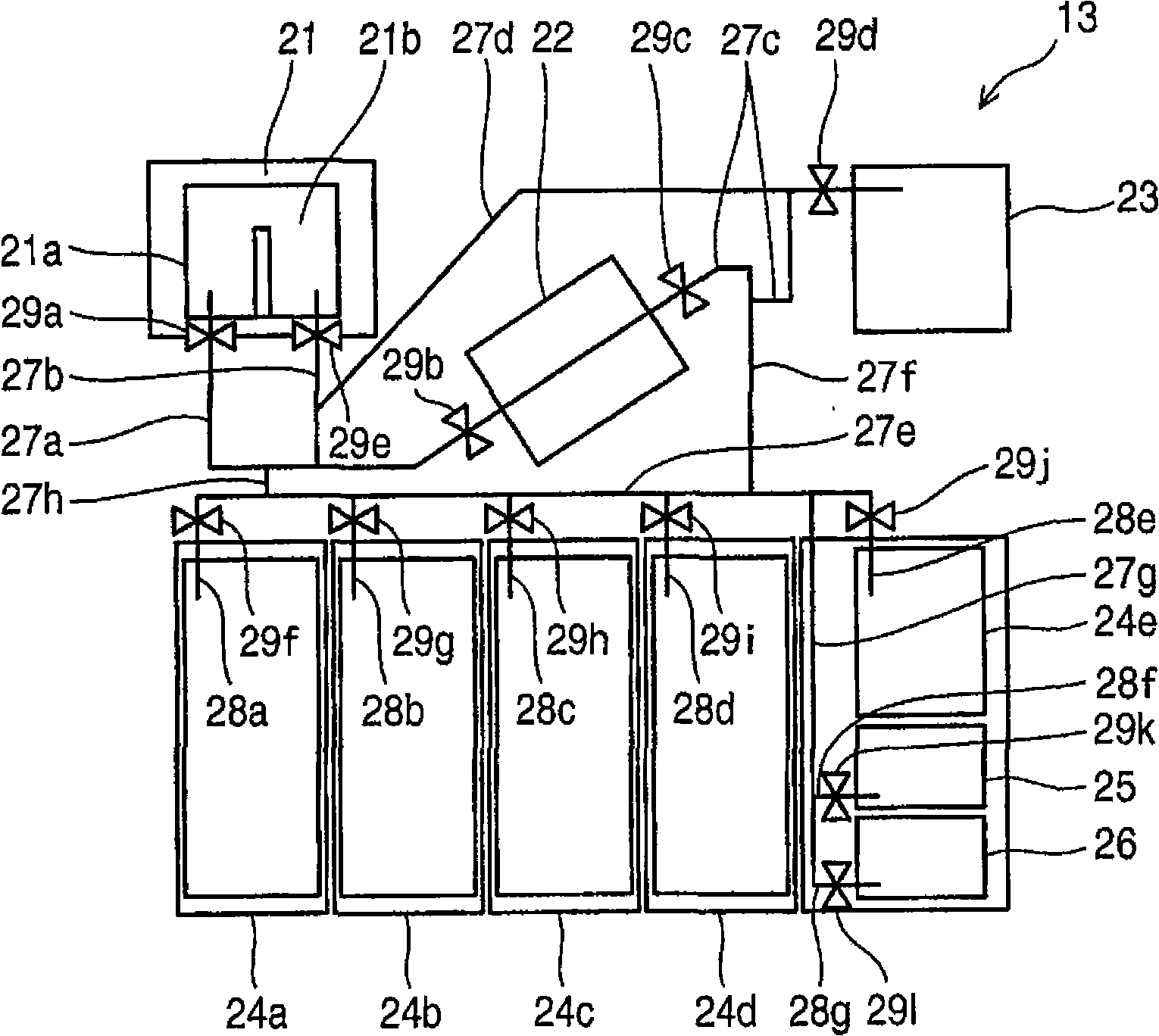

Paper processing apparatus

InactiveCN101353120APrevent fullComplete banking machinesCoin/currency accepting devicesImpellerEngineering

The invention provides a scrip processing device which avoids judging the holding part to be filled in error by detecting projection of scrip piled on the carrier table or scrip hooked on the bill block. The carrier table moving mechanism moves the carrier table from the scrip pulling and pressing position to the piling preparation position when the scrip piled at the top of the carrier table is flapped with the blade of a rotary impeller, and the projection of the scrip is eliminated and pulled near.

Owner:OKI ELECTRIC IND CO LTD

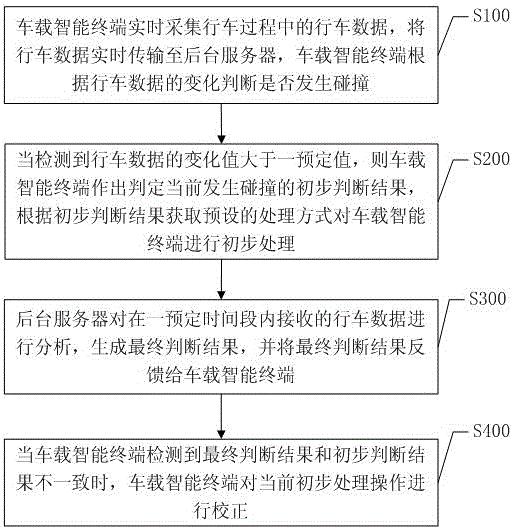

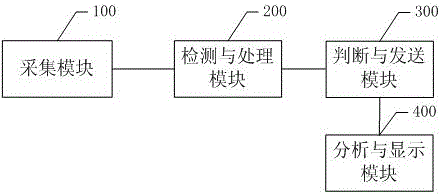

Vehicle collision detection method and system based on vehicle-mounted intelligent terminal

ActiveCN106230940APrevent fullImprove driving habitsRegistering/indicating working of vehiclesTransmissionCollision detectionError reporting

The invention discloses a vehicle collision detection method and system based on a vehicle-mounted intelligent terminal. The method comprises the following steps: the vehicle-mounted intelligent terminal acquiring driving data in the driving process in real time, transmitting the driving data to a background server in real time, and then the vehicle-mounted intelligent terminal judging whether the collision occurs according to the change of the driving data; when detecting that the change value of the driving data is greater than a predetermined value, the vehicle-mounted intelligent terminal judging that that the collision occurs at present, acquiring a preset processing mode to primarily process the vehicle-mounted intelligent terminal; the background generating a final judgment result, and feeding back to the vehicle-mounted intelligent terminal; when detecting that the final judgment result and the primary judgment result are inconsistent, the vehicle-mounted intelligent terminal correcting the current primary processing operation. Through the adoption of the method and system disclosed by the invention, the error reporting can be reduced, the condition that disc volume is fully occupied since the video is frequently locked in the driving record is avoided; the detection accuracy is improved, the available information can be immediately obtained, and the collision can be immediately processed.

Owner:苏州智行畅联科技有限公司

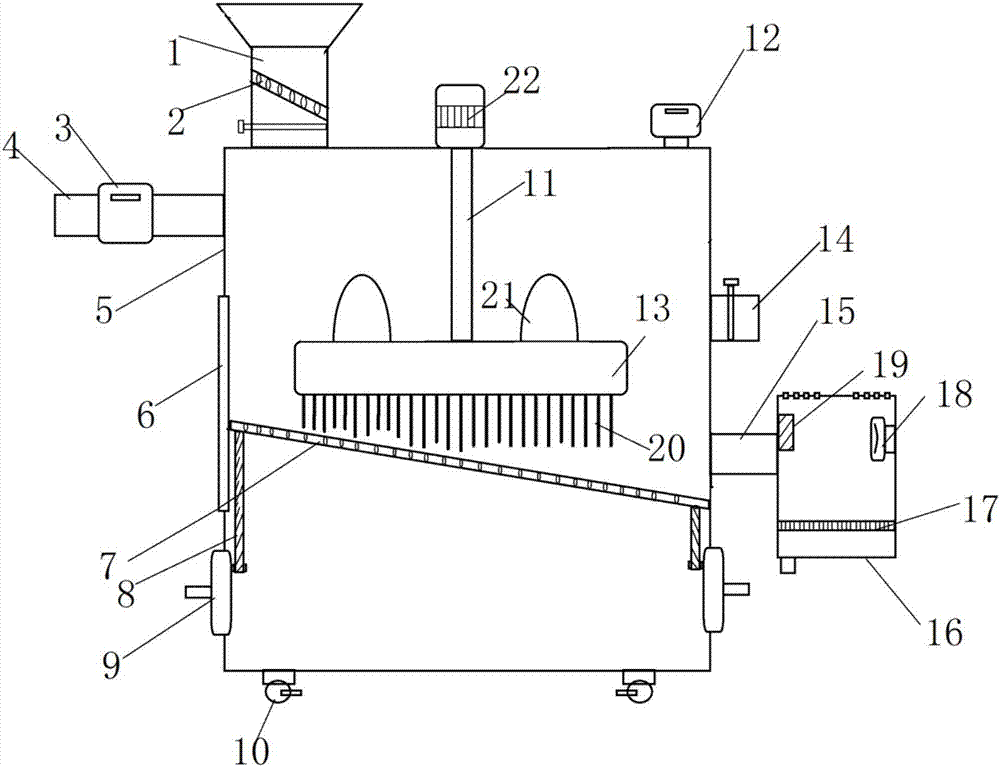

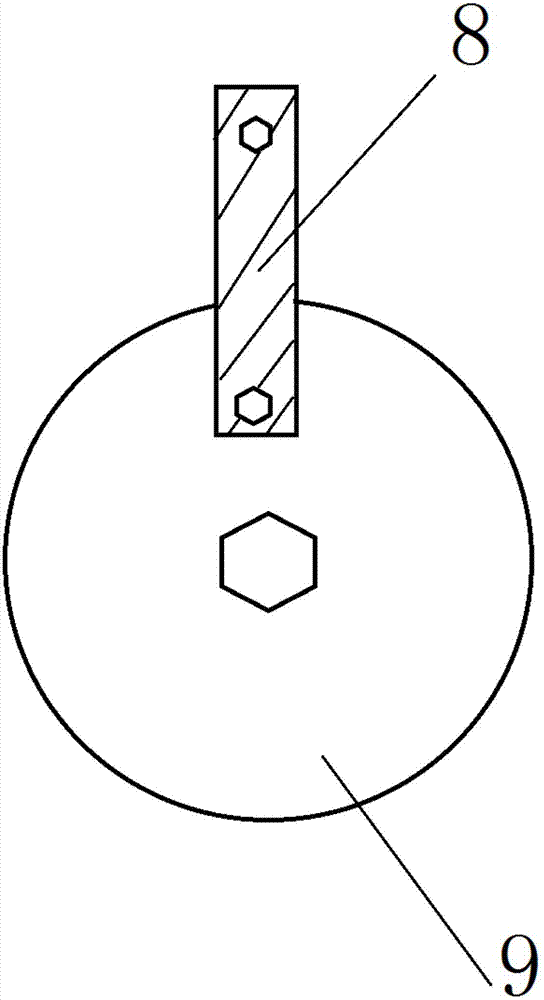

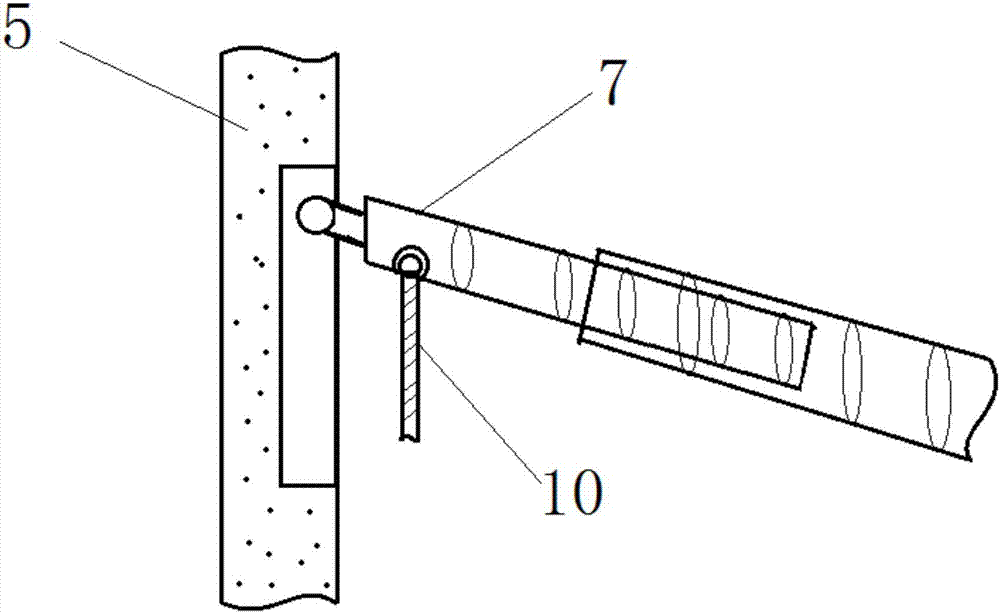

High efficiency cereal flotation, dust removing and sand gravel removing device

InactiveCN107470014AEasy feedingEasy to scrubSievingUsing liquid separation agentImpellerEngineering

The invention discloses a high efficiency cereal flotation, dust removing and sand gravel removing device. The device comprises a feed pipe, a flow meter, a water inlet pipe, a screen box, a vibrating screen plate, rotating wheels, a rotating shaft, a liquid-level meter, an impeller, a sundries discharge pipe, a cereal discharge pipe and a drying box, wherein the feed pipe is connected with the screen box; an inclined filter screen is arranged in the feed pipe; the water inlet pipe communicates with the upper part of the screen box; the flow meter is arranged on the water inlet pipe; the liquid-level meter is arranged on the screen box; a piece of transparent glass plate is mounted on one side wall of the screen box; the rotating shaft is arranged in the screen box; the impeller is mounted at the bottom end of the rotating shaft; the vibrating screen plate is arranged in the screen box; the two ends of the vibrating screen plate are in point connection with the outer side ends of the rotating wheels through connecting pieces separately; the sundries discharge pipe and the cereal discharge pipe are arranged on one side of the screen box from top to bottom; and one end of the cereal discharge pipe communicates with the drying box. According to the high efficiency cereal flotation, dust removing and sand gravel removing device, that the air is covered with dust is avoided, the peasants' health is ensured, sand gravels and the like sink to the bottom due to buoyancy, the product quality is ensured, the structure is simple, the use is convenient, and the popularization is facilitated.

Owner:胡忠义

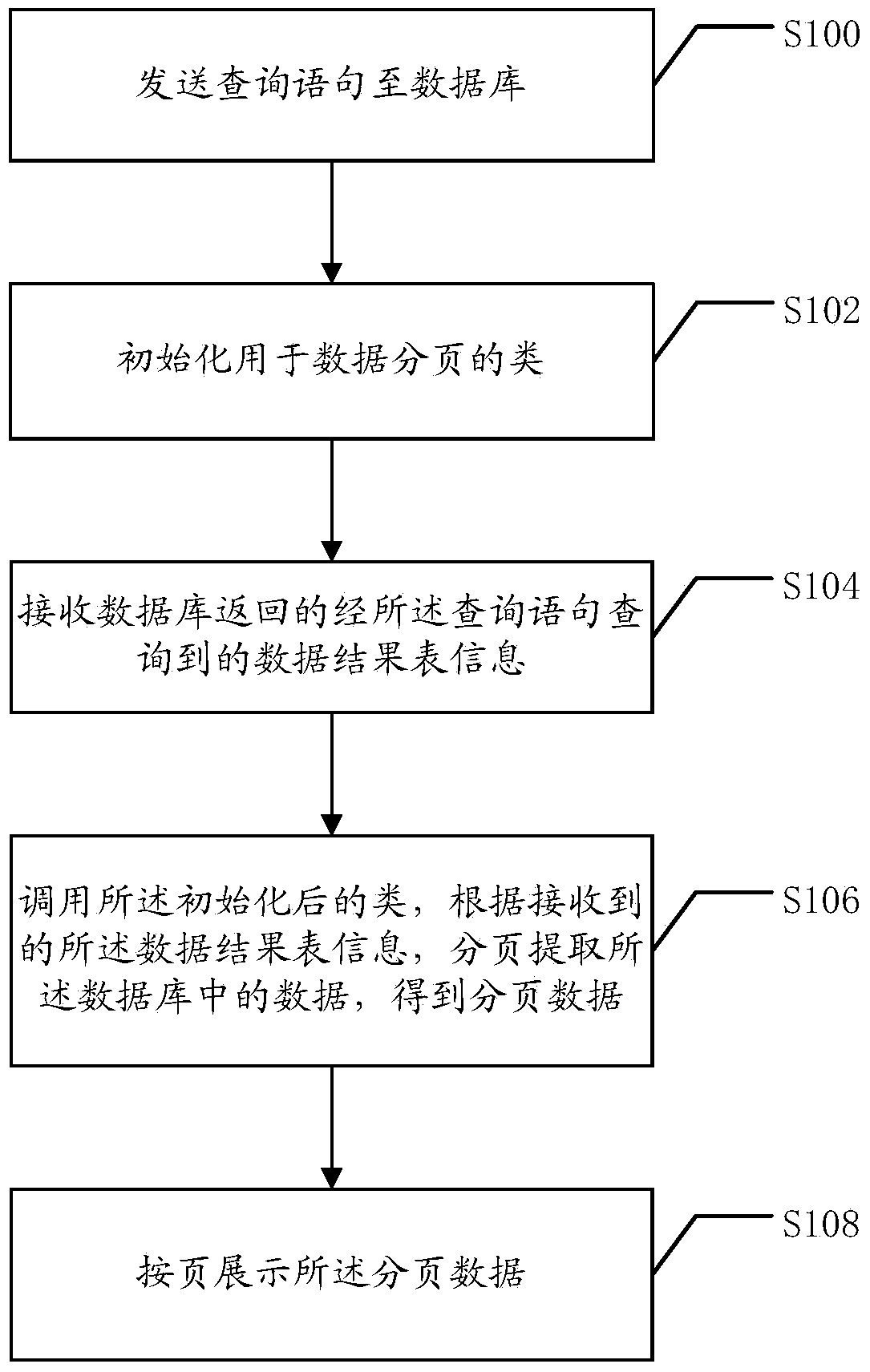

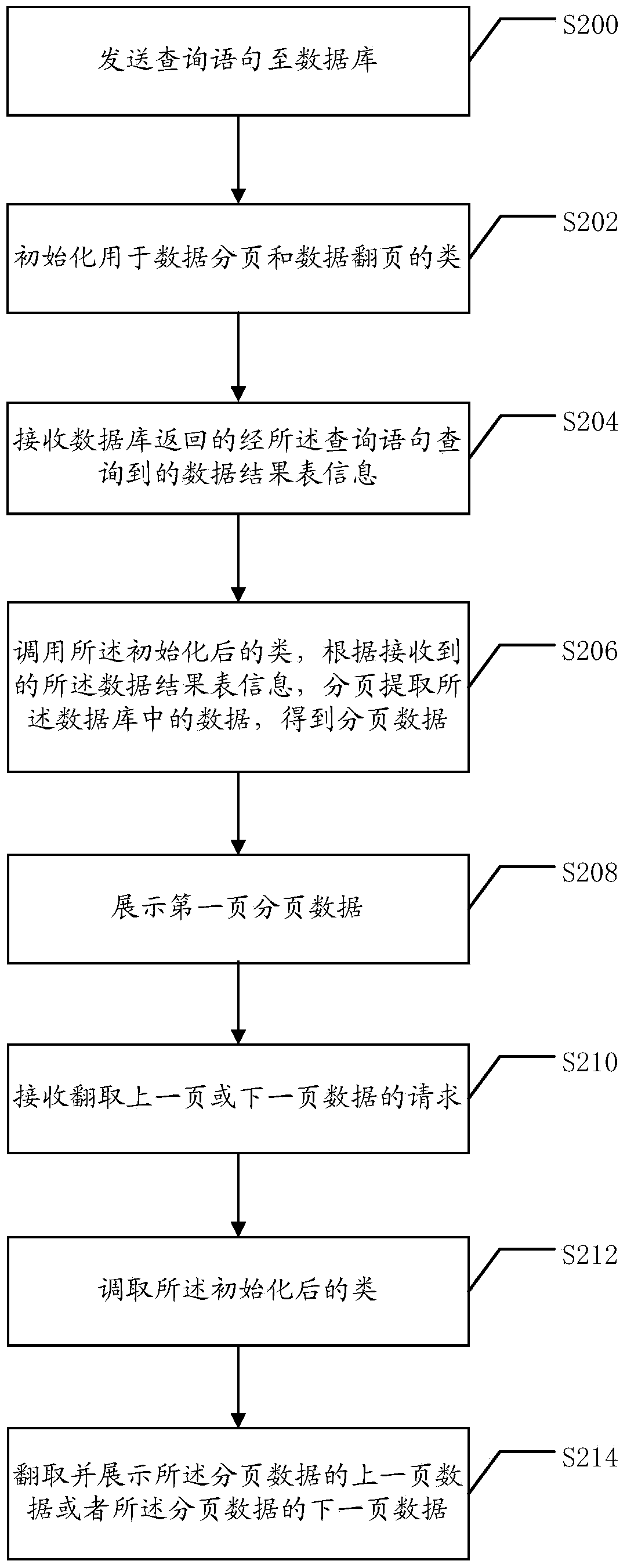

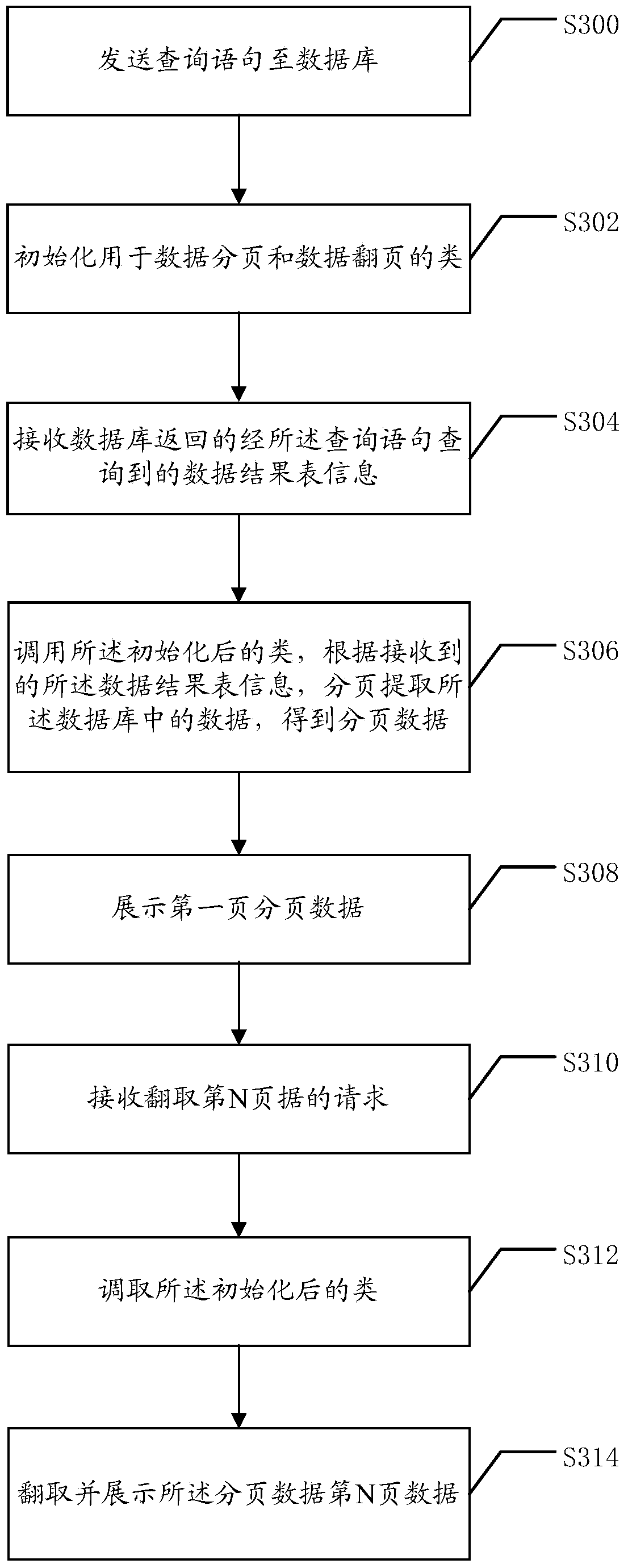

Method and system for quickly expressing data of database

The embodiment of the invention discloses a method for quickly expressing data of database. The method comprises the following steps: sending a query statement to the database, wherein the query statement is used for inquiring data stored in the database; initializing classes used for data paging; receiving data object list information fed back by the data base and inquired through the query statement; calling the initialized classes and extracting the data in the database in a paged manner to obtained paged data according to the received data object list information; expressing the paged data in pages. After the method is adopted, a user can regulate and obtain the data in the data base, so that the problems of low data transmission efficiency of a database, low expression efficiency, large occupied space and memory and the like of the prior art can be solved, individual needs of users can be met, data can be expressed in a paged manner, and the users can obtain clear data expression conveniently.

Owner:CHINA CONSTRUCTION BANK

Circuit board comprising blind hole and manufacturing method of circuit board

InactiveCN103917046AReduce production processSimple processElectrical connection printed elementsPrinted element electric connection formationCopper platingOn board

The invention discloses a circuit board comprising a blind hole and a manufacturing method of the circuit board and belongs to the technical field of printed circuit boards. The manufacturing method comprises the steps that the processes of daughter board hole drilling, electroless copper plating, board plating, hole plating, inner layer pattern manufacturing, brownification, resin hole blocking, board drying and daughter board lamination. In the resin hole blocking process, a pre-manufactured hole blocking aluminum piece is arranged on the surface of a daughter board in a covering mode, a window-opening zone corresponding to a zone which needs resin hole blocking on the daughter board is arranged on the hole blocking aluminum piece, and then resin hole blocking is carried out. Accordingly, the problem that a whole board face is full of resin is avoided, ceramic board grinding is of no need, and the problem that surplus resin stays in concave parts on the board face or base materials are exposed out of the board face is solved. The manufacturing method of a resin blocking hole is suitable for blind hole resin filling of various boards, and limitation on boards of the resin blocking hole is removed.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

