Centrifugal gas way type gas purifier

A gas purification and airway-type technology, applied in the field of centrifugal airway gas purifiers, can solve the problems of low capture rate, low efficiency, and rapid drop in airflow rotation speed, and achieve the effect of efficiently purifying gas and improving sedimentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

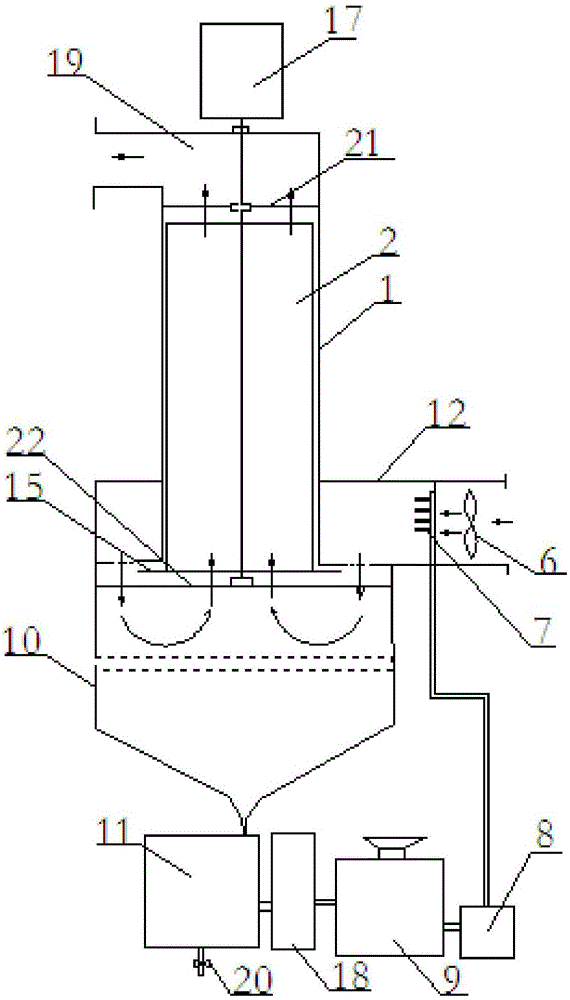

[0056] Such as figure 1 As shown, a centrifugal airway type gas purifier includes an aerosol mixing device, a casing 1, a centrifugal rotor 2 and a power unit, the aerosol mixing device is used to mix gas and water mist, and the casing A centrifugal rotor 2 for absorbing suspended particles in the gas is installed inside. The centrifugal rotor 2 is provided with several centrifugal air passages 4 for airflow to flow through. The power device includes a motor 17, and the motor 17 is in the position of Outside the casing 1, the output shaft of the motor 17 is connected to the rotating shaft of the centrifugal rotor 2 through a coupling.

