Patents

Literature

111results about How to "Ensure cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

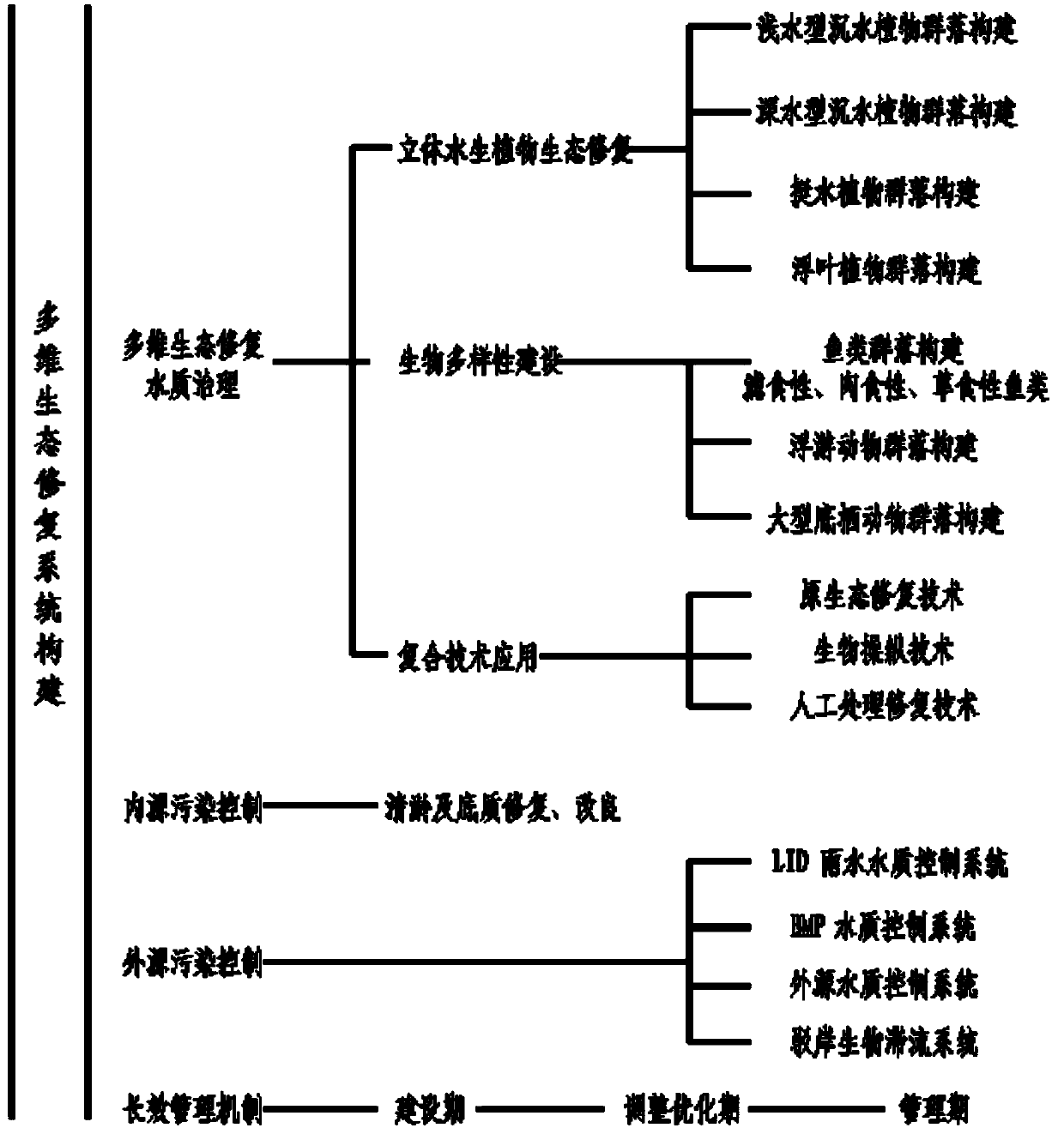

Multi-dimensional ecological system remediation method

ActiveCN103739077AEnsure water qualityImplement the buildWater resource protectionSustainable biological treatmentWater sourceWater quality

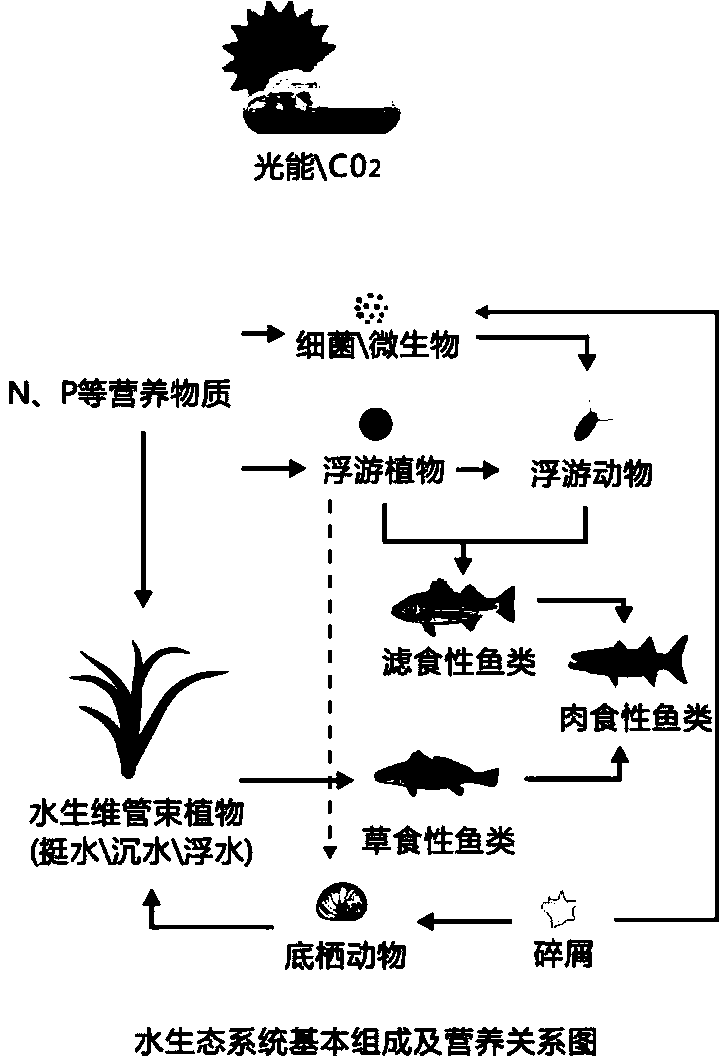

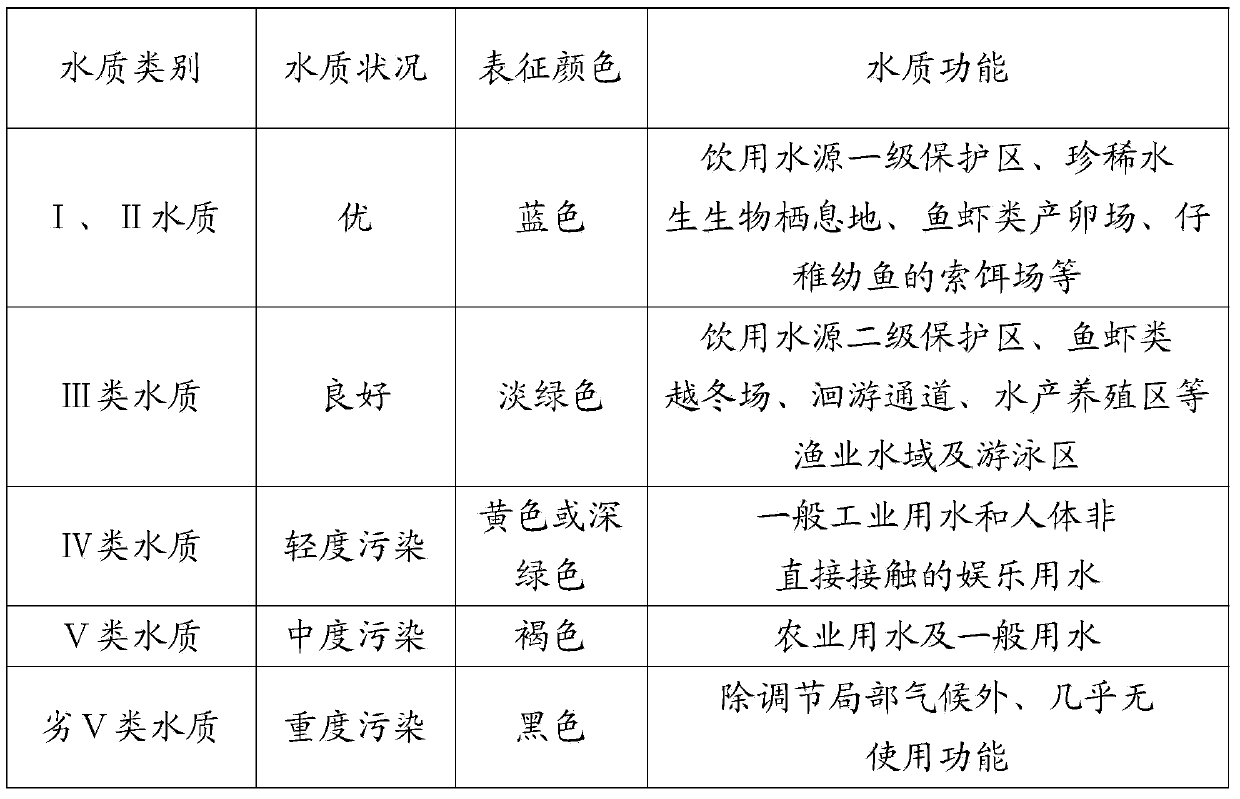

The invention provides a multi-dimensional ecological system remediation method. The remediation method comprises the steps of: treating multi-dimensional ecological water quality, controlling internal contamination and controlling external contamination, wherein the step of treating the multi-dimensional ecological water quality is mainly for constructing a multi-dimensional ecological system in a water body; the step of controlling the internal contamination is mainly for eliminating contamination caused by release of nutritive salts from bottom mud of a lake body and performing dredging and bottom mud remediation improvement on an artificial lake, an original lake body or river which is seriously contaminated; and by the step of controlling the external contamination, an external water body entering the lake body mainly includes rainwater and a part of life non-drinking water so that the water quality of water bodies entering the lake can not generate a destructive influence on a lake body ecological system and a water quality effect. The remediation method has the beneficial effects that from the angle of internal contamination and external contamination influencing water body quality, a general survey of the whole process from a water source to completion of a waterscape function of the water body is combined with all advantageous measures for maintaining the water body quality, so that the water body quality effect is all-around ensured and the multi-dimensional remediation is realized.

Owner:SHENZHEN TONGRUI ENVIRONMENTAL PROTECTION WATER SYST ENG

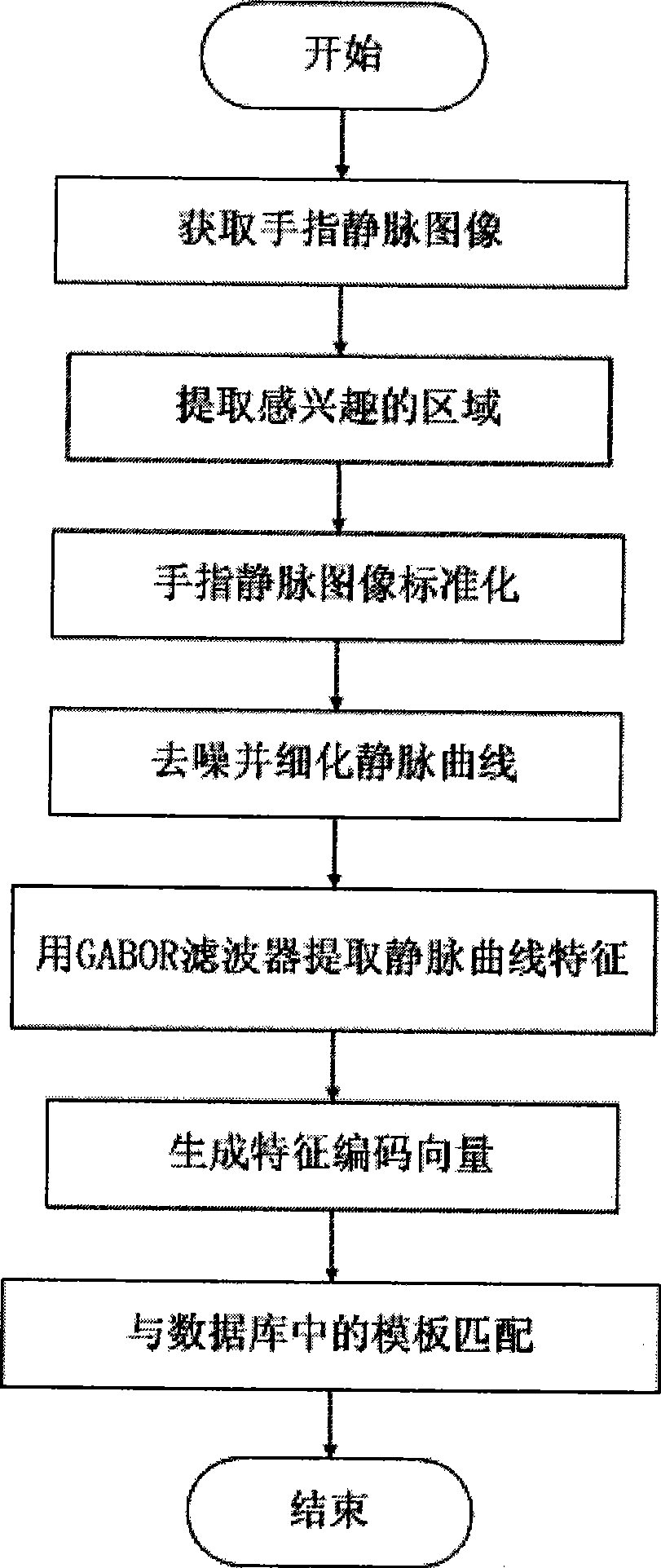

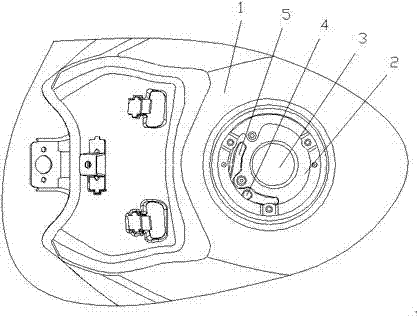

Finger vein recognition system

InactiveCN101477622AAvoid breakingEnsure convenienceCharacter and pattern recognitionVeinFinger vein recognition

The invention discloses a finger vein recognizing system which belongs to the technical field of biometric identification. The invention further discloses equipment which comprises a finger vein image collecting device, an image processing device and an image recognizing and storing device. The image collecting device is connected with the image processing device through a USB interface, and the image processing device is connected with the mage recognizing and storing device through the USB interface. The finger vein recognizing system comprises two modes: an authentication mode and a recognition mode, wherein, the authentication mode is used for verifying whether a person to be verified is a designated person or not, that is, a user first selects a corresponding user number when the system verification is performed; after finger vein images of the person to be verified are collected, a comparison is made between the finger vein images and the template which is stored in a database and corresponds to the user number, so that whether the user is valid or not can be determined; the recognition mode is used for verifying which registered person the person to be verified is, that is, a comparison is made between finger vein image characteristics of the user and the template of the user in the database; and then a template number with the greatest similarity is found, so as to determine the identity of the person to be verified.