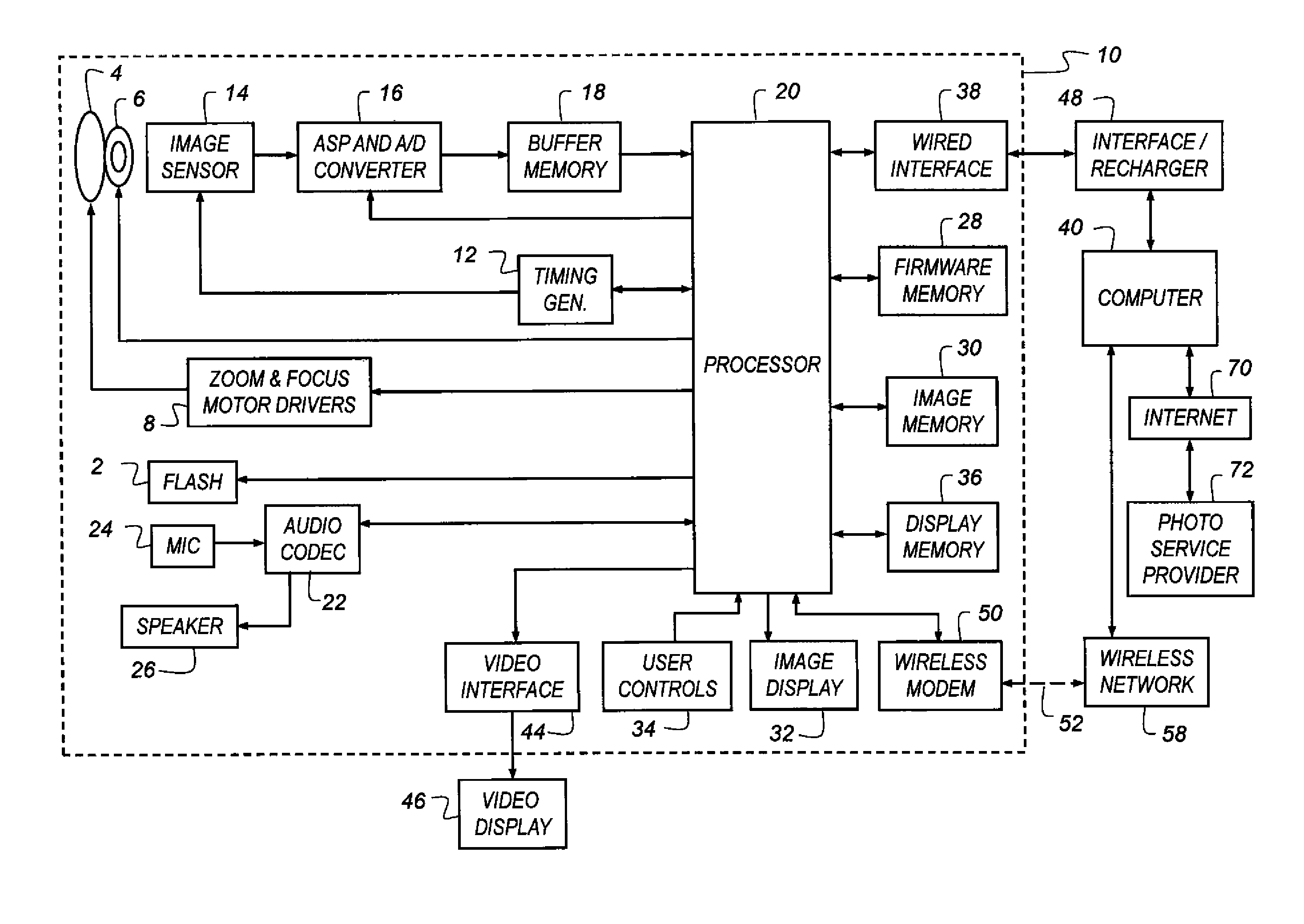

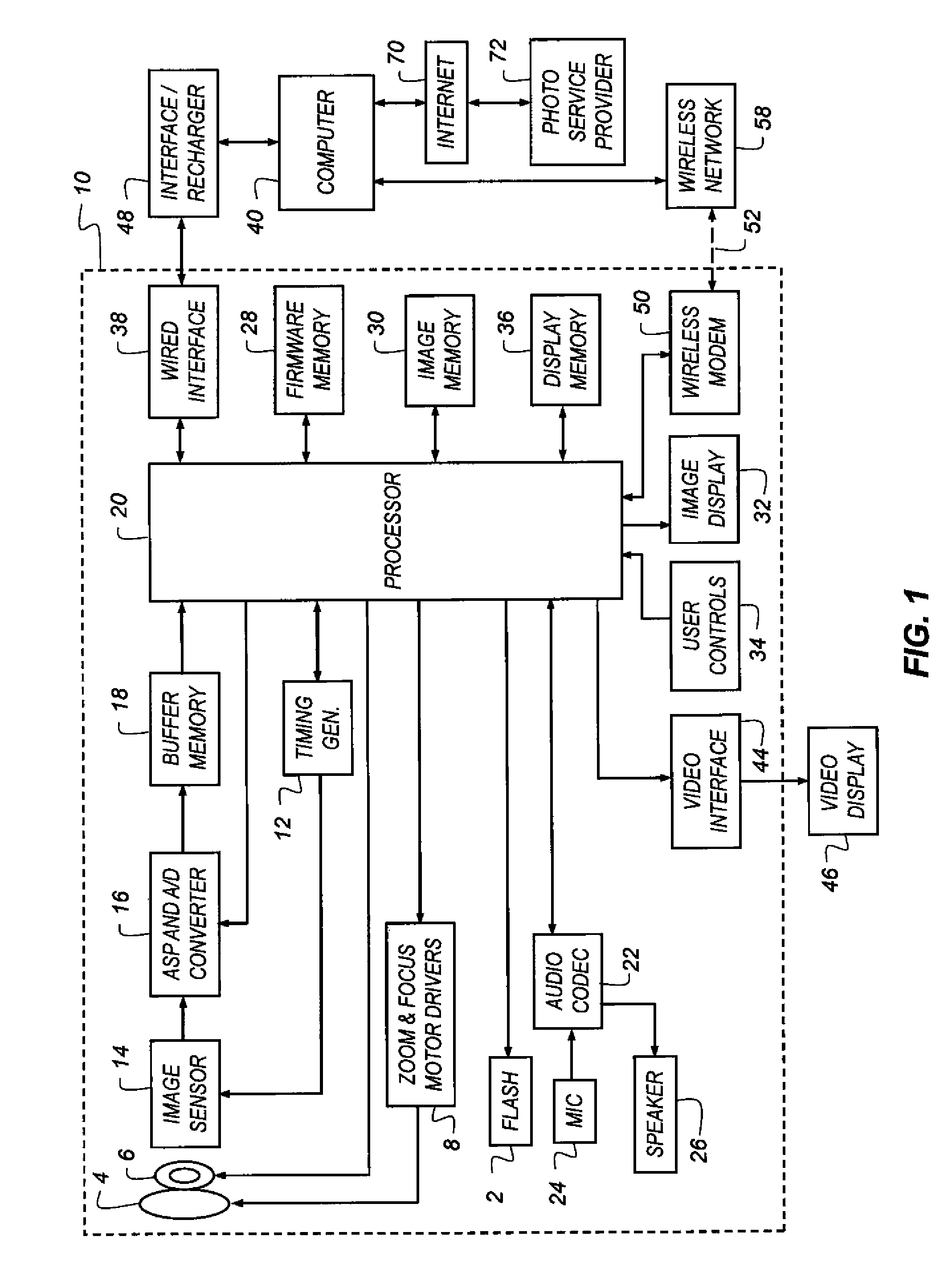

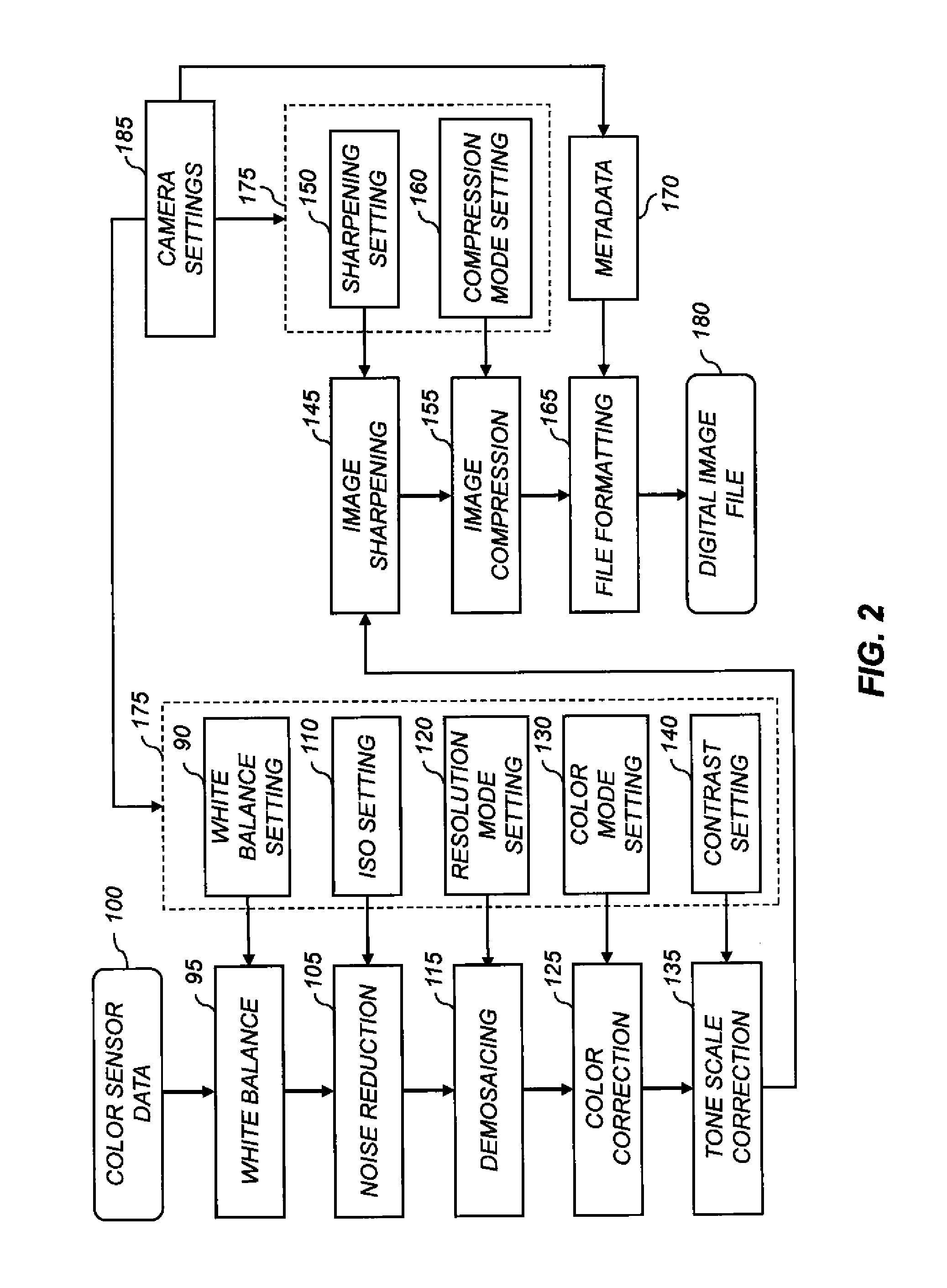

Digital camera system having a retail mode

InactiveUS20120169897A1Prevent fullEasy to identifyTelevision system detailsColor television detailsData processing systemComputer graphics (images)

A digital camera system having a retail mode, comprising: an image sensor; an optical system for forming an image of a scene; a data processing system; an storage memory; and a program memory storing instructions configured to implement a method for automatically deleting captured digital images. The stored instructions include setting the digital camera system to operate in the retail mode in response to detecting a predefined first condition; enabling a user to capture a plurality of digital images, storing any digital images captured while the digital camera system is operating in the retail mode in the storage memory; and automatically deleting at least some of the stored digital images from the storage memory in response to detecting a predefined second condition, wherein any stored digital images that were not captured in the retail mode are not deleted from the storage memory.

