Circuit board comprising blind hole and manufacturing method of circuit board

A manufacturing method and circuit board technology, which is applied to printed circuit components, electrical connection formation of printed components, electrical connection of printed components, etc., can solve problems such as inability to effectively polish resin, inability to complete grinding board, and substrate surface grinding. , to achieve the effect of tight filling, reduced production process, and no layering of resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A circuit board manufacturing method including blind holes, including pre-process, sub-board drilling, copper sinking, plate plating, plated holes, inner layer pattern making, browning, resin plugging holes, baking board, sub-board lamination, post-processing process, of which:

[0027] In the preceding process, including sub-board cutting, inner layer graphics transfer, inner layer etching, inner layer AOI, and sub-board lamination processes, the above-mentioned pre-processes are all produced according to conventional technology, and the sub-board is made of RO4350B plate, and combined Laminated with RO4450 prepreg.

[0028] The sub-board drilling, copper sinking, plate plating, plated hole, inner layer pattern making, browning process are also all made according to conventional technology, wherein, in the inner layer pattern making process, the method of positive etching can also be used. Pattern transfer is carried out by means of negative electroplating.

[0029] ...

Embodiment 2

[0037] The manufacturing method of the circuit board including blind holes in this embodiment is basically the same as the method in embodiment 1, except that in this embodiment, a PTFE plate is used as the substrate of the circuit board.

[0038] In the resin plugging process, the length of each side of the window opening area on the plugging aluminum sheet is 6 mil larger than the length of each side of the sub-board requiring resin plugging. Use SKY-2000 type resin, and use Nanda FL-6080PSR-TM semi-automatic plug hole screen printing machine or Dongyuan ATMAOE-67 semi-automatic plug hole screen printing machine, the inclination angle of the scraper is 5°, the swivel angle of the scraper is 3°, and the screen printing pressure is 6kg / cm 2 , The plugging speed is 14 Hz, the ink filling speed is 4 scales (1 scale = 10 Hz), the screen mesh is 36T, and the screen tension is 27N / cm 2 Under the conditions of the plug hole.

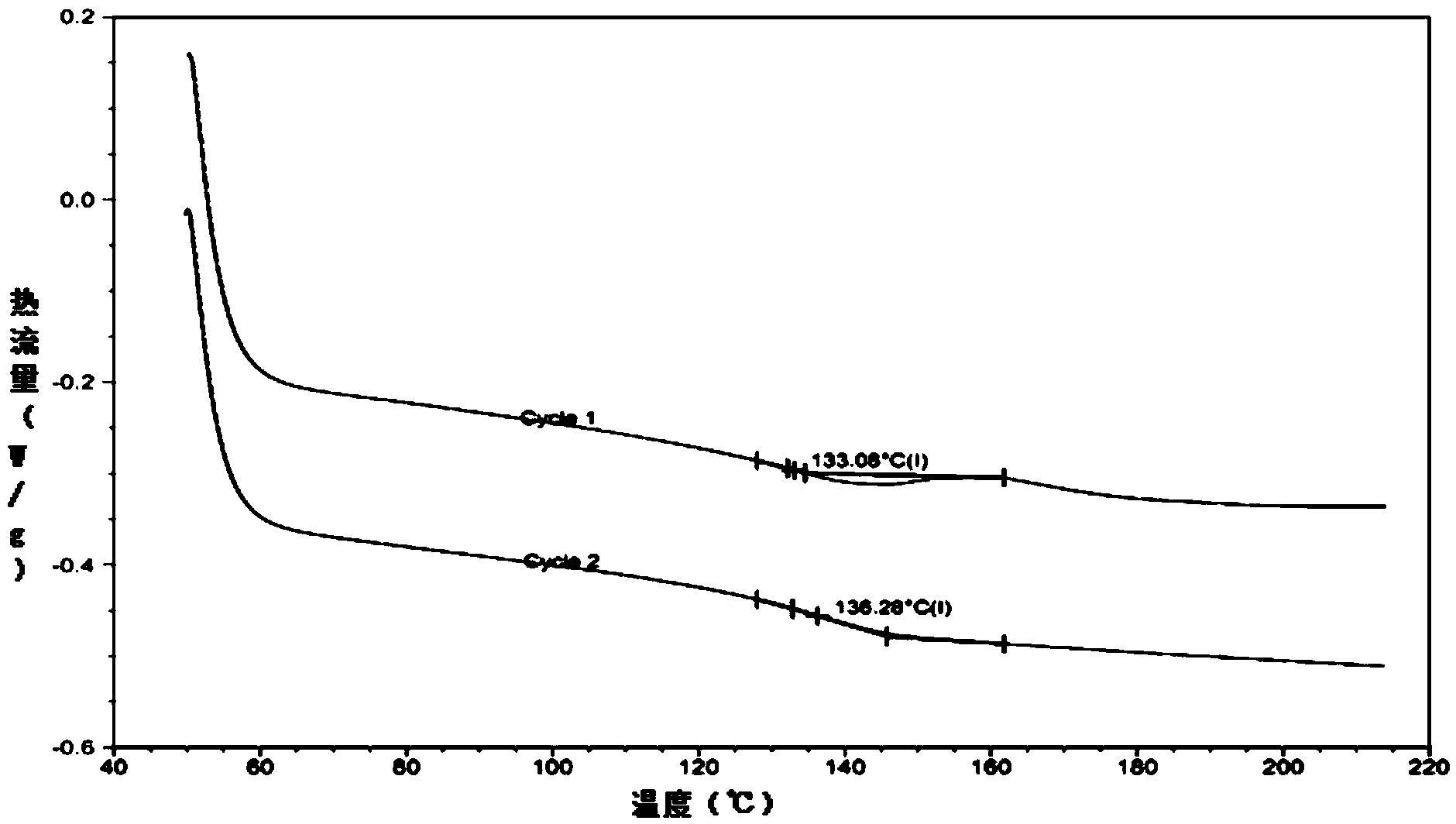

[0039] In the baking process, the temperature of the ...

Embodiment 3

[0042] The manufacturing method of the circuit board including blind holes in this embodiment is basically the same as the method in Embodiment 2, except that in this embodiment, the sub-board is made of RO4350B board and combined with RO4450 prepreg for pressing.

[0043] In the resin plugging process, the length of each side of the window opening area on the plugging aluminum sheet is 4 mil larger than the length of each side of the area requiring resin plugging holes on the sub-board. Using SKY-2000 resin, the inclination angle of the scraper is 4°, the swivel angle of the scraper is 0°, and the screen printing pressure is 5kg / cm 2 , The plugging speed is 8 Hz, the ink filling speed is 3 scales, the screen mesh is 36T, and the screen tension is 26N / cm 2 Under the conditions of the plug hole.

[0044] In the baking process, the temperature of the baking board is 100° C., and the drying time is 30 minutes.

[0045] Through the above method, the circuit board C is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com