Owner:SHANDONG UNIV

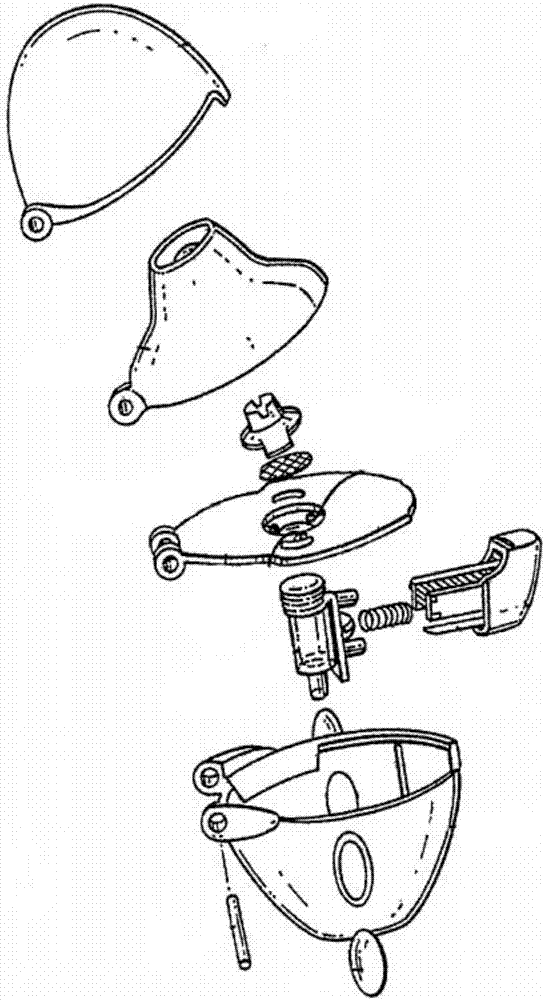

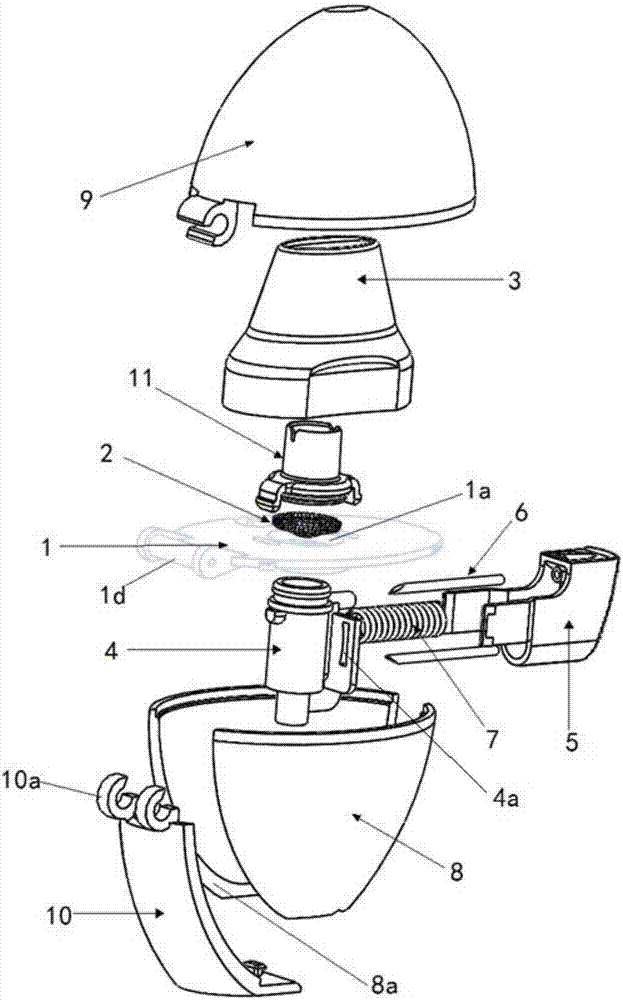

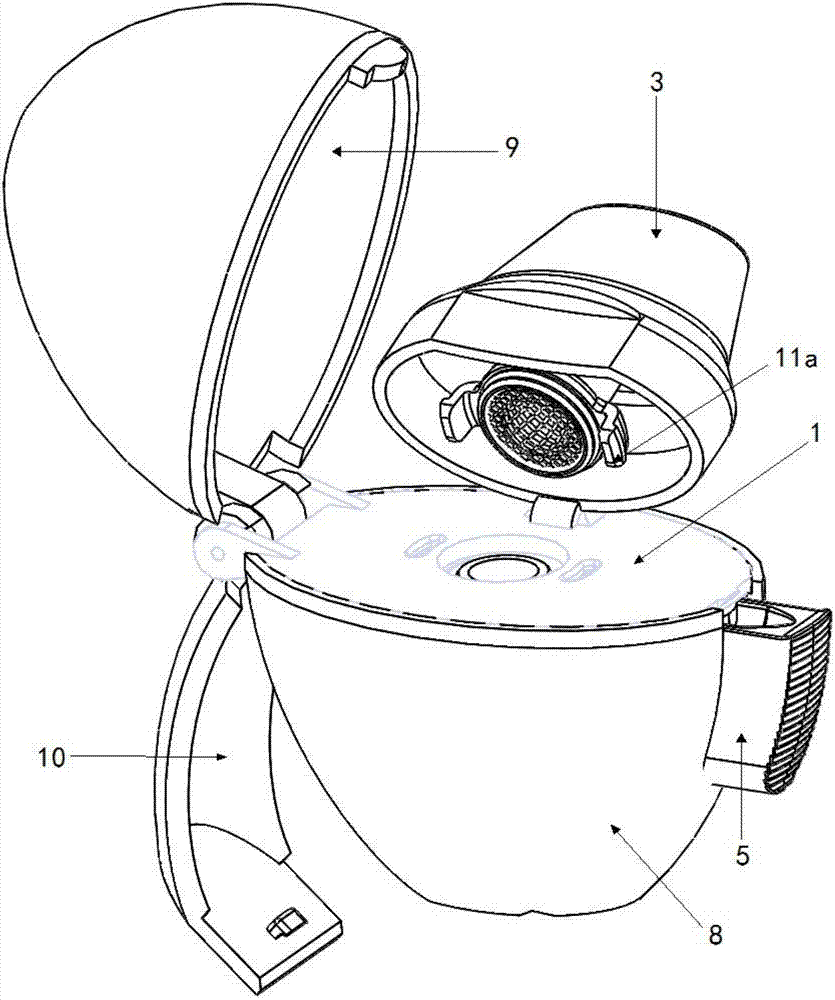

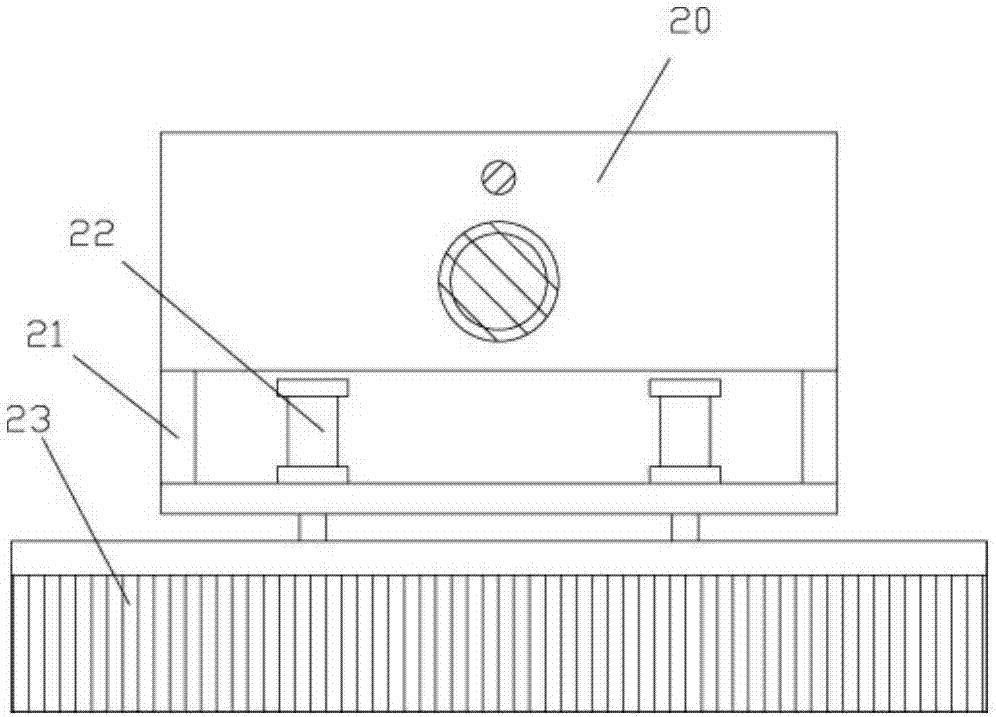

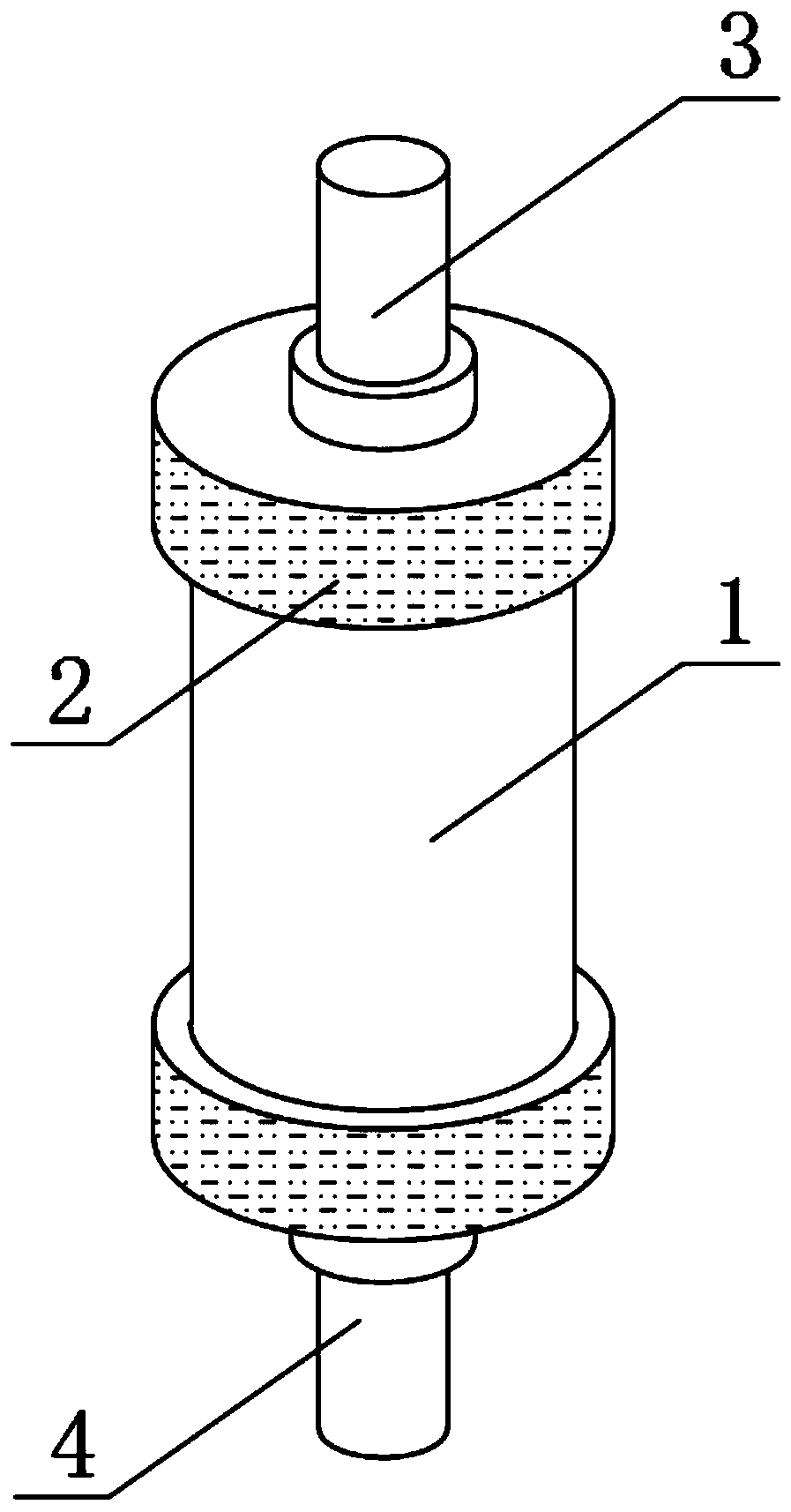

Dry powder inhaler

PendingCN106924845AEasy to assembleReduce manufacturing costMedical devicesInhalatorsBiomedical engineeringDry-powder inhaler

The invention discloses a dry powder inhaler, which comprises a bearing plate, a suction nozzle, a capsule chamber, a button, a spring and a lower shell, wherein through holes are formed in the bearing plate in a going-through mode; the suction nozzle is connected to the upper side of the bearing plate and is arranged on the through holes; the capsule chamber is connected to the lower side of the bearing plate and is located on the through holes; tip pins, which are made from metal, are connected to the button, and the tip pins, through a pressing action of the button, can extend into the capsule chamber; the spring is clamped between the button and the capsule chamber, and by virtue of the spring, elasticity away from the direction of the capsule chamber is exerted; the upper side of the lower shell is of an opening structure; the bearing plate is connected to an opening of the upper side of the lower shell, and meanwhile, the capsule chamber is accommodated within the lower shell; the tip pins are fixedly connected to the button by virtue of a plastic tip pin seat; the tip pins and the tip pin seat are fixed in an injection-molding mode; and the tip pin seat and the button are fixed in a clamping mode. According to the dry powder inhaler, the tip pins, when used, are prevented from getting fallen or displaced easily; and moreover, the capsule chamber can be cleaned by a user more conveniently.

Owner:SUZHOU SINGMED MEDICAL DEVICE SCI & TECH LTD

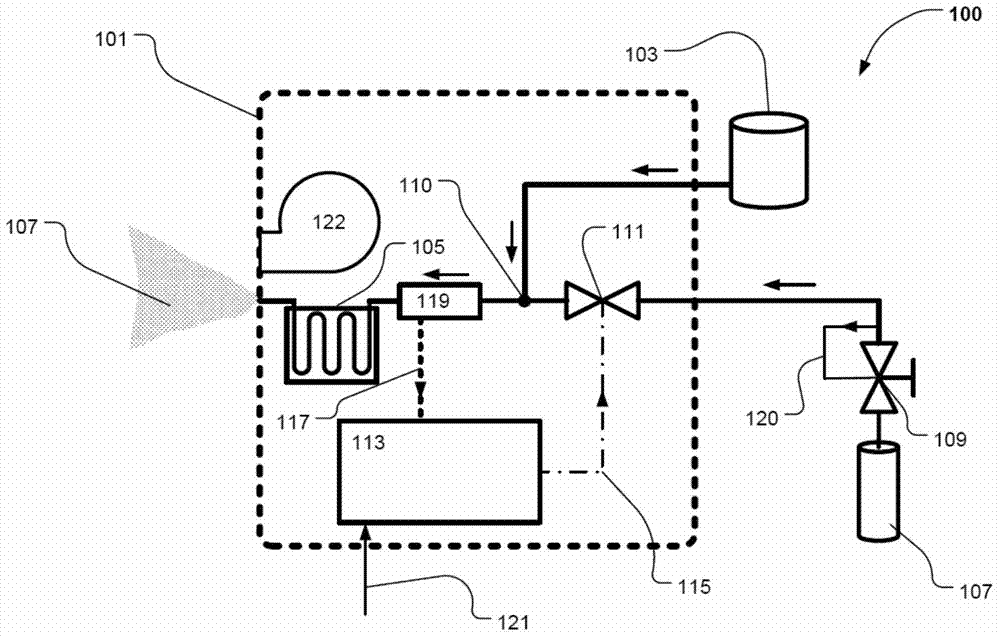

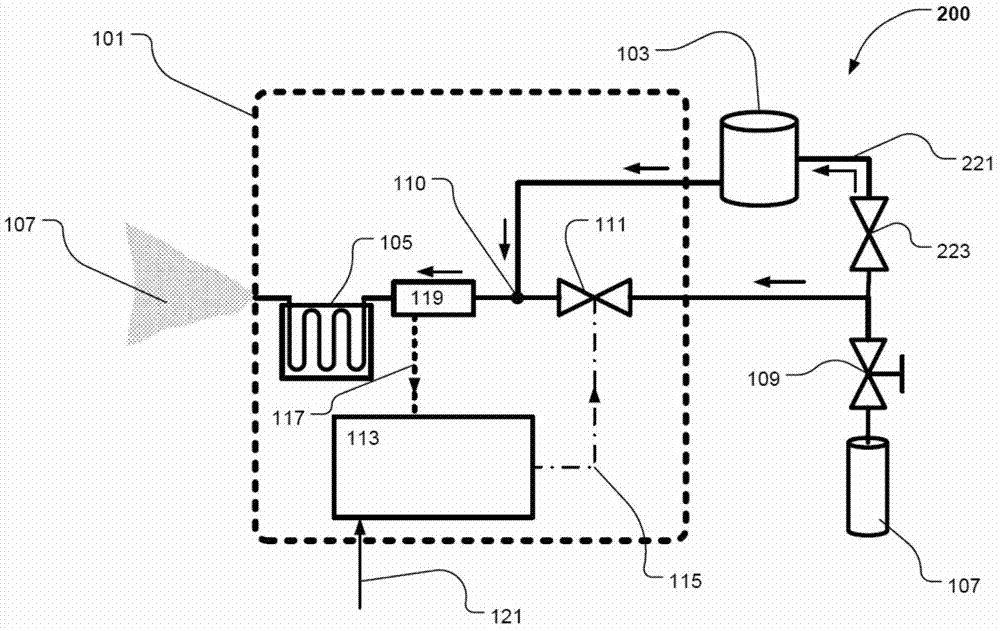

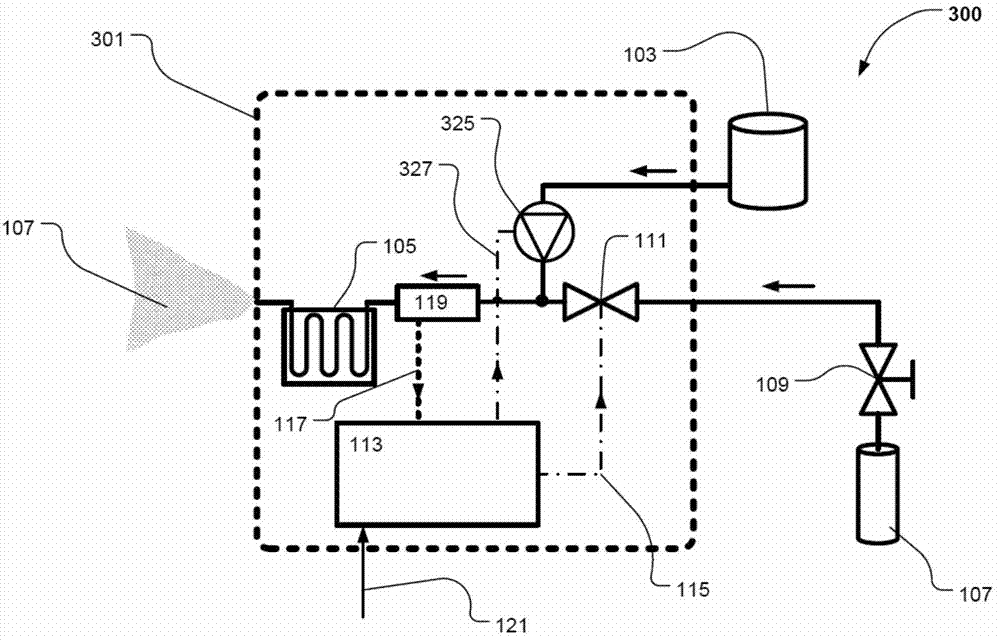

Smoke generator and method of controlling a smoke generation

ActiveCN104274988AAvoid cloggingGood light effectMeat/fish preservationStage arrangementsLiquid smokeEngineering

The invention relates to a method of controlling a smoke generator. The smoke generator is adapted to be connected to a supply of a pressurized gas and a supply of a smoke liquid and further comprises a valve to regulate the pressure of the gas, a fluid driving means, a mixing unit for mixing the smoke liquid and the gas, and a heat exchanger heating the mixture of the pressurized gas and the smoke liquid to vaporize the smoke liquid and form a smoke upon ejection into surrounding air. The control method according to the invention then comprises the steps of receiving a smoke density parameter indicative of a desired amount of smoke to be generated by the smoke generator, measuring a gas pressure at a position between the valve and the heat exchanger, and using these parameters in controlling the valve. The invention further relates to a smoke generator arranged for performing the control method.

Owner:MARTIN PROFESSIONAL

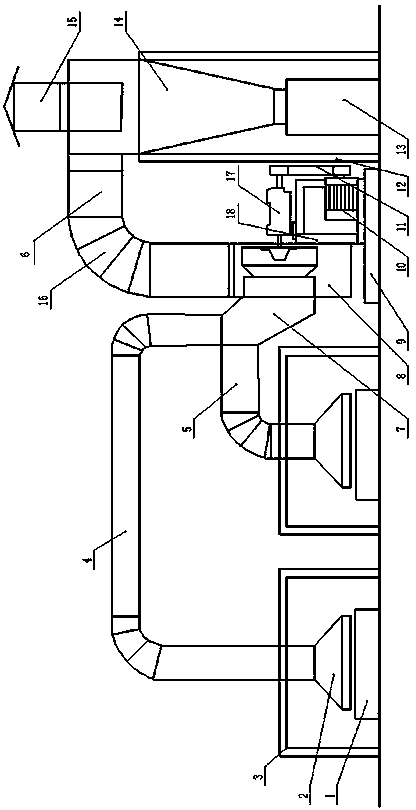

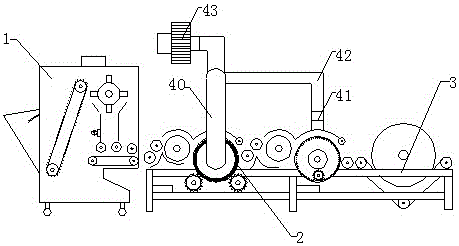

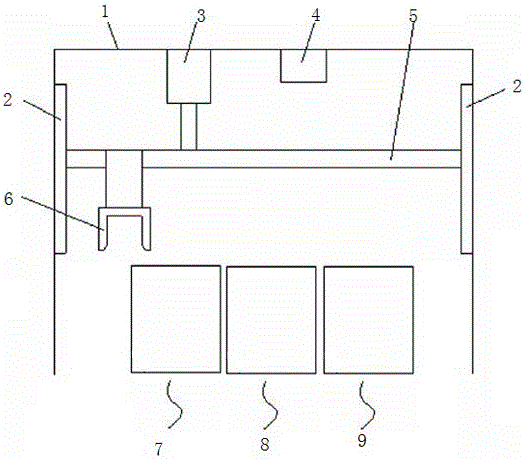

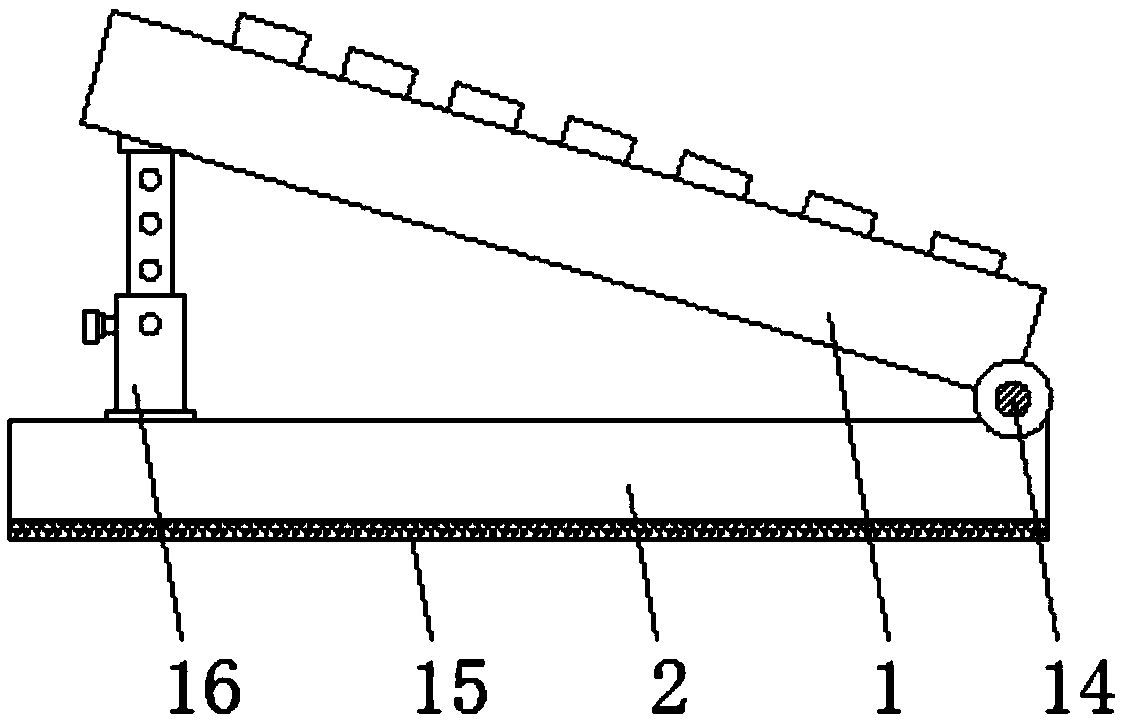

Efficient textile machine dust removing plant

InactiveCN104353287AEnsure cleanlinessImprove efficiencyGas treatmentDispersed particle separationMachine toolTextile

Owner:SUQIAN CITY SUYU DISTRICT ZHUOWEI SILK

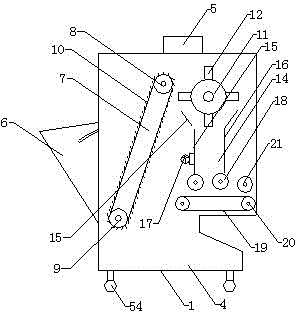

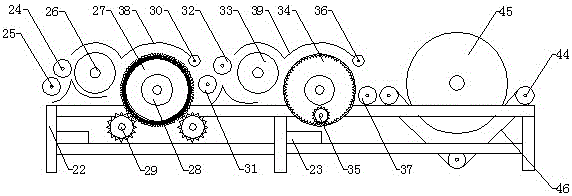

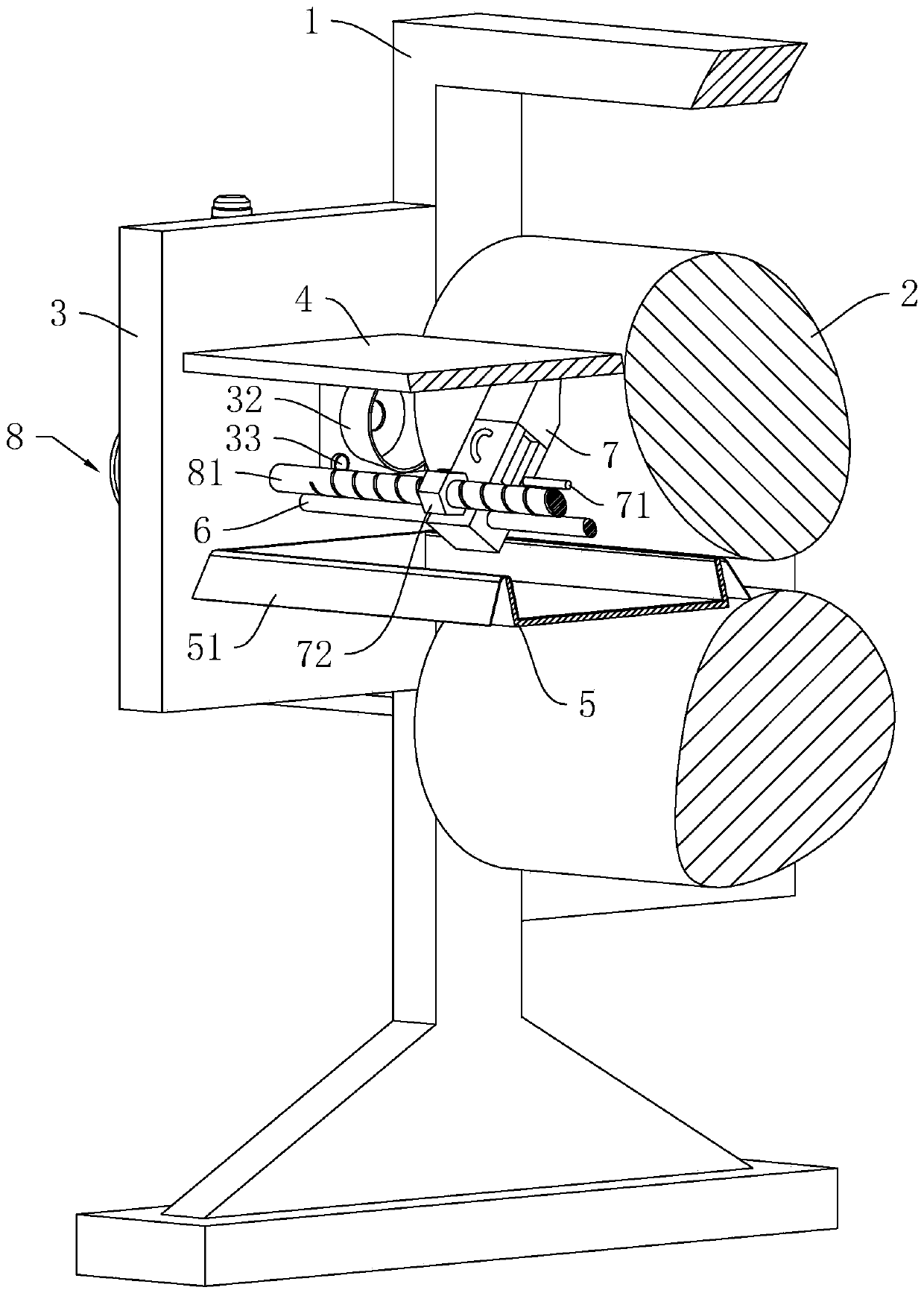

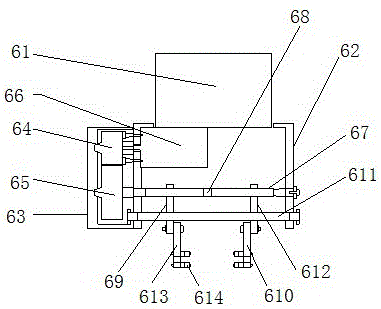

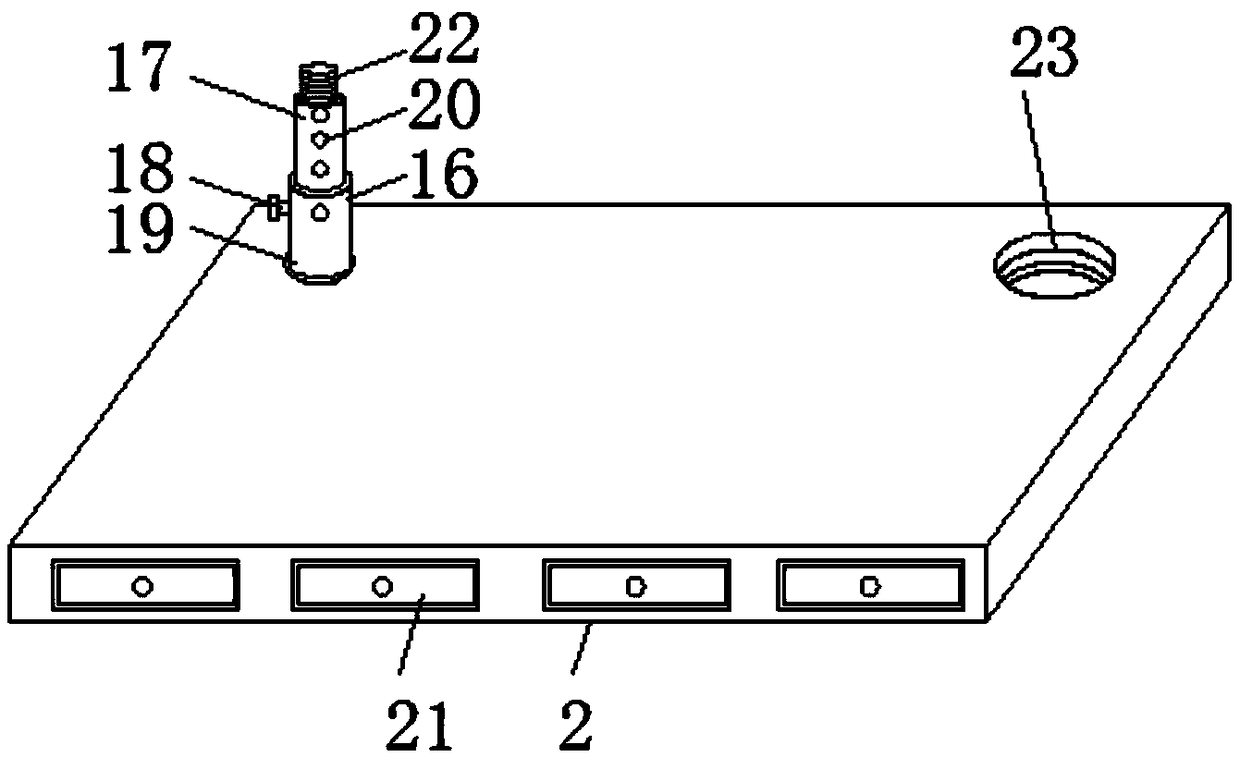

Highly-efficient cotton fluffer

InactiveCN105040169AGuaranteed cleanlinessEnsure cleanlinessFibre cleaning/opening by toothed membersFibre cleaning/opening machinesAgricultural engineeringAgricultural science

The invention belongs to the technical field of textile equipment and relates to a highly-efficient cotton fluffer. The highly-efficient cotton fluffer comprises an automatic cotton-feeding device, a cotton-carding device and a cotton-collecting device. Compared with a conventional cotton-feeding device, the automatic cotton-feeding device is more mechanized so that input of manual power is greatly reduced and helps to ensure personal safety of operators and achieve automated cotton-feeding with great safety factor. The automatic cotton-feeding device is connected with the cotton-carding device in order to realize synchronous drive. Double licker-in roller devices and double dust cage devices are employed by the cotton-carding device and used for carding cotton and dedusting twice in one process in order to satisfy requirements for high quality and high cleanliness. The cotton-collecting device located at the tail end adopts a cotton-accumulating drum to automatically collect cotton under drive of a driving belt so that cotton collection without manual labor is realized, thereby greatly saving manpower of a company. Additionally, cost of production and manufacture of the company is decreased. As a whole, the highly-efficient cotton fluffer is advantaged by being reasonable in structure layout, high in working efficiency, great in safety factor of manufacture and production and in cotton cleanliness and few in input of manpower.