Owner:MONUMENT PEAK VENTURES LLC

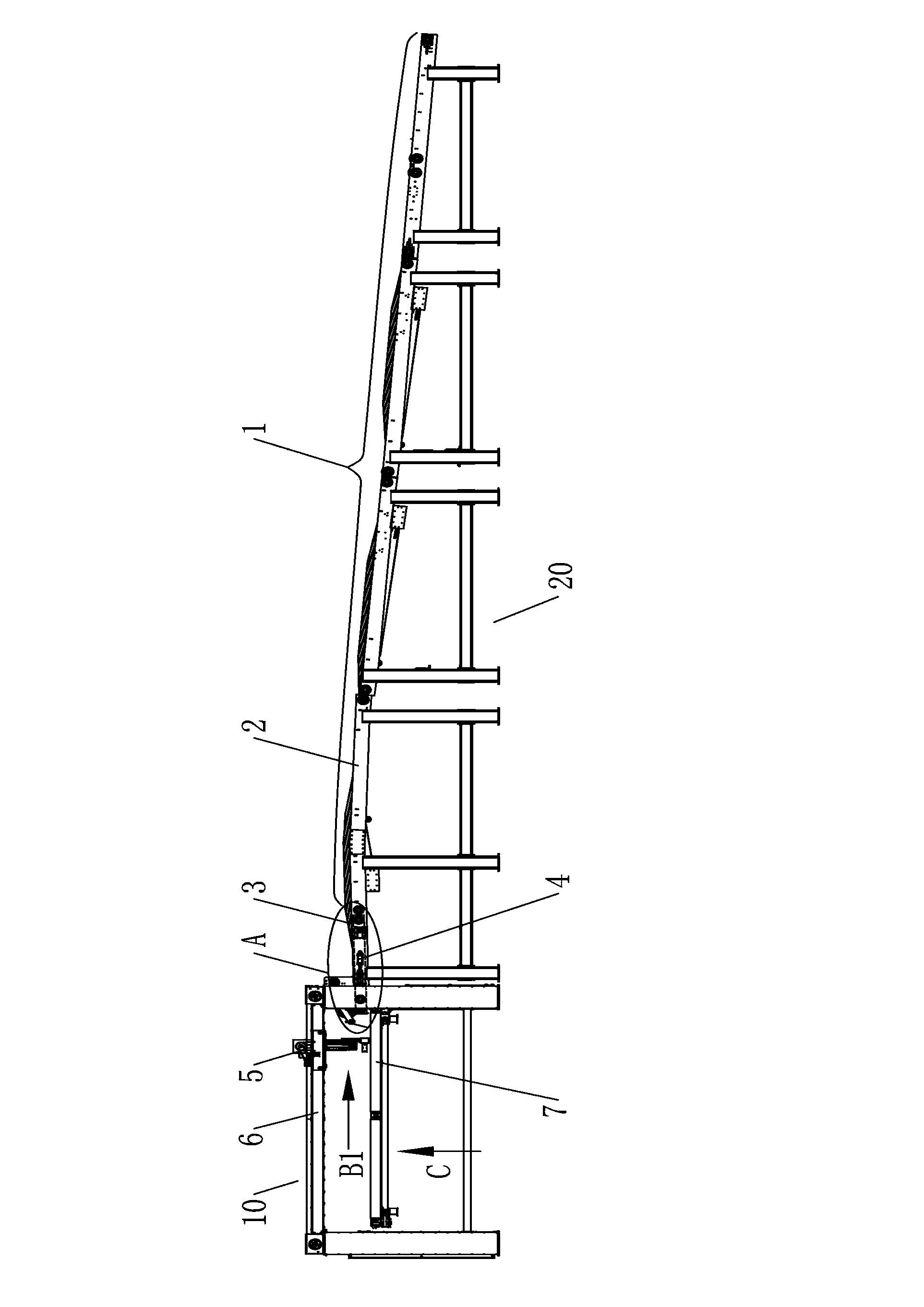

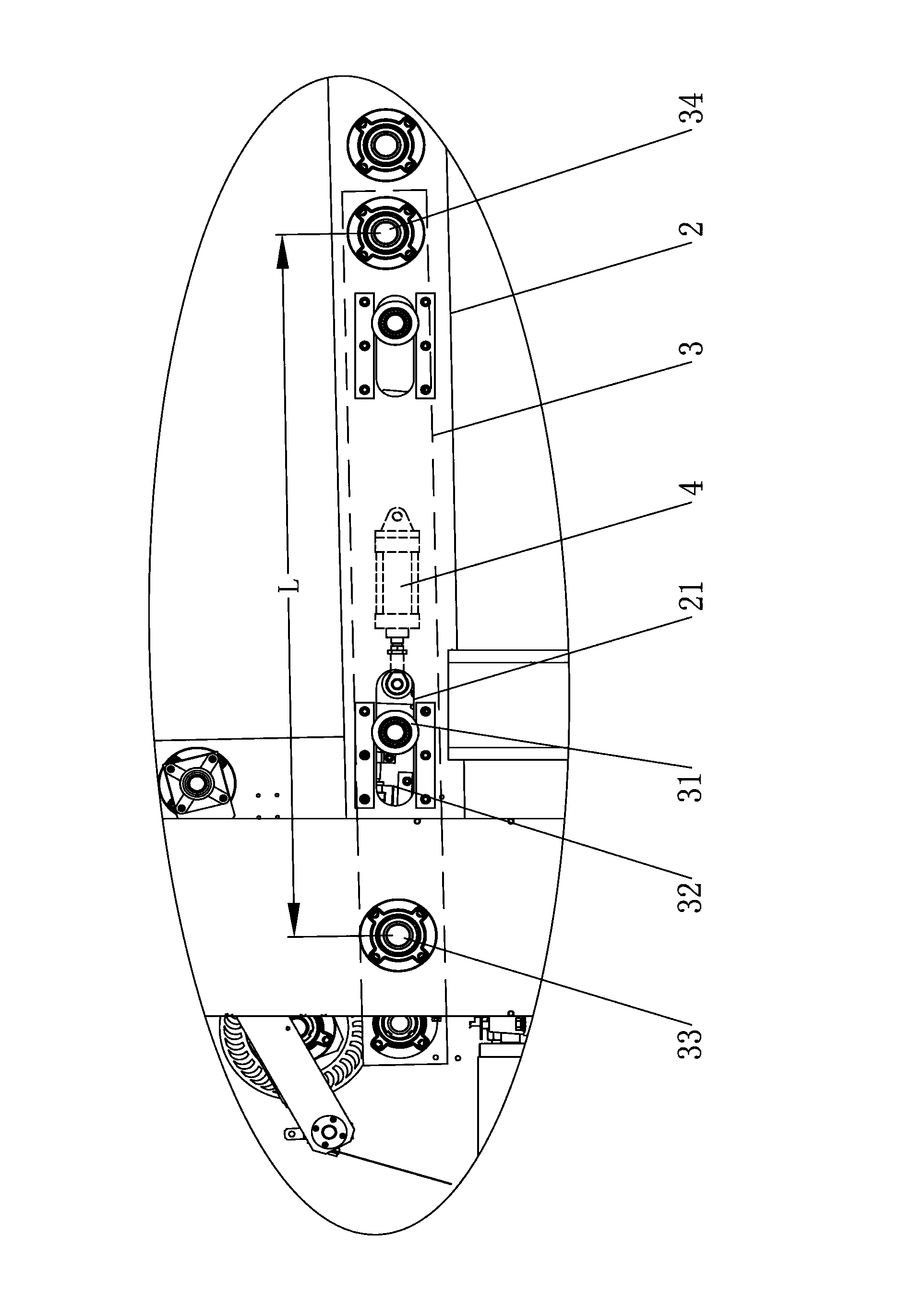

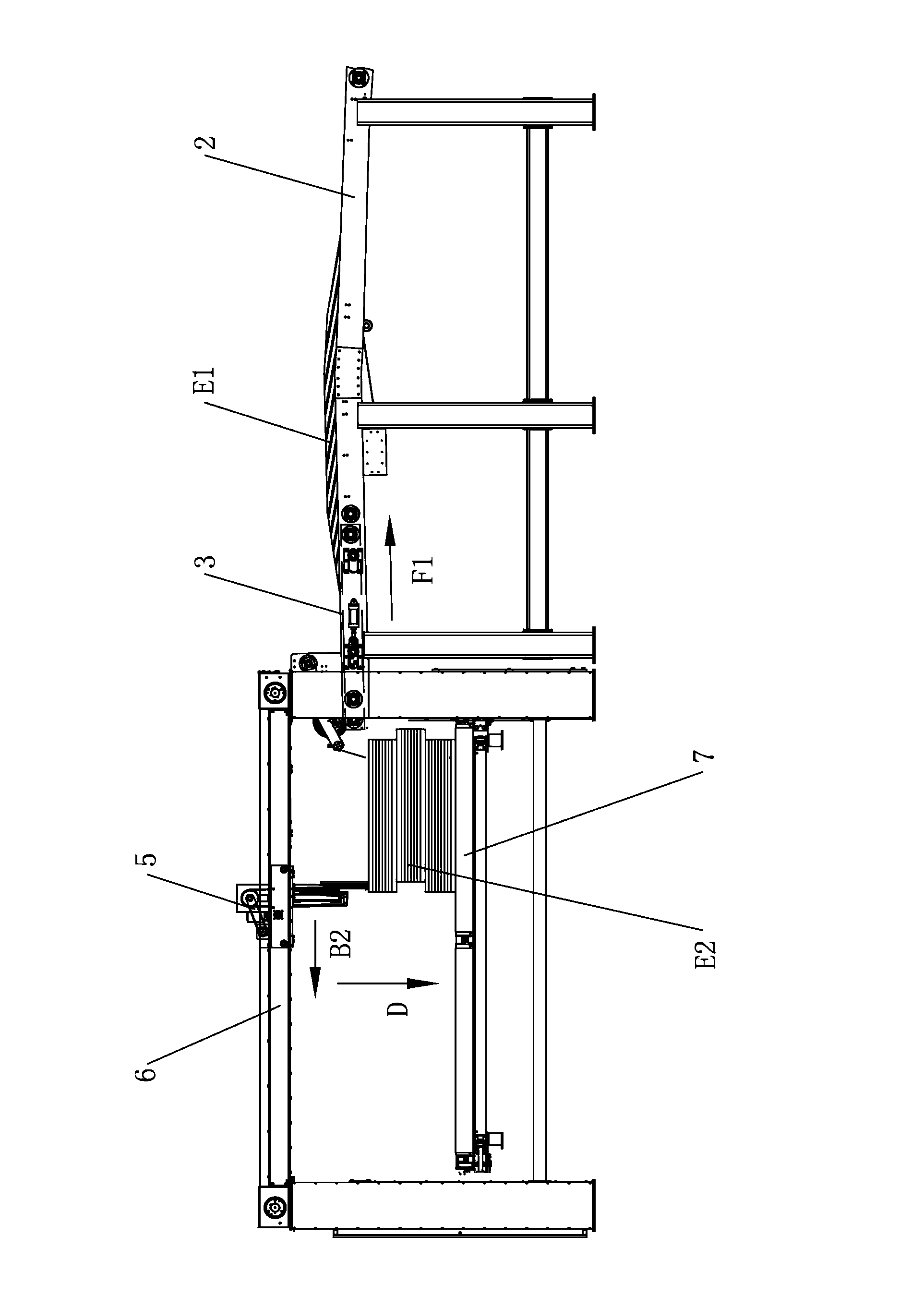

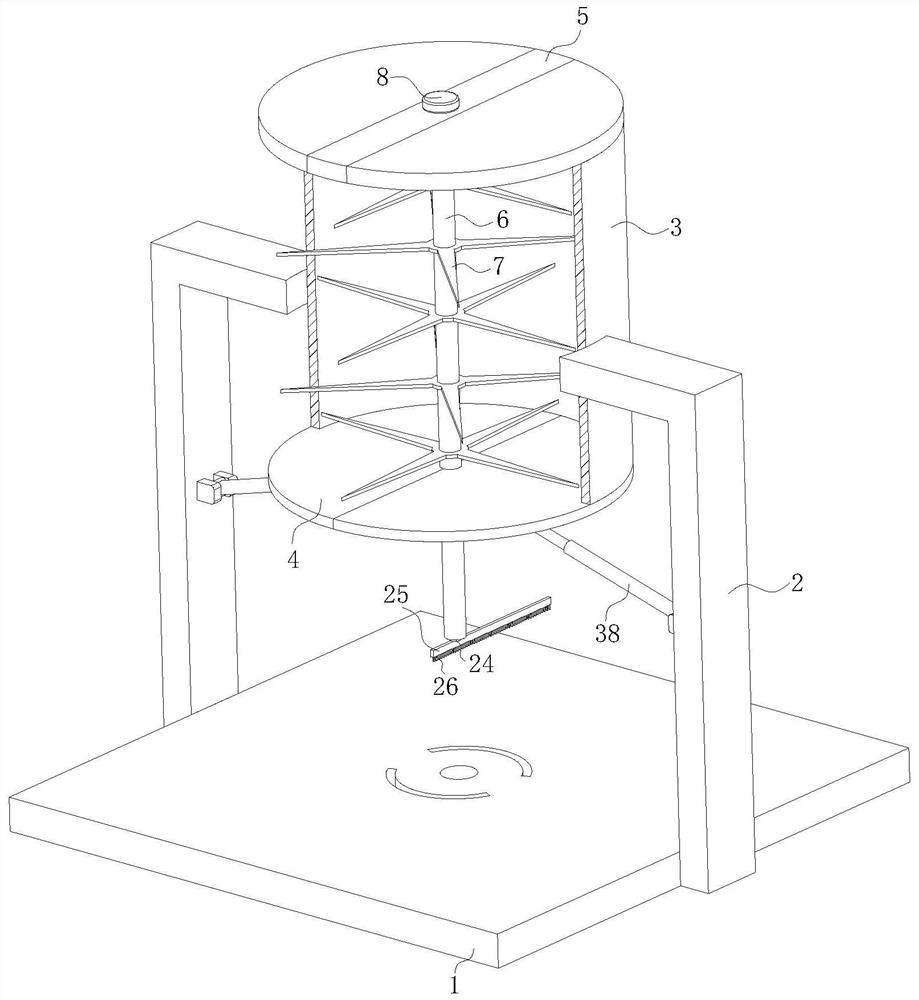

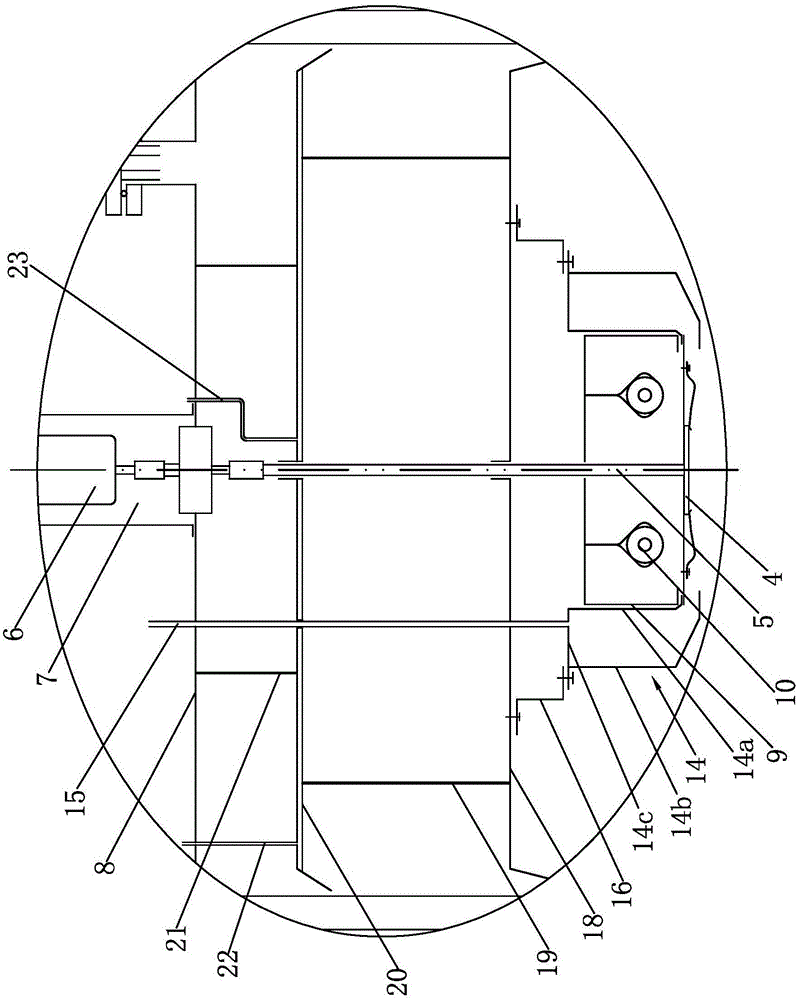

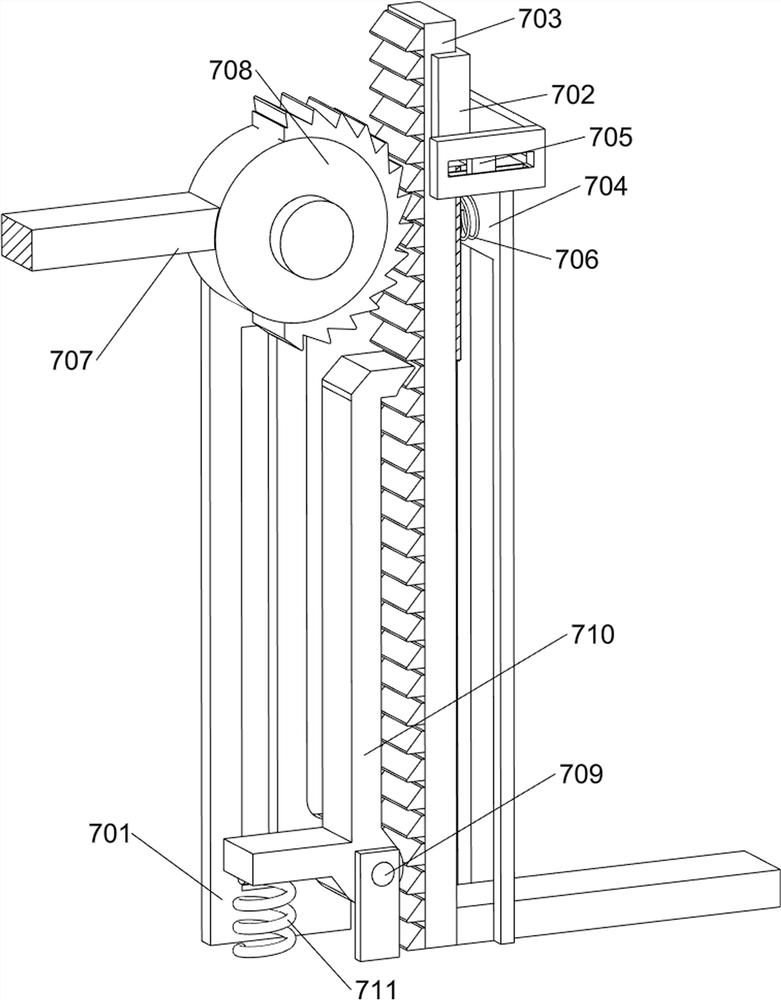

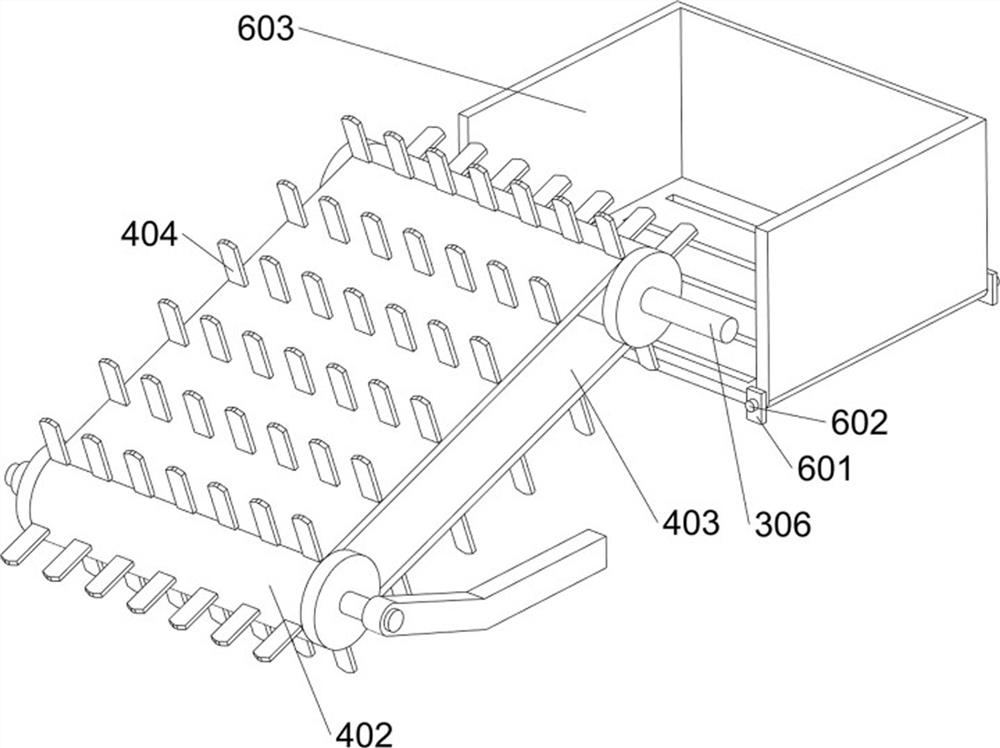

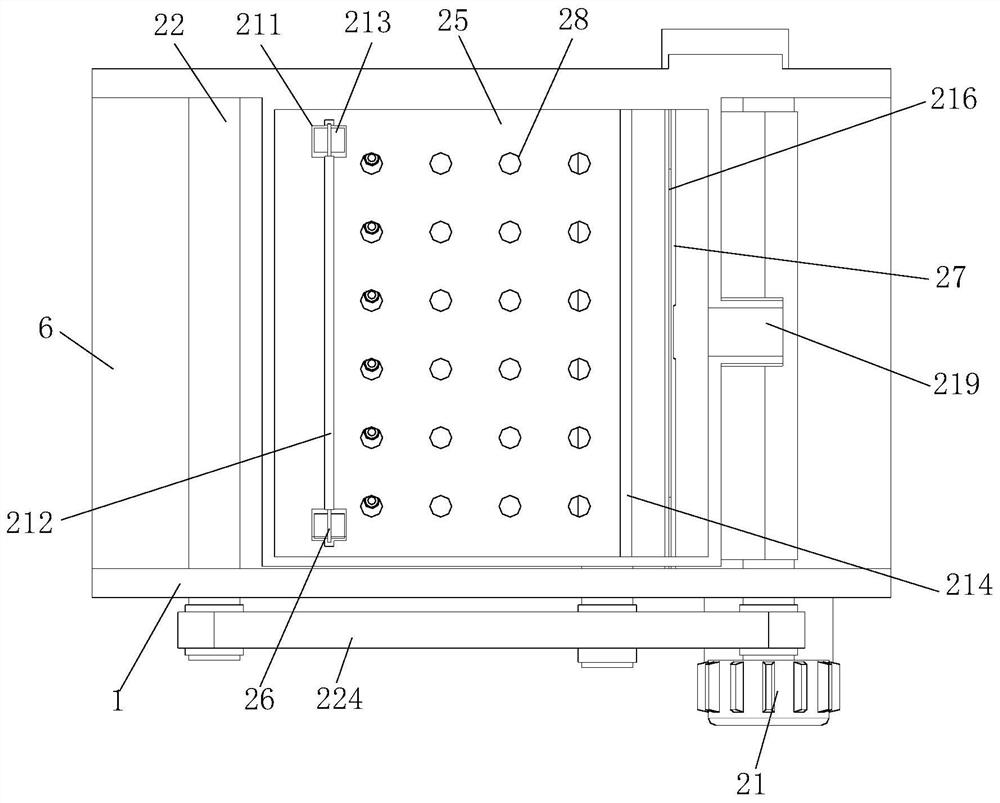

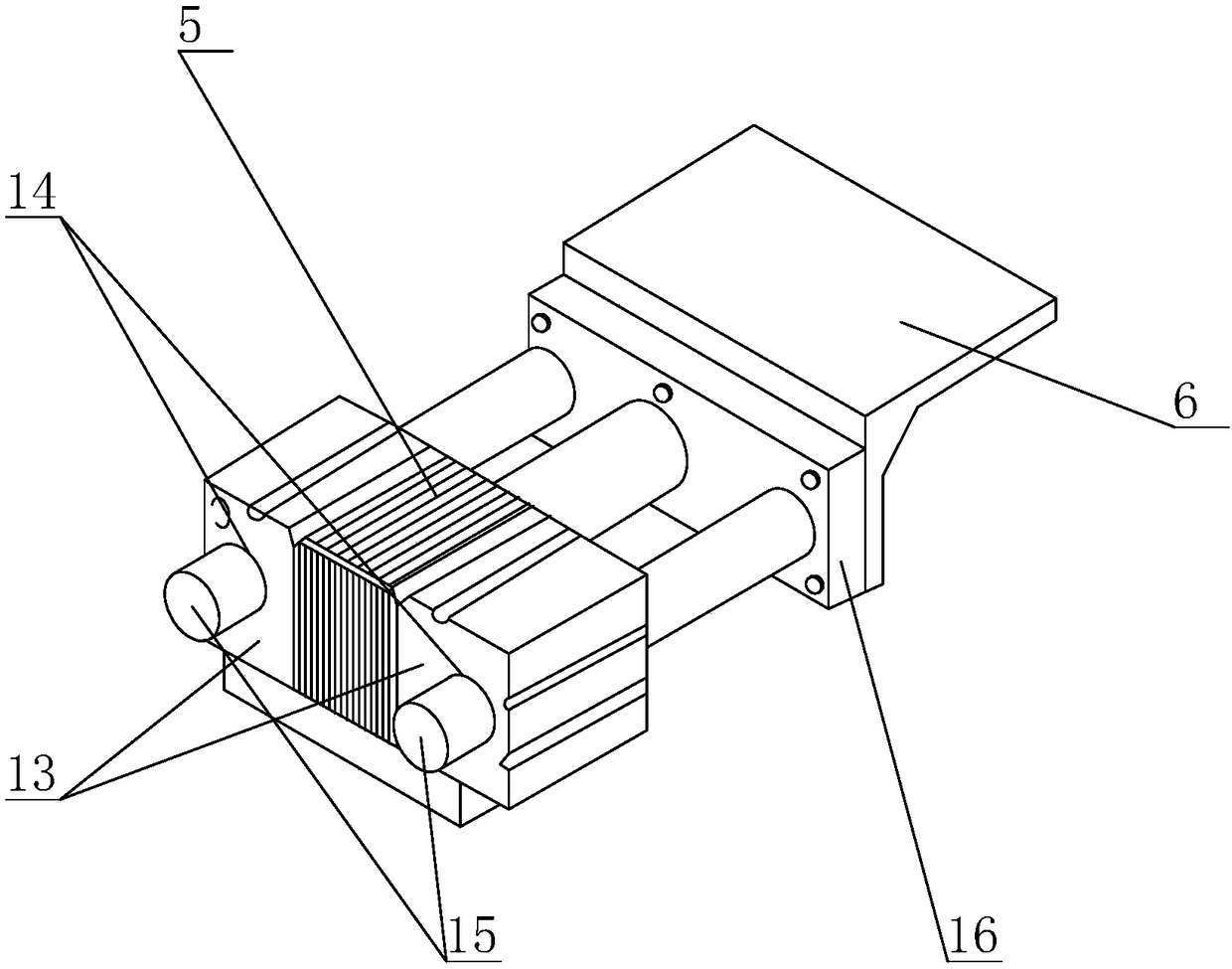

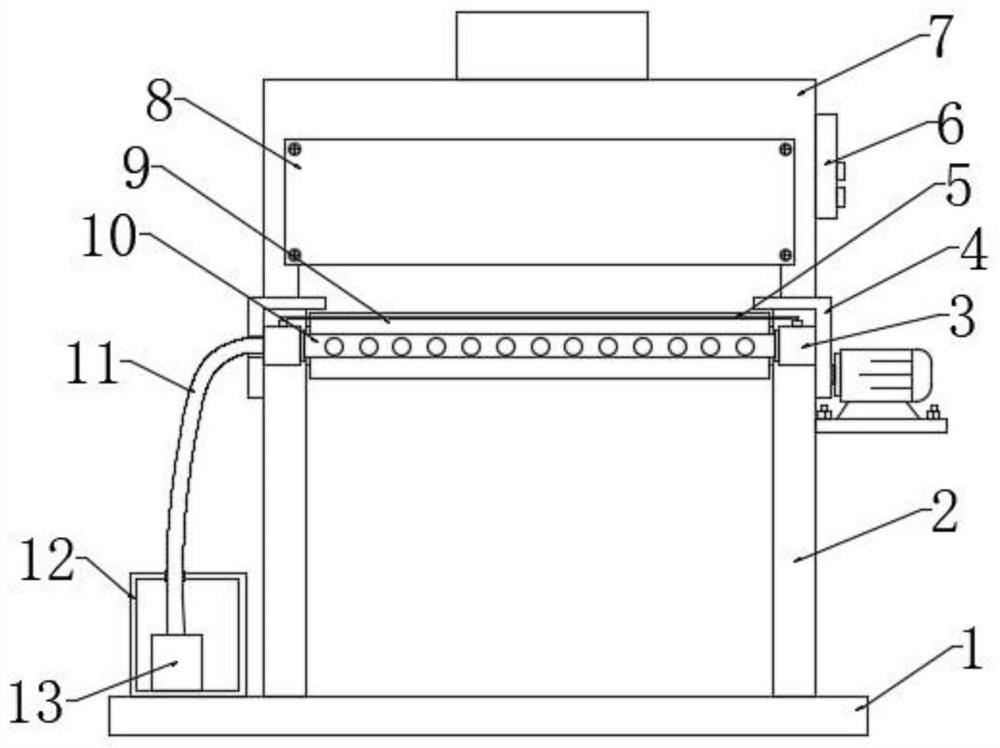

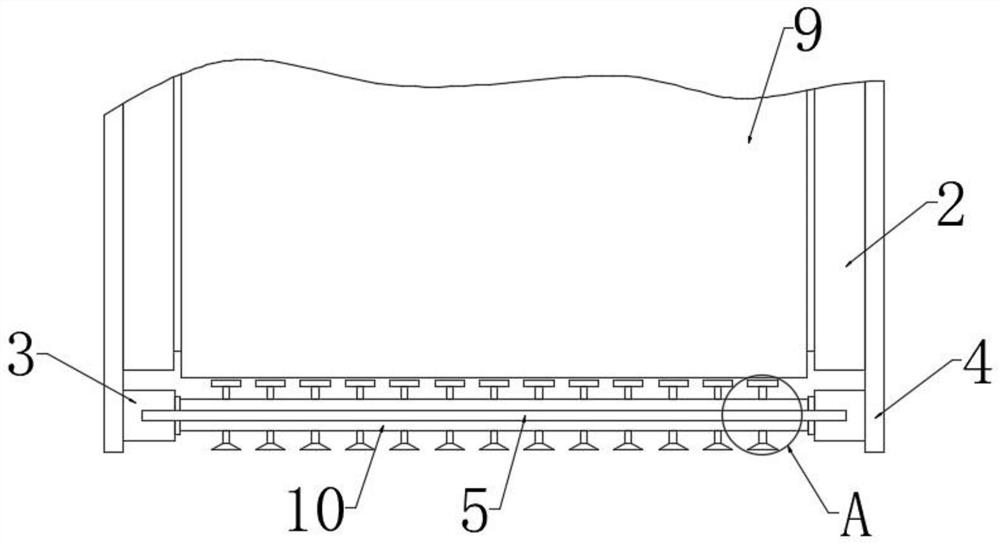

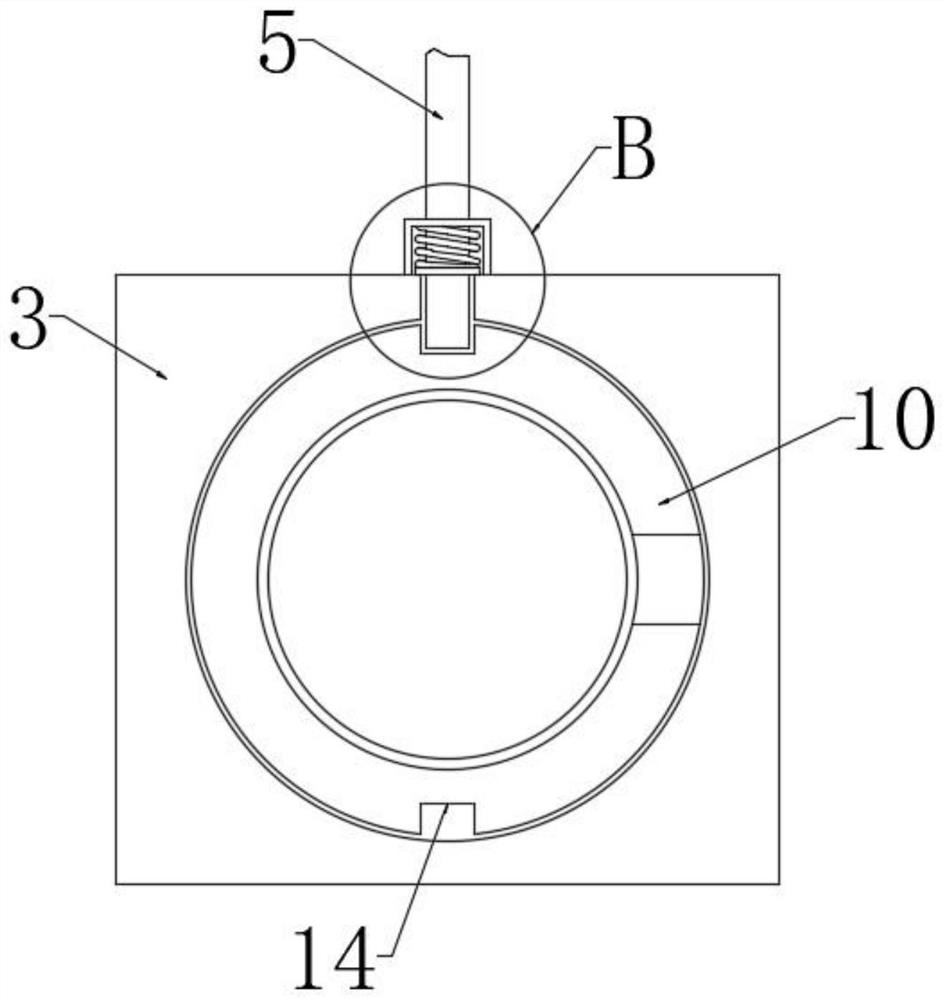

Automatic paperboard staggered stacking device

The invention relates to the technical field of packaging machinery, in particular to an automatic paperboard staggered stacking device. The automatic paperboard staggered stacking device comprises a paperboard stacking mechanism and a paperboard conveying mechanism, the paperboard stacking mechanism comprises a liftable layboy, a conveyer belt is arranged on the layboy, and the paperboard conveying mechanism comprises a rack, an acceleration conveying device, an air cylinder and a conveying belt. The acceleration conveying device sliding front and back is arranged on a front end of the rack, the conveying belt is arranged on a rear section of the rack, an air cylinder body is connected with the rack, and a piston rod of the air cylinder is connected with the acceleration conveying device. Effective bearing length of the conveying belt of the acceleration conveying device is 1600mm to 2500mm (millimeter), and the maximum operating speed can reach 200meters / minute which is 2-3 times of conveying speed of a rear section of the conveying belt. The automatic paperboard staggered stacking device is particularly applicable to a paperboard production device with a length of more than 800 mm, is capable of timely clearing paperboards stacking on the conveying belt during lifting and resetting of the layboy, and the paperboards sent out of the paperboard production device are prevented from full stacking on the conveying belt.