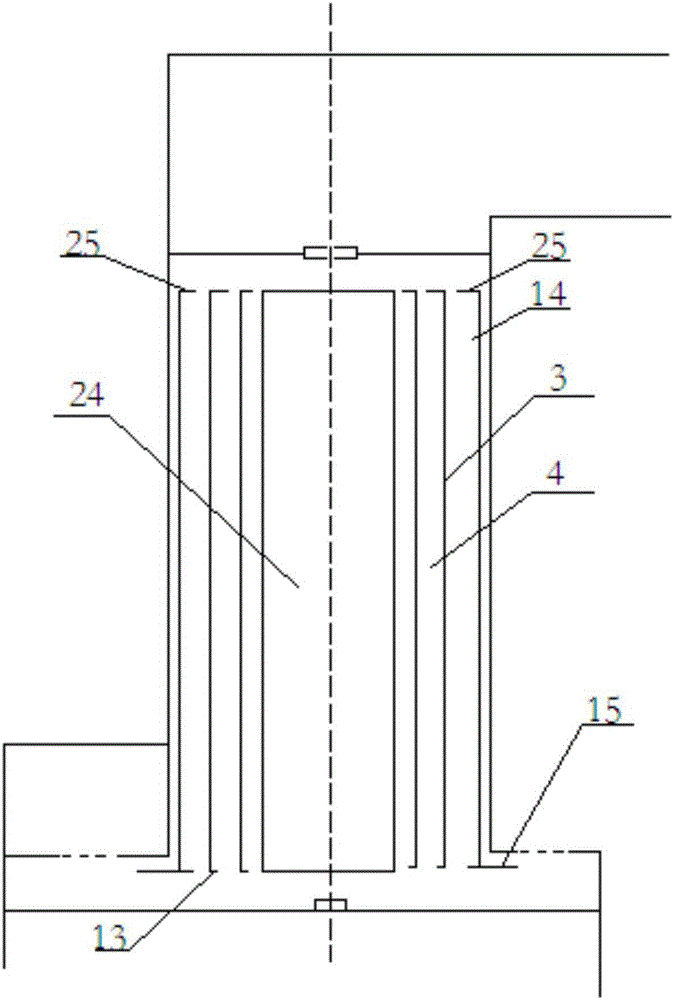

[0057] The air inlet of the centrifugal rotor 2 is connected with the air outlet of the aerosol mixing device, and the air outlet of the centrifugal rotor 2 is connected with the air outlet of the casing 1 . The centrifugal rotor 2 includes several cylinders 3 with unequal diameters that are coaxially fitted together, and the cylinders 3 are c...

Embodiment 2

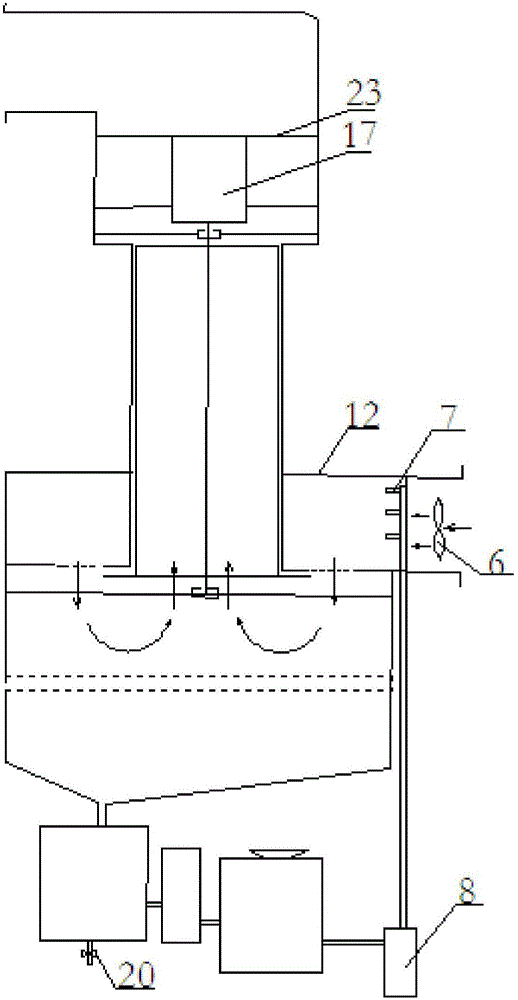

[0069] Such as figure 2 , is the structural representation of embodiment 2. The structure of the second embodiment is basically the same as that of the first embodiment, the only difference lies in the installation position of the motor 17 . The motor 17 is installed outside the casing 1 in Embodiment 1, and the motor is installed in the casing 1 in Embodiment 2. A motor mounting bracket 23 is provided in the air outlet section 19 of the casing 1 , and the motor 17 is mounted on the motor mounting bracket 23 . Adopting the installation method of the motor 17 in Embodiment 2 makes the structure of the product more compact.

[0070] The power device can be an electric motor 17, and other power devices can also be selected, as long as it can provide power to drive the centrifugal rotor 2 to rotate.

[0071] Those skilled in the art can also design the shapes and placement directions of various centrifugal rotors 2 according to the technical features of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com