Owner:HENAN XINPUFENG COTTON GIN TECH CO LTD

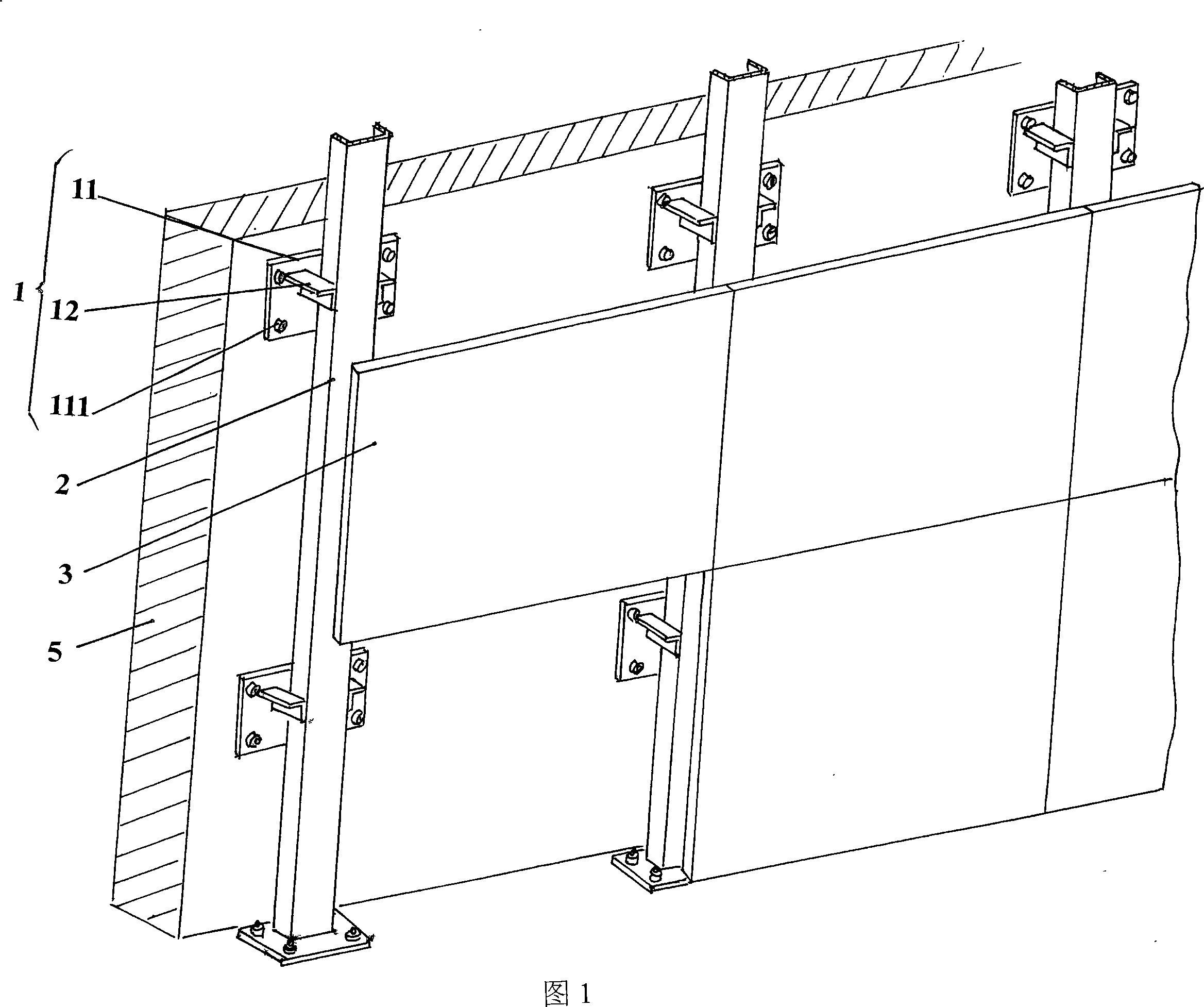

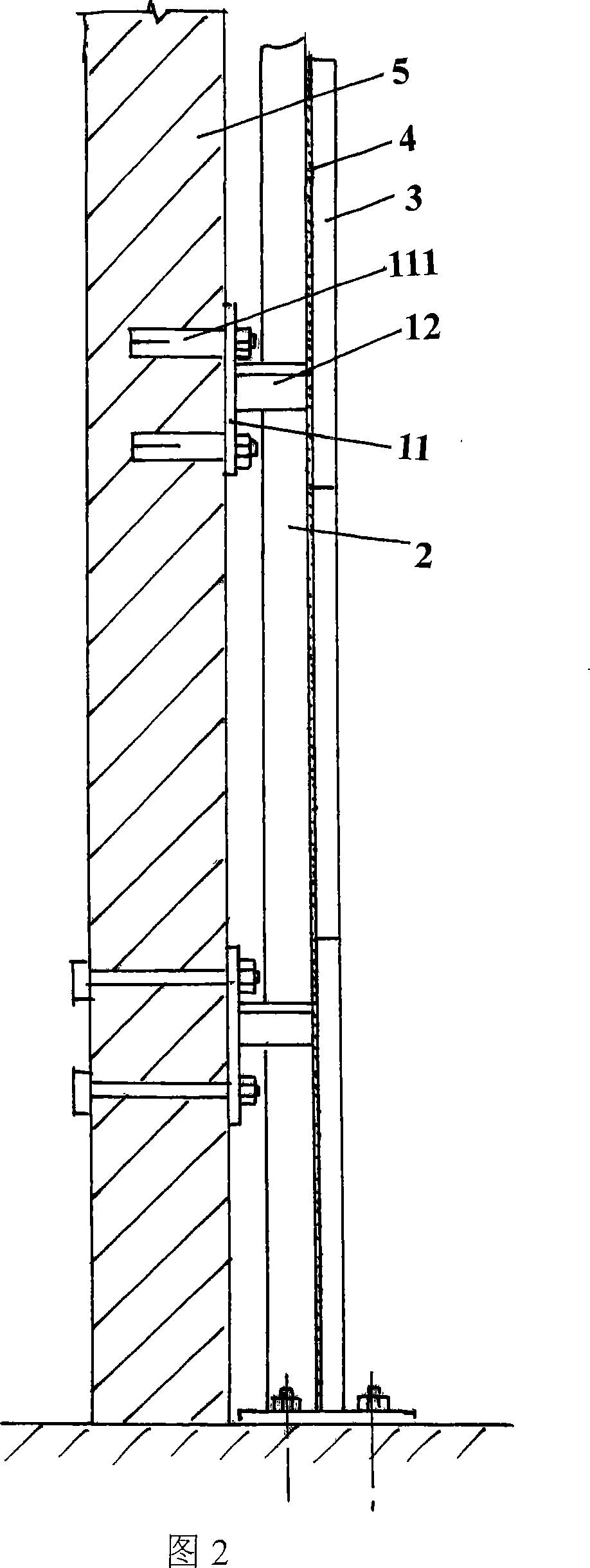

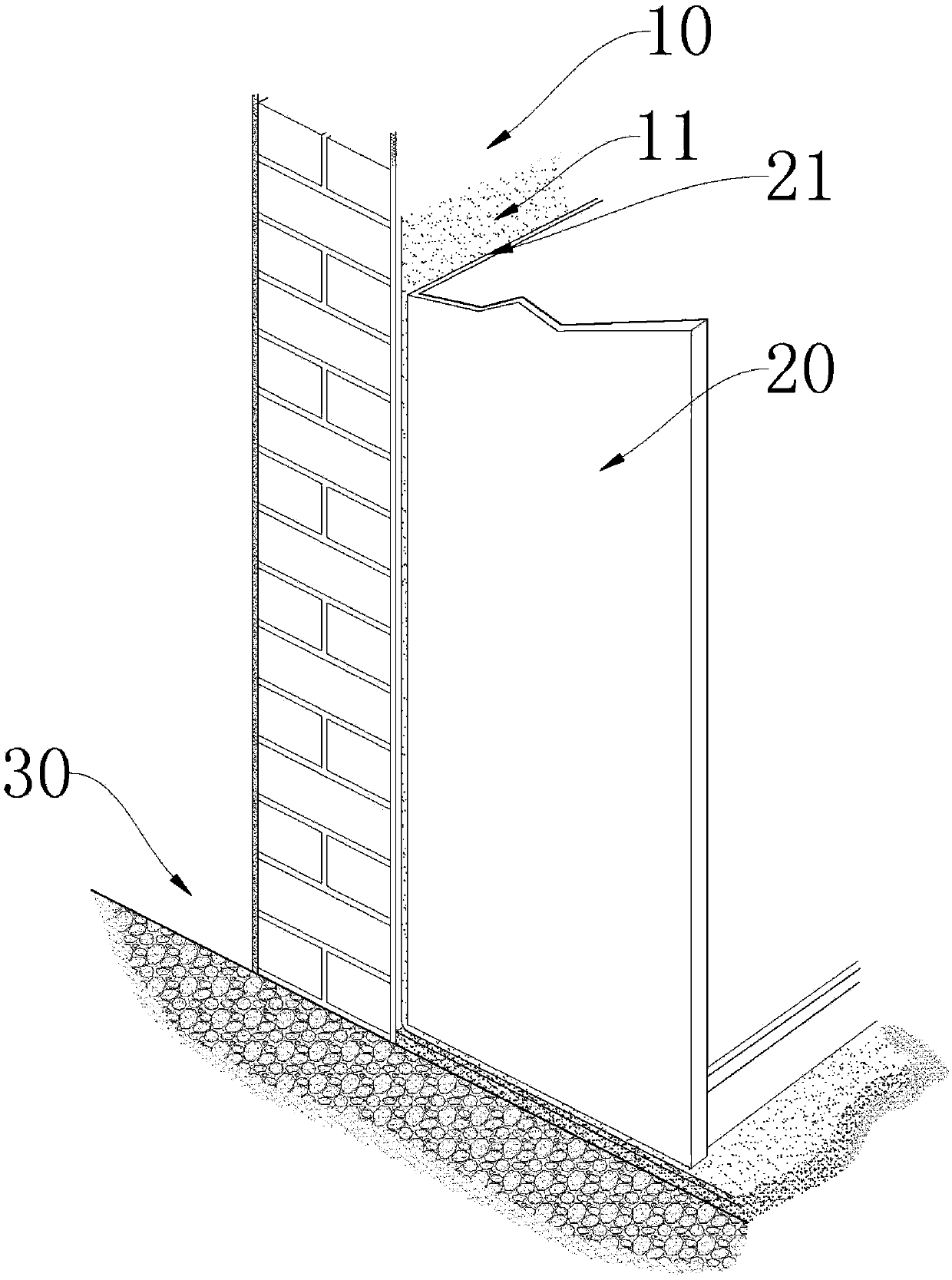

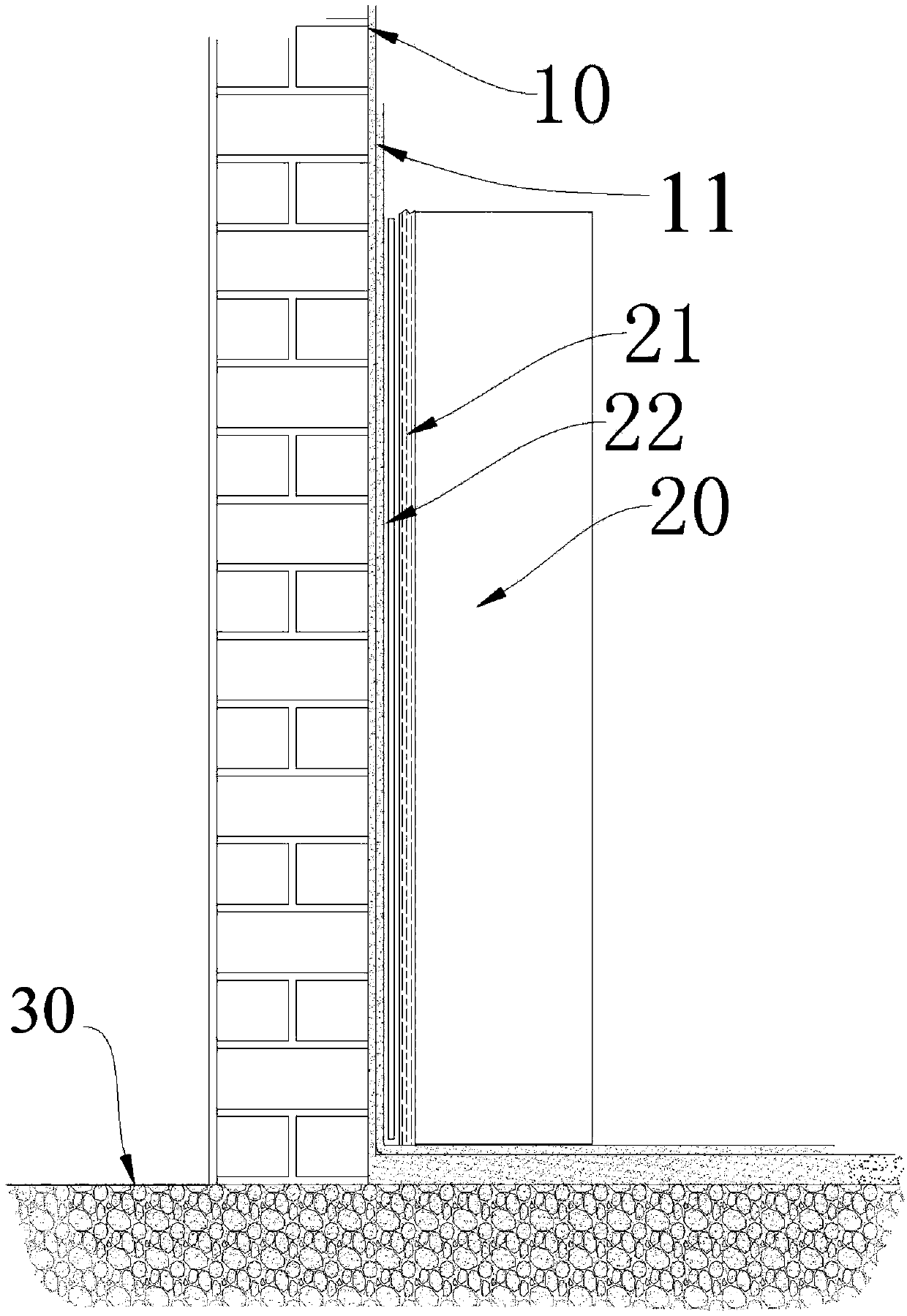

Sticking method for decorative brick

The invention relates to a method for adhering facing tiles, and belongs to the architectural decoration technical field. The method comprises the following steps: firstly, first holding pieces protruding the surface of a wall are arranged on the wall at intervals; secondly, second holding pieces are fixed and connected on the first holding pieces; thirdly, the facing tiles are adhered on the second holding pieces by using adhesion agent; fourthly, joint pointing treatment is performed to the joint positions among the facing tiles; fifthly, the surfaces of the facing tiles are cleaned finally. The invention has the advantages that the wet method adhesion in the prior art is changed into the dry method adhesion, the cement slurry and dust pollution is not existed in an operation site, thereby ensuring the environment of the construction site to be clean and sanitary; the adhering efficiency is improved by three times than the prior art; the adhering effect is ideal, and the post cleaning is simple.