Owner:GUANGDONG WANLIAN PACKAGING MACHINERY

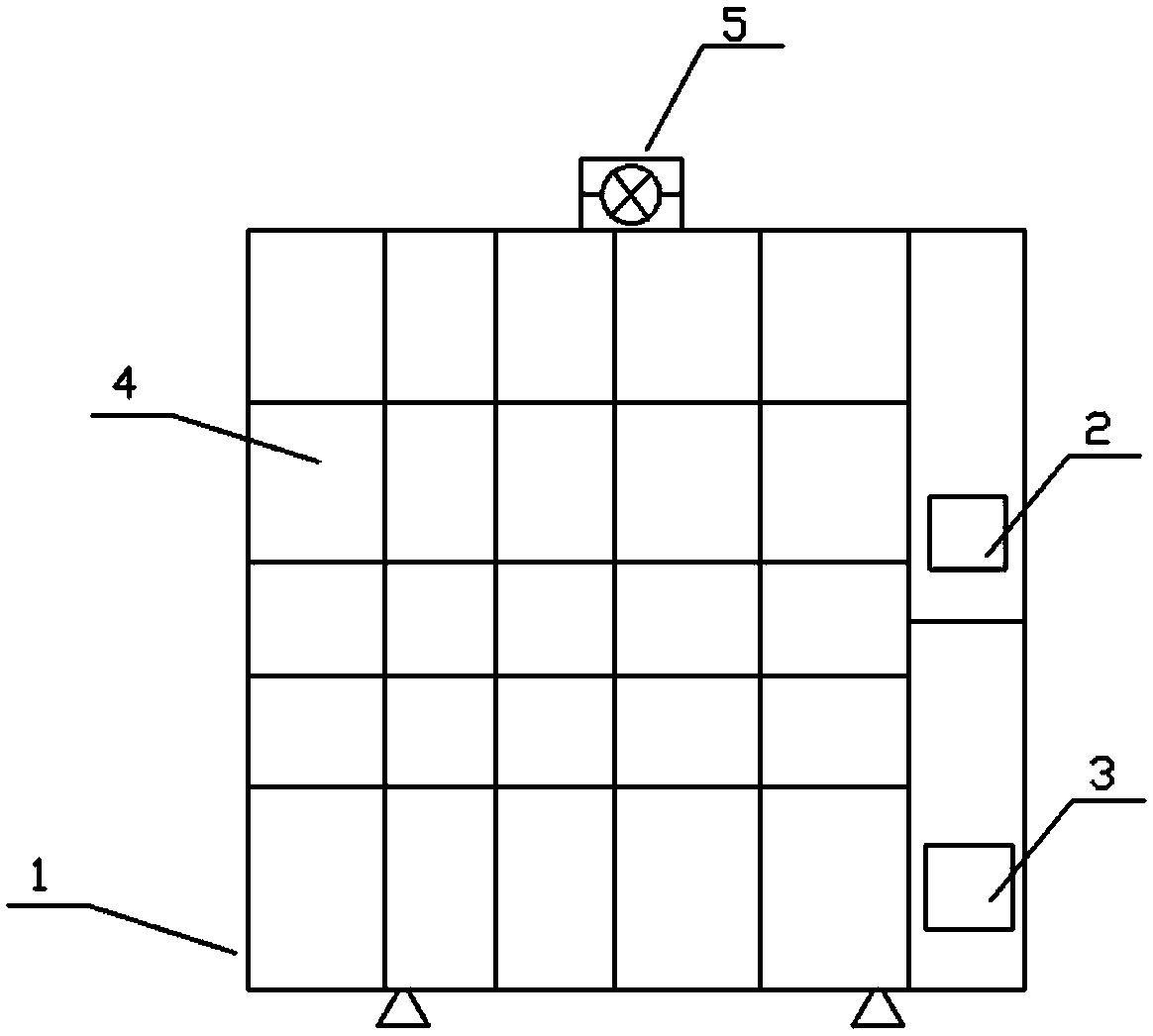

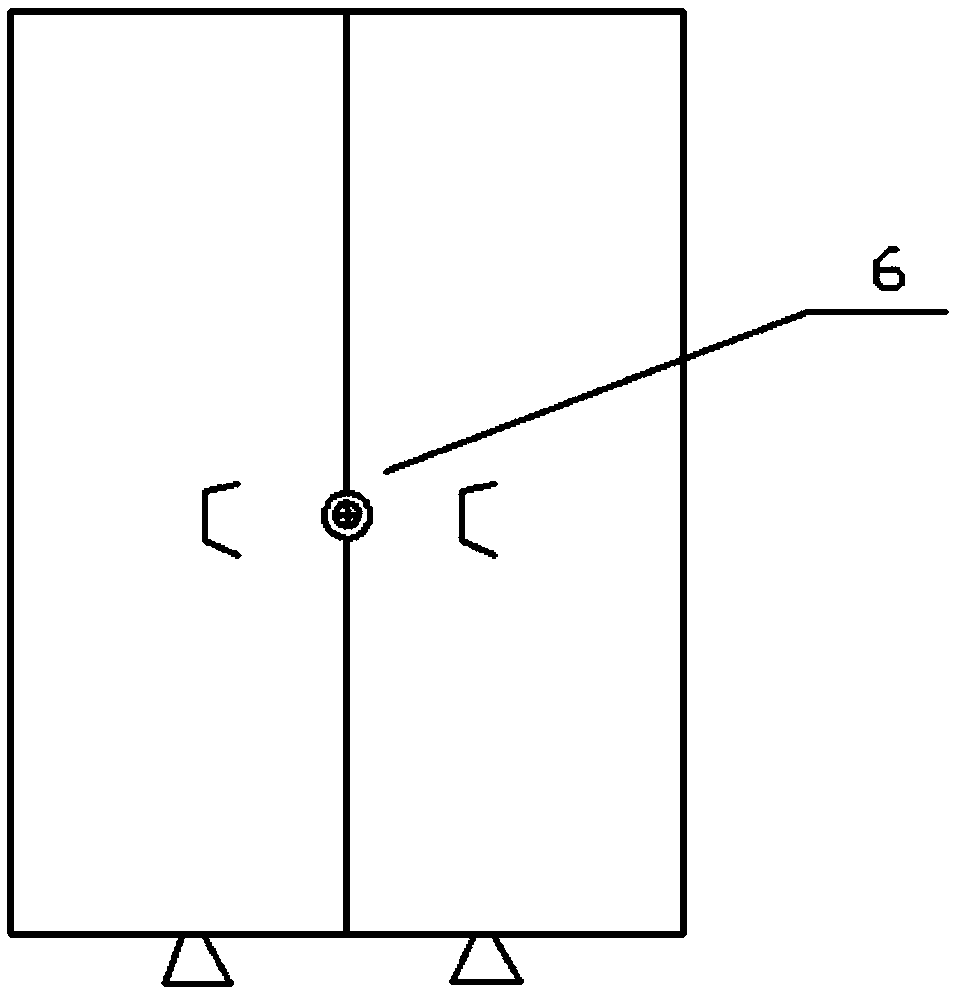

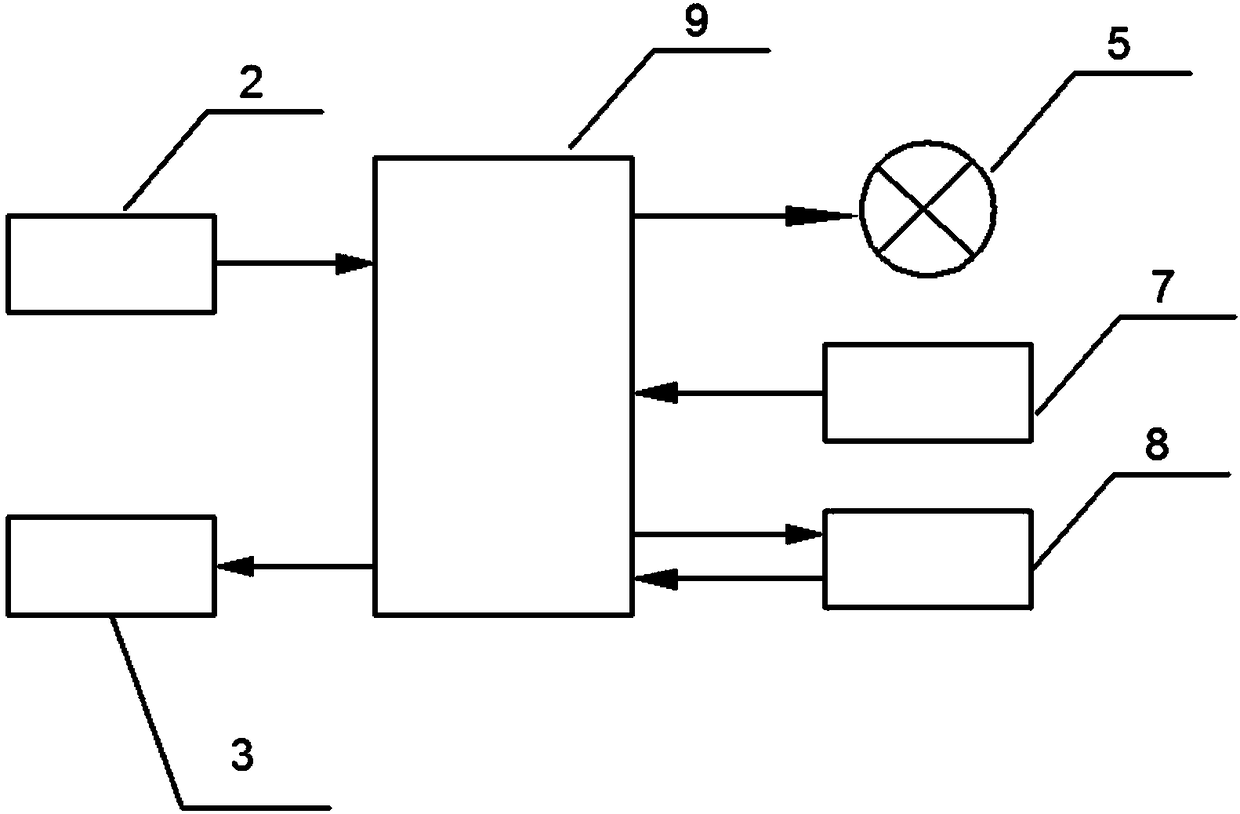

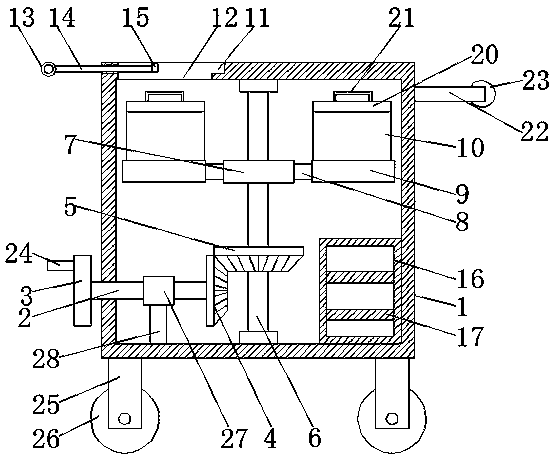

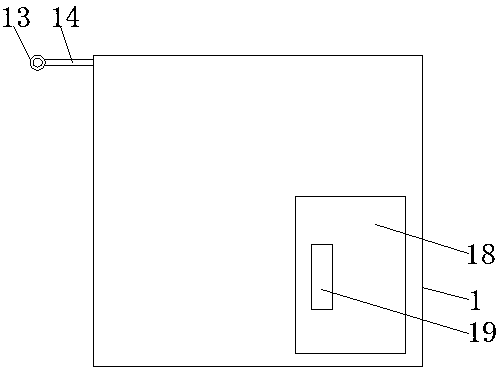

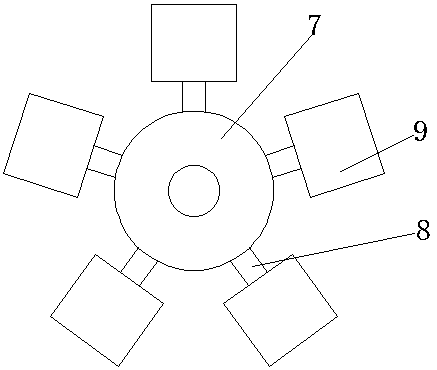

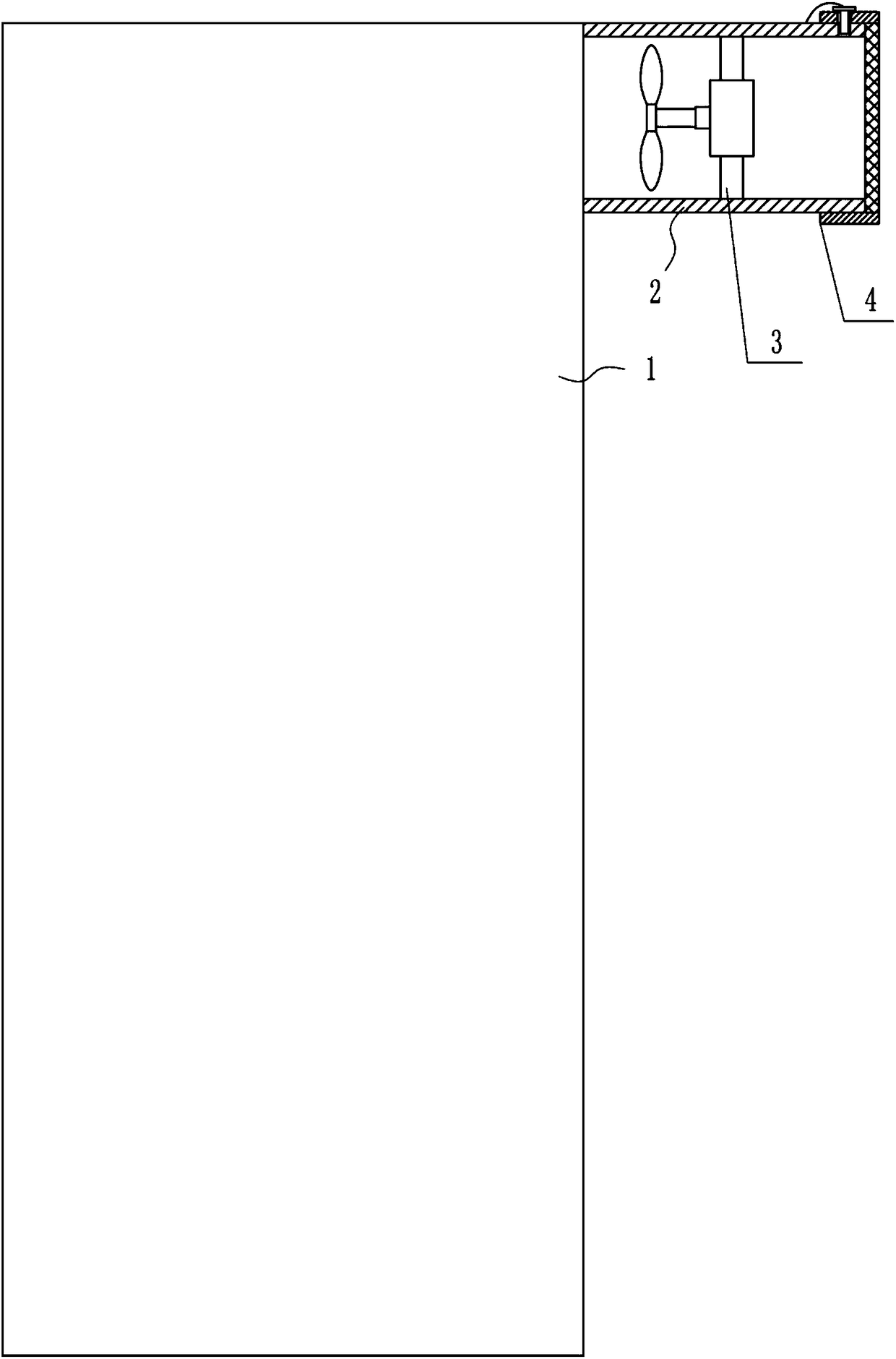

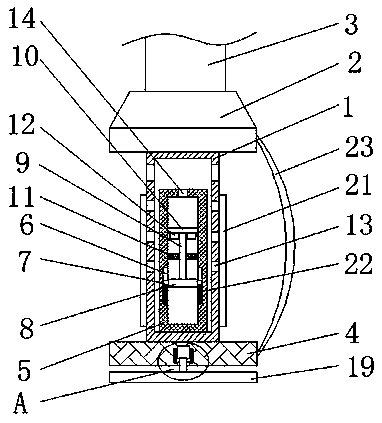

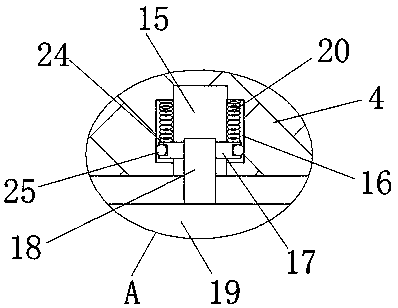

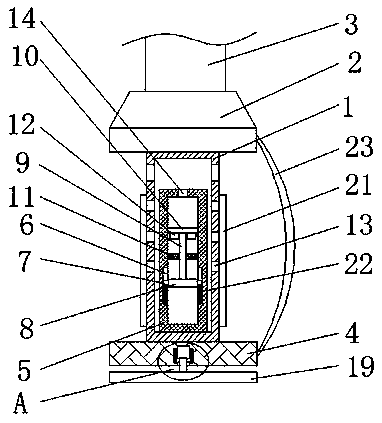

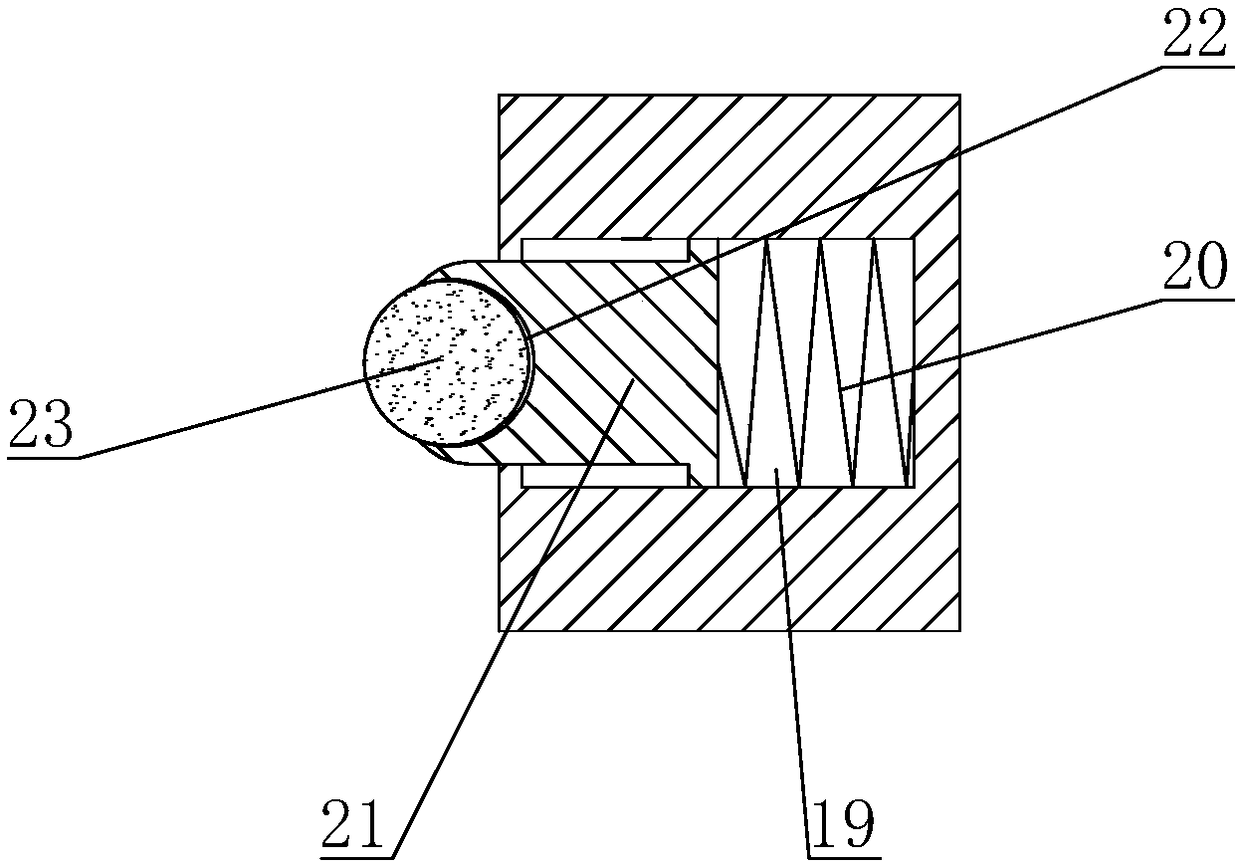

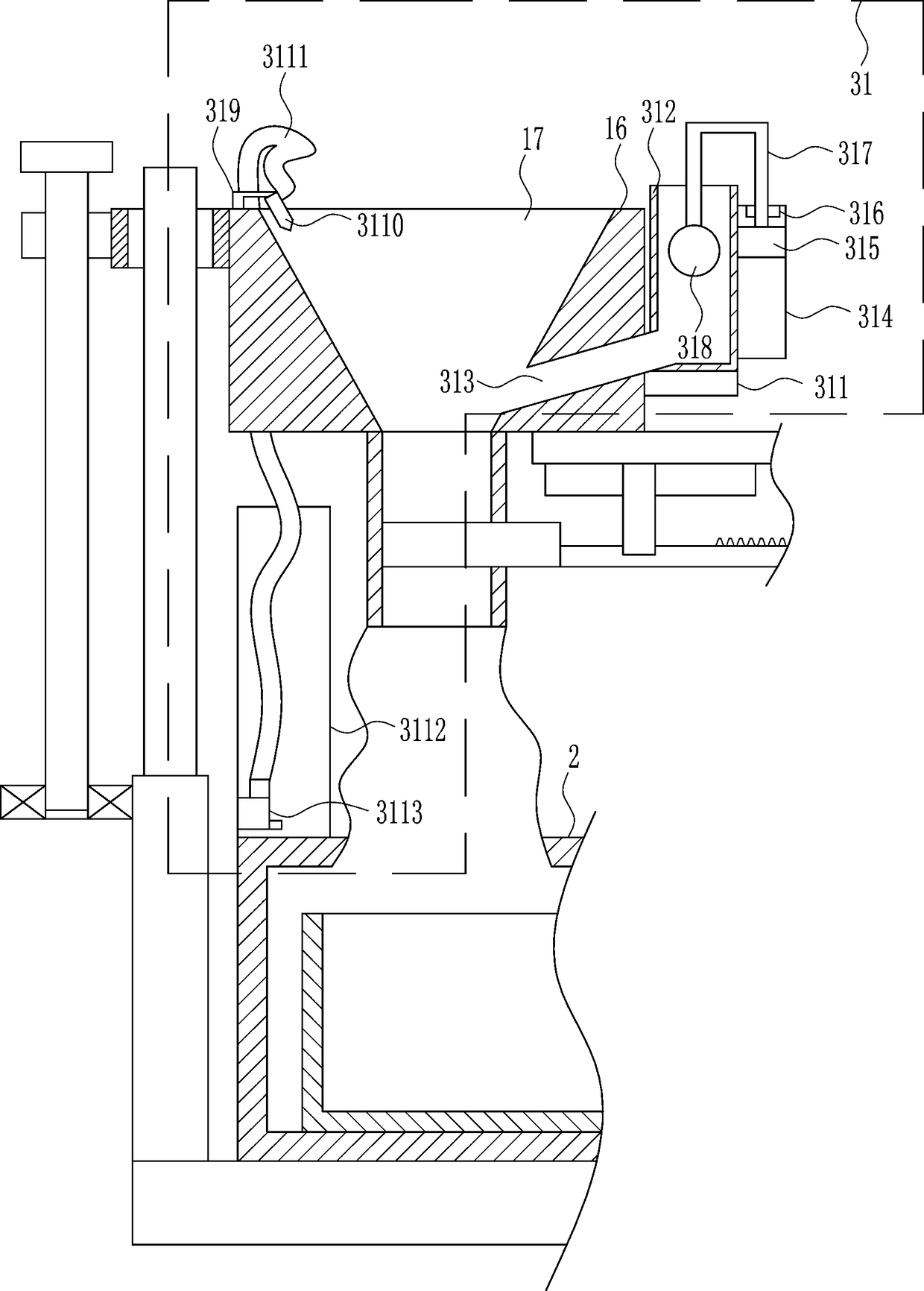

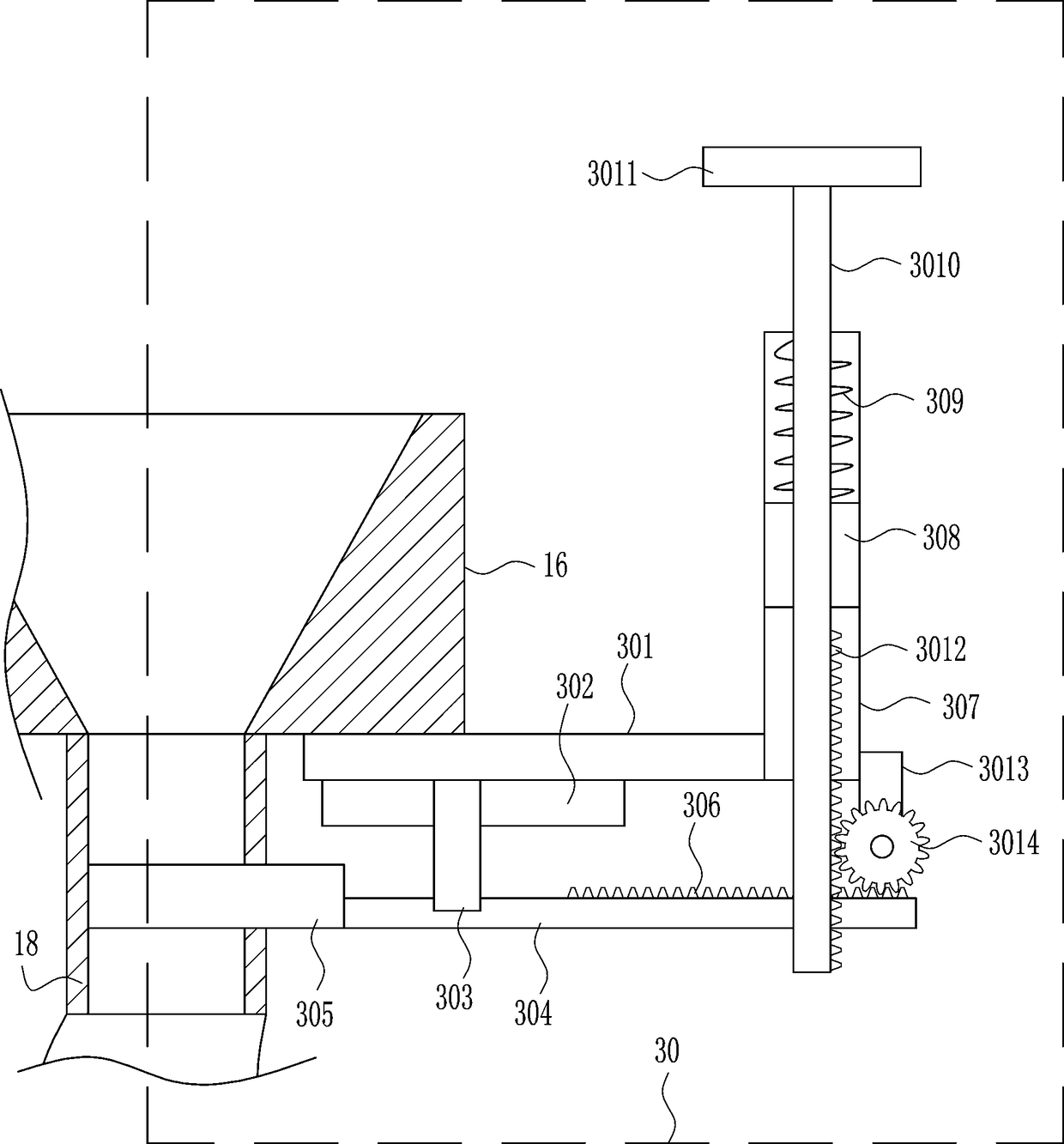

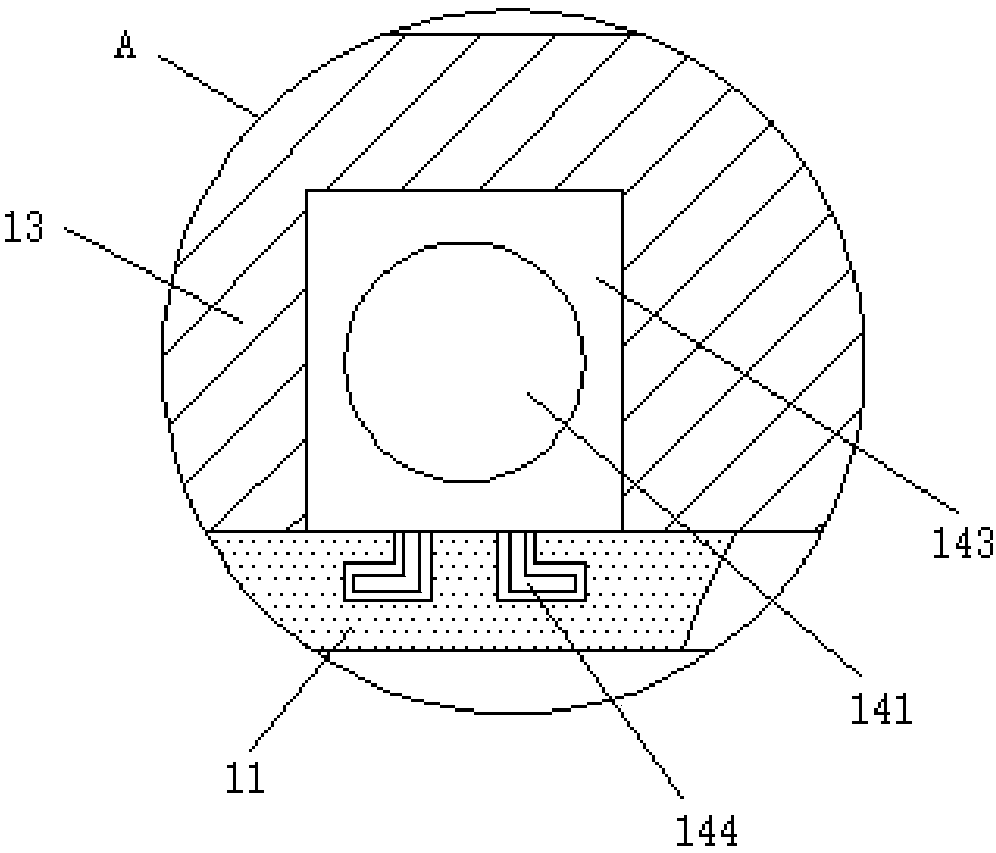

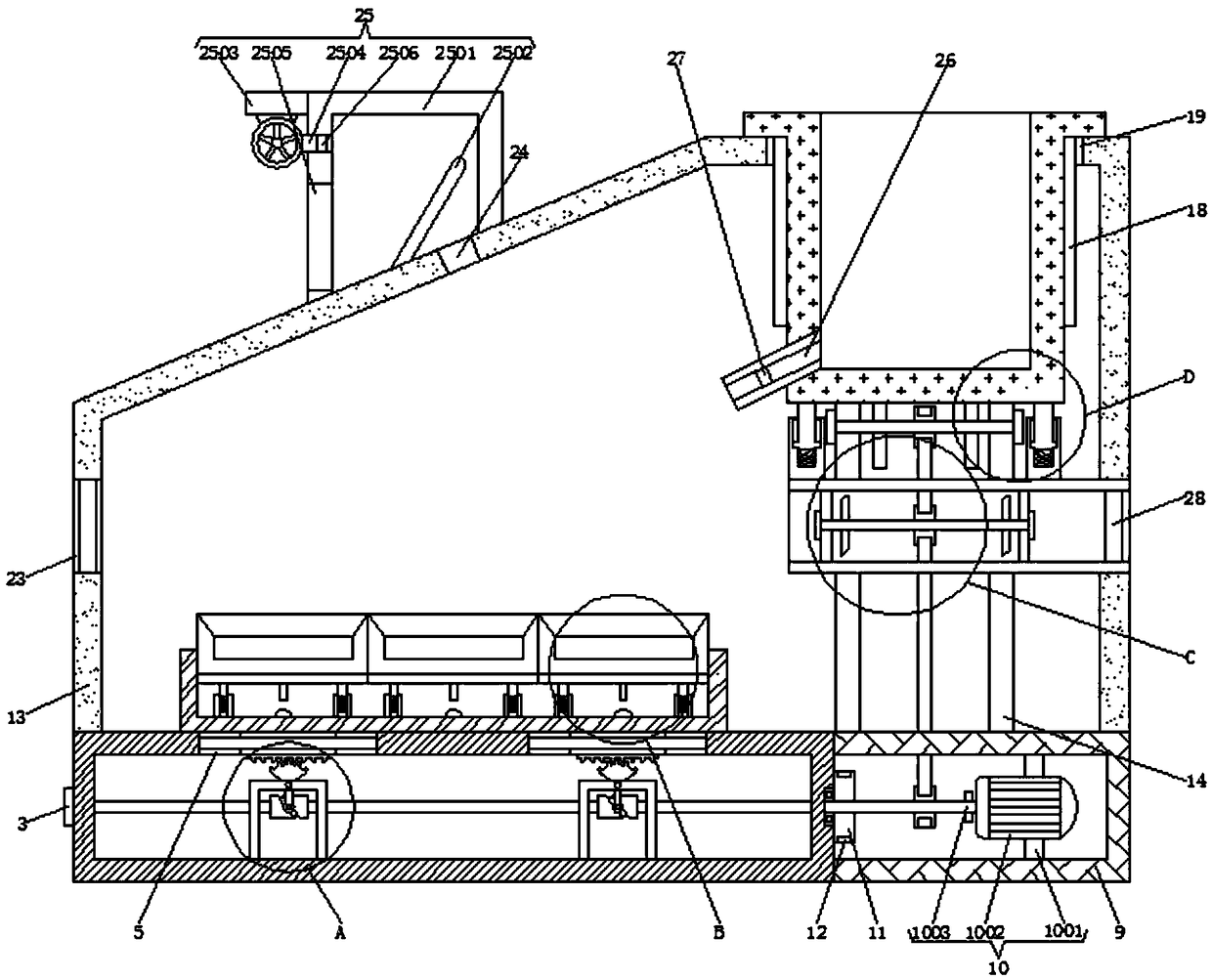

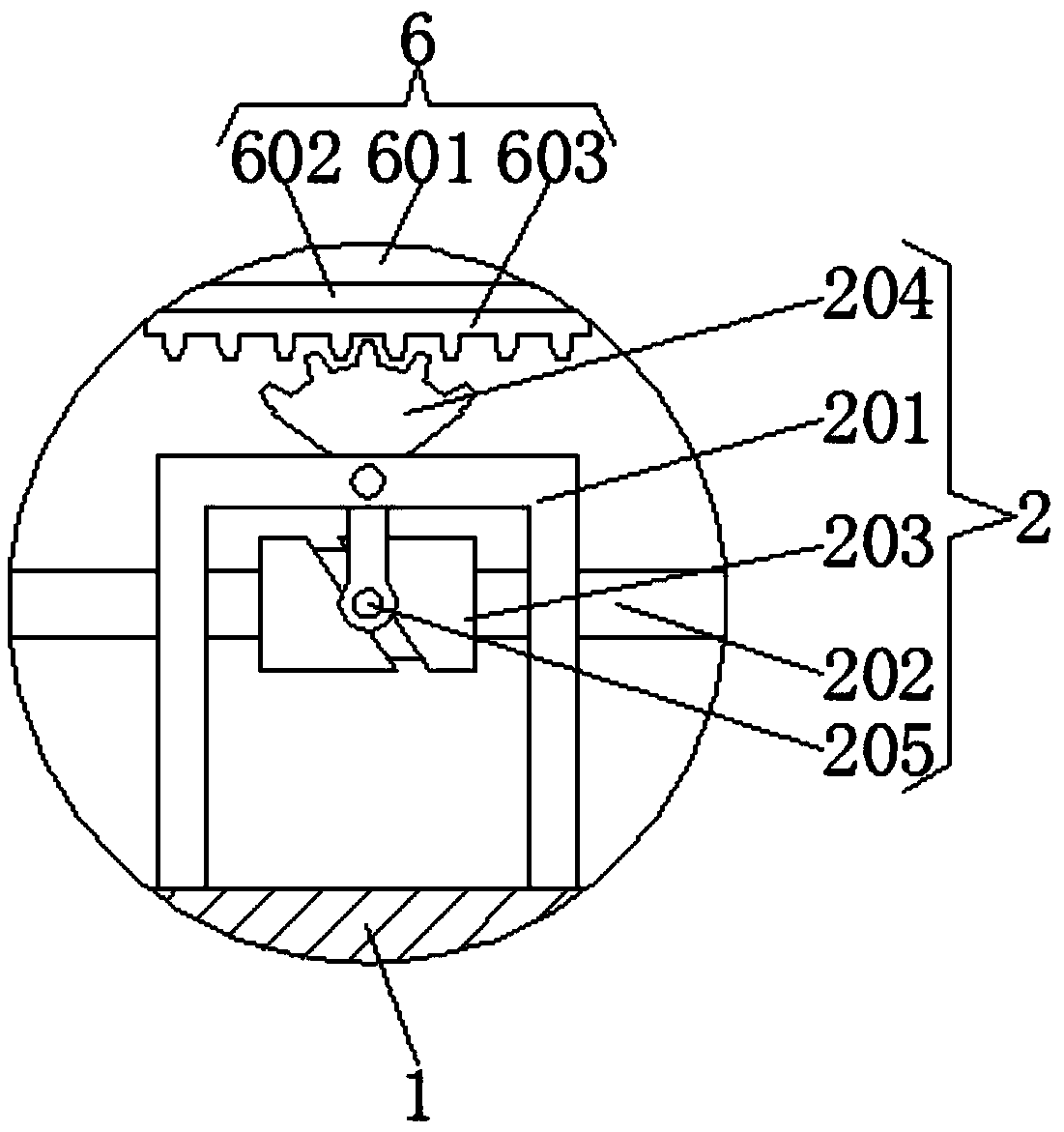

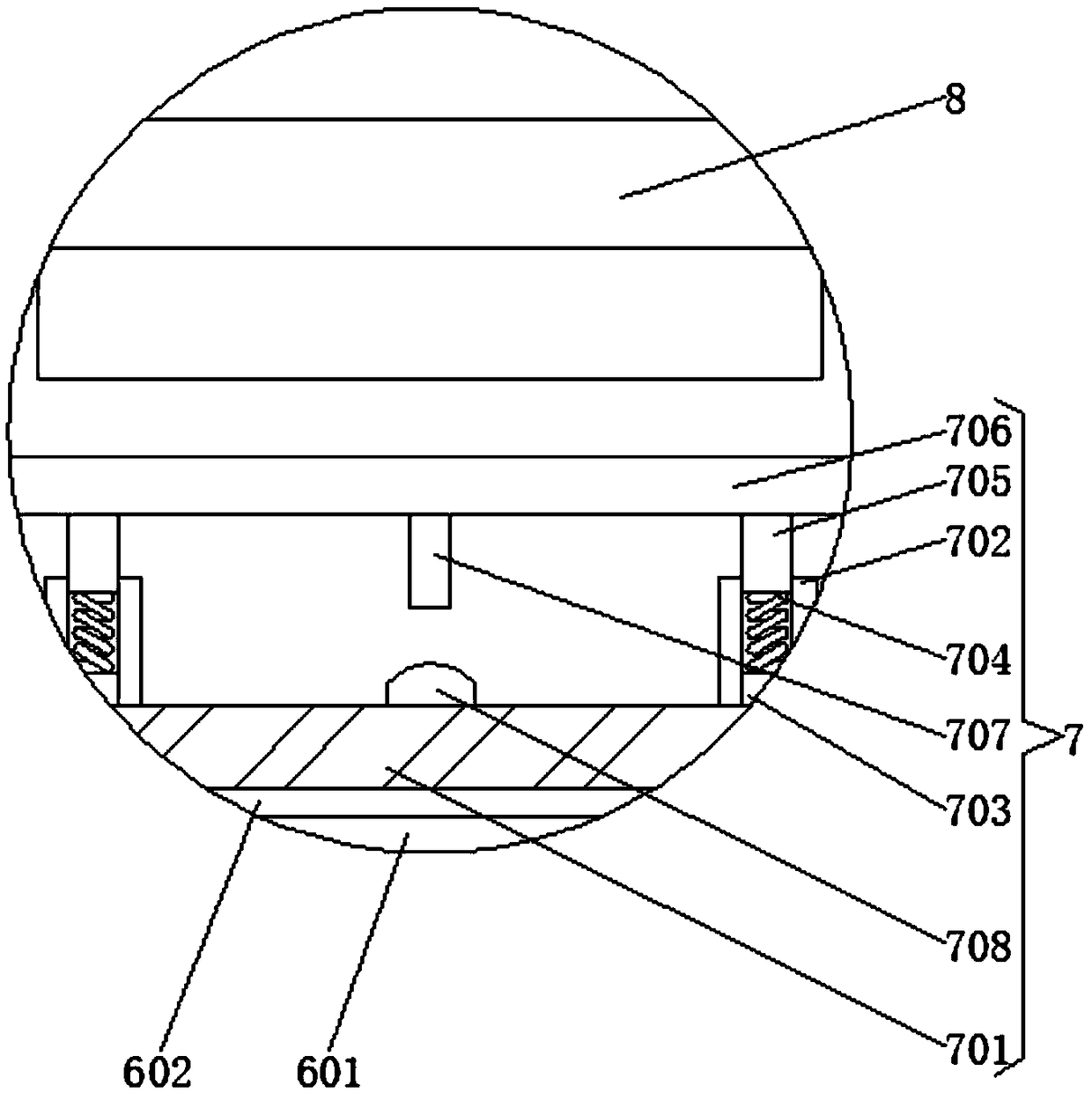

Automatic express box recycling machine

InactiveCN108109280AEasy to put backHigh recovery rateApparatus for meter-controlled dispensingMechanical engineeringGps positioning

The invention relates to an automatic express box recycling machine. The machine is used for recycling express boxes with identification codes and comprises an automatic recycling machine body (1), ascanning identifier (2), a coin outlet device (3), storage rooms (4), a lighting device (5), two large doors (6), a GPS positioning chip (7), a wireless communication module (8) and a corresponding controller (9). The scanning identifier (2) and the coin outlet device (3) are connected in parallel and located in the middle and lower portions of one side of the automatic recycling machine body (1)respectively; each storage room (4) is distributed on the front surface of the automatic recycling machine body (1); the lighting device (5) and the two large doors (6) are installed on the upper portion and back surface of the automatic recycling machine body (1) respectively; the GPS positioning chip (7) is connected in series with the wireless communication module (8). When in use, customers align the identification codes on the surfaces of the express boxes with the scanning identifier, the doors of the corresponding storage rooms are opened, and after the expressed boxes are well placed,a system rewards the users according to the types of the express boxes; when the storage rooms are almost full, the GPS positioning chip transmits the location information to the merchant, and workersopen the two large doors located on the back surface of the automatic recycling machine body through a key and take out the express boxes in each storage room from the back surface.

Owner:王文婧

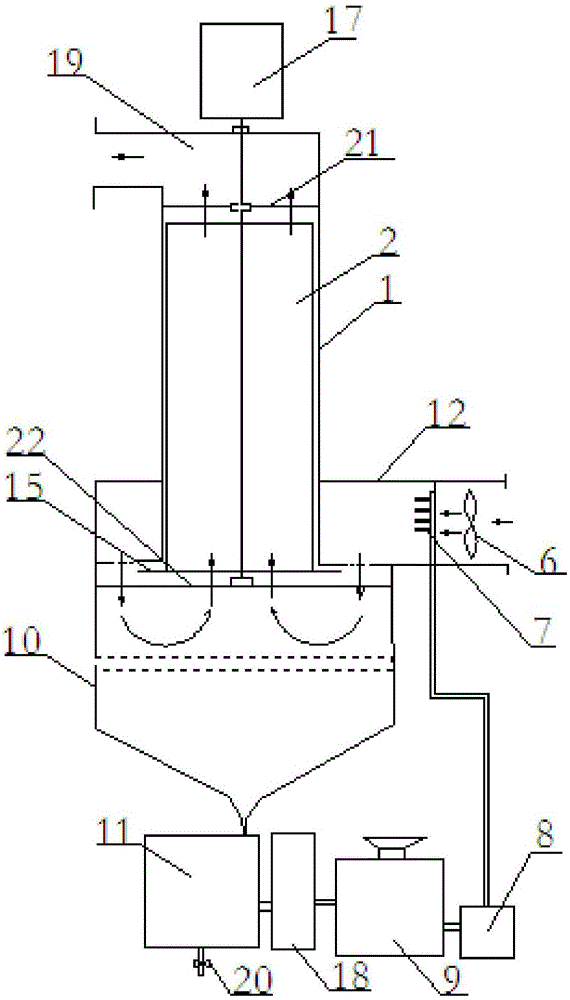

Centrifugal gas way type gas purifier

ActiveCN105771516AEfficient purificationImprove settlement efficiencyCombination devicesTreatment involving filtrationParticulatesSuspended particles

The invention relates to a centrifugal gas way type gas purifier which comprises a gas and spray mixing device, a purifier shell, a centrifugal rotor and a power device. The gas and spray mixing device is used for mixing gas with spray, the centrifugal rotor used for adsorbing suspended particles in the gas is mounted in the purifier shell, a plurality of centrifugal gas ways for gas flow to flow unidirectionally are arranged in the centrifugal rotor, the power device is in transmission connection with the centrifugal rotor to drive the same to rotate, and a gas inlet of the centrifugal rotor is connected with a gas outlet of the gas and spray mixing device. The gas and spray mixing device mixes the gas with the spray and provides power to feed mixed gas to the centrifugal gas ways, the centrifugal rotor driven by the power device rotates at a high speed, and the suspended particles in the mixed gas entering the centrifugal gas ways are adhered on the inner walls of the centrifugal gas ways under action of centrifugal force, so that the suspended particles and harmful gas in the gas are removed circularly to achieve the objective of efficiently purifying the gas.

Owner:翁跃勤

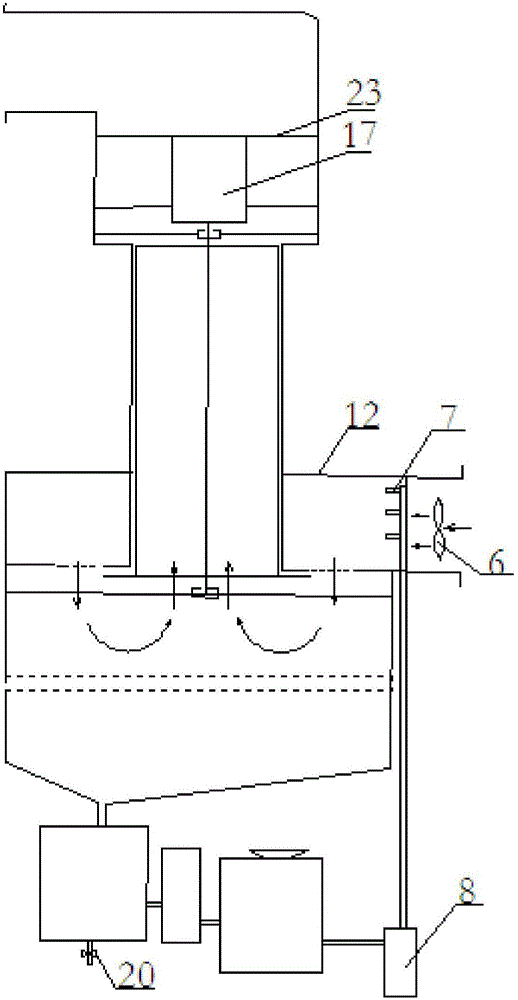

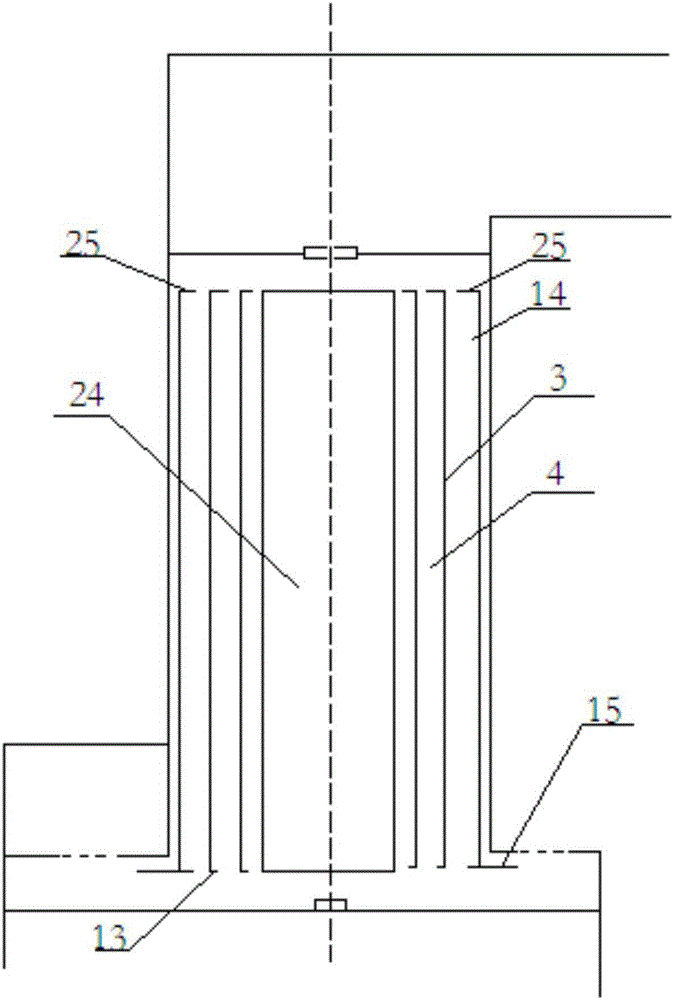

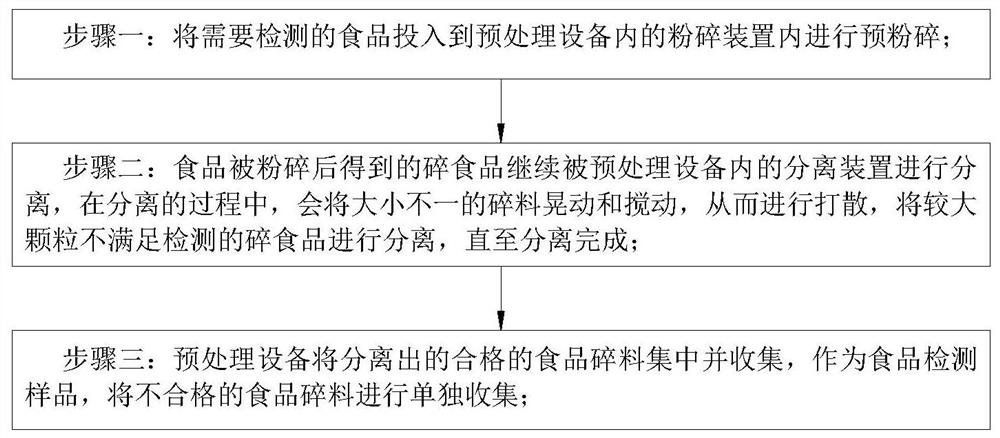

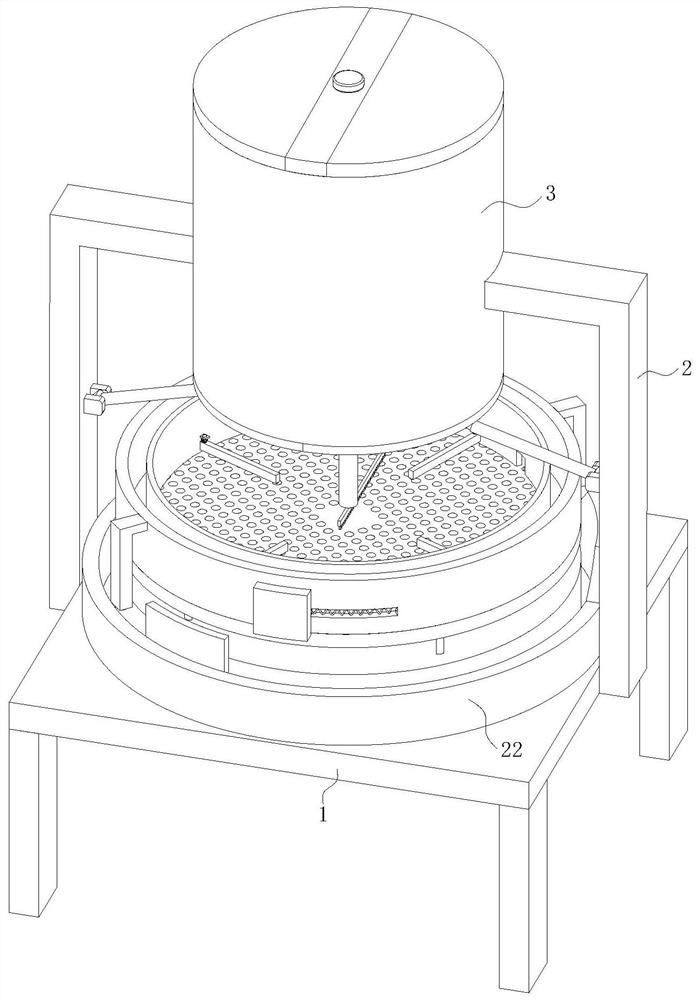

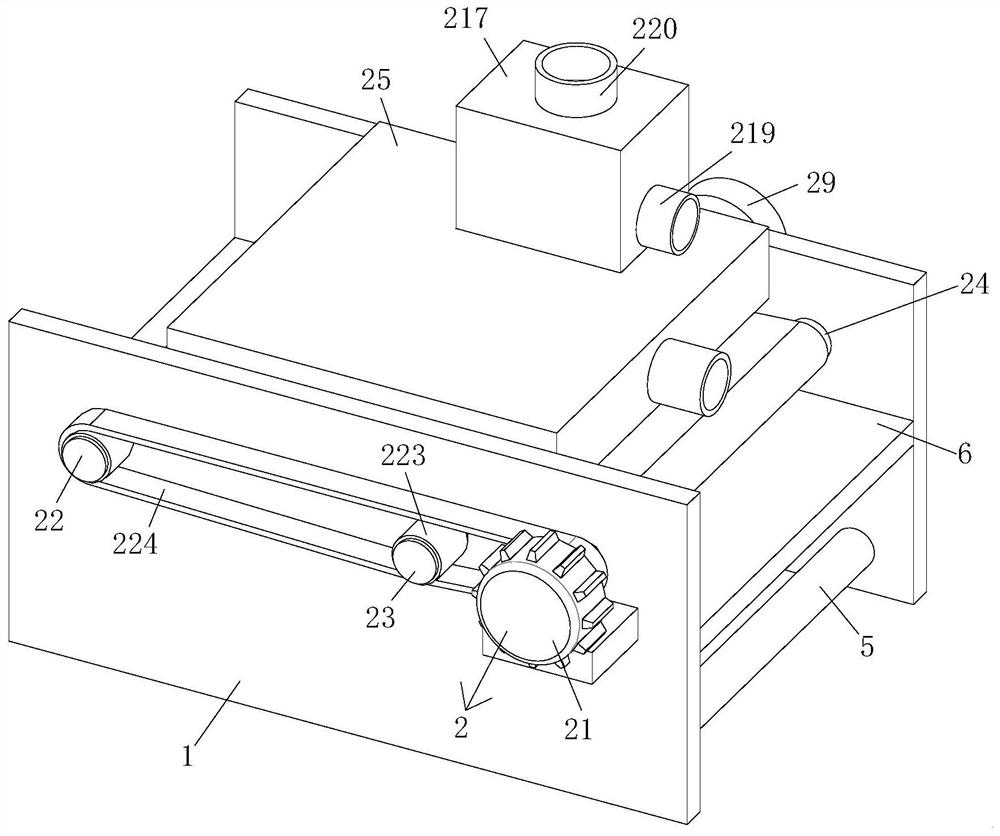

Sample pretreatment process for food detection

InactiveCN112452464AAvoid cloggingSpeed up the separation processSievingScreeningProcess engineeringFood item

The invention discloses a sample pretreatment process for food detection in the technical field of food detection. The sample pretreatment process comprises the following step of 1, putting food to bedetected into a crushing device in pretreatment equipment for pre-crushing. By means of the sample pretreatment process, through centrifugal force, the food which is not smashed thoroughly and has large particles can be isolated into an isolation area, the situation that the food with large particles blocks filtering holes in a separation plate can be avoided, and filtering of the food with smallparticles can be accelerated in the rotating, inclining and rebounding processes of the separation plate; and through rotation of a first cleaning rod and a second cleaning rod, the food with the large particles can be scraped on the separation plate, the separation process of the food with the large particles can be accelerated, the food with the small particles on the separation plate can be scraped through the first cleaning rod and the second cleaning rod, and the filtering process of the food with the small particles can be accelerated.

Owner:安徽省棉小胖餐饮管理有限公司

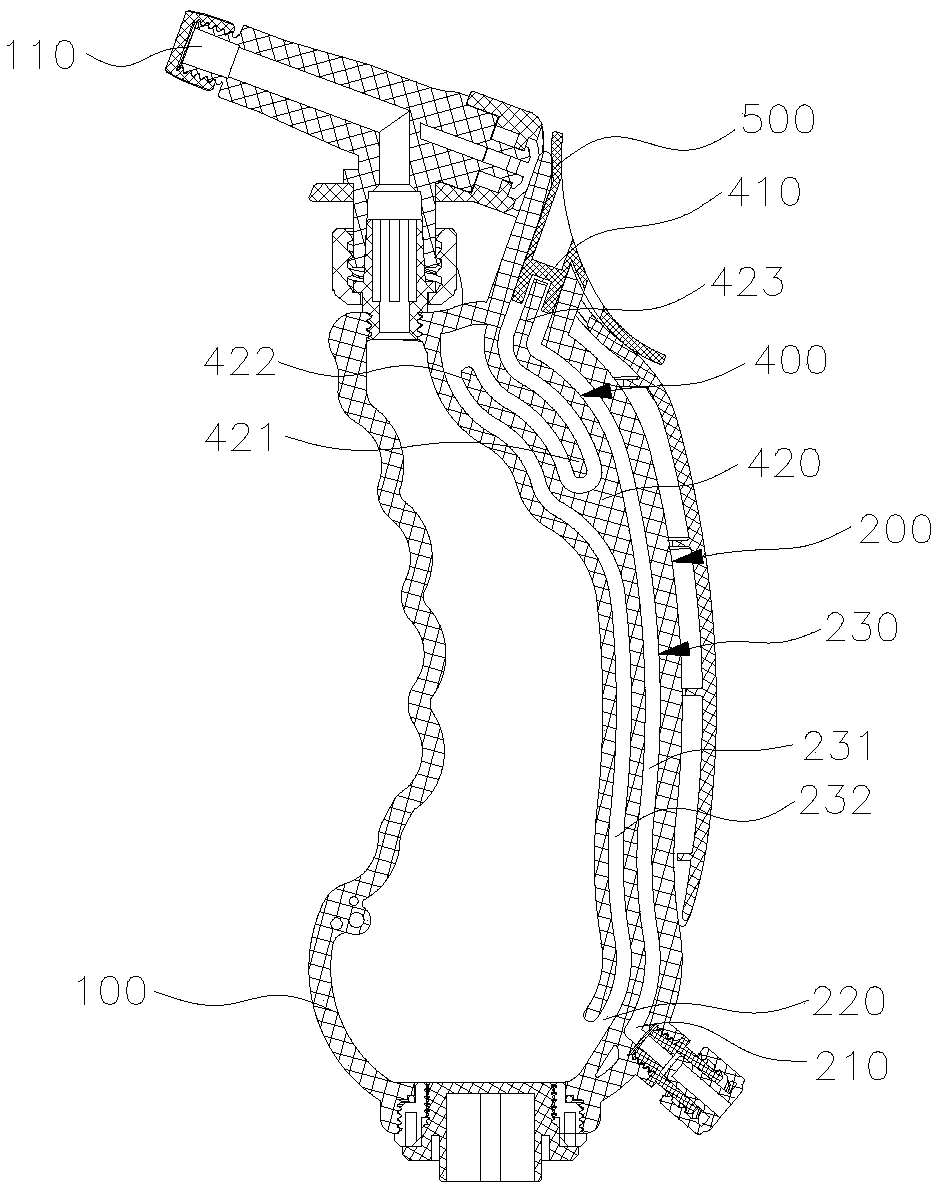

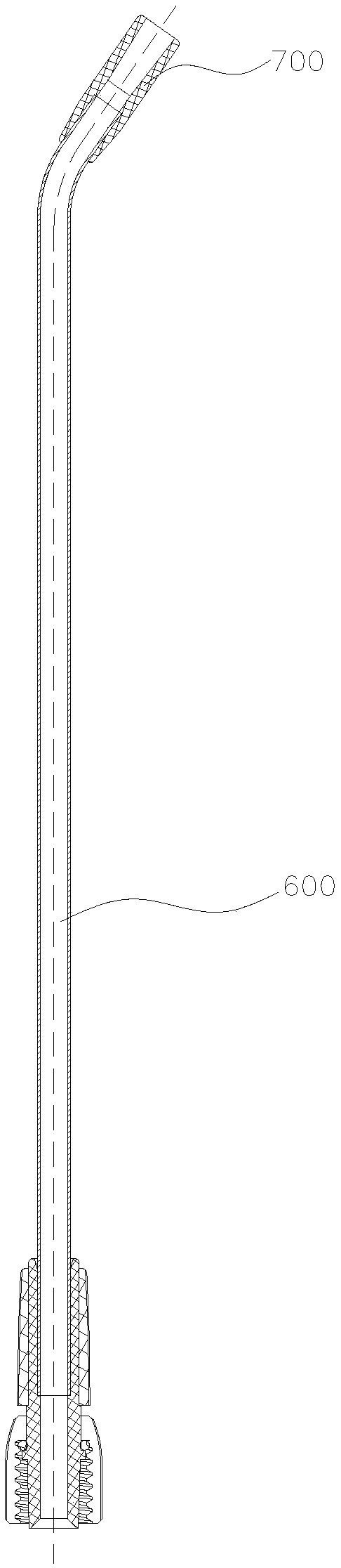

Administration method and device thereof

ActiveCN109674495AAvoid repeated hemostasisGentle and precise deliverySurgeryMedical devicesEngineeringField of view

The invention provides an administration method, which includes the following steps that: a fluid is introduced into a container for holding a medicament, so that the fluid flows along a pressure relief channel, and discharged at a pressure relief through hole of the container, after the flow velocity of the fluid is stabilized, during use, the pressure relief through hole is closed and the fluidenters into a pressurized channel, flows along the pressurized channel, is discharged from the outlet of the pressurized channel and the medicament is pushed into the outlet of the container. The method provided by the invention can deliver the medicament in the container in a more stable and consistently balanced manner and in a more gradual manner, effectively avoiding the medicament being spread on the mirrored field due to the counteraction of target tissue caused by the sudden release of pressure, making administration (such as hemostatic agent) more precise, improving the continuity of the laparoscopic operation, improving the hemostatic effect, and shortening the operation time.

Owner:ZHEJIANG SANCHUANG BIOTECHNOLOGY CO LTD

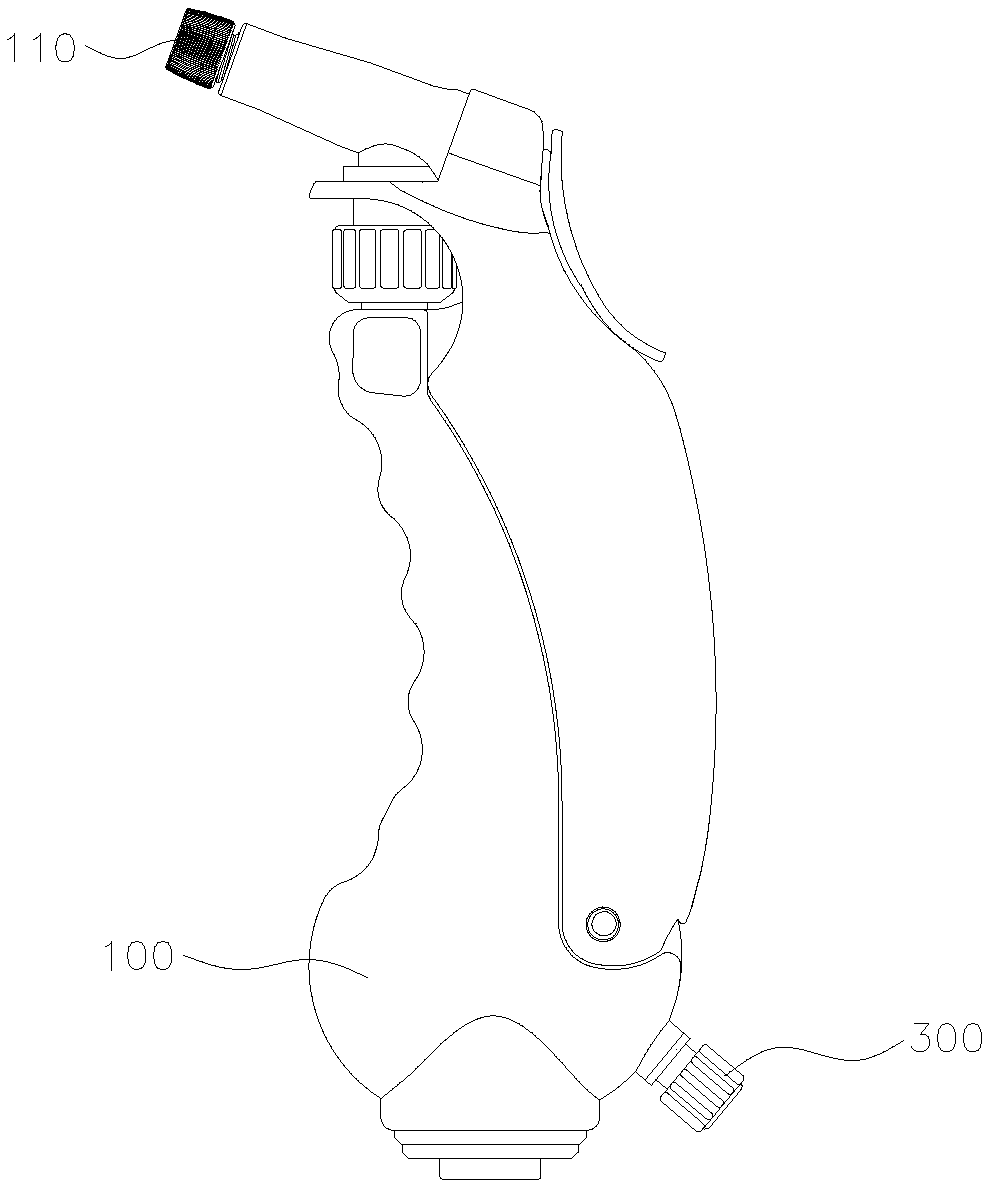

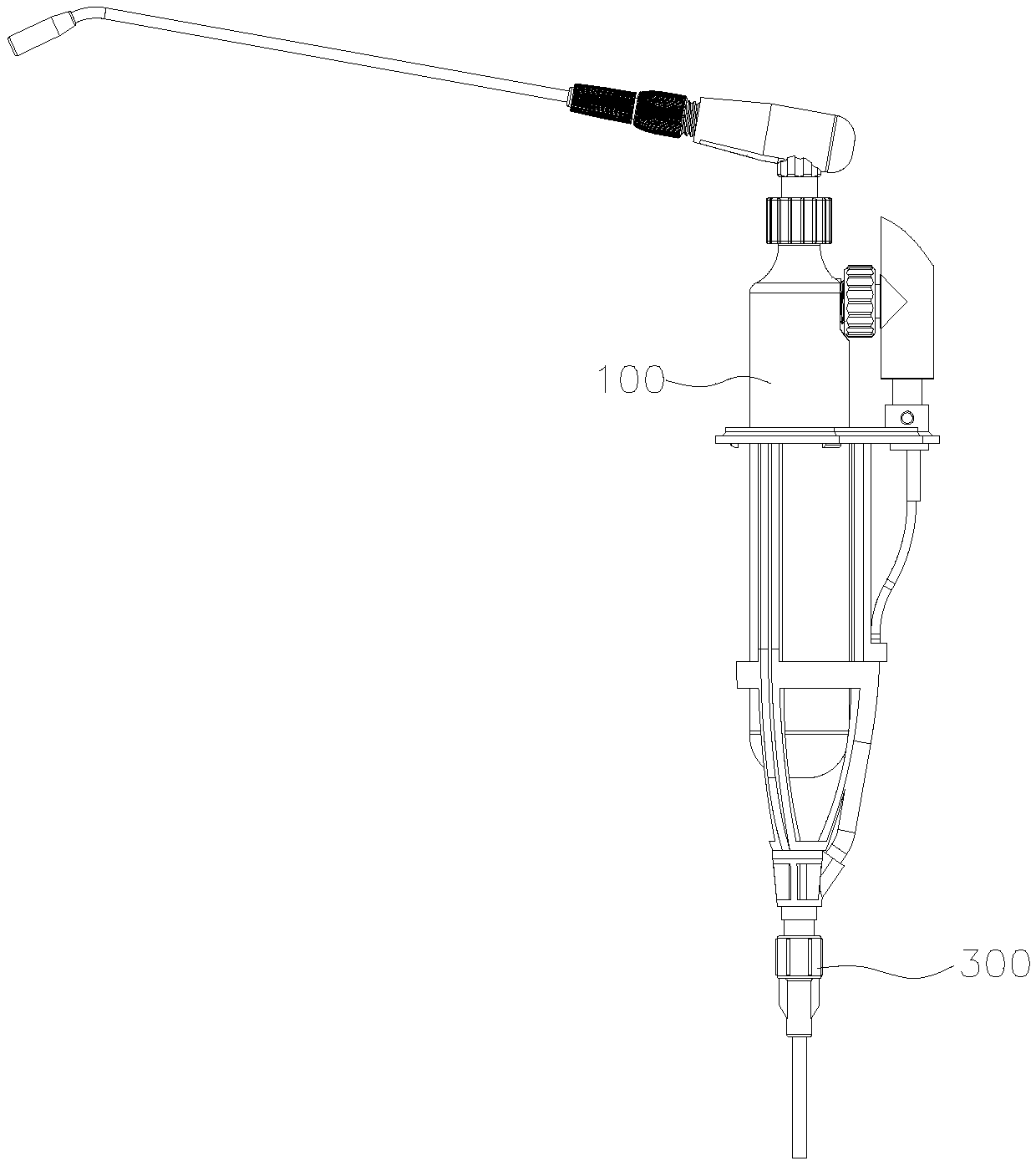

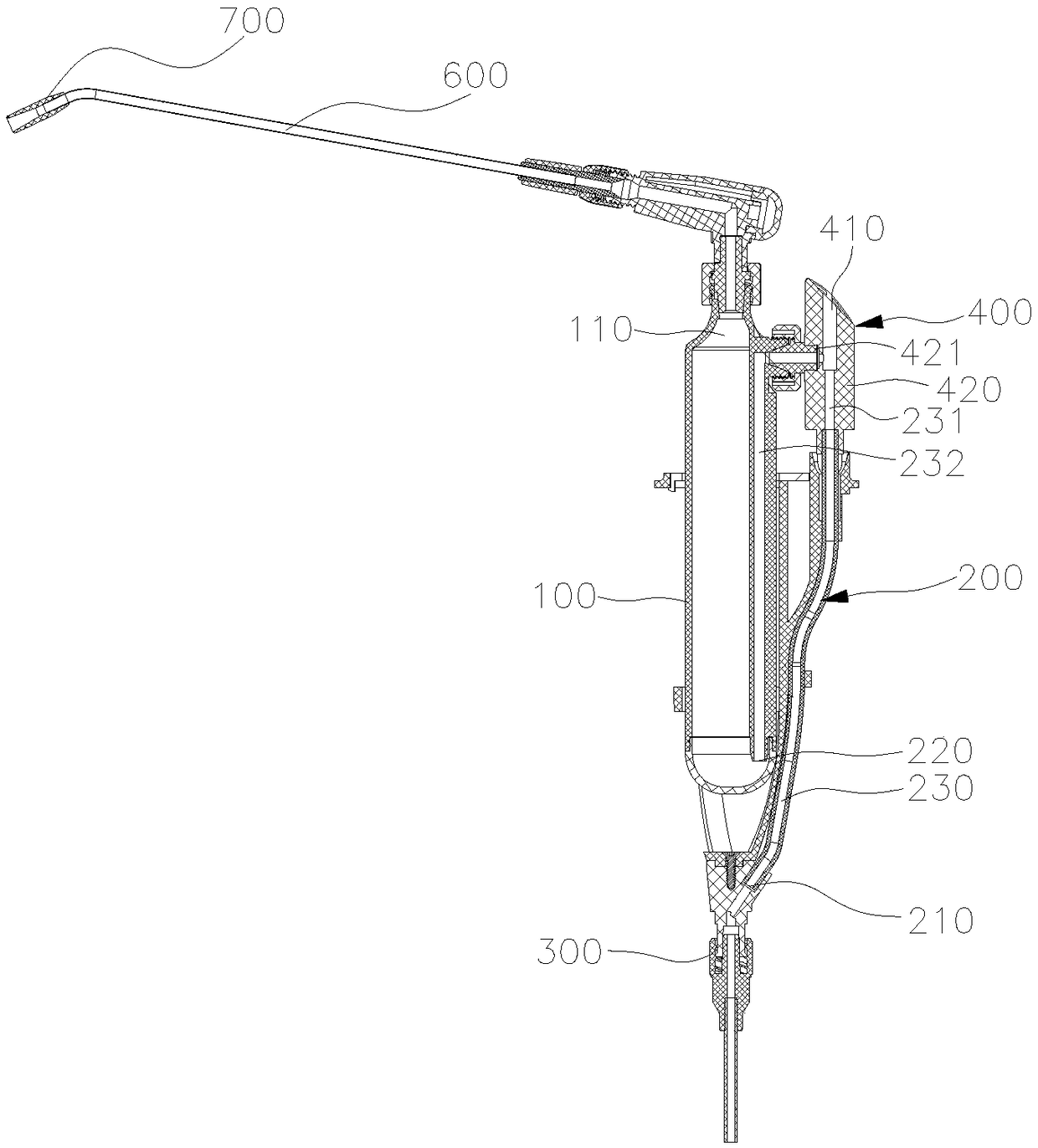

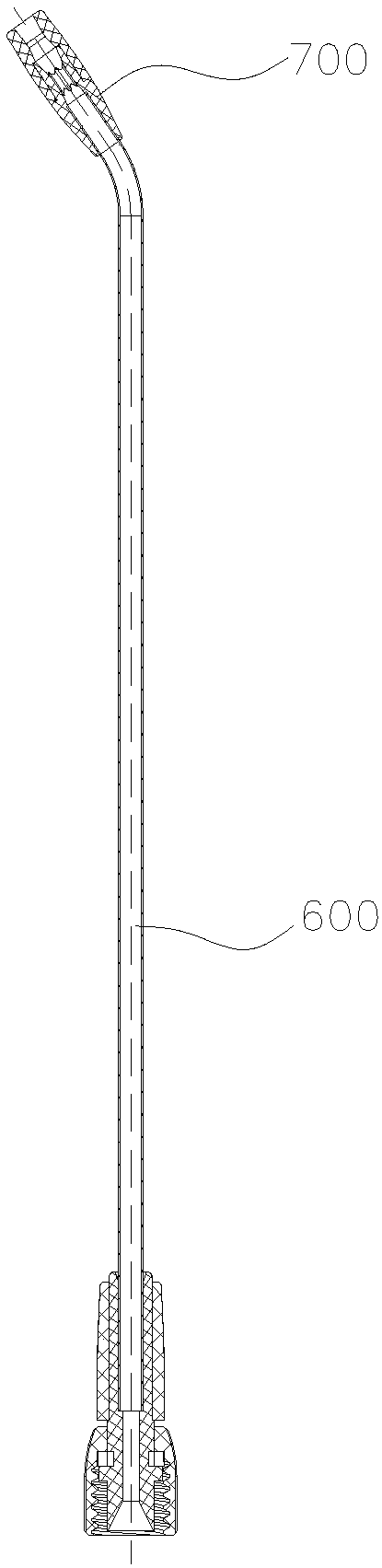

Device for agentia conveying

PendingCN108938015AContinuously Balanced Propelling MethodImprove continuitySurgeryEndoscopesHemostaticsEndoscope

The invention discloses a device for agentia conveying. The device comprises a container used for containing agentia, a cavity body and a valve. The cavity body comprises a cavity passage, a cavity body inlet and a cavity body outlet, the cavity body inlet is communicated with a connecting port, and the cavity body outlet faces the bottom of the container. The valve comprises a first through holeand a valve body, the first through hole is separately communicated with the cavity body inlet and the cavity body outlet, and the cavity passage is partitioned into a decompression cavity passage anda compressed cavity passage by the valve body. The provided device can convey the agentia in the container in a more stable, continuous and balanced pushing mode and a more relaxative mode, it is effectively avoided that the sudden releasing of pressure makes the agentia subjected to the reaction of the target tissue, so that the agentia covers the view of an endoscope, the administration (such as a hemostatic) is more accurate, the surgical operation continuity of the endoscope is improved, the hemostatic effect is improved, and the time of the surgical operation is shortened.