Owner:常熟市金龙装饰有限责任公司

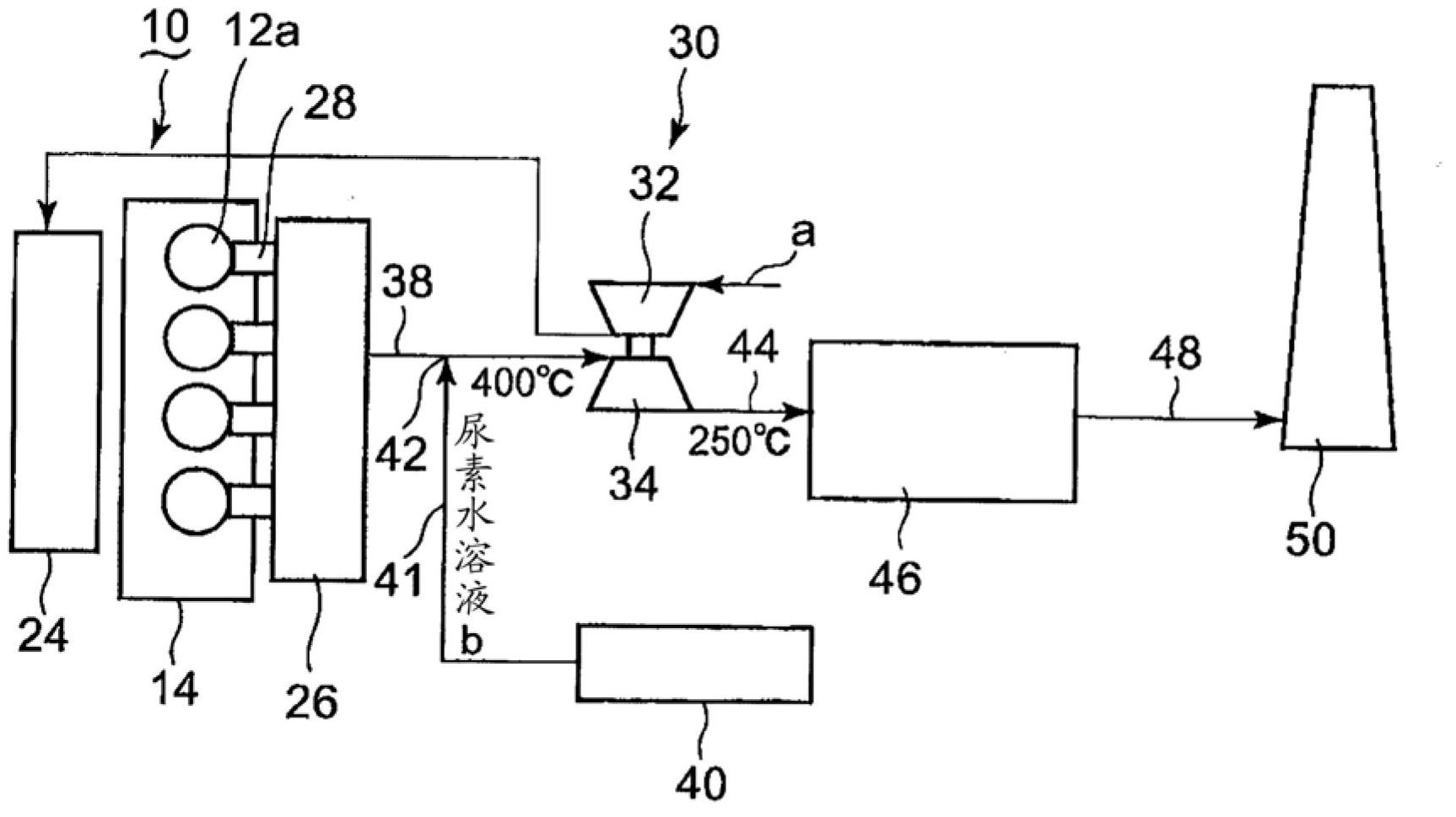

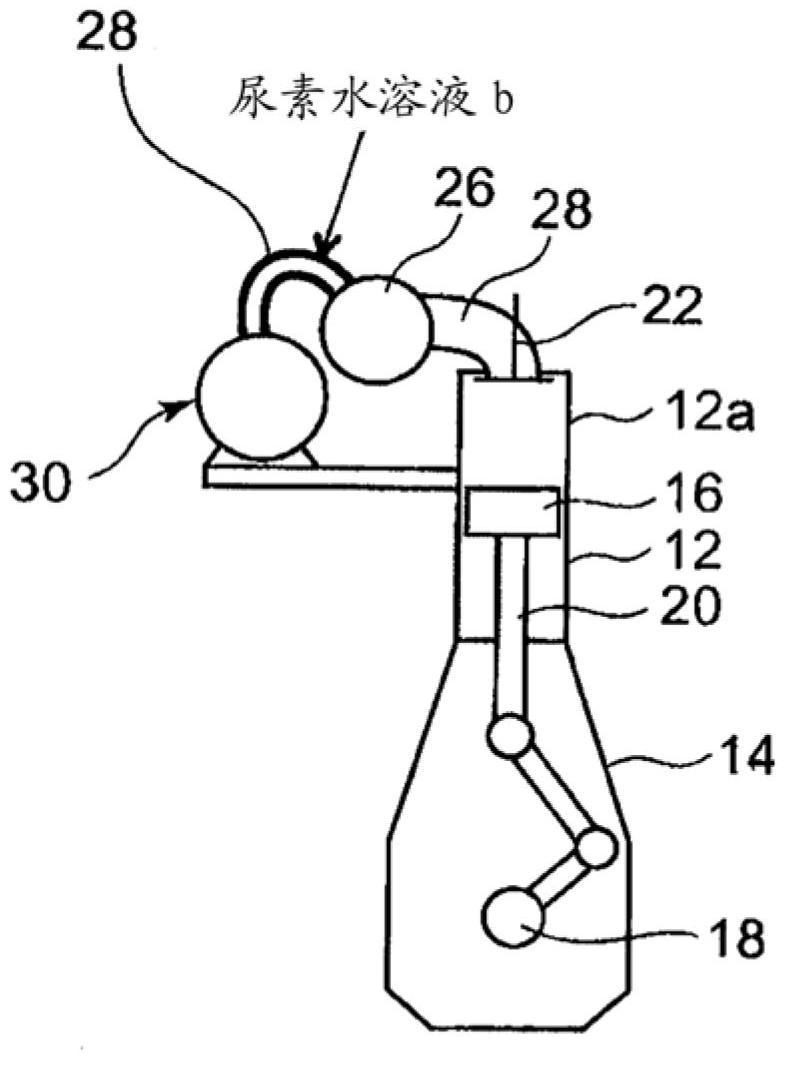

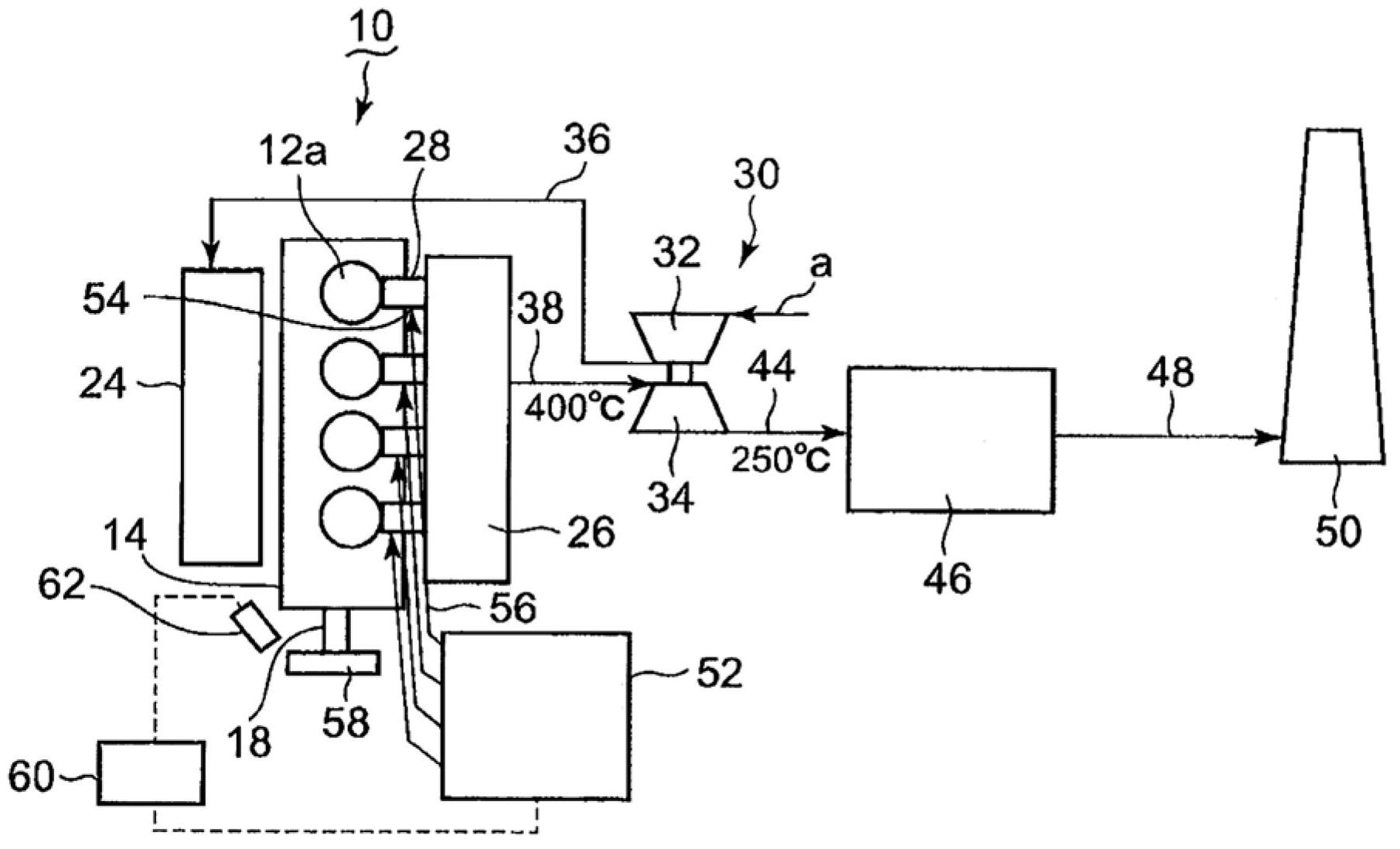

Exhaust gas purification method and exhaust gas purification system for reciprocating internal combustion engine

InactiveCN102695855ASuppress excessive characteristic deteriorationEnsure cleanlinessElectrical controlInternal combustion piston enginesForced inductionSupercharger

In order to suppress extreme deterioration in the properties of a reciprocating internal combustion engine and enable the removal of NOx in exhaust gas in cases in which the NOx within the exhaust gas of a reciprocating internal combustion engine equipped with a supercharger is removed with an SCR system, a reciprocating marine diesel engine (10) in which a supercharger (30) has been disposed in an exhaust pipe (38, 44, 48) is provided with an aqueous urea solution supply unit (42) in the exhaust pipe (38) upstream of a turbine (34), whereby an aqueous urea solution (b) is supplied from an aqueous urea solution tank (40). The aqueous urea solution (b) is evaporated by the reserved heat of the exhaust gas and is hydrolyzed into ammonia gas. The ammonia gas is uniformly stirred and mixed with the exhaust gas in a highly turbulent flow field of the turbine (34). Thereafter, the ammonia gas deoxidizes the NOx within the exhaust gas in an SCR catalyst converter (46), which is disposed in the exhaust pipe (44) downstream of the supercharger (30), and converts the NOx to nitrogen and water vapor. Since the aqueous urea solution (b) is supplied to the exhaust pipe (38) upstream of the turbine (34), ammonia gas can be generated without installing additional heating equipment such as an auxiliary burner.

Owner:MITSUBISHI HEAVY IND LTD

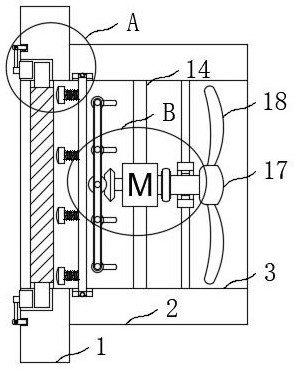

Dust removal and ventilation device for building heating and ventilation engineering

InactiveCN112682890AGuaranteed stabilityReduce the difficulty of disassemblyMechanical apparatusDispersed particle filtrationElectric machineryStructural engineering

The invention discloses a dust removal and ventilation device for building heating and ventilation engineering. The dust removal and ventilation device for building heating and ventilation engineering comprises an air pipe fixedly installed on an installation plate, wherein air guide grooves are formed in the air pipe and the installation plate in a matched mode; multiple clamping grooves are formed in the side wall of the end, close to the installation plate, of each air guide groove; a clamping block is connected onto each clamping groove in a clamped mode; a filter screen is arranged among the clamping blocks in a matched mode; multiple positioning mechanisms are arranged on the side wall of the installation plate; each positioning mechanism is matched with the corresponding clamping block; and multiple fixing rods are fixedly arranged on the air guide grooves. The dust removal and ventilation device for building heating and ventilation engineering has the advantages that air entering the air pipe can be filtered, so that the problem that dust enters the air pipe to cause abnormal operation of heating and ventilation equipment is avoided; multiple round rods can be driven to rotate simultaneously in the operation process of the motor, and driving force is provided for cleaning operation of the dust on the filter screen, so that manual dust removal is not needed; and meanwhile, kinetic energy does not need to be additionally arranged, so that the production and use cost of the device can be effectively reduced.