Owner:ZHEJIANG SANCHUANG BIOTECHNOLOGY CO LTD

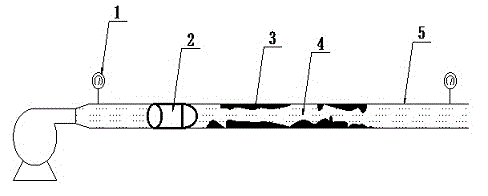

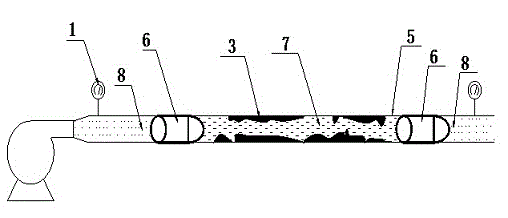

Pipeline targeted descaling method

The invention discloses a pipeline targeted descaling method. The pipeline targeted descaling method comprises following steps: S1, the position of a segment with dirt is calculated based on a pipeline inlet pressure break point when a positioning spherical pig runs in a pipeline; S2, the segments before and after the segment with dirt are provided with a soft spherical pig respectively for isolation, the two ends of the segment with dirt are blocked so as to form a descaling area, and a descaling agent is delivered to fixed points of the descaling area so as to form a descaling system, wherein the descaling agent comprises a solid retarded acid, a corrosion inhibitor, a penetrant, and a complexing agent; S6, after standing of 0.5 to 1h, full contact and dissolving of the descaling agent with accumulated dirt are realized; and S7, the descaling agent and the soft spherical pigs are removed. According to the pipeline targeted descaling method, the segment with dirt is isolated from the rest segments, qualified and fixed point delivering of the scaling agent can be realized, descaling of the segment with dirt can be carried out with pertinency, a result that the whole pipeline is full of the descaling agent is avoided, damage caused by the descaling process on the pipeline is reduced, high efficiency using of the descaling agent is realized, and operation cost is reduced greatly.

Owner:CHINA NAT OFFSHORE OIL CORP +1

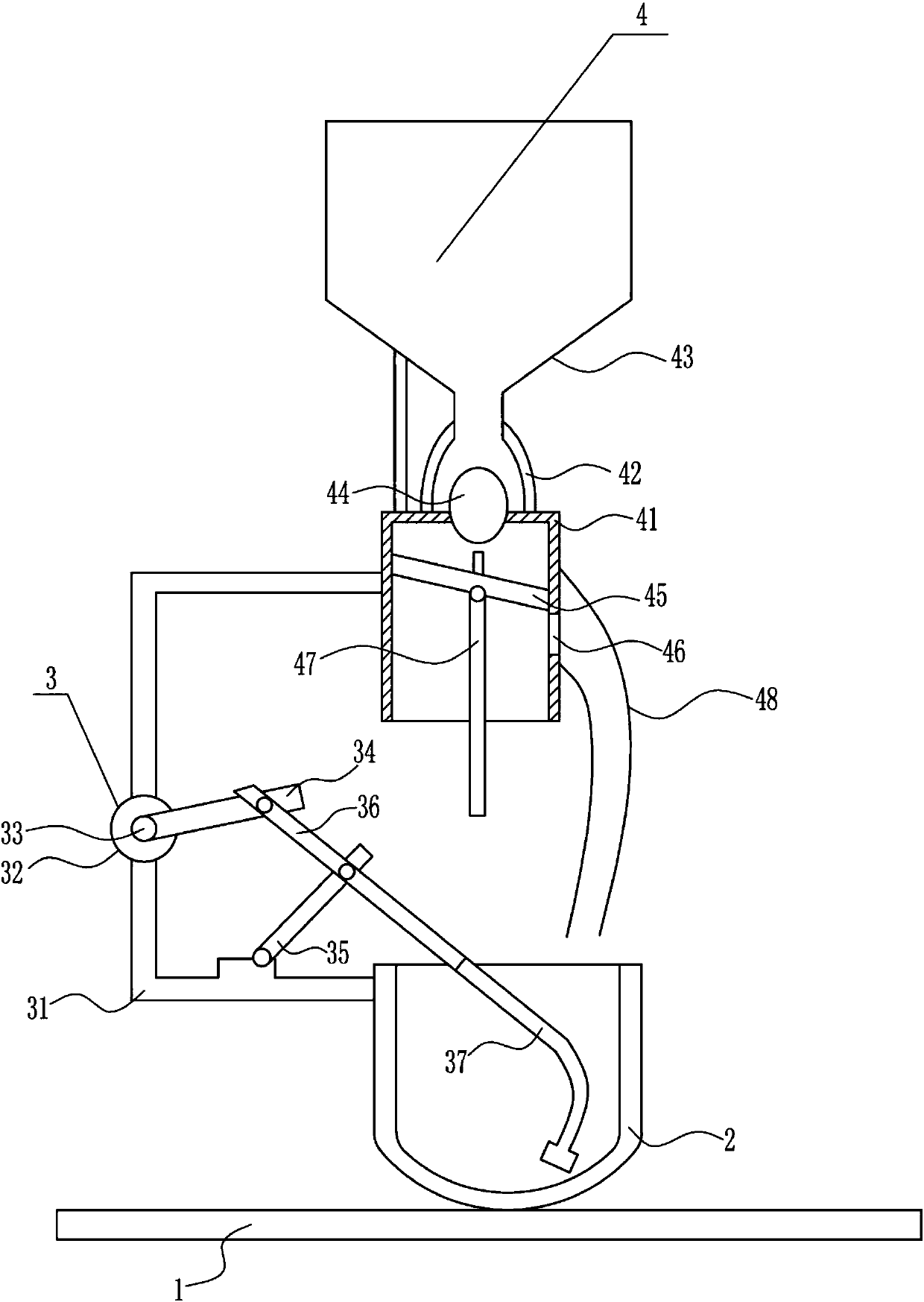

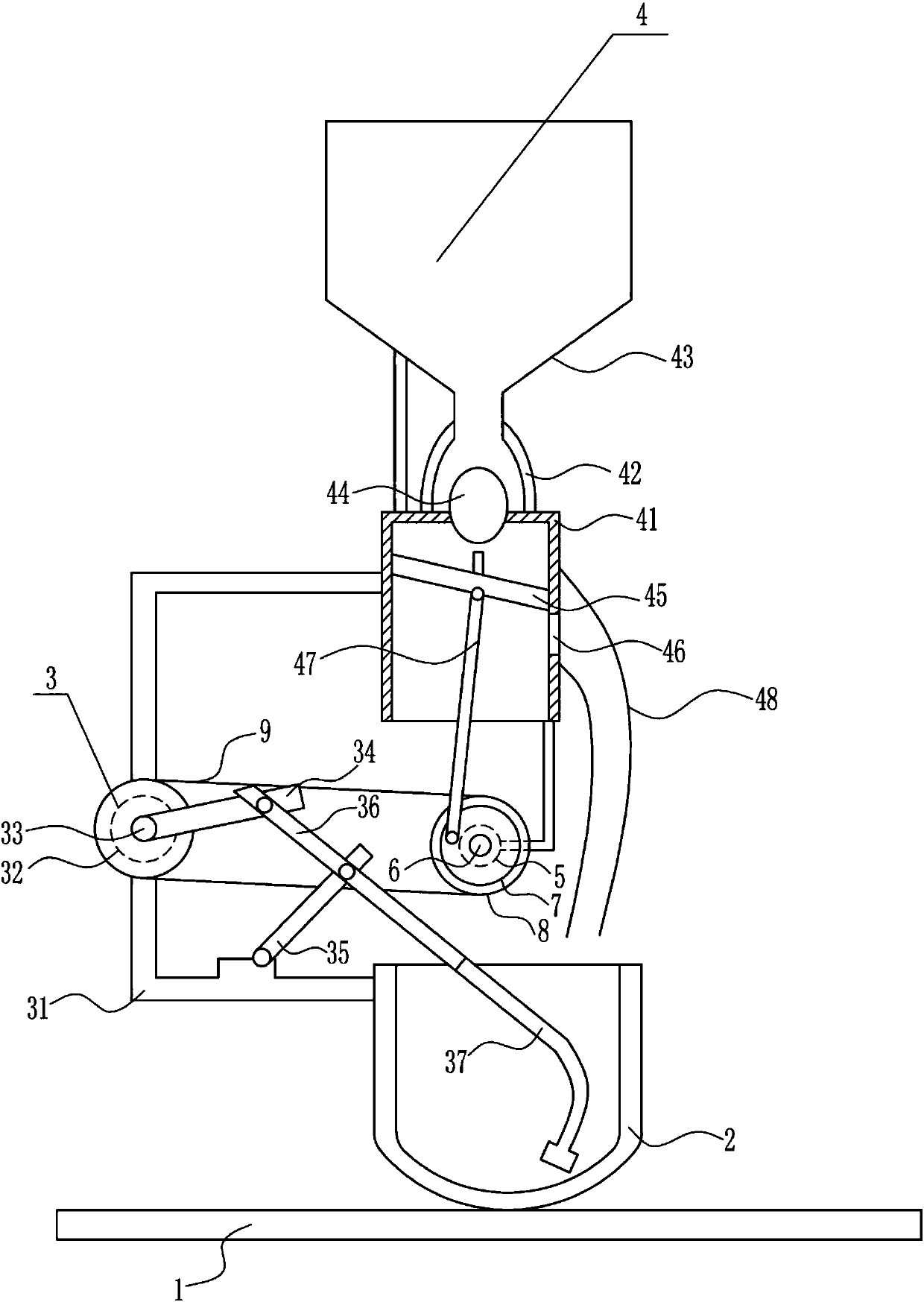

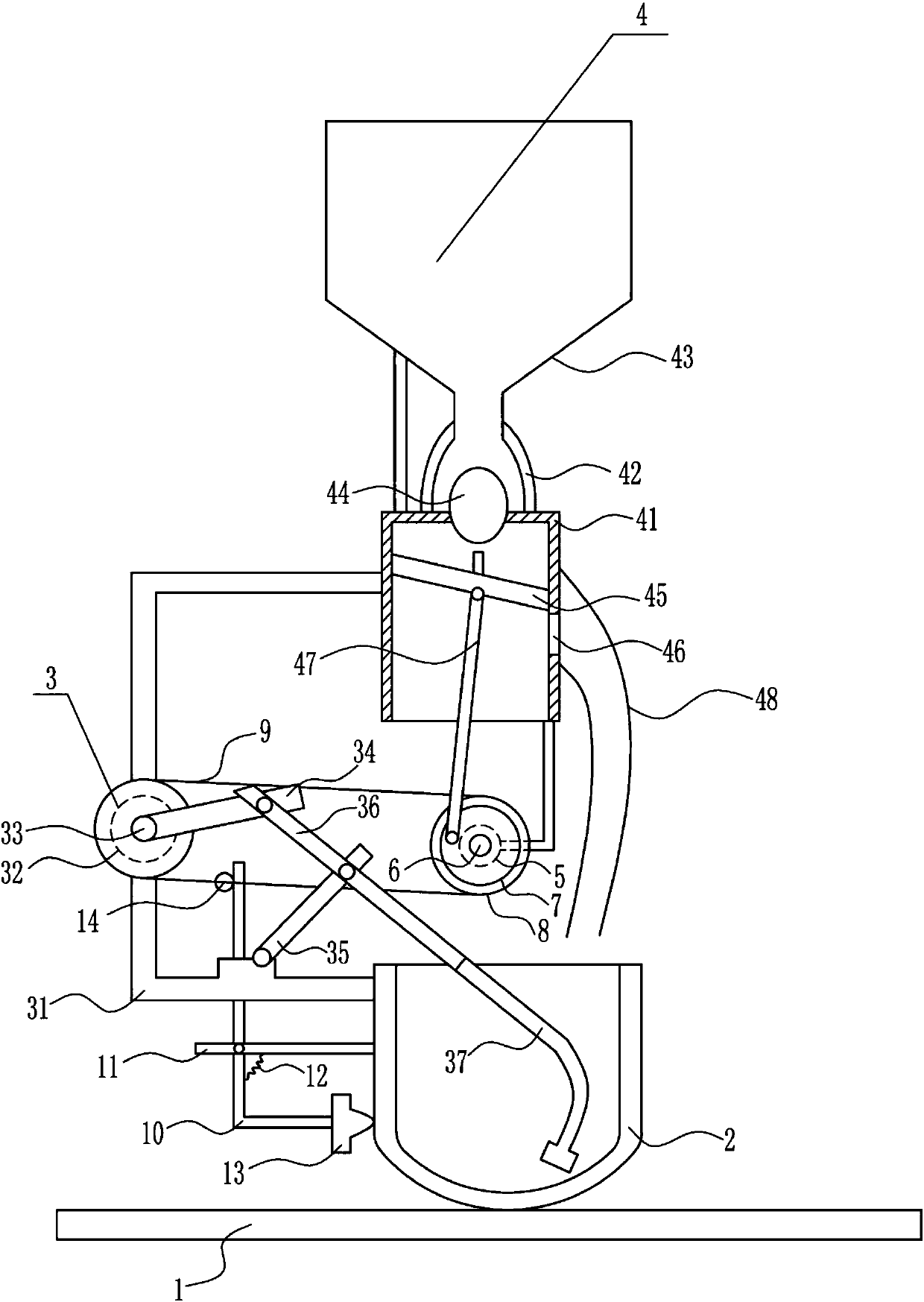

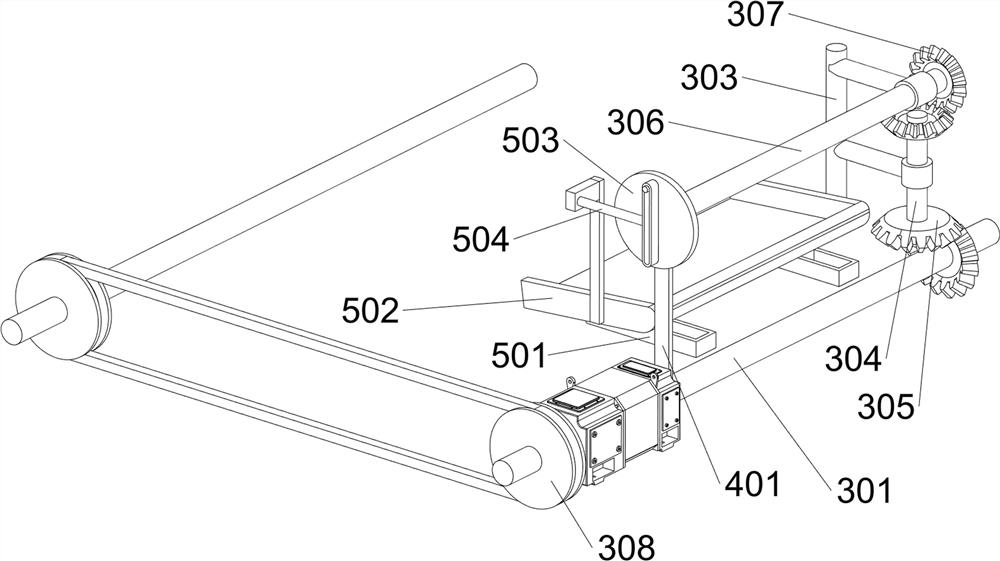

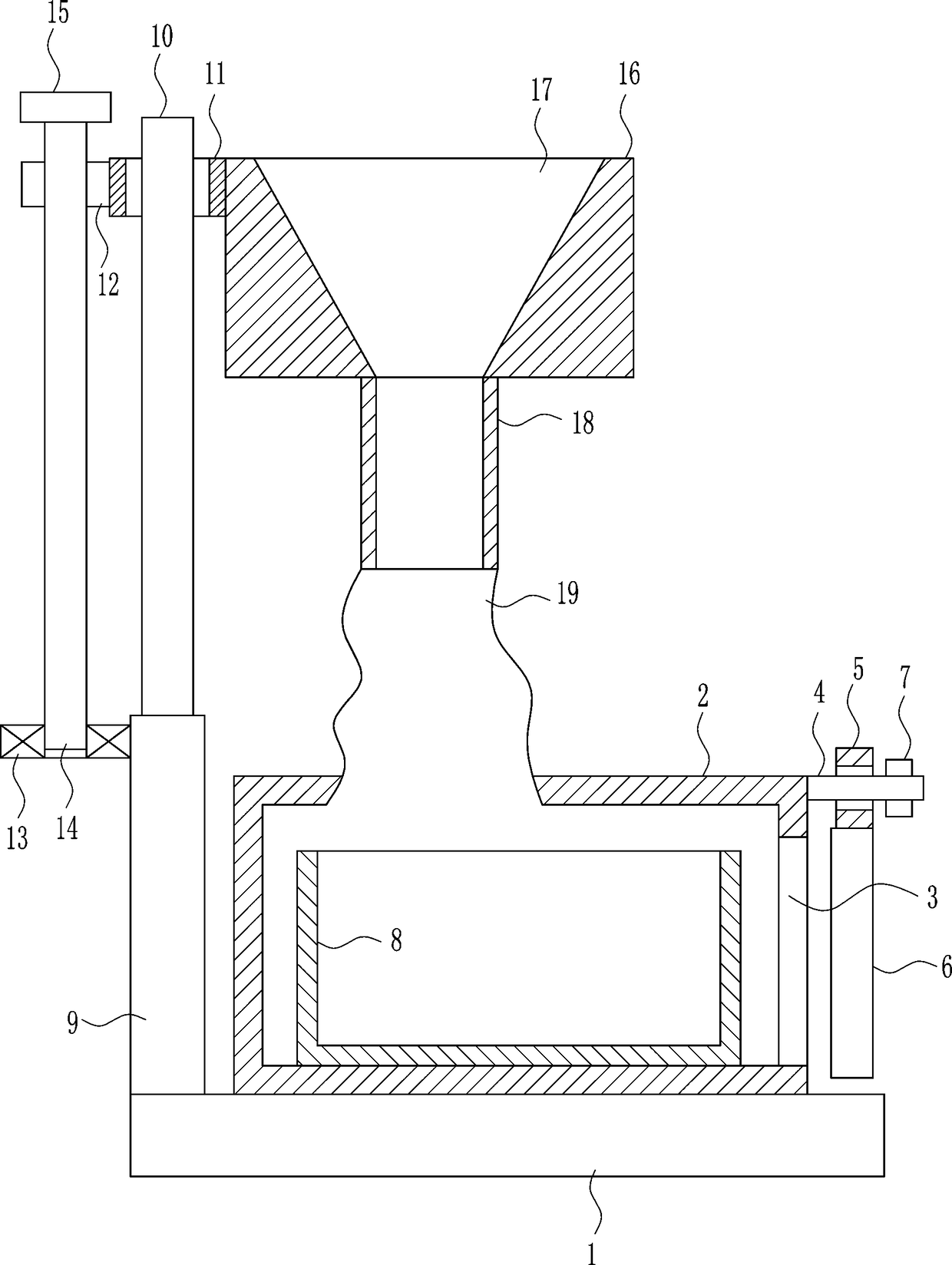

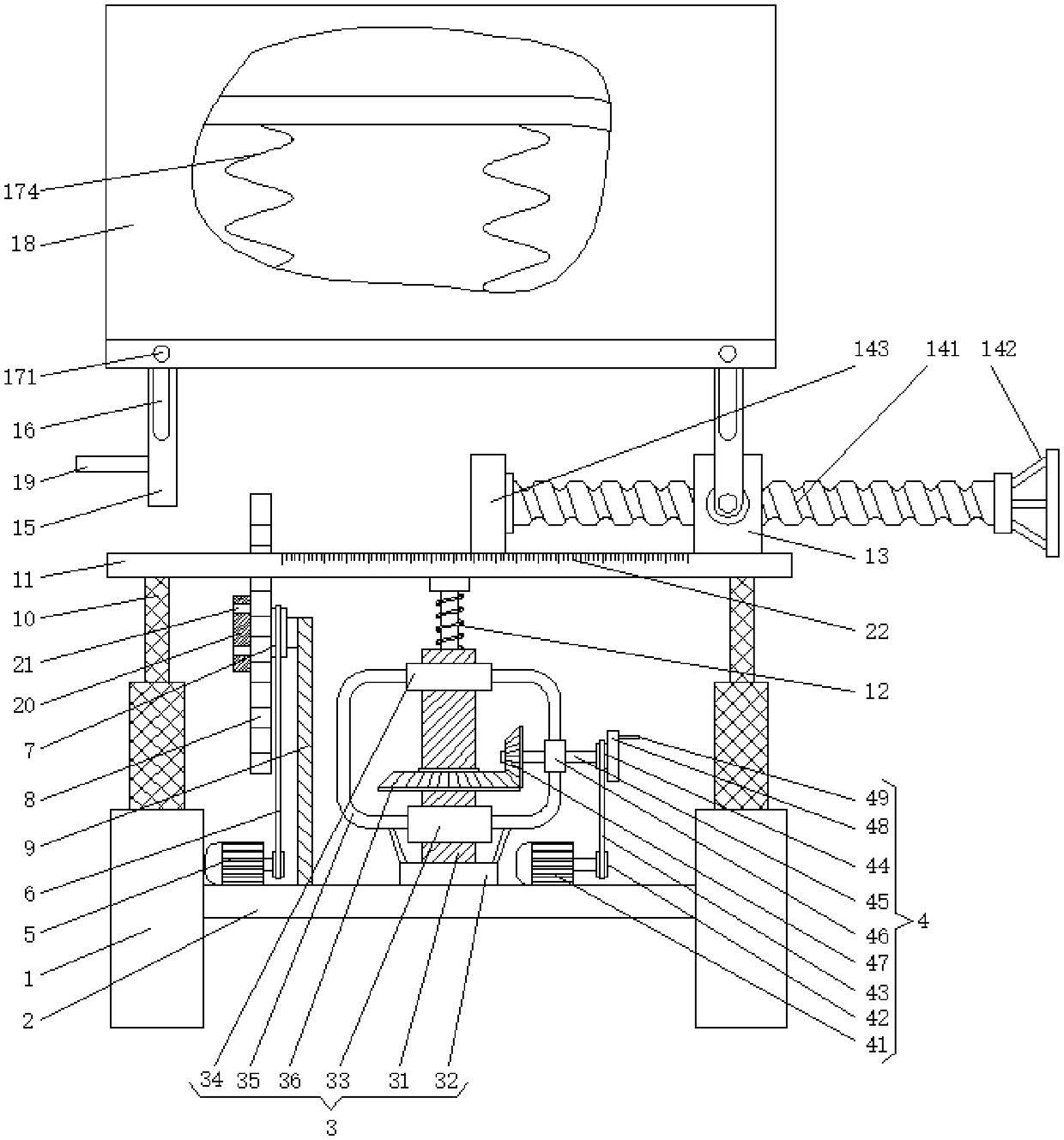

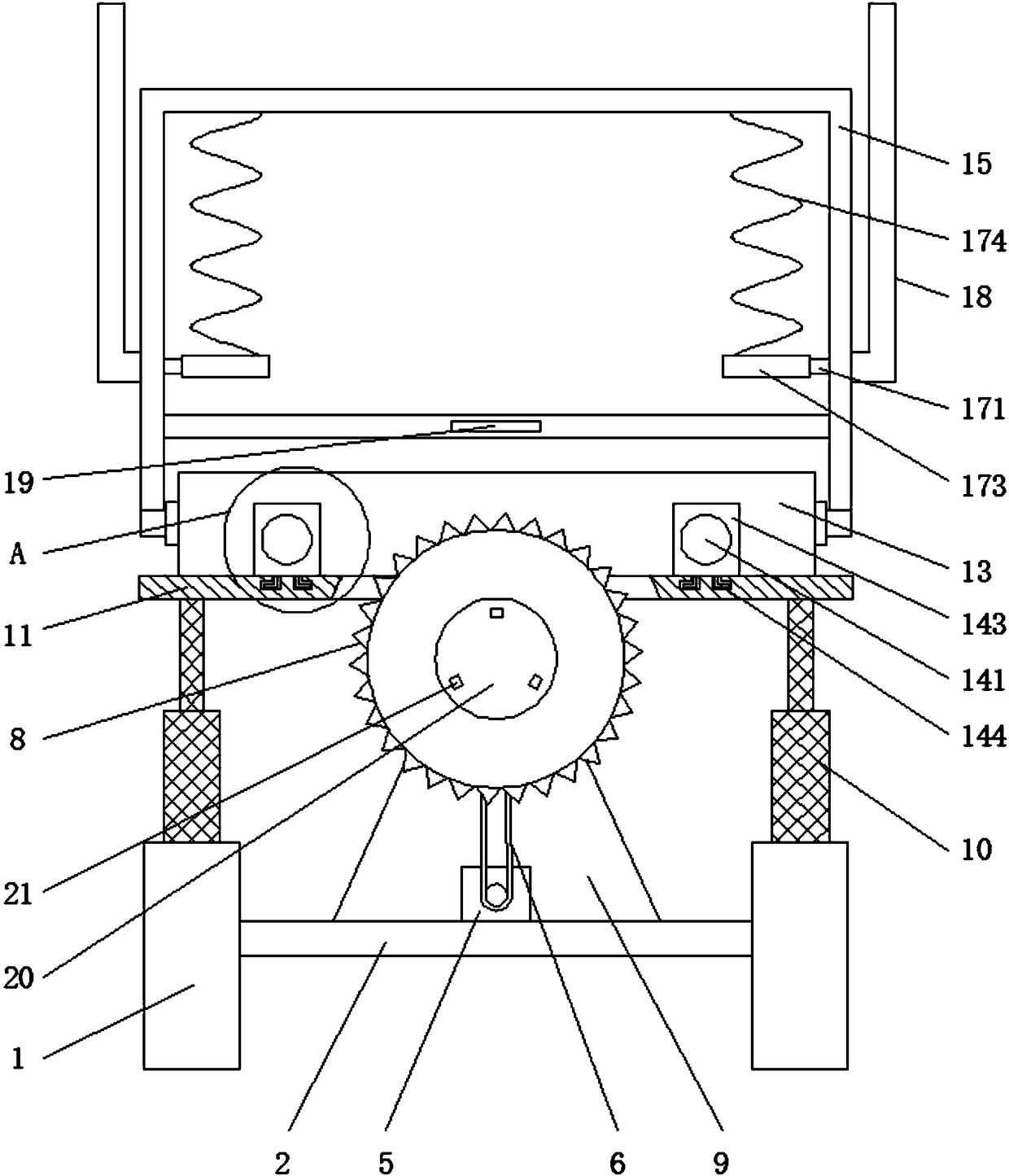

Automatic material feeding, stirring and pickling device for preservation of aquatic products

ActiveCN107593879AAutomatically stir evenlyImprove pickling efficiencyMeat/fish preservation using solidsAquatic productEngineering

The present invention relates to a pickling device and particularly relates to an automatic material feeding, stirring and pickling device for preservation of aquatic products. A technical problem tobe solved is to provide the automatic material feeding, stirring and pickling device for the preservation of the aquatic products, and the device is free of artificial stirring and can realize an automatic salt adding and automatic stirring. In order to solve the above technical problem, the provided automatic material feeding, stirring and pickling device for the preservation of the aquatic products comprises a base seat, etc. A pickling box is connected with a middle part of a top part of the base seat, a stirring mechanism is connected with an upper side of a left wall outside the picklingbox and arranged in the pickling box, and a material feeding mechanism is connected with a right end of a top part of the stirring mechanism and located at an upper side of the pickling box. The designed automatic material feeding, stirring and pickling device for the preservation of the aquatic products is free of the manual stirring and prevents hands from being stabbed by the aquatic products.By arranging an inserted rod and two nuts, the automatic material feeding, stirring and pickling device is convenient for working staff to pick out the pickled aquatic products.

Owner:乐安县恒源食品有限公司

Multifunctional experimental table for chemical experiments

The invention discloses a multifunctional experimental table for chemical experiments. The multifunctional experimental table comprises a box, wherein a rotating shaft penetrates through the bottom onthe left side of the box; a turntable is fixedly connected with the left side of the rotating shaft; a first conical gear is fixedly connected with the right end of the rotating shaft; a second conical gear is meshed with the top of the right side of the first conical gear; a moveable column penetrates through the second conical gear. According to the invention, the box, the rotating shaft, the turntable, the first conical gear, the second conical gear, the moveable column, the sleeve block, the connecting rod, the support plate, the first storage box, the groove, the through hole, the pull ring, the pull plate, the limiting block, the second storage box and the baffle are used together for solving the problem of less functions of the present chemical experimental table. The multifunctional experimental table for chemical experiments has the advantage of multifunction, meets the student requirement, is capable of preventing the chemical experimental tools from excessively occupying the experimental table, is convenient for the user to experiment and is convenient to move.

Owner:杨红娜

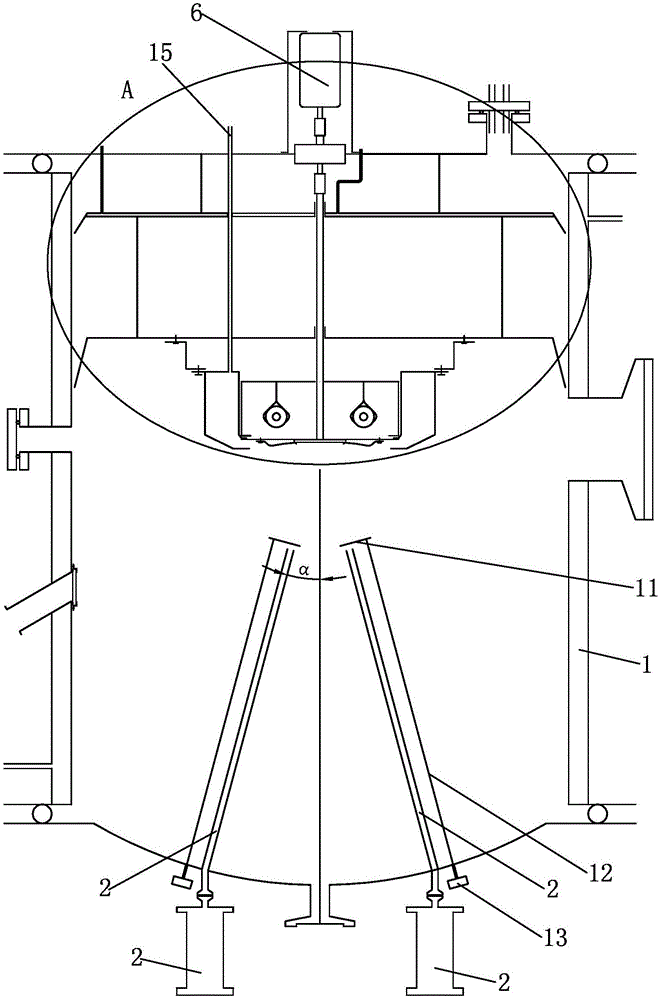

Independent-type multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber

ActiveCN105057154AFacilitate depositionPromote formationLiquid surface applicatorsLiquid spraying apparatusSpray nozzleEngineering

The invention discloses an independent-type multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber. A sample bearing table is arranged in the reaction chamber, a heating body shell is arranged on the upper portion of the sample bearing table, and heating bodies are arranged in the heating body shell; at least two atomization sources are mutually independent and are arranged in the circumferential direction of the reaction chamber, and a spraying nozzle on the upper portion of each atomization source is connected with a spraying pipe; the upper portions of the spraying pipes both face the axis line of the reaction chamber and both form a spraying angle alpha with the axis line of the reaction chamber; and a nozzle at the upper portion of each spraying pipe is provided with a baffle, and the baffles can block or open the spraying nozzles at the upper ends of the corresponding spraying pipes. By means of the independent-type multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber, a thin film containing required components can be obtained, and the defect of cross contamination caused by a traditional structure is overcome; and high-temperature reaction tail gas near the sample bearing table is hooded through a tail gas pumping hood, heat reflection can be achieved through a heat reflection hood, and cooling is further achieved through a water-cooling heat shield plate.