Owner:朱翠红

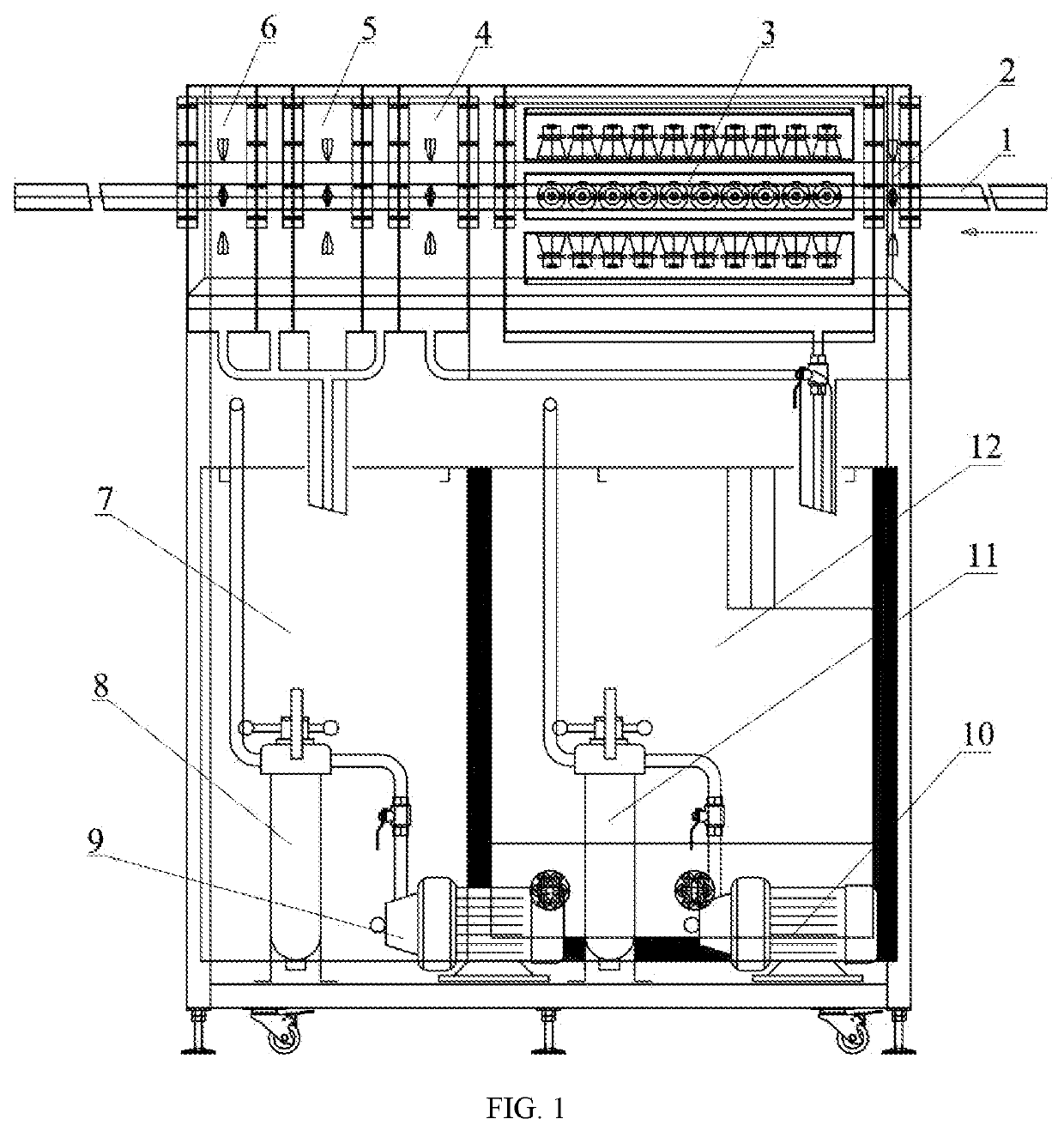

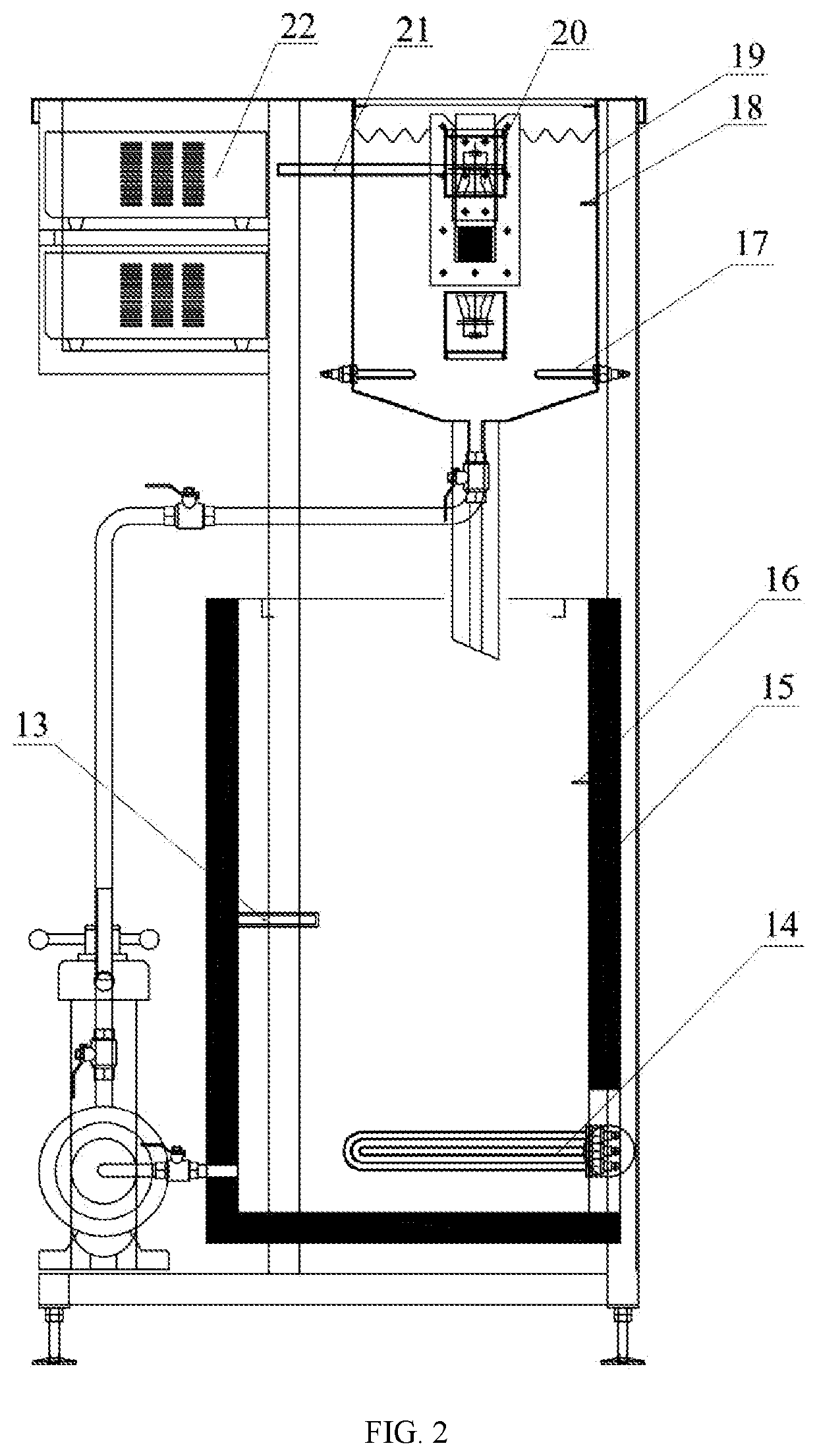

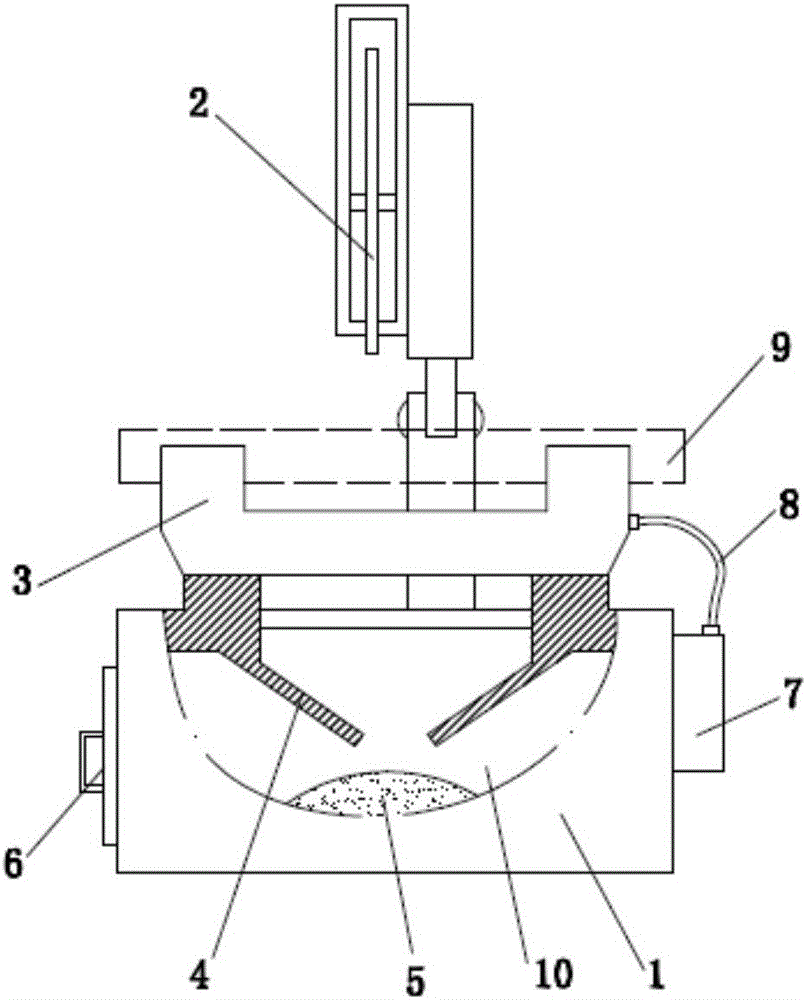

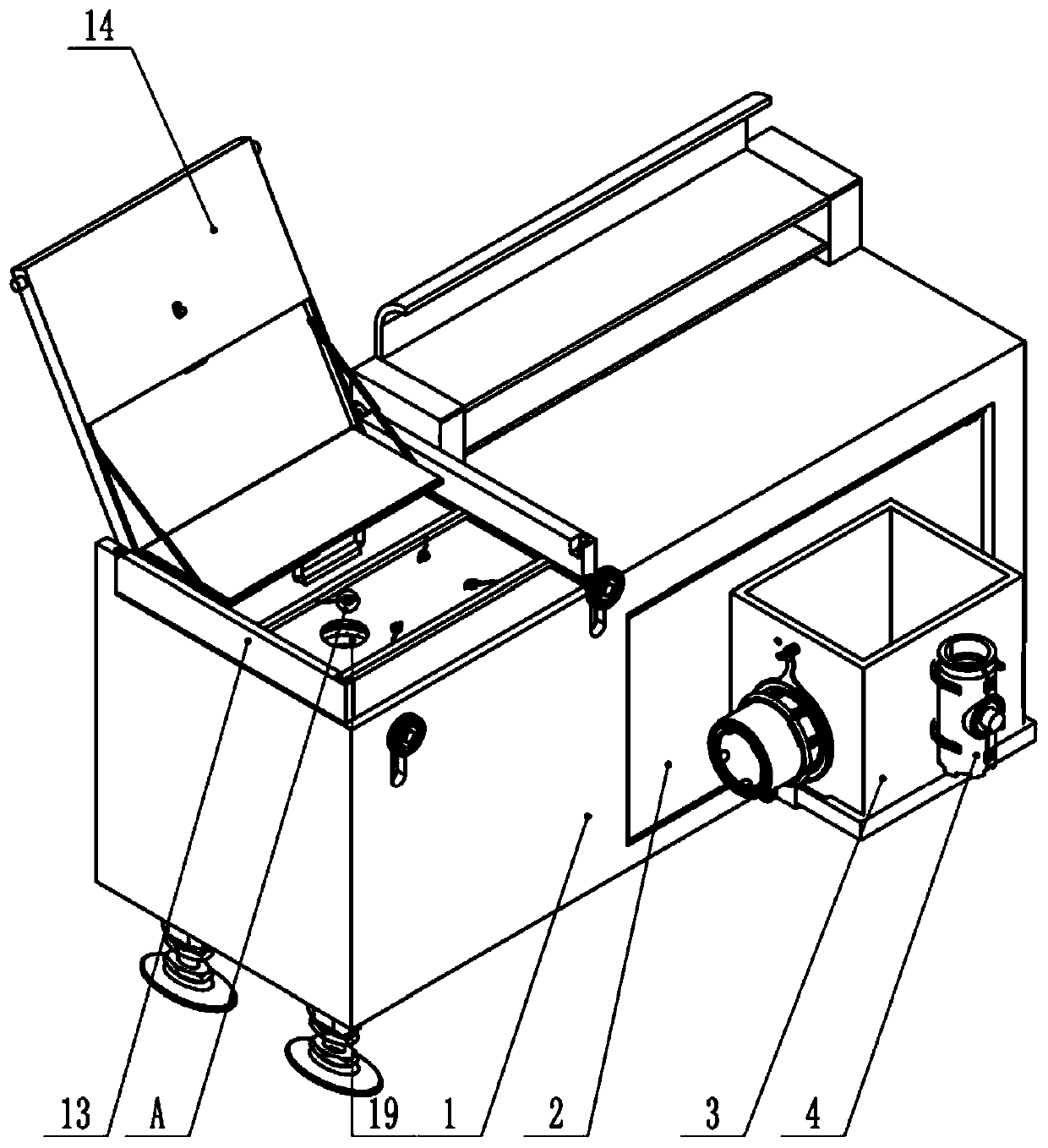

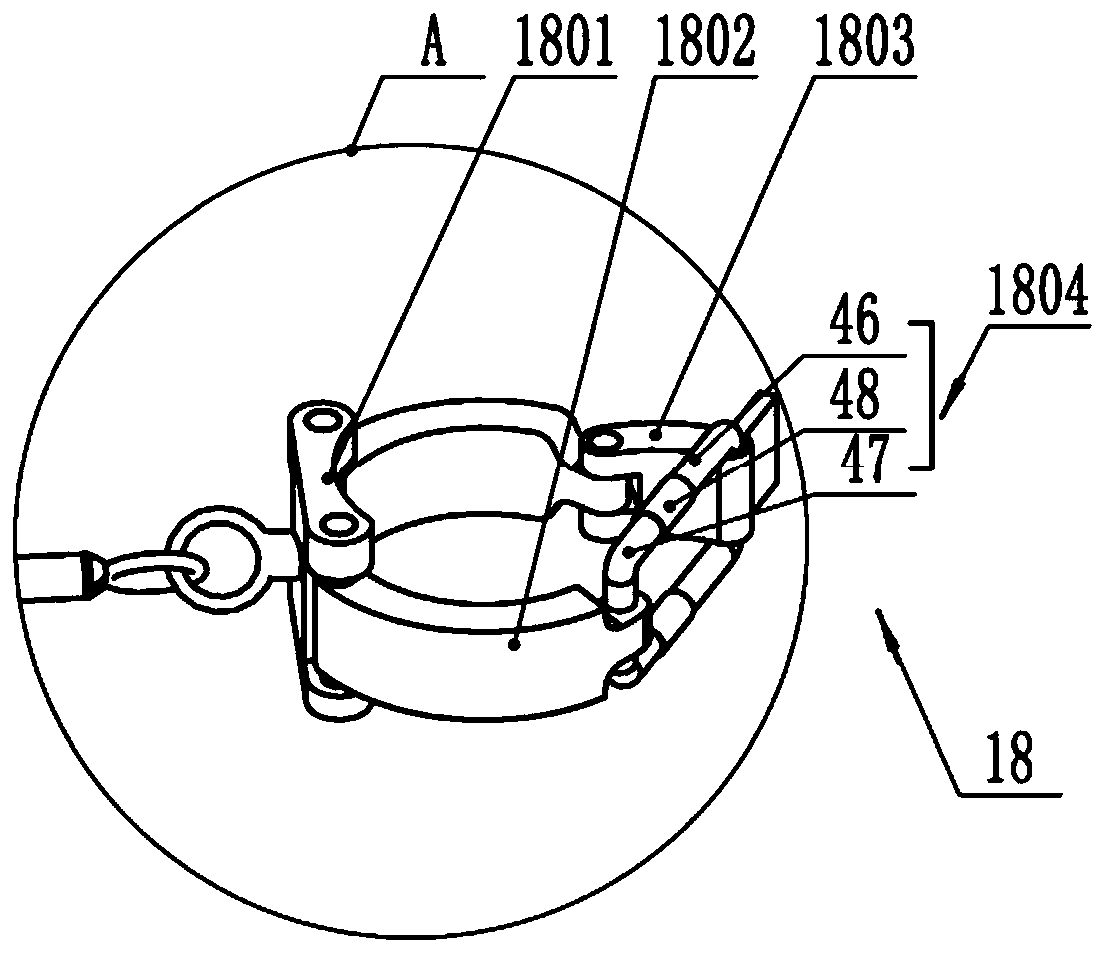

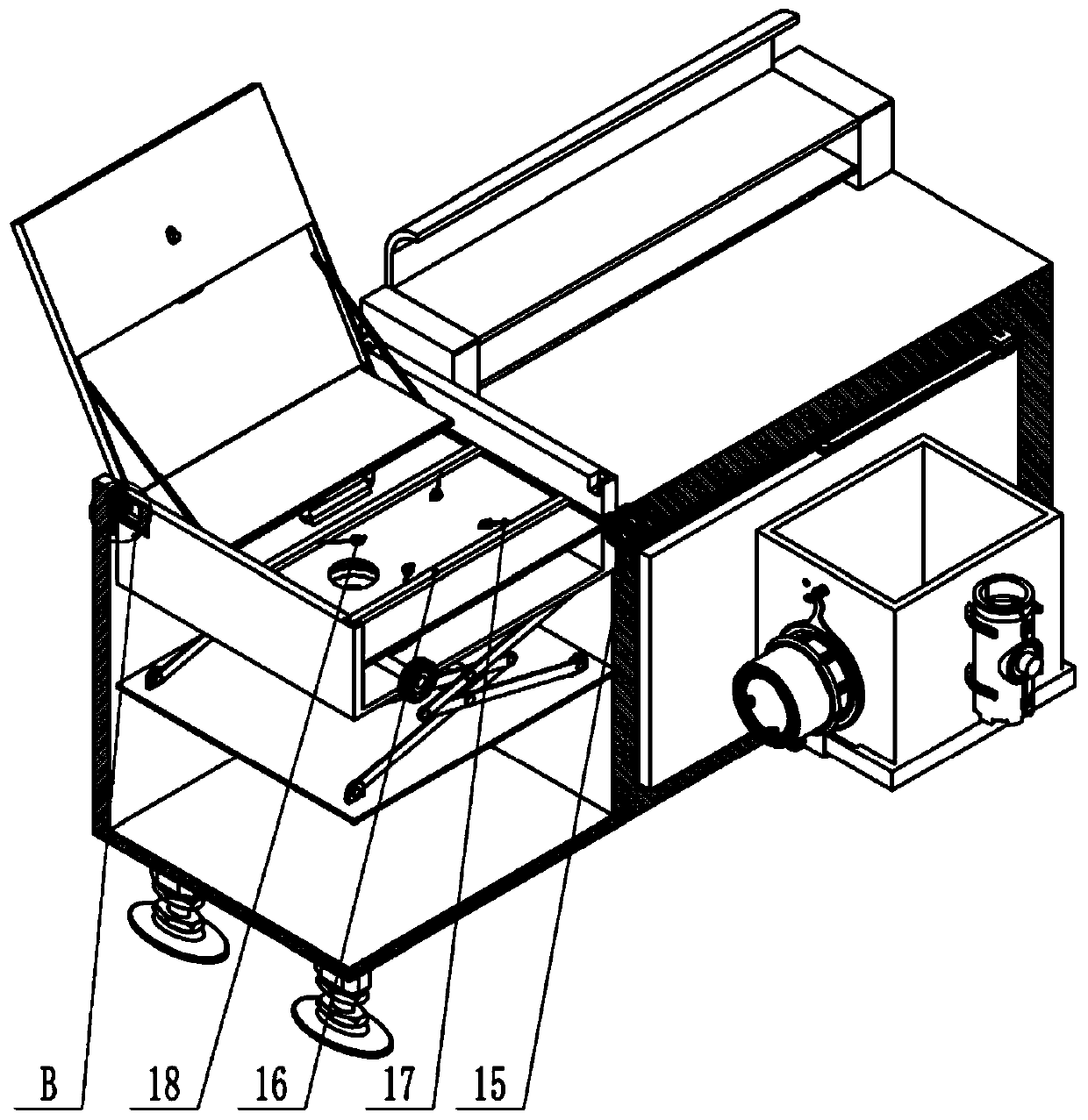

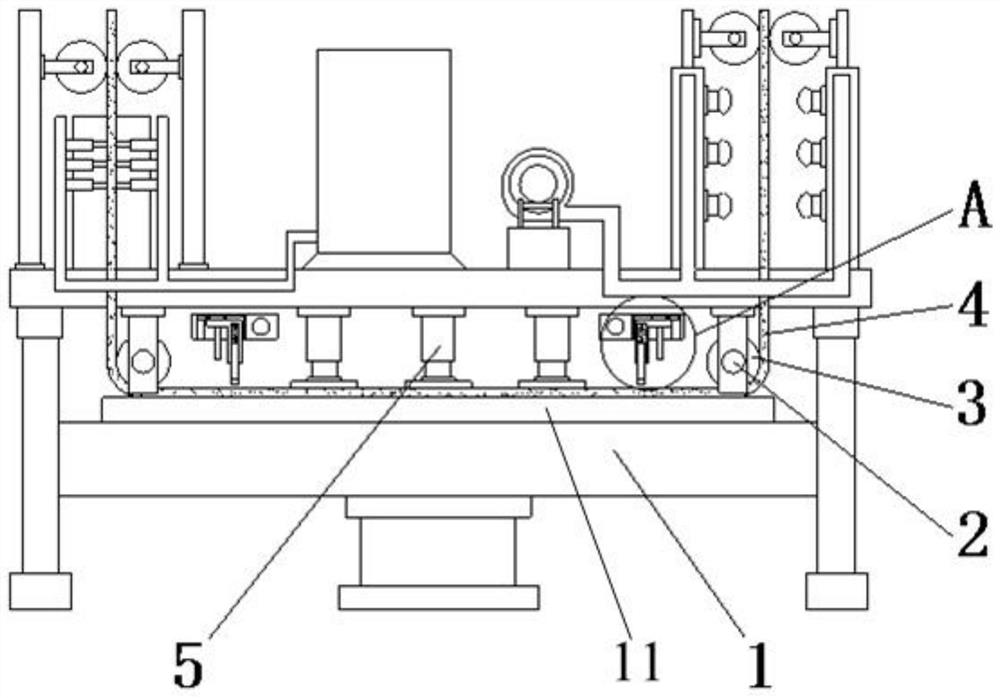

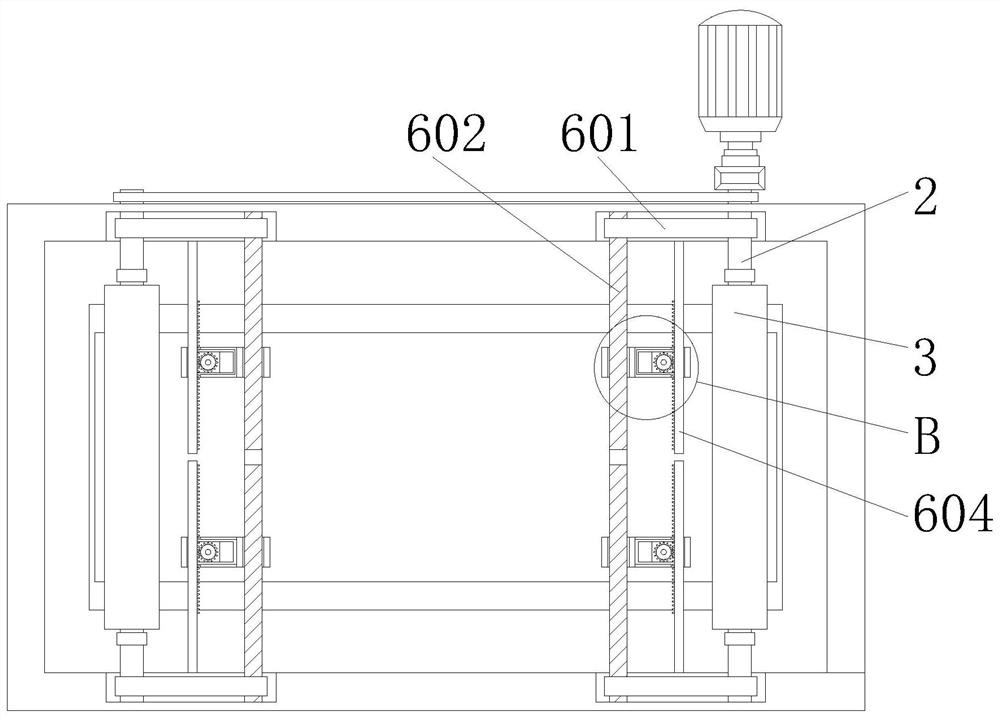

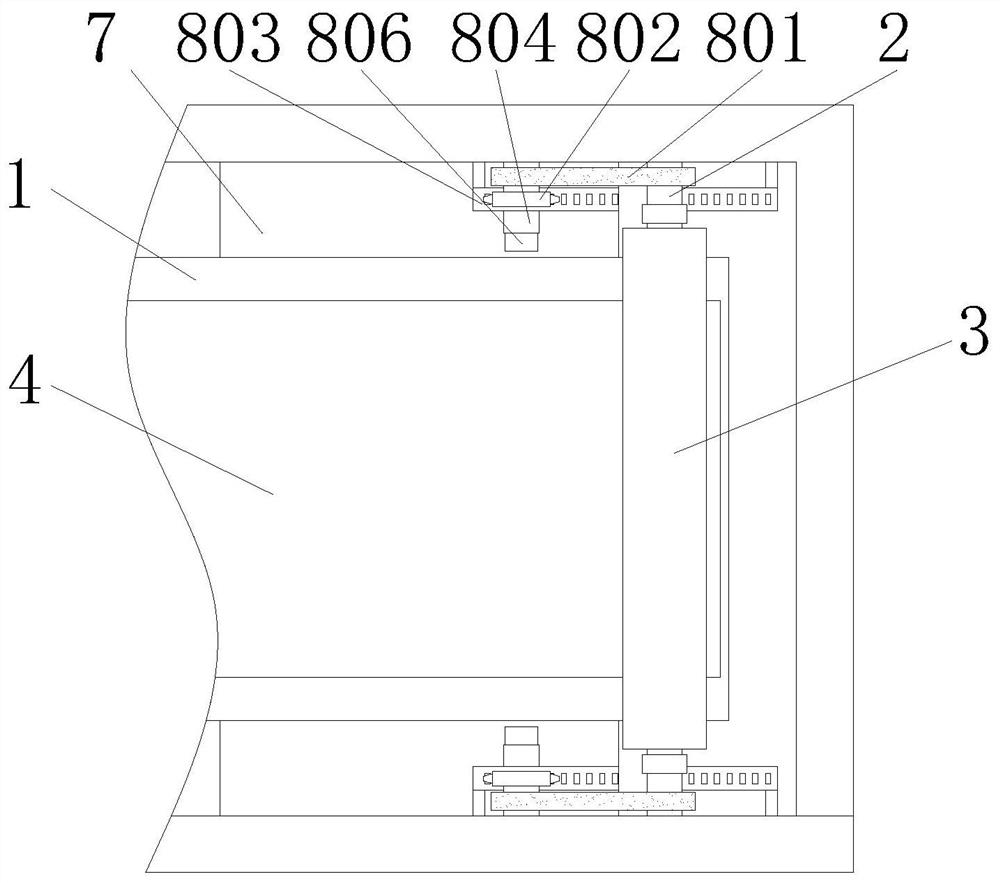

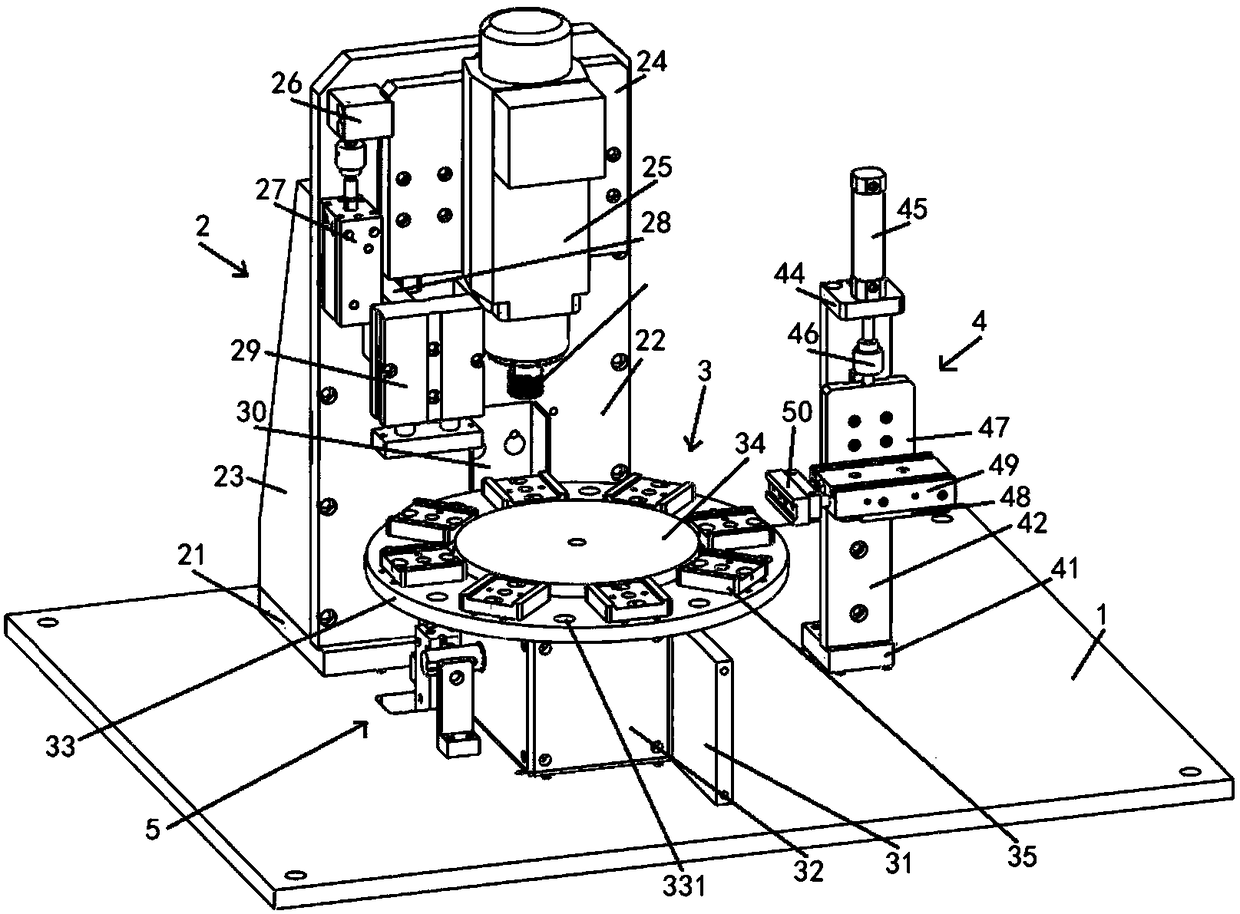

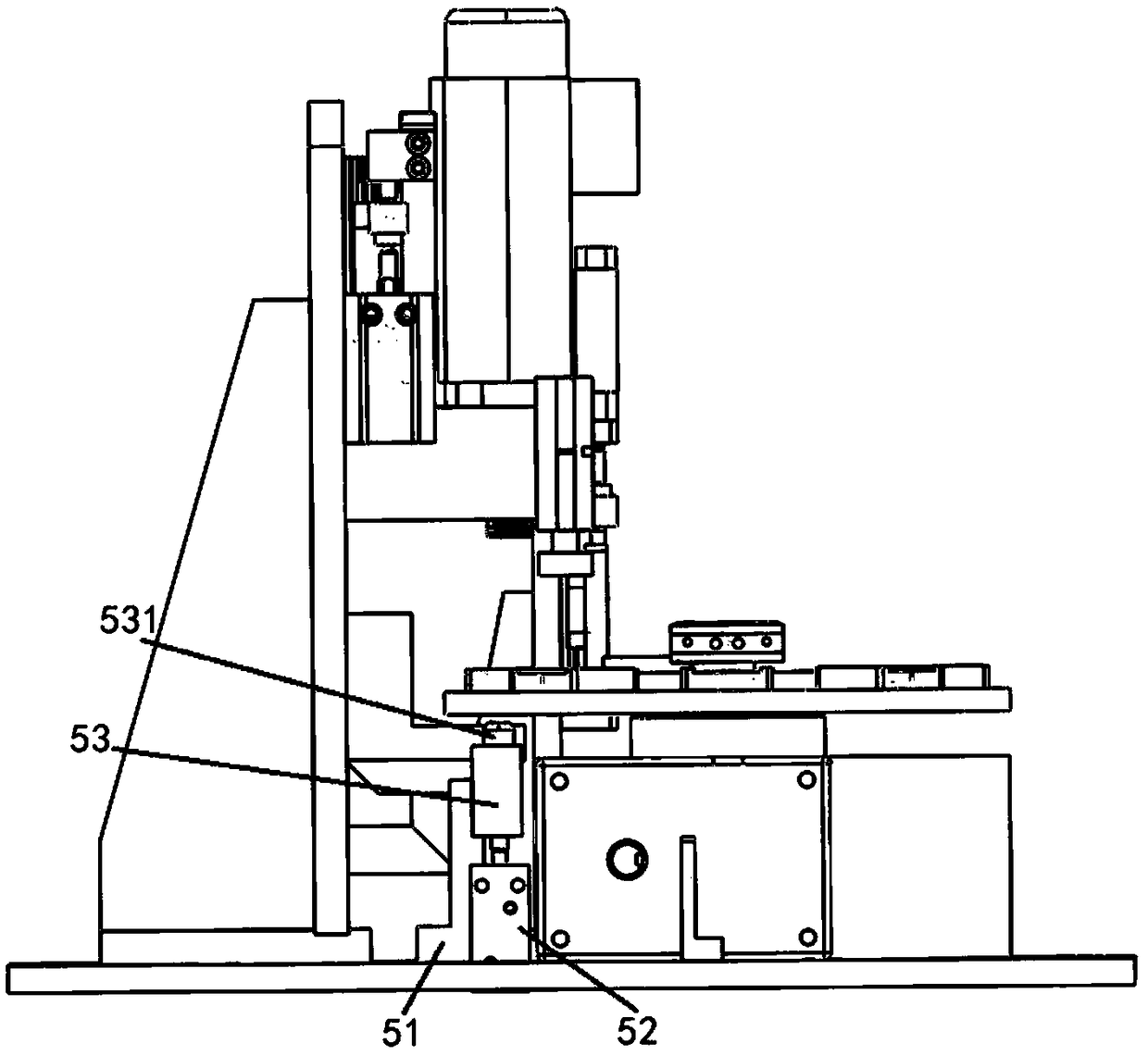

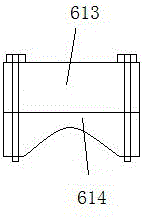

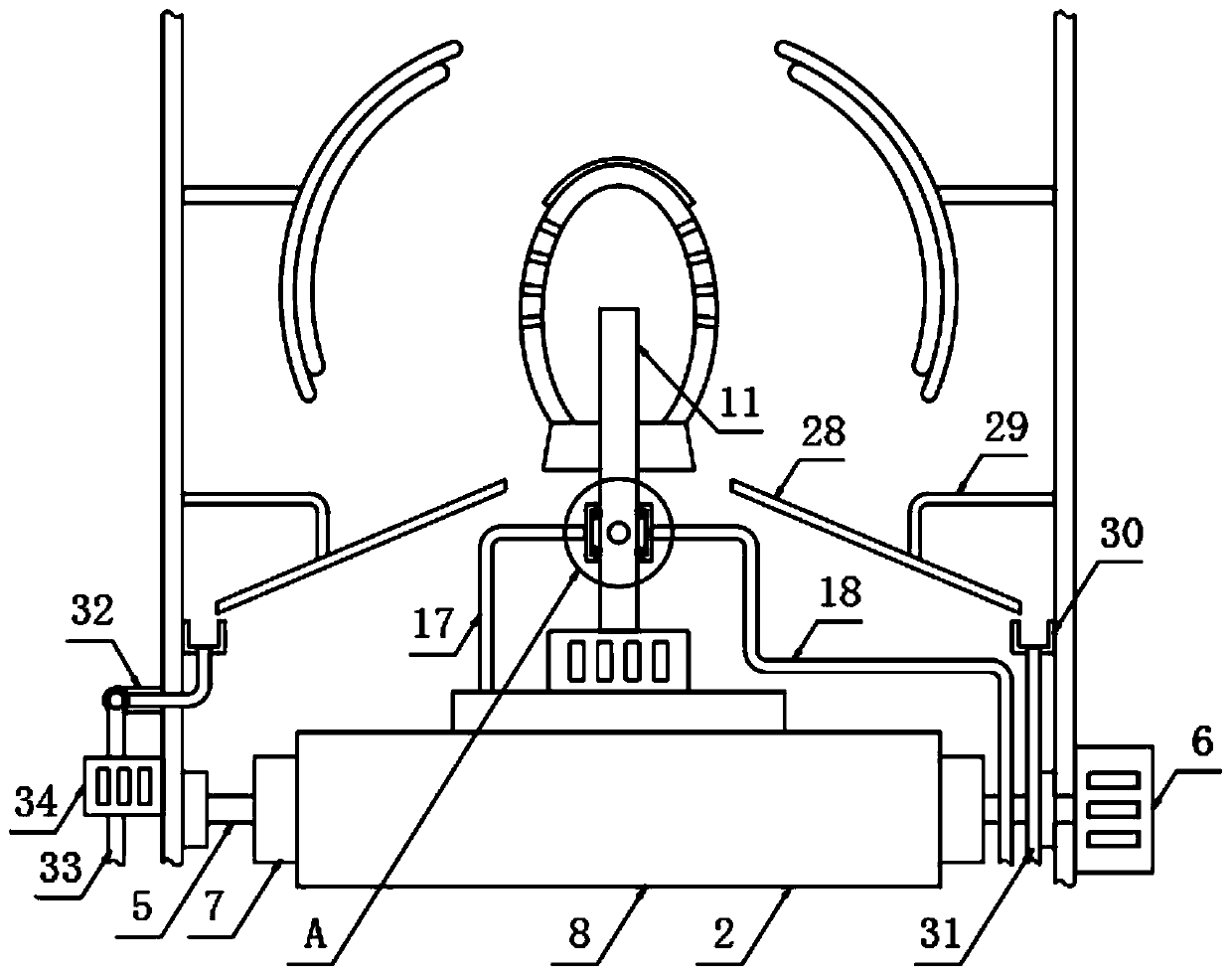

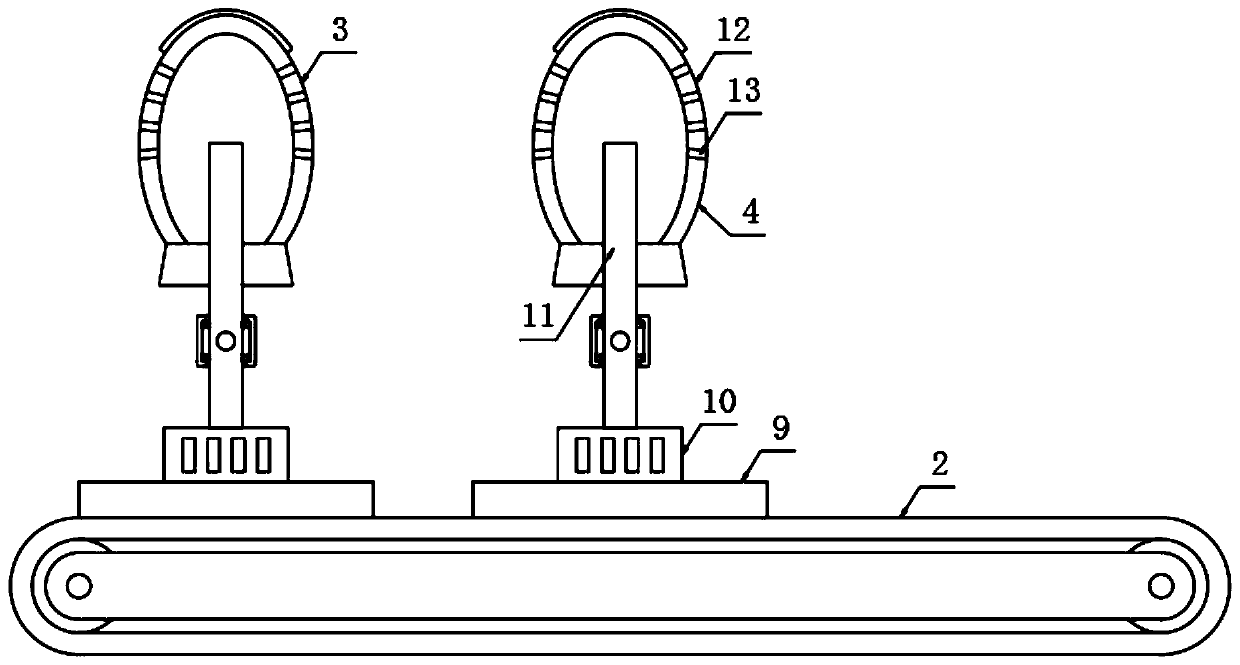

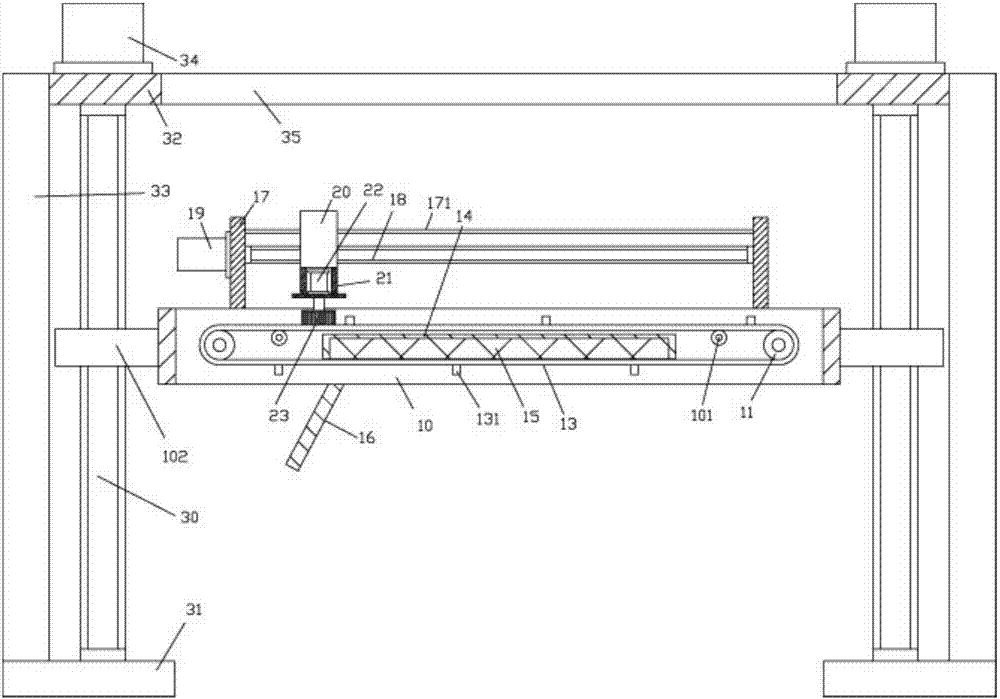

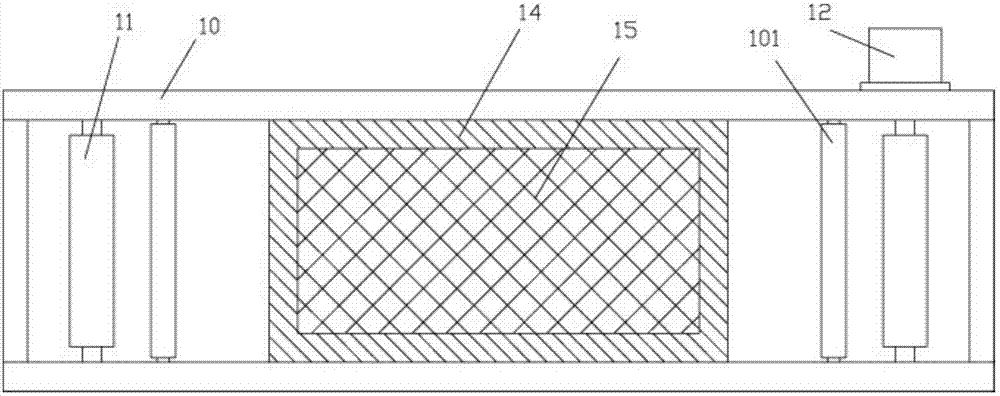

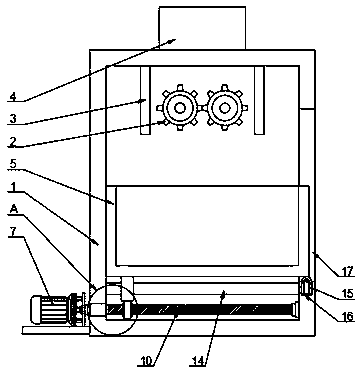

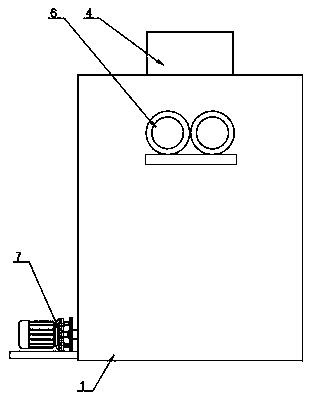

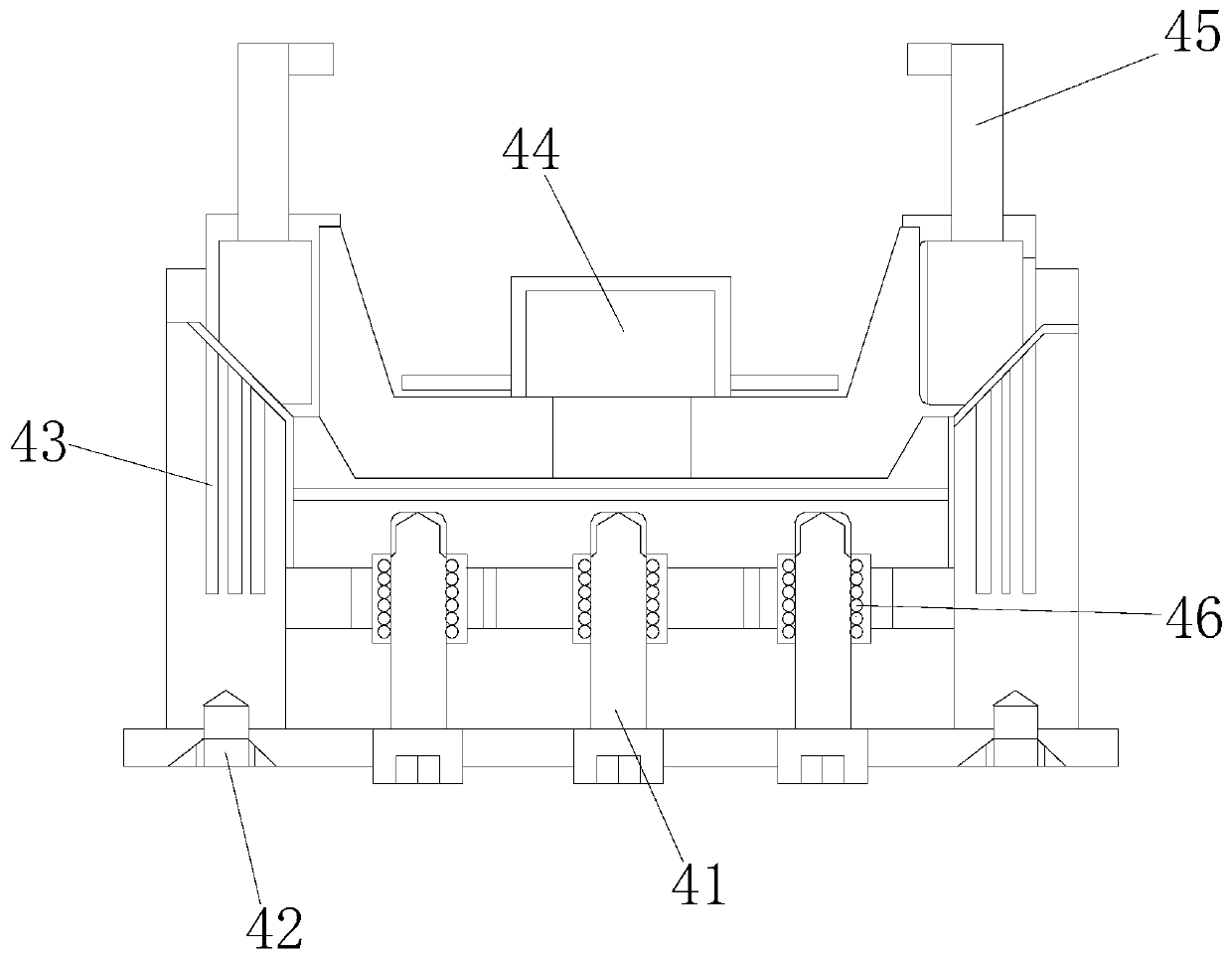

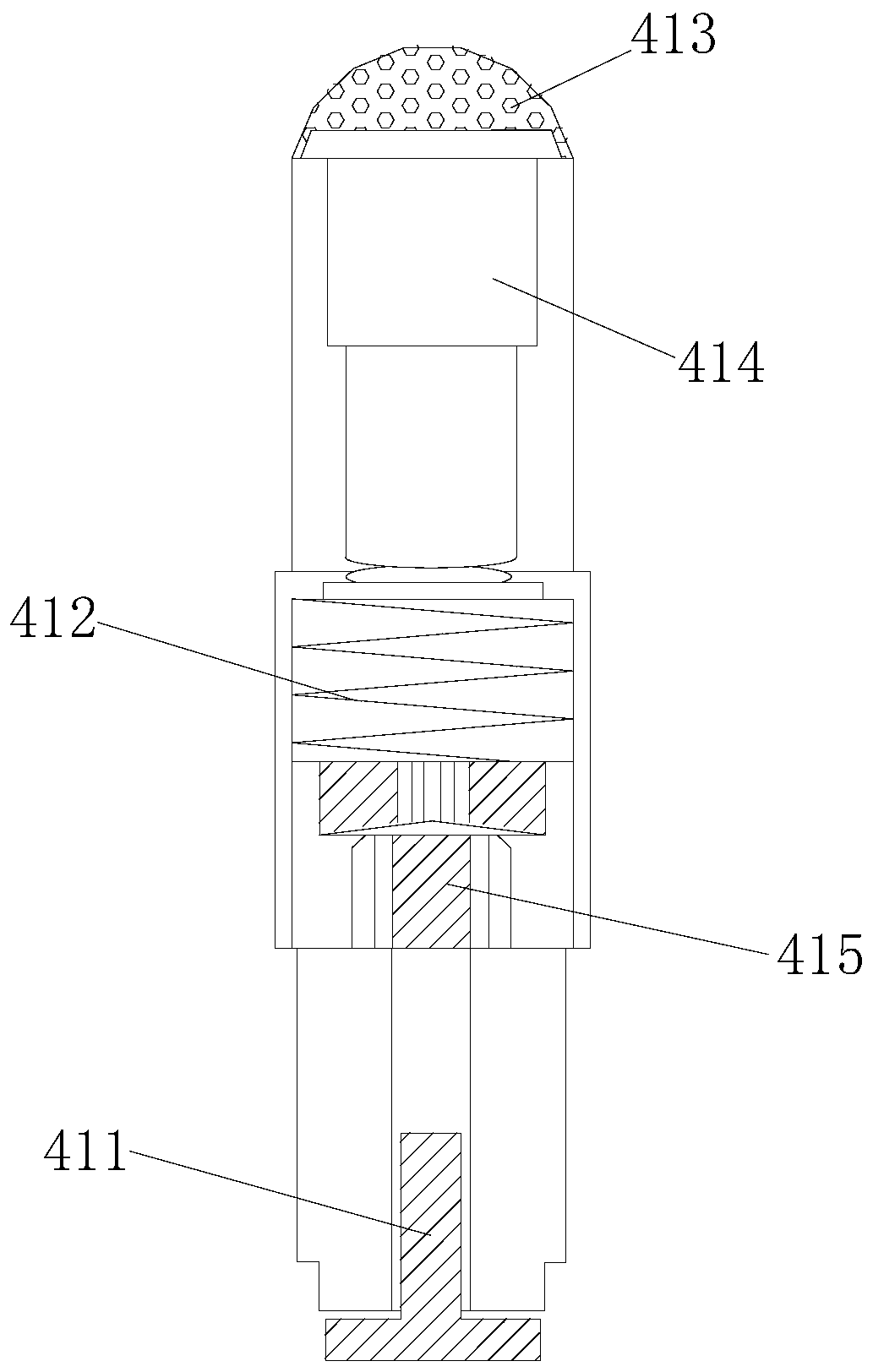

Feed-through ultrasonic cleaning system for winding of large-sized superconducting coils

ActiveUS20190366392A1Ensure cleanlinessQuality improvementDrying solid materials with heatDrying gas arrangementsSuperconducting CoilsAutomatic control

A feed-through ultrasonic cleaning system for winding of a large-sized superconducting coil, including a sealed chamber system, a main ultrasonic cleaning system, a deionized water spraying system, a compressed air blow-drying system, an automatic control system. During the winding of an armored superconducting coil, a superconducting conductor which is fed at a constant speed successively passes through a sealed chamber, an ultrasonic cleaning chamber, a first compressed air blow-drying chamber, a deionized water spray chamber, and a second compressed air blow-drying chamber in the ultrasonic cleaning system. By integrating mechanical dynamic sealing, ultrasonic cleaning and automatic control, the present invention meets a special requirement of removing oil and completely cleaning the conductor during the winding of large-sized superconducting coils.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

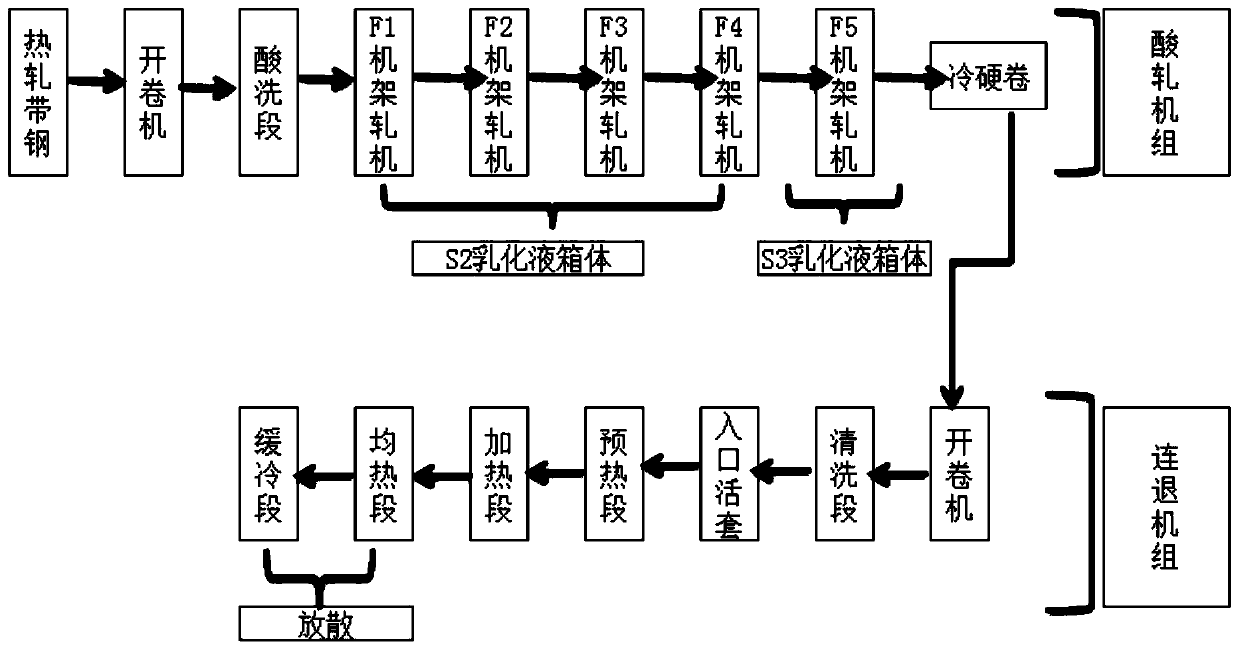

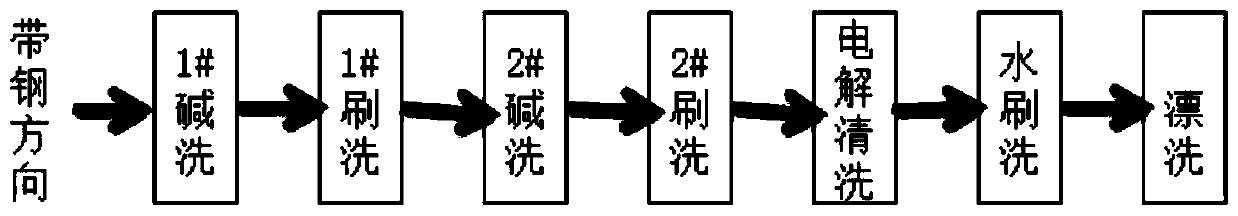

Method for relieving nodulation of furnace roller of continuous annealing furnace

ActiveCN110238208AEnsure cleanlinessGuarantee stabilityWork treatment devicesFurnace typesStrip steelNodulations

The invention discloses a method for relieving nodulation of a furnace roller of a continuous annealing furnace and belongs to the field of cold rolling continuous annealing. The method is characterized in that after alkali washing, scrubbing, electrolytic cleaning, water washing and rinsing are carried out on a cleaning section, the reflectivity of the strip steel surface is larger than or equal to 92%. According to the method for relieving the nodulation of the furnace roller of the continuous annealing furnace, the reflectivity of the cleaned strip steel is accurately controlled, so that the nodulation of the furnace roller of the continuous annealing furnace can be effectively relieved, the furnace roller of the continuous annealing furnace can be achieved to not be replaced by more than 150 days, and the number of less replacement furnace roller is accumulated to more than 10; and the method can effectively and continuously organize production, the yield can be improved, the capacity can be released, and the production and processing cost can be reduced.

Owner:马钢(合肥)钢铁有限责任公司

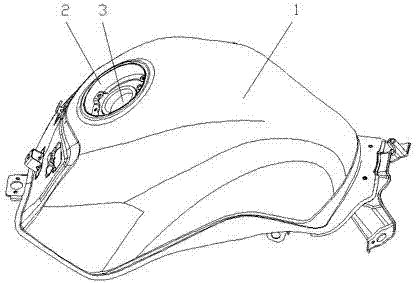

Oil tank and motorcycle thereof

The invention discloses an oil tank which is characterized by comprising an oil tank body, wherein a sunken slot for mounting an oil tank cover is formed in the oil tank body; an oil inlet and a water leakage opening are formed in the bottom surface of the sunken slot; a water drainage slot corresponding to the water leakage opening is formed in the bottom surface of the sunken slot; the oil inlet and the water leakage opening are arranged adjacently, and an annular boss is arranged between the oil inlet and the water leakage opening. According to the oil tank and the motorcycle thereof, the motorcycle is better in water drainage effect during running and when being placed under the support of a lateral bracket, so that water can be prevented from being gathered in the sunken slot, which is used for mounting the oil tank cover, in the oil tank, and cleanness and sanitation of the oil tank cover are kept.