Owner:CHONGQING UNIV OF TECH

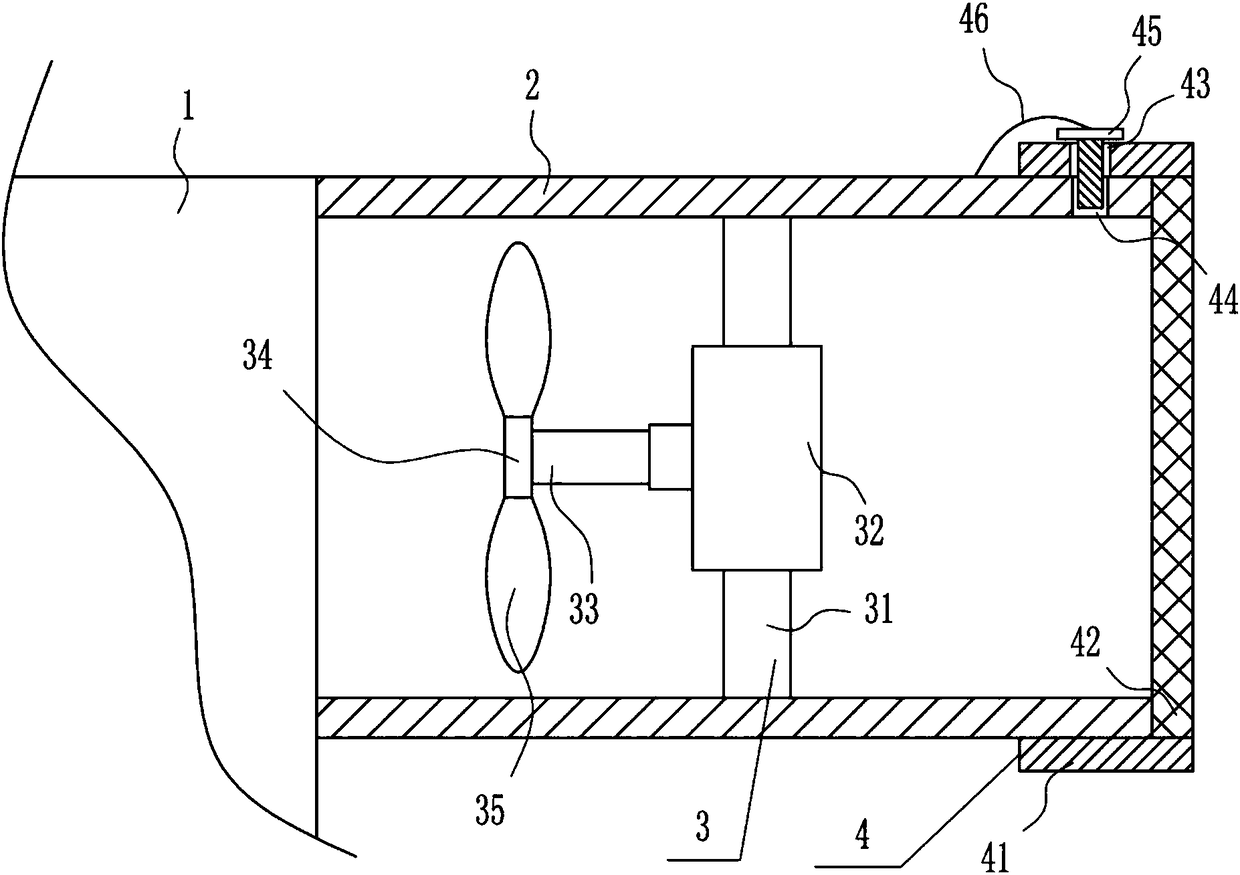

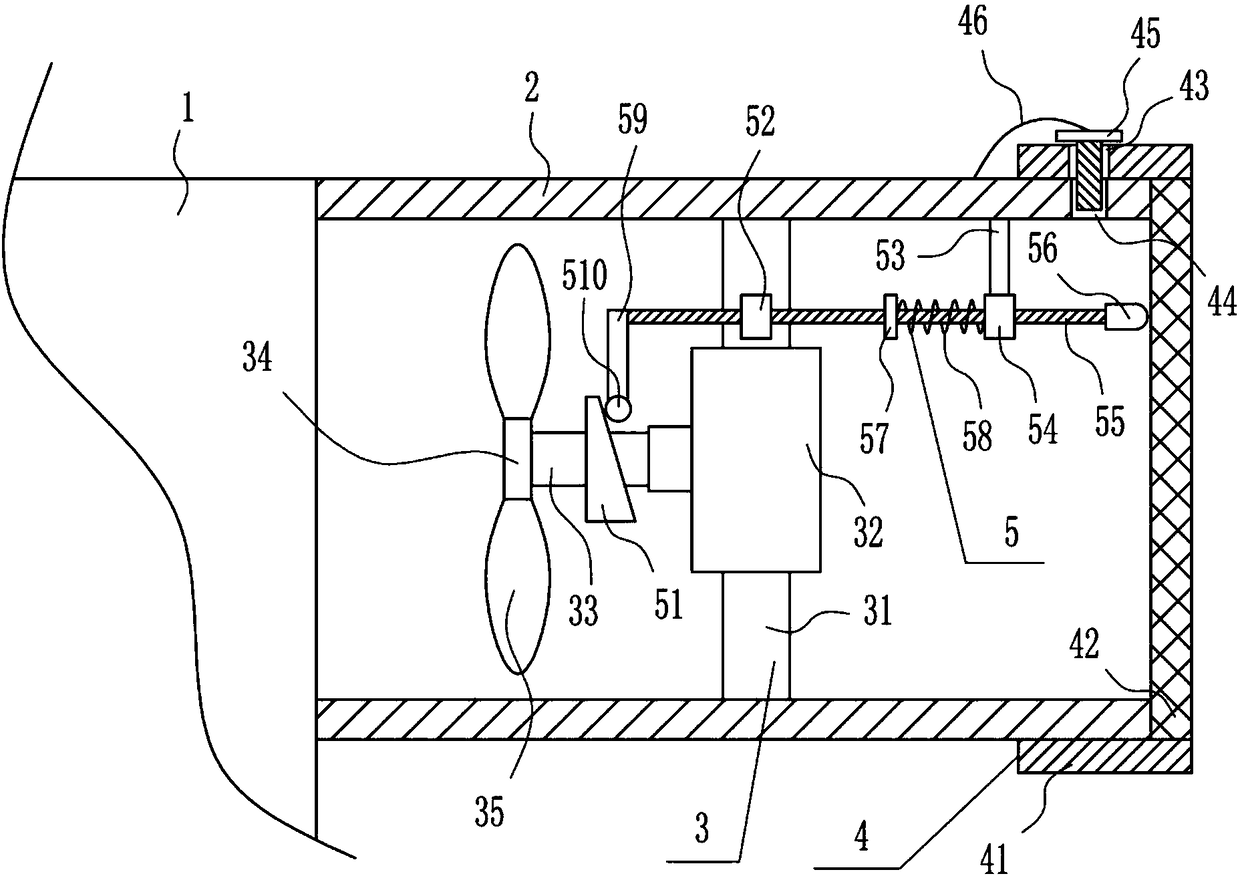

Switch cabinet ventilating apparatus

ActiveCN108493786APrevent fullNot easy to damageSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringSwitchgear

Owner:嘉兴奥腾电子科技有限公司

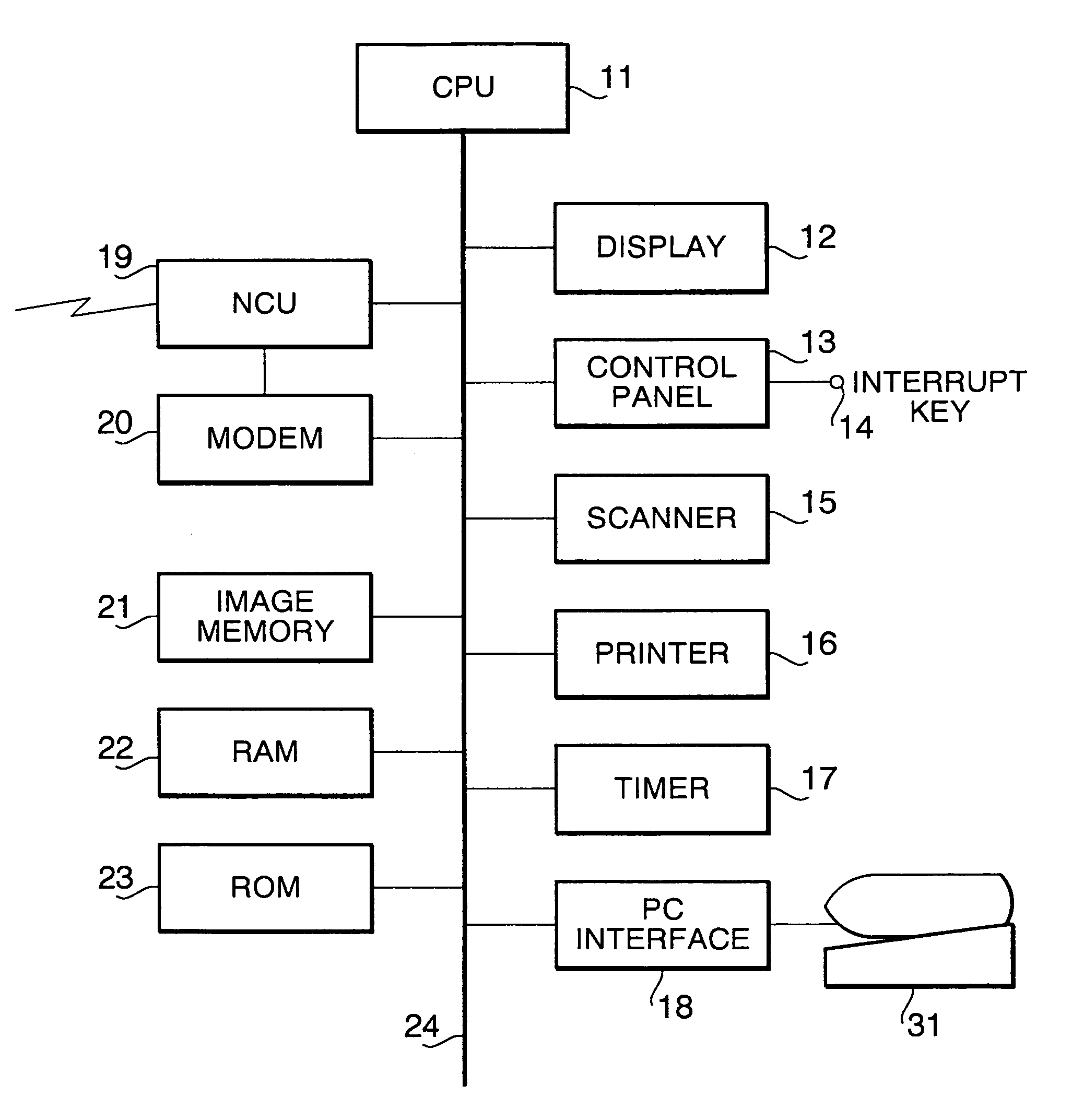

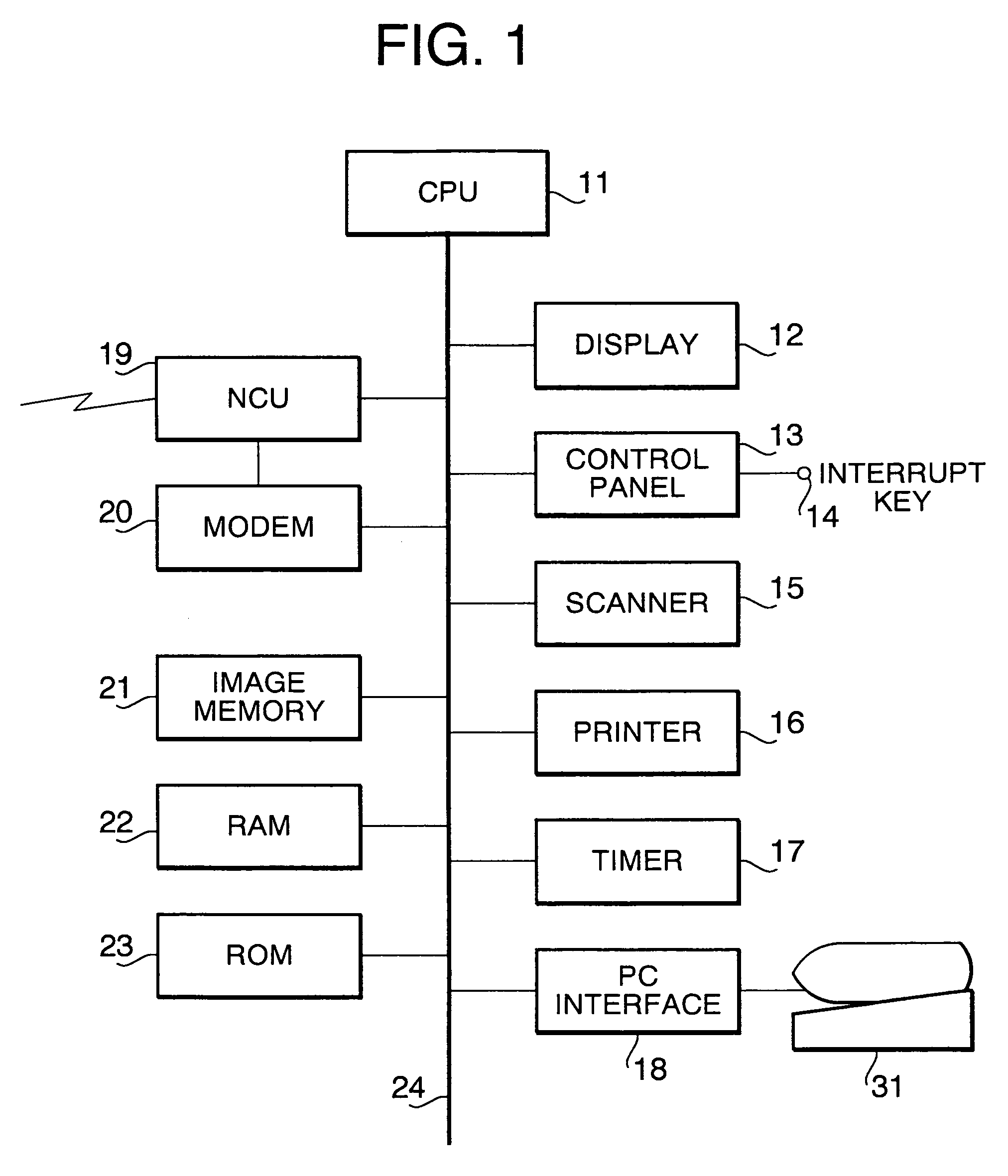

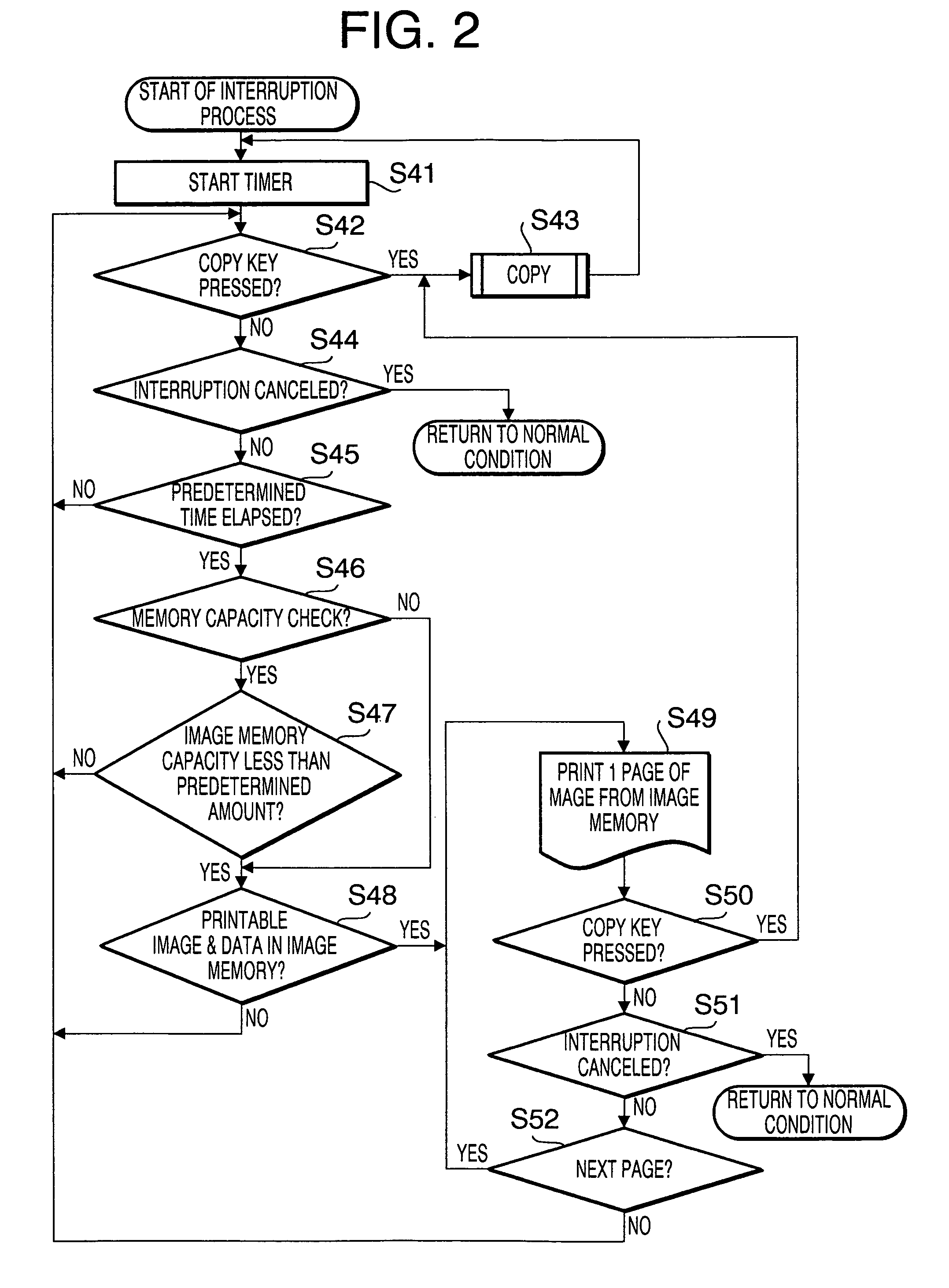

Communication terminal device

InactiveUS6947165B1Reduce the possibility of spillagePrevent fullInput/output to record carriersDigital computer detailsModem deviceUser input

Owner:MURATA MASCH LTD

River channel garbage salvaging device

PendingCN113356165AEasy to storeAutomatic salvage with high safetyWater cleaningWaterborne vesselsAnimal scienceRiver routing

The invention relates to a salvaging device, in particular to a river channel garbage salvaging device. According to the technical aim, the river channel garbage salvaging device is high in automatic salvaging safety and convenient to store garbage. According to the technical scheme, the river channel garbage salvaging device comprises a base, a double-shaft motor, a driving assembly and a salvaging assembly; the double-shaft motor is arranged on the rear side of the left portion of the base, the driving assembly is arranged on the front side of the middle portion of the base, and the salvaging assembly is arranged on the left side of the base. Effects that the automatic salvaging safety is high, and the garbage is convenient to store are achieved; according to the river channel garbage salvaging device, people start the double-shaft motor, the double-shaft motor drives the driving assembly and the salvaging assembly to rotate, the salvaging assembly can bring the garbage onto a ship body during rotation, people can manually clean the garbage conveniently, and the effect of high automatic salvaging safety is achieved.

Owner:曾伟明

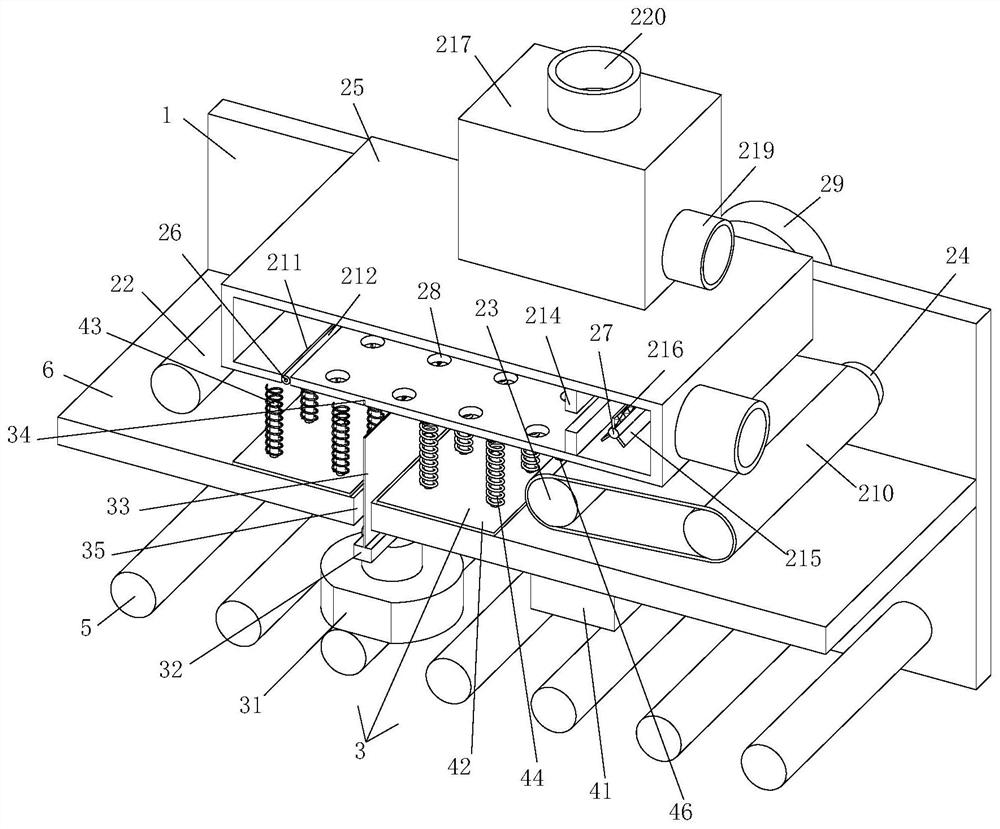

Cutting device based on waste cloth recycling

InactiveCN112030531ALess consumablesReduce lossMechanical cleaningPressure cleaningDust controlEnvironmental engineering

The invention provides a cutting device based on waste cloth recycling, the cutting device comprising two side plates for supporting equipment, a roll-off type conveying mechanism for conveying cloth,a cutting mechanism for cutting the cloth during conveying, and a dust removal mechanism for removing dust, wherein a supporting plate is fixedly connected to the surfaces of the side plates, reinforcing rods are fixedly connected between the two side plates, the roll-off type conveying mechanism is arranged between the two side plates, and the dust removal mechanism is arranged on the supportingplate, and the invention relates to the field of textile processing. According to the cutting device based on waste cloth recycling, a special structure capable of concentrating procedures, reducingthe dust dispersion amount and saving energy and materials is designed according to the problems of cutting and dust existing in current waste cloth recycling and processing, and therefore the problemthat a large amount of dust is generated when common waste cloth is processed, and the dust is deposited on a conveying device in the conveying process, so that adverse effects are caused to the workshop environment is effectively solved.

Owner:陈东东

Antiskid badminton racket handle

The invention discloses an antiskid badminton racket handle comprising a racket handle, the racket handle is of a hollow structure; the upper end of the racket handle is fixedly connected with a connector; the upper end of the connector is fixedly connected with a racket rod; the bottom end of the racket handle is fixedly connected with a base disc; an air cylinder is fixedly mounted at the bottomof an inner cavity of the racket handle; limiting grooves are symmetrically formed in the opposite side walls, close to the bottom end, of the air cylinder, limiting blocks are slidably connected into the limiting grooves, the ends, away from the groove bottoms of the limiting grooves, of the limiting blocks penetrate through groove openings of the limiting grooves and extend outwards, and are fixedly connected with a connecting plate; and a piston rod is fixedly connected to the upper end of the connecting plate. According to the antiskid badminton racket handle, flowing of air on the rackethandle is increased, the heat dissipation effect of the hand of a user is obviously enhanced, the racket handle is prevented from being full of sweat, the anti-skid effect is enhanced, and damage tothe badminton racket due to the fact that the racket handle falls off from the hand is avoided.

Owner:江苏威尔顺体育用品有限公司

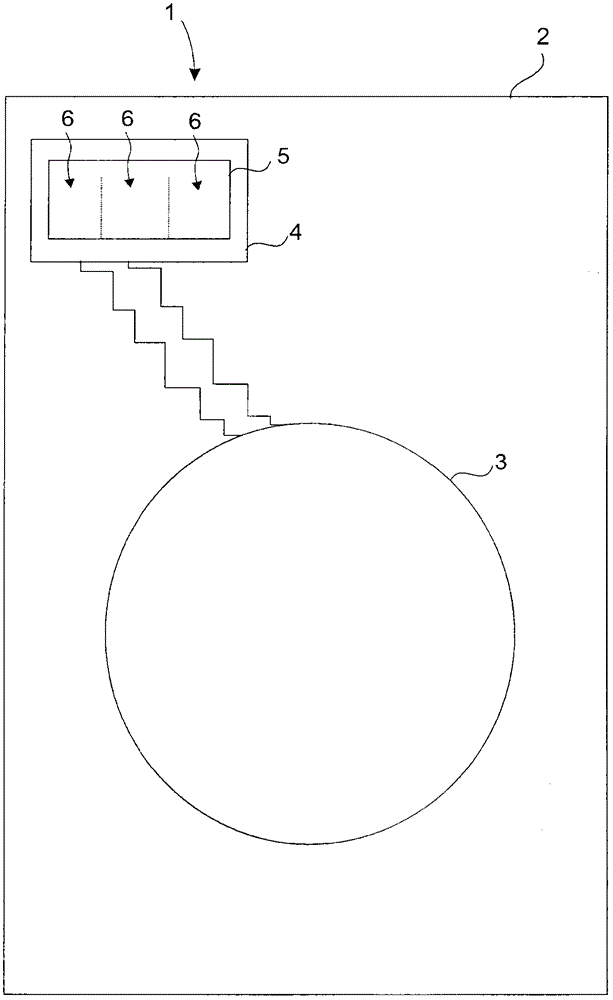

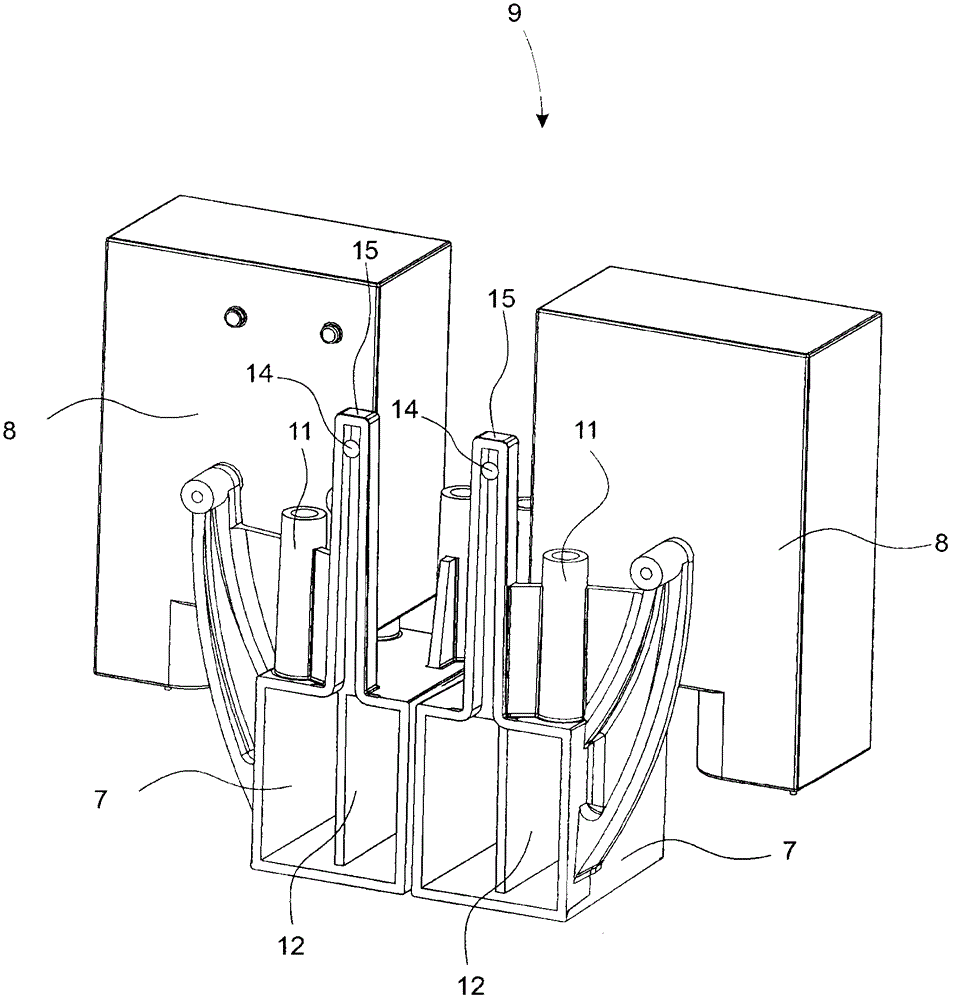

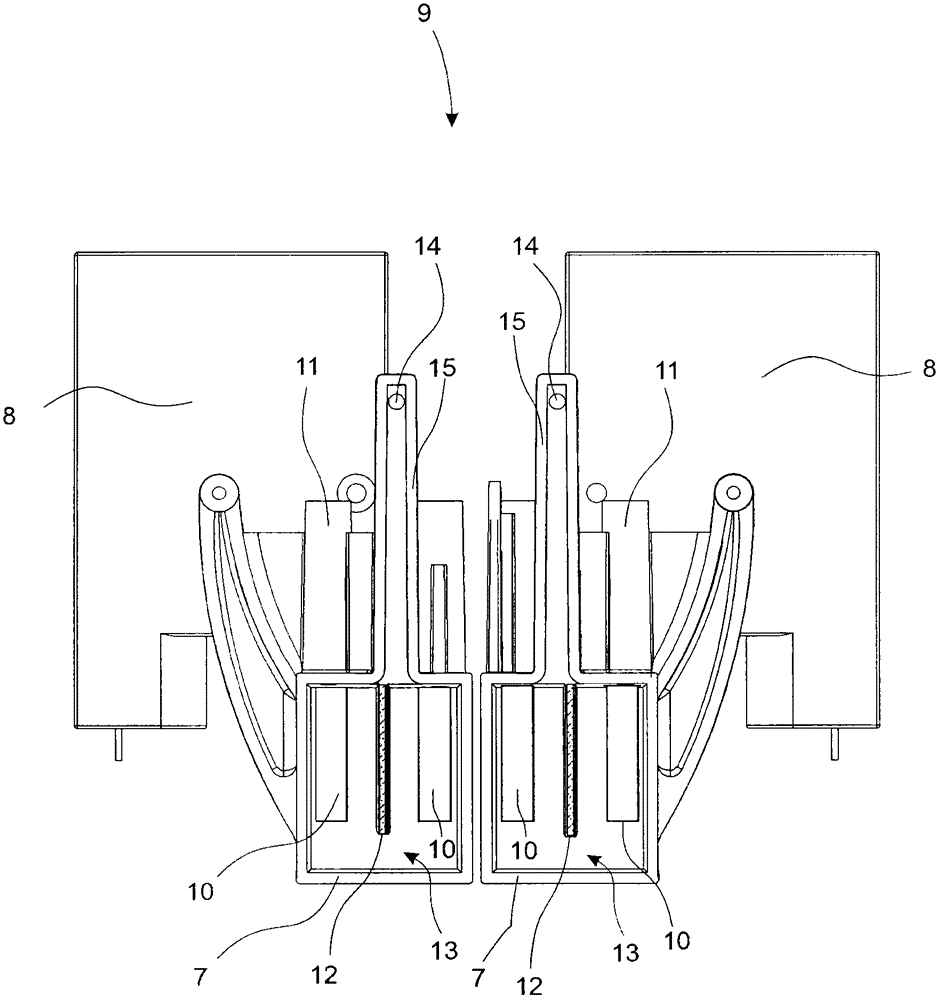

Washer comprising automatic dosing unit

InactiveCN105722444AReliable level measurementIncrease distanceTableware washing/rinsing machine detailsOther washing machinesBiomedical engineeringDosing units

The present invention relates to a washer (1) comprising a body (2); a tub (3) disposed within the body (2) wherein the washing - drying processes are performed; a housing (4) that extends from the outer surface of the body (2) into the body (2); a dispenser (5) that is disposed inside the housing (4) and that has more than one division (6) wherein the cleaning agents are stored; a dosing unit (9) adjacent to the housing (4), with flow connection between the housing (4) and itself, having at least one dosage receptacle (7) wherein cleaning agents filled into the dispenser (5) are stored for dosing and at least one dosage pump (8) that is disposed on the dosage receptacle (7) and that sucks the cleaning agents in the dosage receptacle (7) and enables them to be transferred into the housing (4) in order to be delivered to the tub (3); and at least two pins (10) that are situated in the dosage receptacle (7) and used for determining the type and the level of the liquid cleaning agents.