Owner:CHONGQING LONCIN MOTOR

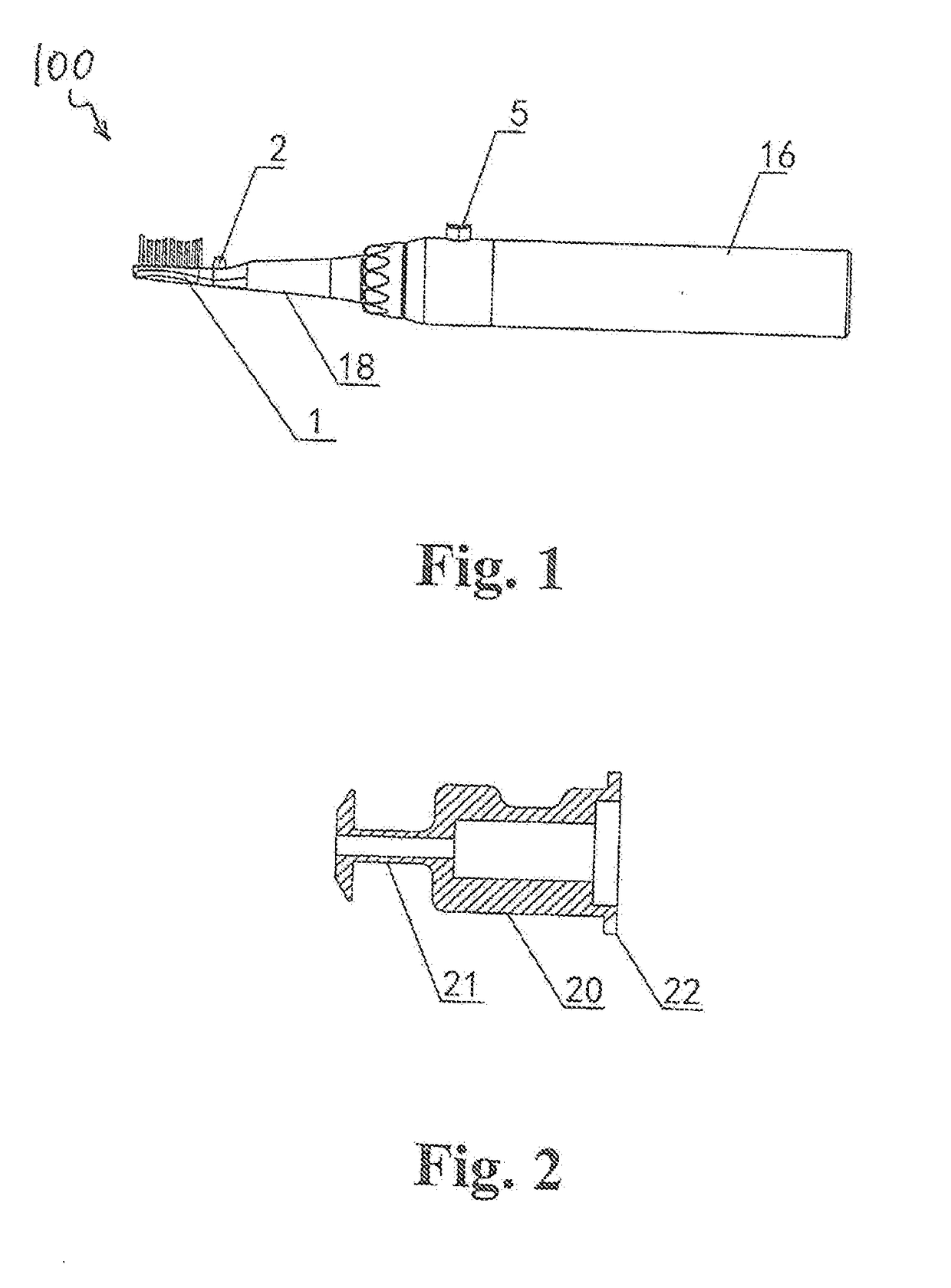

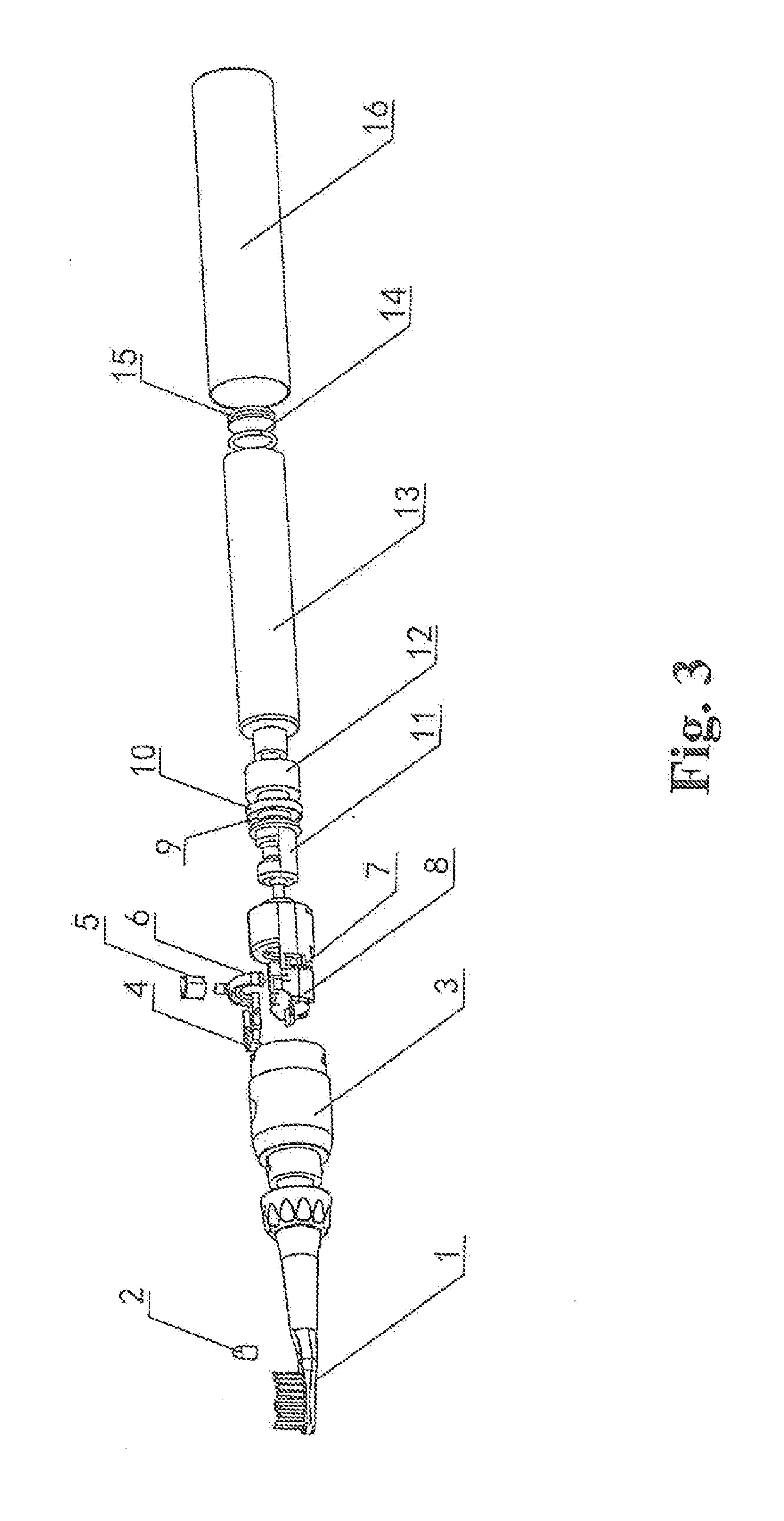

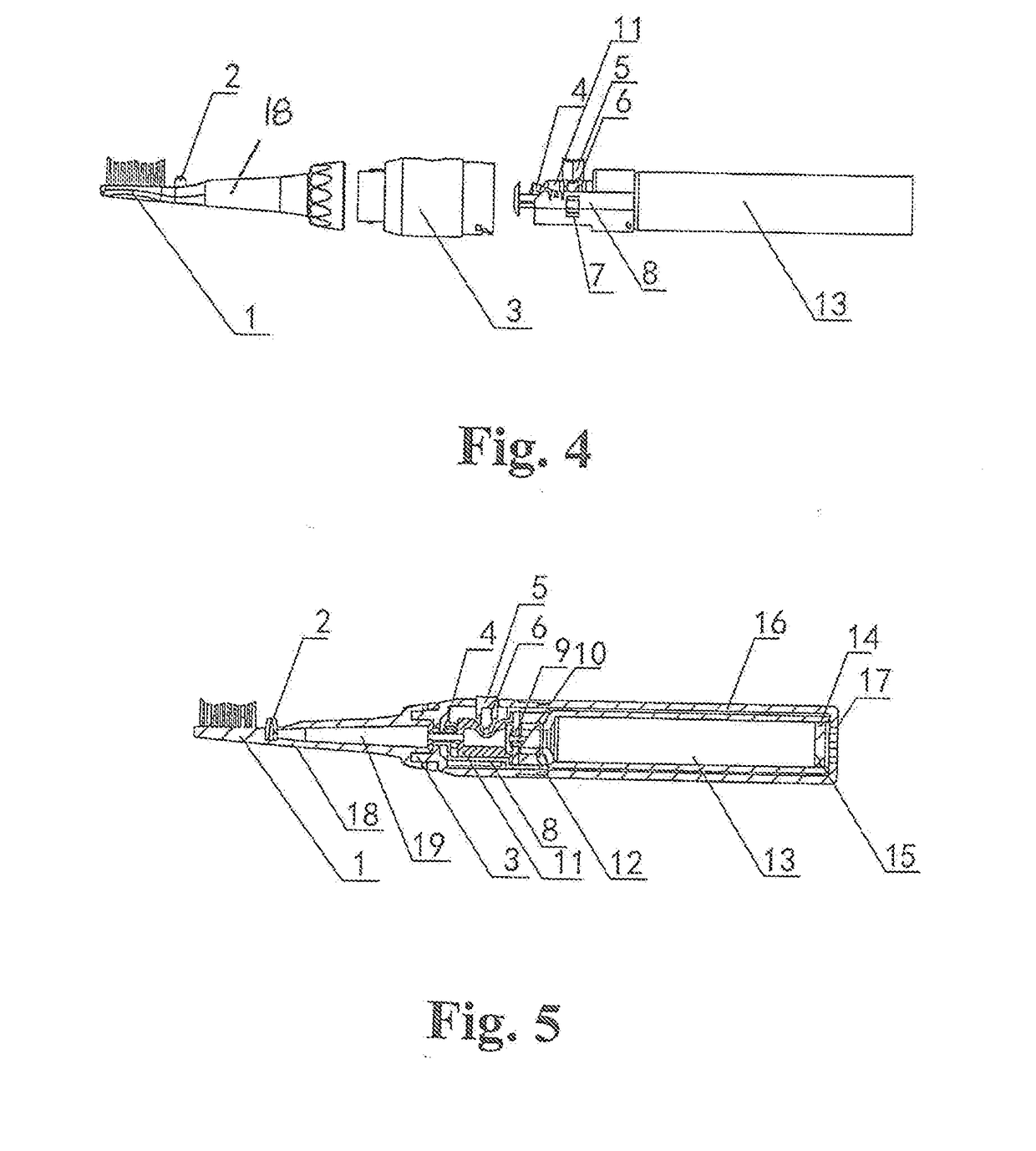

Pet toothbrush

InactiveUS20190059569A1Ensure cleanlinessThe method is simple and convenientBristle carriersAnimal teeth treatmentToothpasteMechanical engineering

A pet toothbrush includes a hybrid brush head populated by both stiffer plastic bristles and softer TPE bristles, a brush handle and a connecting neck connecting the brush head and the brush handle. A toothpaste tube accommodates pet toothpaste. A toothpaste outlet is provided in the vicinity of the brush head. The connecting neck is provided with a toothpaste channel connected with the toothpaste outlet. The connection between the connecting neck and the brush handle is provided with a one-way delivery valve of toothpaste from the toothpaste tube to the toothpaste channel and then extruded from the toothpaste outlet. The toothbrush can continuously squeeze the toothpaste by way of a push cap or button to ensure the cleaning effect. The toothbrush has replaceable brush heads. The toothpaste outlet can be closed to maintain toothbrush cleanliness.

Owner:RAKU SHOWAI

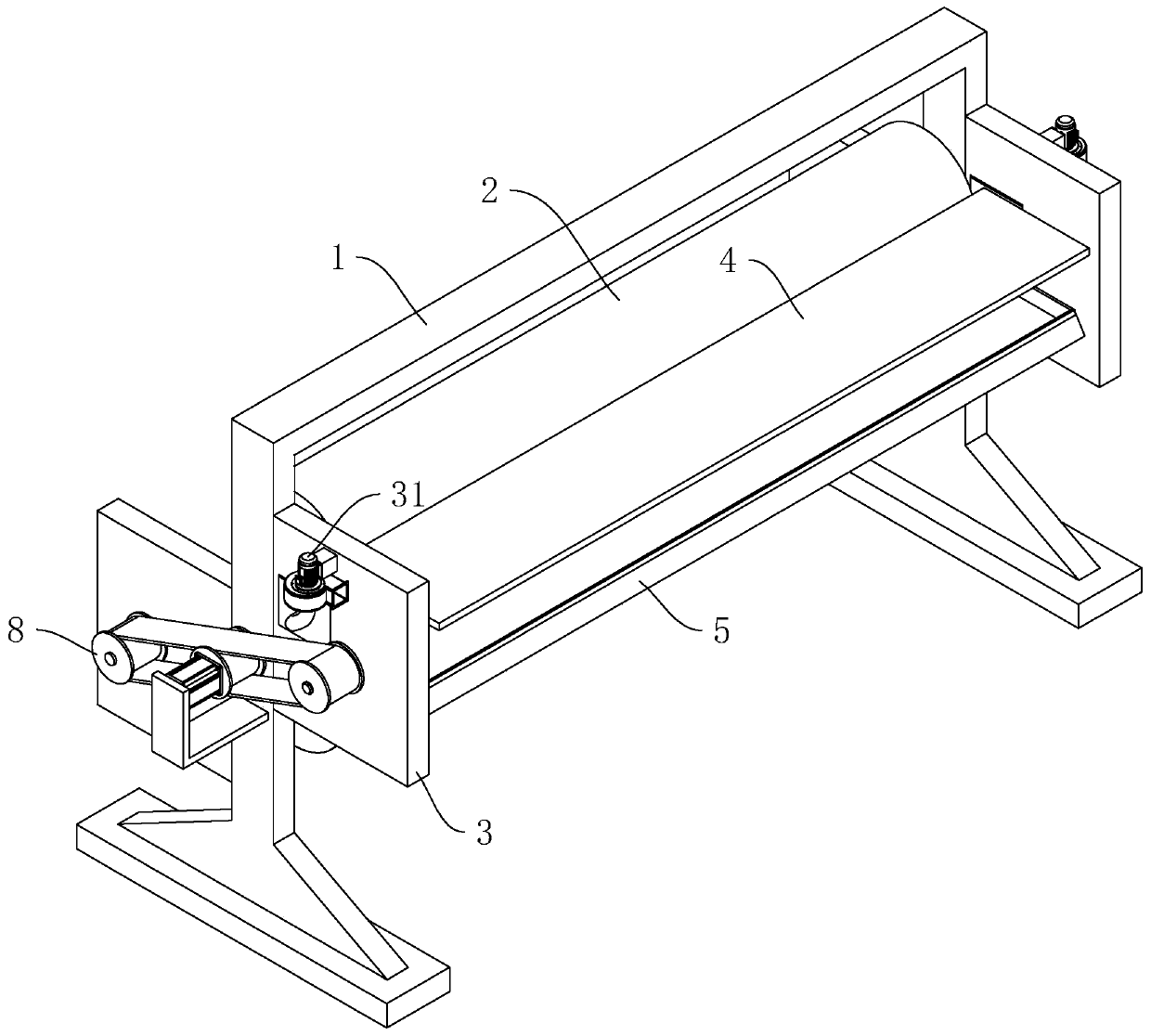

Natural luster finishing machine for warp-knitted ultrasoft sofa fabrics and production process thereof

ActiveCN110538817AEasy to cleanImplement automatic cleanupCleaning using toolsCleaning using gasesEngineeringMechanical engineering

The invention discloses a natural luster finishing machine for warp-knitted ultrasoft sofa fabrics and a production process thereof, and relates to the field of spinning equipment. The machine comprises a frame; a pair of natural luster finishing rollers distributed up and down is rotationally connected into the frame; two pairs of mounting bases are arranged on the front and back sides of the frame; each pair of the mounting bases are distributed at the two ends of the frame; and scrapers butting against the outer walls of the pair of the natural luster finishing rollers and trays positionedunder the scrapers are horizontally arranged between each pair of the mounting bases. The machine has the following advantages and effects: through arrangement of the scrapers always butting against the outer walls of the natural luster finishing rollers, attachments on the outer walls of the natural luster finishing rollers are automatically scraped into the trays, so that the automatic cleaningof the outer walls of the natural luster finishing rollers is realized, and meanwhile, the effect of conveniently cleaning the attachments is achieved.

Owner:HANGZHOU KELIDA HOME TEXTILE CO LTD

Cutting machine capable of collecting residues

InactiveCN105772860ANot easy to damageEnsure cleanlinessMetal sawing accessoriesMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses a cutting machine capable of collecting residues. The cutting machine comprises a base. An electric saw is arranged on the base. The base is further provided with a fixing frame used for clamping a cutting piece. A cavity is formed in the base and is used for collecting the residues falling from the cutting piece. The upper portion of the base is provided with inclined plates used for allowing the residues to slide and fall into the cavity. By means of the cutting machine capable of collecting the residues, the residues accumulated on the base after cutting can be collected conveniently, and the cleanliness degree of equipment can be maintained without manual treatment.

Owner:藤县正钻门业有限公司

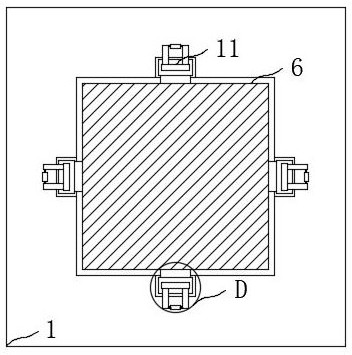

Functional experiment fixing device

InactiveCN111388135AEasy to operateEnsure cleanlinessOperating tablesAnimal trapsEngineeringStructural engineering

The invention discloses a functional experiment fixing device. The fixing device includes an operation table; the right side of the operation table is slidingly connected to an overturning plate capable of turning over; the overturning plate is fixedly connected to a rearing cage; the sidewall on the left side of the rearing cage is provided with an opening-closing mechanism; the left side of theopening-closing mechanism is in clamping connection with a splicing mouse-trapping cylinder; the upper part of the mouse-trapping cylinder is in clamping connection with a mouse-trapping clamp; the left side of the operation table is provided with an elevating anatomical table; the anatomical table is rotatably connected to an opening and closing cover in synchronous movement; a fixing rod is rotatably connected to a two-way lead screw; the two-way lead screw fixedly coordinates with opening rods in relative movement; the opening rods are fixedly connected to pulling ropes; the pulling ropes are fixedly connected to fixing buckles; the left sides of the fixing buckles are provided with a placing hole; the lower part of the placing hole is fixedly connected to a three-jaw chuck; and a mousehead-neck fixing device is formed through the cooperation of the three-jaw chuck, the placing hole and the mouse-trapping clamp. Through the fixing device, the problems, that the capturing of mice isdifficult and fixing devices cannot be adjusted, can be effectively solved.

Owner:HENAN UNIV OF CHINESE MEDICINE

Coating wrinkle removing device and coating production equipment

ActiveCN113578687AEnsure cleanlinessImproves gloss and smoothnessLiquid surface applicatorsCleaning using toolsStructural engineeringManufacturing engineering

The invention discloses a coating wrinkle removing device and coating production equipment. The coating wrinkle removing device comprises a main body and a driving shaft, the driving shaft is connected into the main body, the outer surface of the driving shaft is sleeved with a conveying roller, the conveying roller is connected with a machined part, a wrinkle removing nozzle is arranged above the machined part, the wrinkle removing nozzle is connected with the main body, a collecting block is arranged on the upper surface of the main body, the driving shaft is connected with a leveling mechanism and a cleaning mechanism, in the process that the driving shaft drives the conveying roller to rotate to convey the machined part, the driving shaft drives the leveling mechanism and the cleaning mechanism to operate at the same time, integrated movement of the device is facilitated, the cost of manual leveling and cleaning work is reduced, the device is more economical and applicable, the leveling mechanism adjusts the position of a limiting block connected with a driven block, meanwhile, the height of the limiting block is adjusted, and the wrinkle removing efficiency of a wrinkle resisting device is improved.

Owner:HAINAN SHINER IND

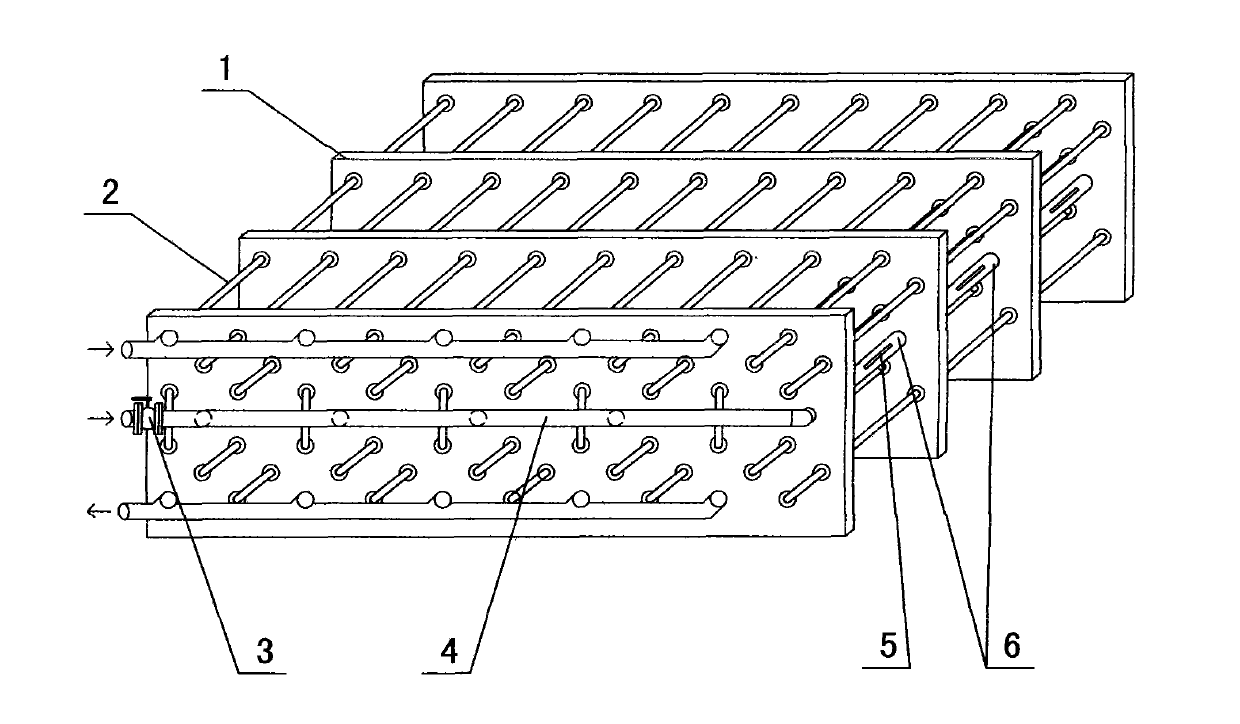

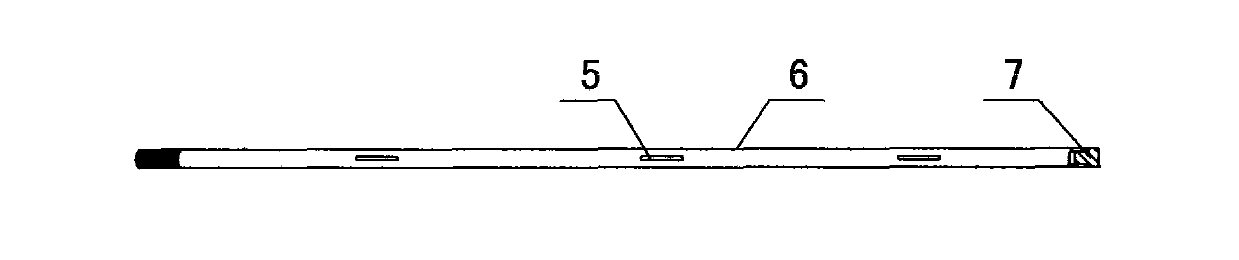

Automatic cleaning device for surface air cooler at tail end of central air conditioner

InactiveCN104215120AEffective cleaning and maintenanceEnsure cleanlinessFlush cleaningEngineeringMechanical engineering

The invention relates to an automatic cleaning device for a surface air cooler at the tail end of a central air conditioner and belongs to the technical field of cleaning of surface air coolers. The automatic cleaning device for the surface air cooler at the tail end of the central air conditioner comprises fins which are arranged at intervals and cold water pipes which penetrate through the fins, are perpendicular to the fins and are arranged at intervals, wherein a water inlet is formed in one end of each cold water pipe, a water outlet is formed in the other end of each cold water pipe, cleaning branch pipes which are arranged at intervals penetrate through the fins, one end of each cleaning branch pipe is connected with a cleaning header pipe, a plug is arranged at the other end of each cleaning branch pipe, and a water orifice is formed in the portion, between every two adjacent fins, of each cleaning branch pipe. According to the automatic cleaning device for the surface air cooler at the tail end of the central air conditioner, the fins can be cleaned and maintained effectively, and the cleanness and the smoothness of the fins are guaranteed. When the automatic cleaning device is used, a maintainer just needs to open a valve at regular times to wash the fins if possible, then the cleanness and smoothness of the fins can be kept for a long time, the situation that a special cleaning company is required for cleaning is avoided, and thus cleaning cost is reduced; when a large amount of dust is accumulated on the surfaces of the fins due to the absence of regular maintenance, chemicals can be injected into the cleaning header pipe for cleaning, and thus the fins can be thoroughly cleaned.