Owner:ARCELIK AS

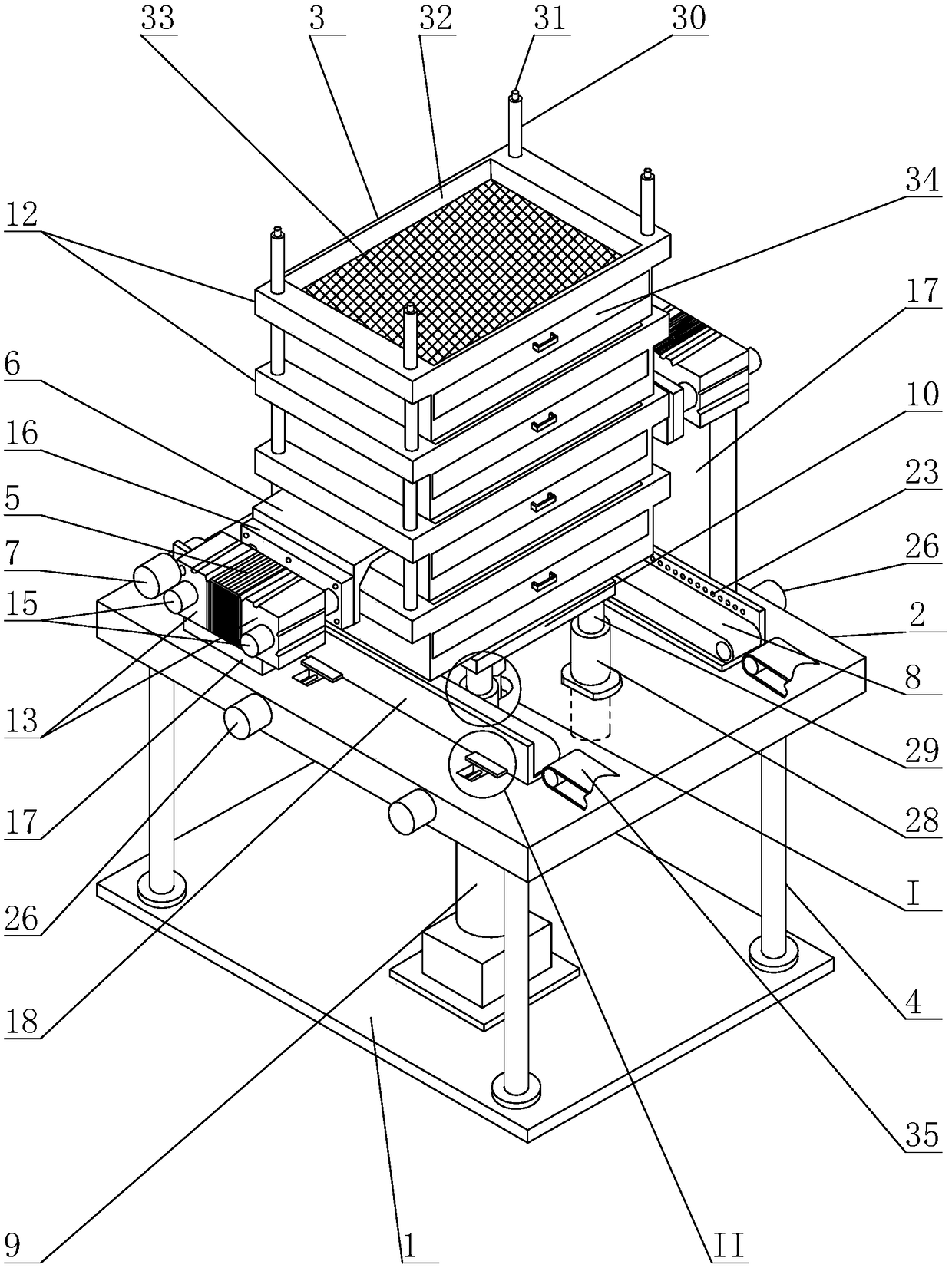

Automatic conveying device for medical surgical instrument cleaning and disinfection

InactiveCN108357940AImprove work efficiencyReduce labor intensityConveyorsDe-stacking articlesPiston rodSurgical device

The invention discloses an automatic conveying device for medical surgical instrument cleaning and disinfection, and mainly relates to the field of medical surgical instrument cleaning and disinfection devices. A support device assembly comprises a support servo cylinder and a support plate; a piston rod of the support servo cylinder is fixedly connected with the support plate; a conveying deviceassembly comprises a conveying servo motor and a box conveying belt; the conveying servo motor and the box conveying belt are in transmission connection; a falling device assembly comprises a liftingservo cylinder and a top plate; a through hole is formed in a worktable surface; a piston rod of the lifting servo cylinder penetrates through the through hole, and is fixedly connected with the bottom of the top plate; multiple cleaning and disinfection boxes are laminated in sequence; and support flanges adapted to the position of the support plate are arranged on the two sides of the cleaning and disinfection boxes. The automatic conveying device has the following beneficial effects: when medical surgical instruments are cleaned and disinfected, automatic conveying of the cleaning and disinfection boxes is realized, so that the labor intensity of workers is relieved, labors are reduced, and the working efficiency of cleaning and disinfection of the medical surgical instruments is improved.

Owner:黄晓静

Bedside filth collecting device for patients of gastroenterology department used for medical care

InactiveCN108578248AWon't leakPrevent fullNursing bedsSpittle receiving devicesEmergency medicineGastroenterology department

The invention relates to a medical care device, in particular to a bedside filth collecting device for patients of the gastroenterology department used for medical care. The invention aims at providing the bedside filth collecting device for patients of the gastroenterology department used for medical care, which enables the patients to vomit towards the proper position, and can rapidly collect filth and isolate odor. The technical scheme is as follows: the bedside filth collecting device for patients of the gastroenterology department used for medical care comprises a bottom plate, a closingbox, a first threaded rod, a sliding sleeve, a cover board, a first nut and the like, wherein the closing box is connected to the bottom plate, a rectangular hole is formed in the right side of the closing box, the first threaded rod is connected to the upper part of the right side of the closing box, and the sliding sleeve is connected to the first threaded rod in a sliding manner. With the bedside filth collecting device, the effects that the patients vomit towards the proper position, the filth is collected rapidly, and the odor is isolated, are achieved, due to the adoption of the manner that a crank is rotated so that a collecting table is driven to move vertically till reaching the position enabling the patients to conveniently vomit, the patients can rapidly realize alignment and vomit, and the filth can not leak out.

Owner:李龙燕

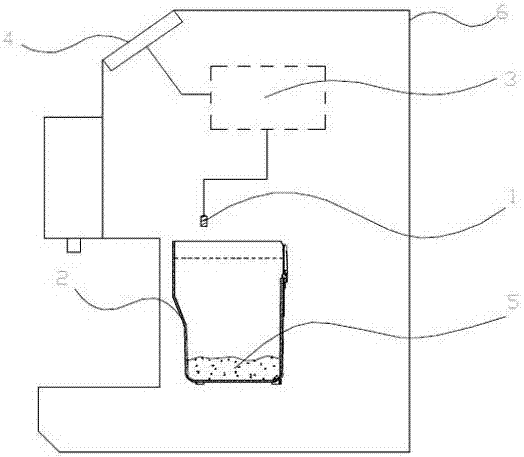

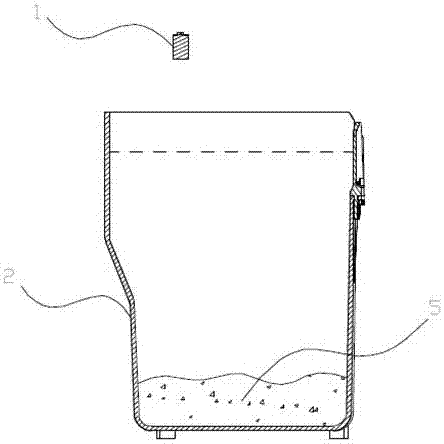

Detection method for coffee grounds inside coffee maker

The invention discloses a detection method for coffee grounds inside a coffee maker. Equipment comprises an infrared detection device, a coffee maker grounds containing box, a coffee maker control circuit, a prompter, coffee grounds and the coffee maker. According to the detection method for the coffee grounds inside the coffee maker, the height of the coffee grounds inside the coffee maker grounds containing box is monitored and fed back in real time in an infrared detection mode, the coffee grounds inside the coffee maker grounds containing box are effectively prevented from accumulating andoverflowing from the coffee maker grounds containing box, full information of the coffee maker grounds containing box is fed back to a user by the prompter, normal use of the coffee maker is ensured,and the detection method has the advantages of simple structure, convenience in use, high sensitivity, rapid response, stable and reliable performance and the like.

Owner:SUZHOU DR COFFEE SYST TECH CO LTD

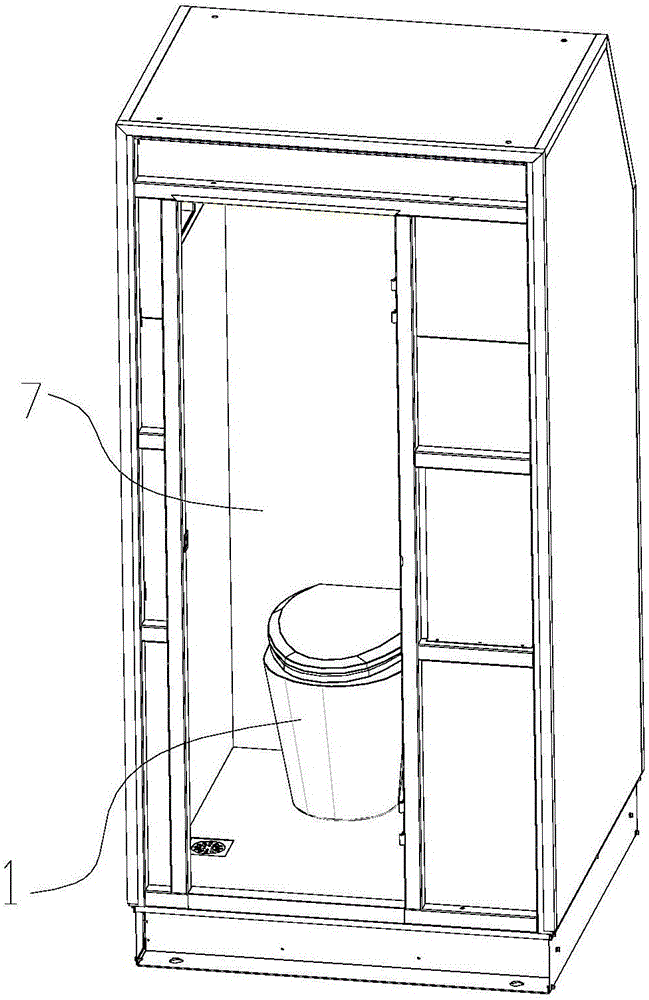

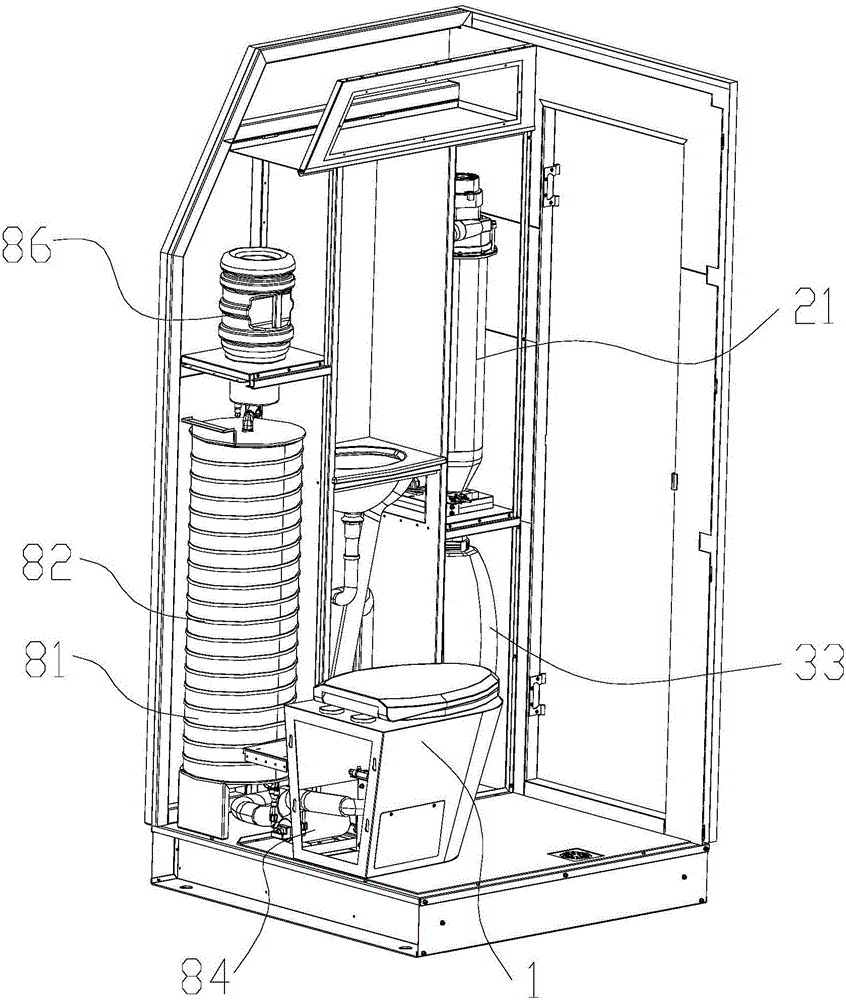

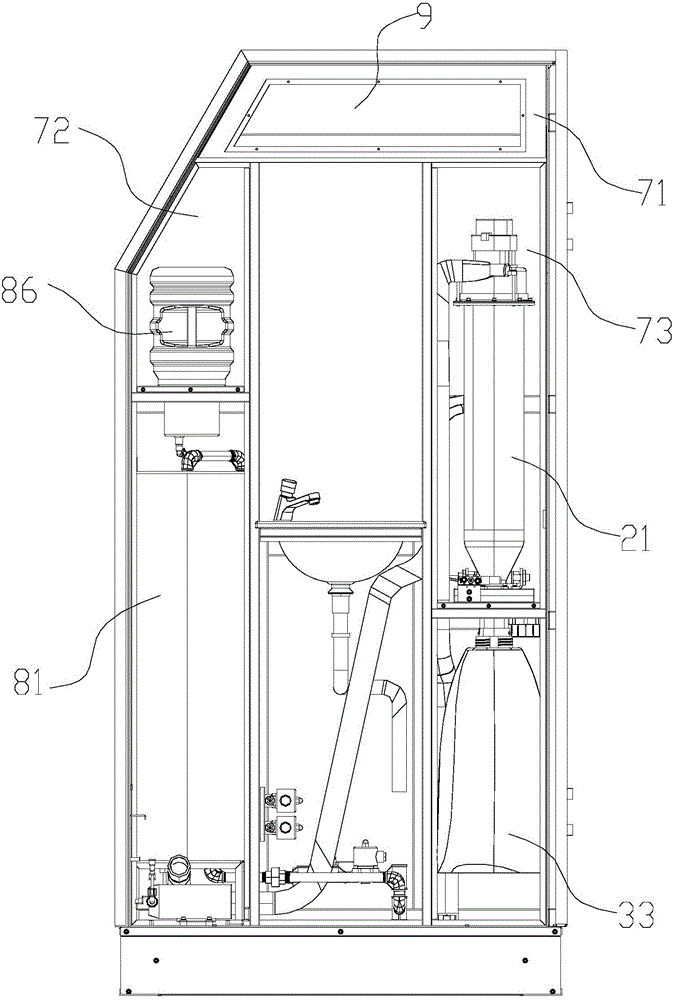

Toilet with automatic dirt collecting function

The invention discloses a toilet with an automatic dirt collecting function.The toilet comprises a chamber, a toilet bowl located in the chamber, a flushing system for flushing the interior of the toilet bowl, a suction mechanism, a dirt collecting assembly and a first valve.The suction mechanism comprises a gas-liquid separation box, a vacuumizing device and a dirt inflow pipe.The gas-liquid separation box comprises a box body and a conical net, a vacuum connector is arranged on the top of the box body, a dirt inflow opening is formed in one side of the box body, a dirt outlet is formed in the bottom of the box body, the conical net is fixedly arranged in the box body and located above the dirt inlet, and the external diameter of the conical net is gradually reduced from top to bottom.The dirt collecting assembly comprises a dirt discharge pipe and a dirt collecting bag, the upper end of the dirt discharge pipe is used for being communicated with the dirt outlet, the dirt collecting bag is detachably installed at the lower end of the dirt discharge pipe, and the interior of the dirt collecting bag is communicated with the lower end of the dirt discharge pipe.The first valve is installed between the dirt discharge pipe and the dirt outlet and used for controlling communication or isolation of the dirt discharge pipe and the dirt outlet.Dirt of the toilet bowl can be automatically collected, and an anti-freezing effect can be achieved.

Owner:BEIJING HUASHENGLUTAI TECH CO LTD

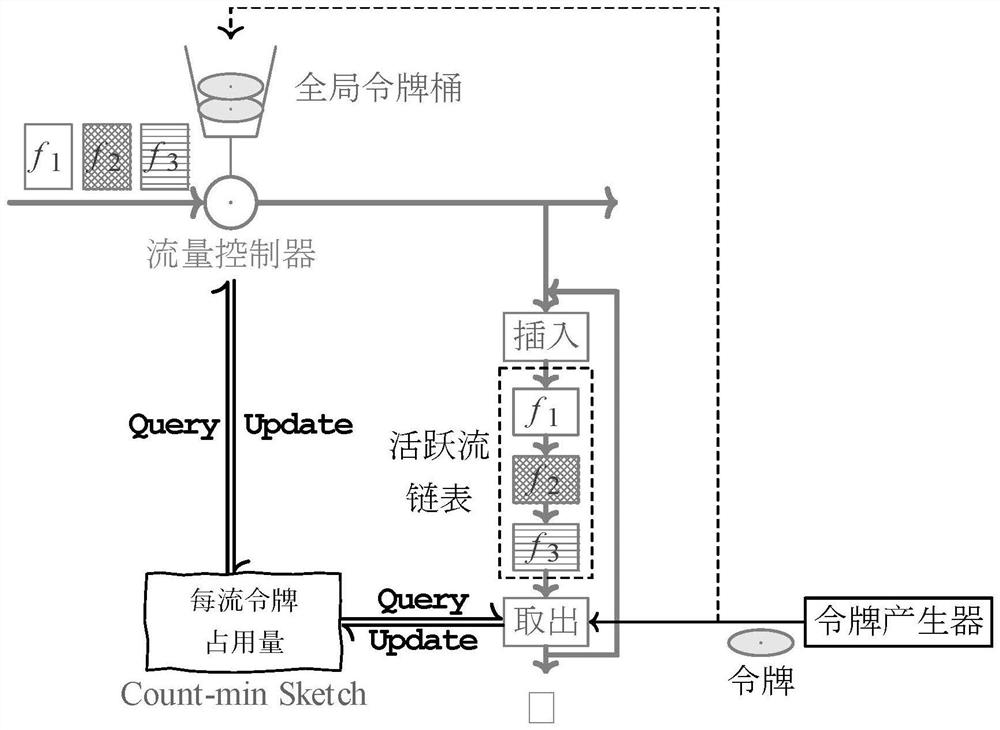

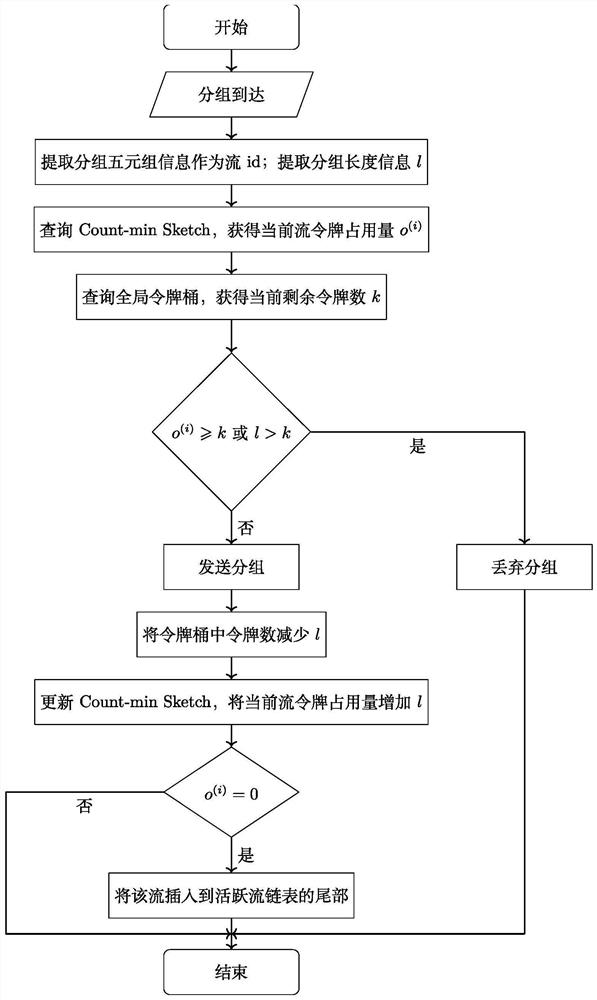

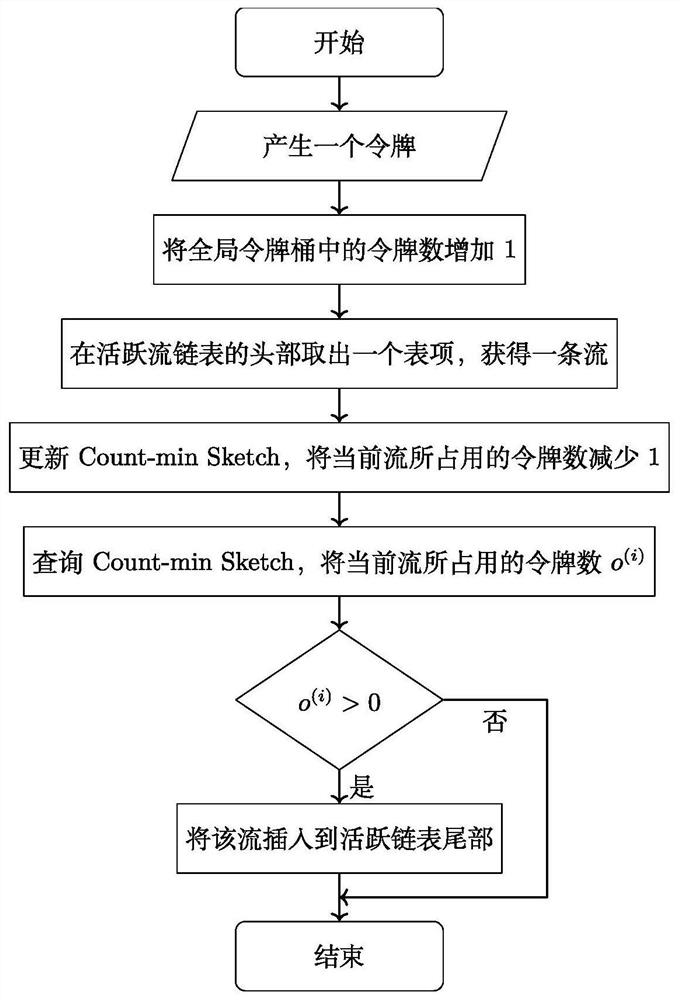

Fair network flow control method and device

ActiveCN112787950APrevent fullReduce transfer timeData switching networksComputer networkInternet traffic

The invention discloses a fair network flow control method and device, and the method comprises the steps of: (1) when a packet with the length of 1 arrives, determining whether to allow the packet to pass by a flow controller according to the token occupation amount of a flow to which the packet belongs and the number of tokens in a current global token bucket; if the packet is allowed to pass, increasing the token occupation amount of the stream by 1 through a Count-min Sketch; if the packet is allowed to pass and the token occupation amount of the stream to which the packet belongs is 0 before the packet arrives, inserting the stream into the tail part of the active stream linked list; and (2) generating the tokens at a preset speed, when the tokens are generated, adding 1 to the number of the tokens in the global token bucket, then taking out a stream from the head of the active stream linked list, reducing 1 to the number of the tokens occupied by the stream through a Count-min Sketch structure, and at the moment, if the token occupation amount of the stream is greater than 0, re-inserting the stream into the tail of the active stream linked list. According to the method, the tokens can be fairly allocated to each active flow, so that each flow passing through the flow controller fairly shares bandwidth resources.

Owner:XI AN JIAOTONG UNIV

Novel wood cutting machine

InactiveCN108326993APrevent the risk of misalignmentImprove work efficiencyGuide fencesBark-zones/chip/dust/waste removalDrive wheelTransmission belt

The invention relates to the technical field of wood processing equipment, and discloses a novel wood cutting machine. The novel wood cutting machine comprises supporting legs. One side of each supporting leg is fixedly connected with one side of a load-bearing plate. A height adjusting device is fixedly installed in the middle of the top end of the load-bearing plate. A driving device and a driving motor are correspondingly arranged on the two sides of the height adjusting device. An output shaft of the driving motor is connected with a driven wheel through a transmission belt II in a transmitting mode. The novel wood cutting machine can cut the wood with various thickness, and is especially for cutting of wood with ultra-thickness, twice cutting forward and backward are not required, therisk of the dislocation of the twice cutting is avoided, and the cutting efficiency is improved; and at the same time, because a precise screw rod is arranged, and the pinch of a thread is 1 mm, whenthe functions of cutting and seam-taking are needed, a crank is manually adjusted, the height of a cutting piece exposed to an operating table is slowly adjusted according to the required cutting depth, so that the precise cutting data parameter is conveniently obtained, and the high-precision cutting operation is realized.

Owner:胡云康

Circulation-type raisin winnowing device based on dynamic shaking and dynamic vibrating

ActiveCN108906626ALow resolutionA large amountFouling preventionGas current separationReciprocating motionEngineering

The invention discloses a circulation-type raisin winnowing device based on dynamic shaking and dynamic vibrating, and relates to the technical field of raisin processing. The device comprises a firsthousing, both front and rear sides of the bottom of the inner wall of the first housing are fixedly connected with shaking devices, both left and right sides of the shaking devices penetrate throughthe first housing and extend to the outer side of the first housing, and first limiting blocks and first rotary discs are fixedly connected with both left and right sides of the shaking devices respectively. According to the device, a straight tooth block is pushed by a sector tooth block to perform left and right reciprocating movement to allow a control device to generate vibration, and therefore the current problem that winnowed raisins easily enter an adjacent collecting box when raisins at the edge of a collecting box are accumulated to a higher position exceeding the height of the collecting box resulting in lower winnowed raisin accuracy is effectively solved.

Owner:金典(山东)食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com