Owner:CHONGQING RUNLAN WATER TREATMENT ENG TECH

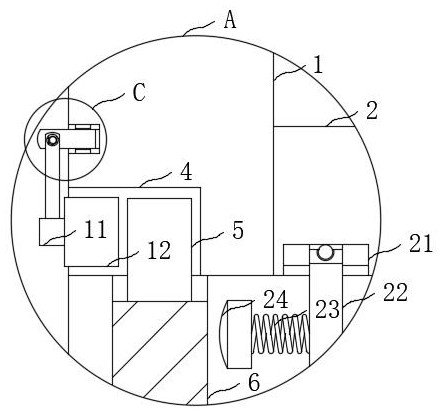

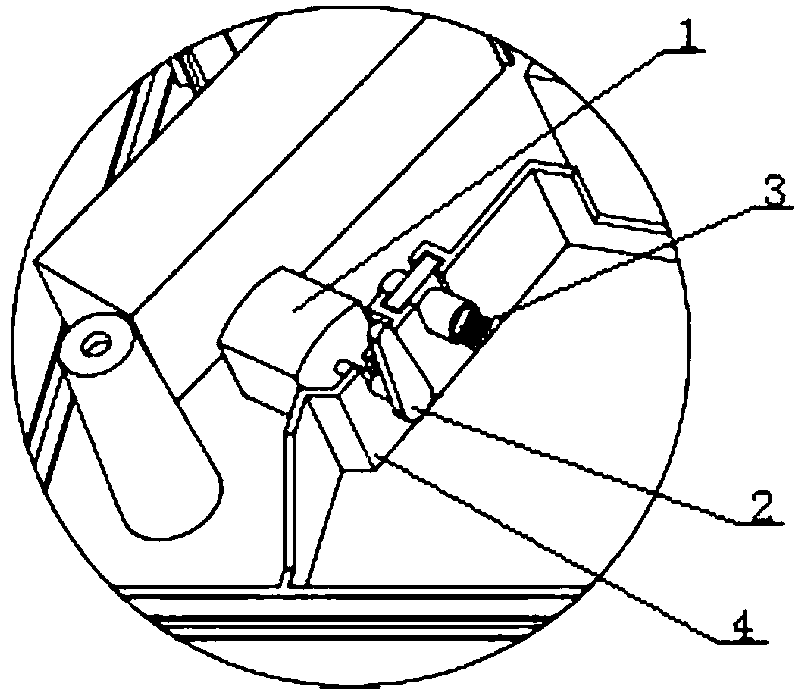

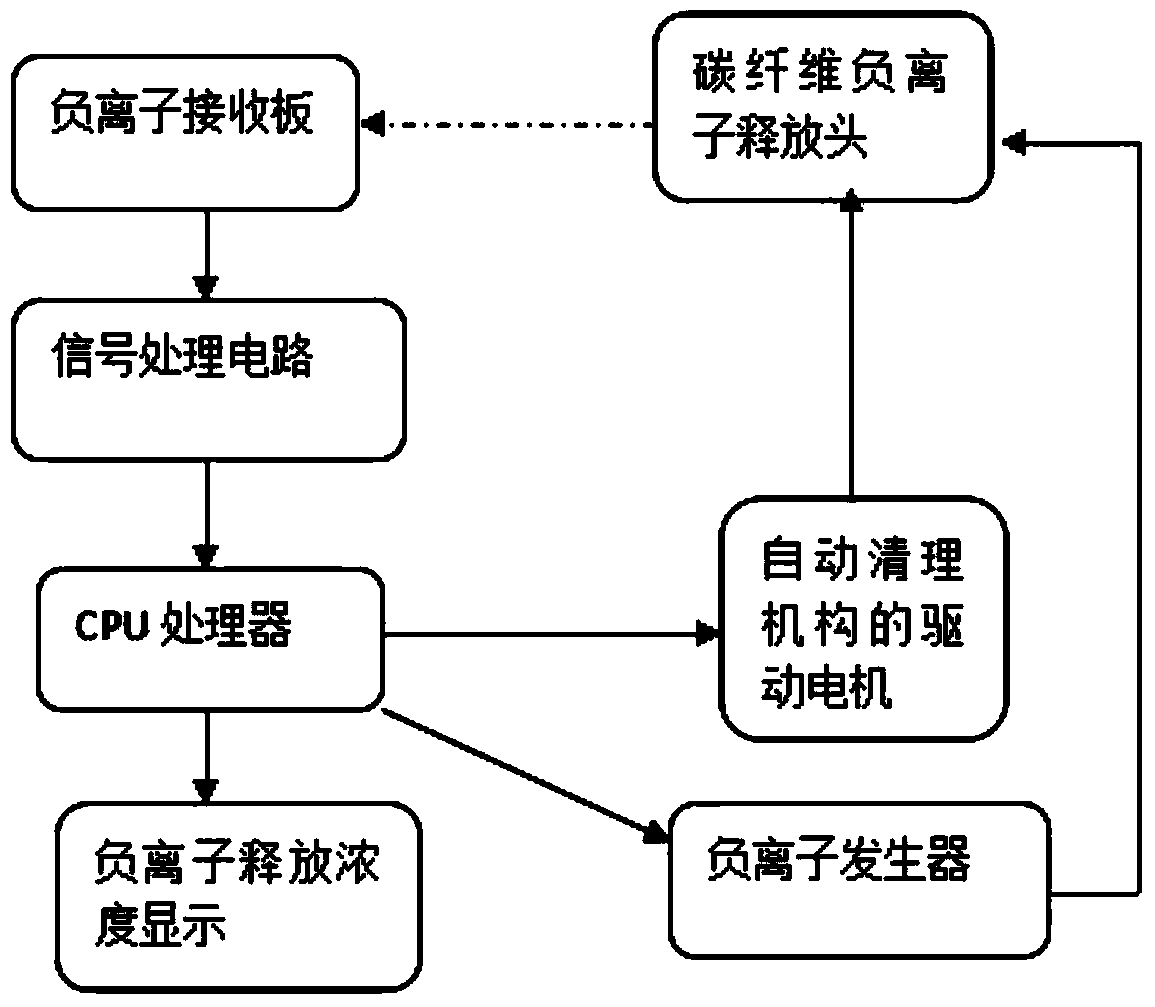

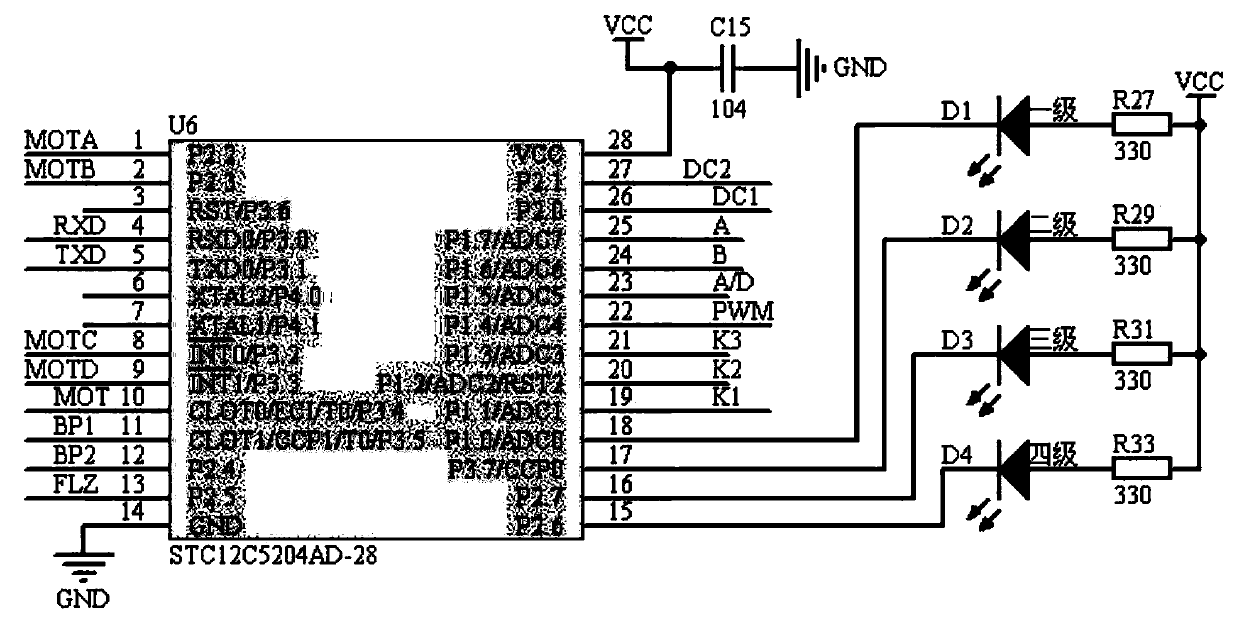

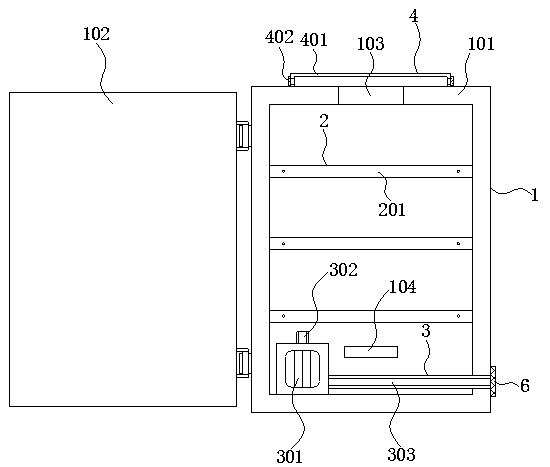

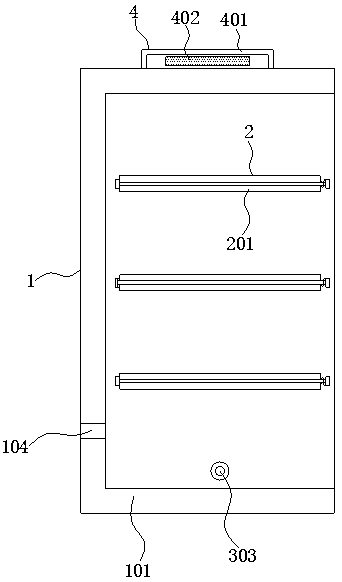

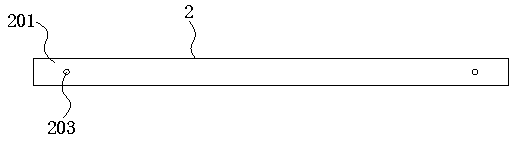

Air purifier with functions of automatically cleaning and displaying negative ion release concentration

The invention relates to an air purifier with functions of automatically cleaning and displaying negative ion release concentration. The air purifier is characterized in that an automatic cleaning mechanism comprises a drive motor and a cleaning rod, wherein the drive motor and a carbon fiber negative ion release head of a negative ion generator are arranged on the same rack; the cleaning rod is arranged at the output end of the drive motor; after the drive motor is started by a PWM signal of a micro processor, the cleaning rod stirs carbon fibers of the carbon fiber negative ion release head; a display mechanism for the negative ion concentration comprises a negative ion receiving plate, a signal processing circuit and a group of display lamps; the signal received by the negative ion receiving plate is fed into an A / D port of the micro processor after being treated by the signal processing circuit, so that the micro processor drives a corresponding LED indicator lamp; when a drive interval is detected to satisfy set timing time, or when negative ion release concentration detected by the negative ion receiving plate is smaller than 2.5 million / cm<3>, the micro processor emits the PWM signals to drive the drive motor of the cleaning mechanism.

Owner:SHANDONG LEKANG ELECTRICAL TECH

Automatic control cabinet for thermal power plant

InactiveCN110690651AEnsure cleanlinessGood heat dissipationBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationAutomatic controlStructural engineering

The invention discloses an automatic control cabinet for a thermal power plant, and the cabinet comprises a cabinet assembly, a bunch installation assembly, a heat dissipation assembly, and a dustproof assembly; the bunch installation assembly is disposed in the cabinet assembly, the heat dissipation assembly is disposed at the bottom of the inner wall of the cabinet assembly, and the dustproof assembly is disposed at the top of the cabinet assembly. The cabinet assembly comprises a cabinet body, a cabinet door, an air outlet and a wire outlet. The cabinet door is installed on the cabinet bodythrough hinges. Through mutual cooperation of the cabinet assembly, the bunch installation assembly, the heat dissipation assembly and the dustproof assembly, the automatic control cabinet for the thermal power plant is realized, so that the control cabinet has a binding function; after a worker installs a control element, wires can be rapidly and orderly bound in the cabinet body, and the cleanness in the cabinet body is improved. In addition, the cabinet body can be well cooled, it is guaranteed that a control element is always in an efficient working state, and the automatic control cabinet is high in practicability and suitable for application and popularization.

Owner:XIAN XINGYI TECH

Hardware button punching device

InactiveCN108890373AEnsure cleanlinessRunning smoothlyPositioning apparatusMaintainance and safety accessoriesEngineeringSlide plate

The invention provides a hardware button punching device, comprising a bottom plate; The bottom plate is fixed with a perforating mechanism, a transplanting mechanism, a cleaning mechanism and a positioning mechanism, wherein the transplanting mechanism is arranged at the front end of the perforating mechanism, the cleaning mechanism is arranged at the right end of the transplanting mechanism, andthe positioning mechanism is positioned between the perforating mechanism and the transplanting mechanism; The perforating mechanism comprises a base plate which is flat on the base plate, and a mounting plate which is perpendicular to the base plate is fixed on the base plate through bolts and card slots; Between that rear side surface of the mount plate and the base plate, a reinforcing rib isfixed, and two right angle edge of the reinforcing rib are respectively bonded with the upper surface of the base plate and the rear side surface of the mounting plate; Two vertical sliding rails arefixed on the front surface of the mounting plate through bolts, and sliding blocks are slidably arranged on the sliding rails; A sliding plate is fixed on the slider by bolts, a rotating electric machine is inherently rotated on the slider by bolts, and an elastic chuck is arranged on the output shaft of the rotating electric machine and extends to the lower end.

Owner:JIASHAN COUNTY FEIHONG BUTTON FACTORY

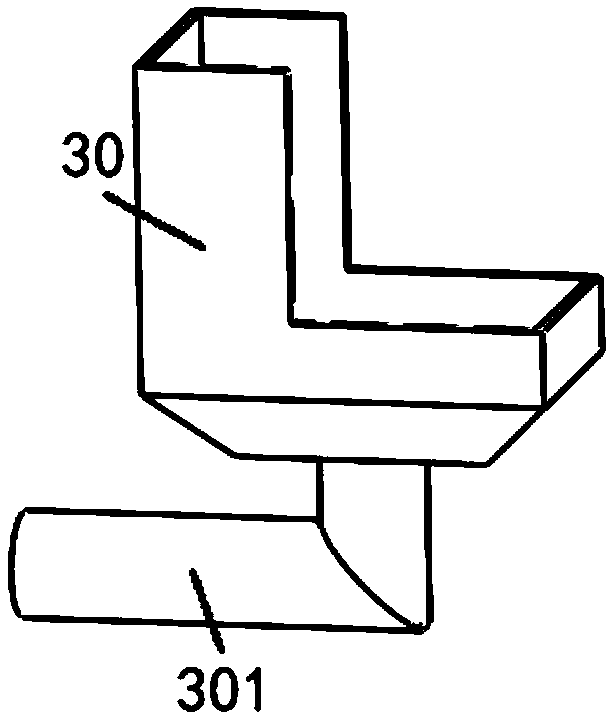

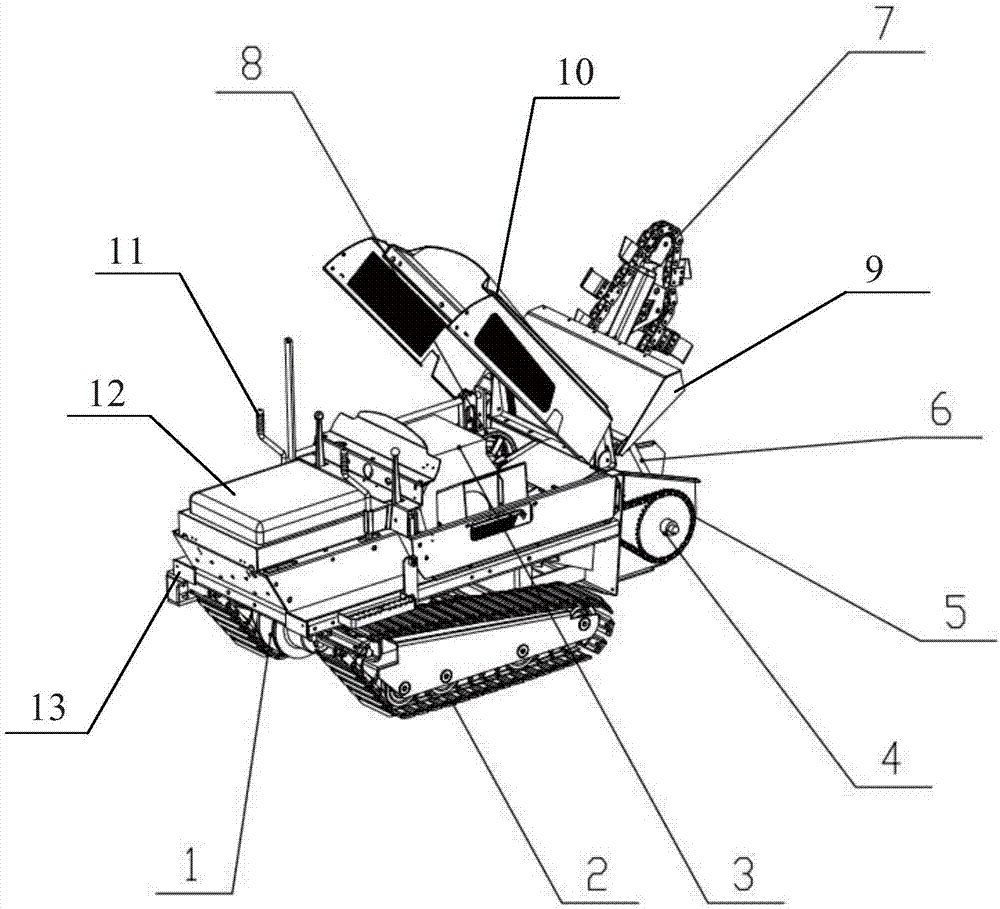

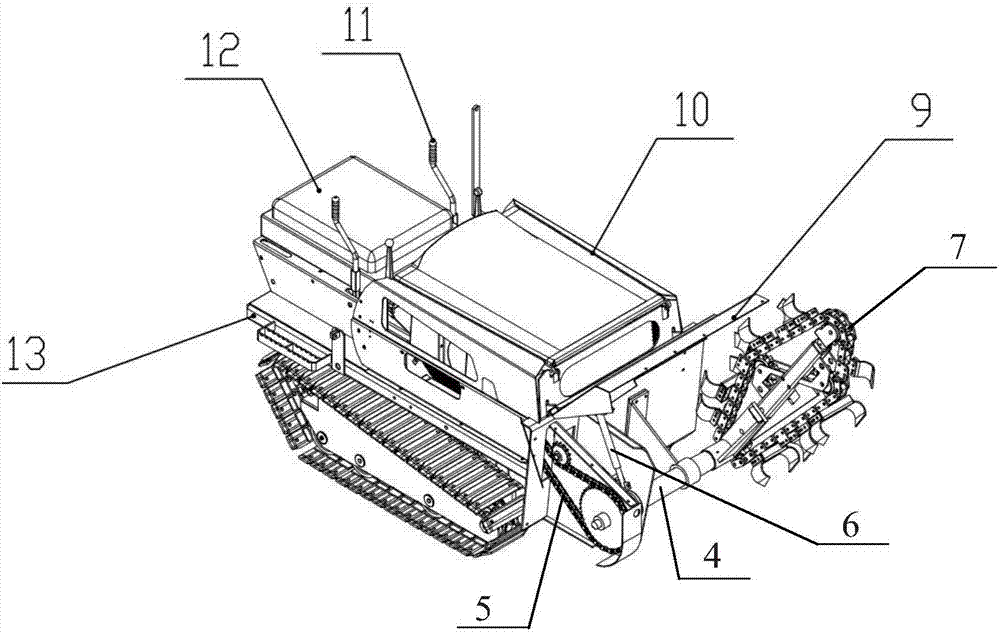

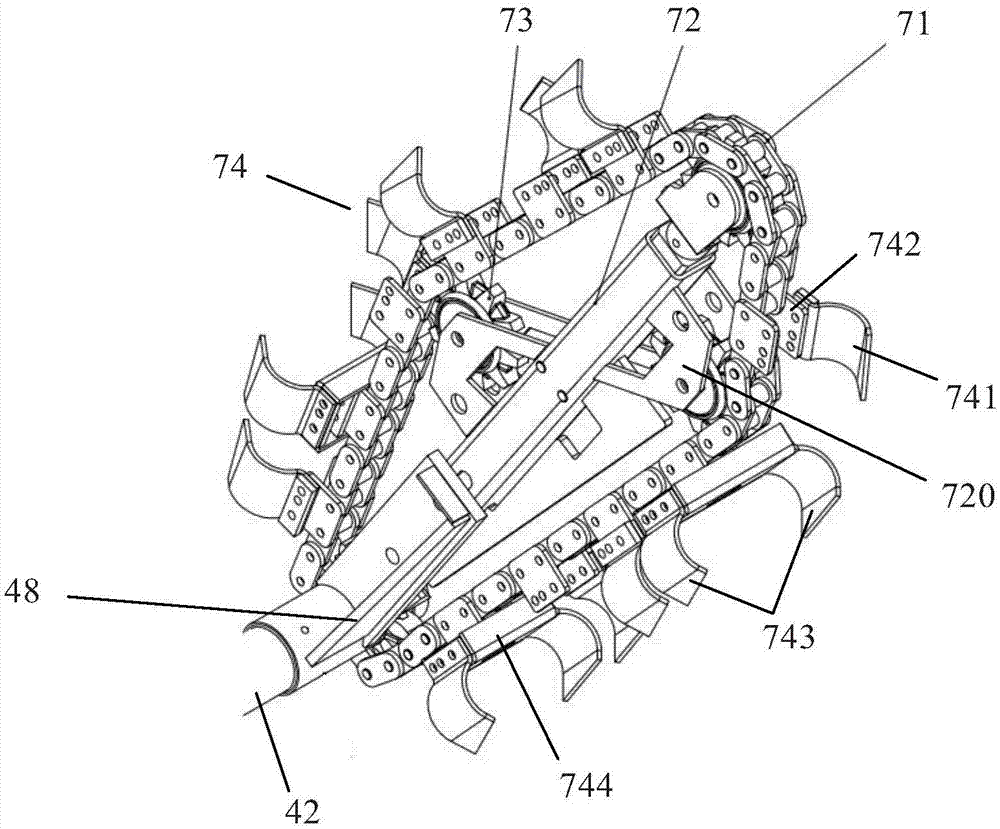

Crawler trencher with adjustable trenching depth

InactiveCN107326951AReasonable structural designCompact designSoil-shifting machines/dredgersTerrainEngineering

The invention discloses a crawler trencher with adjustable trenching depth. The crawler trencher comprises a rack, and a driver seat, an operation device, a hydraulic control device and a driving device are arranged on the rack. A walking transmission mechanism and walking crawlers are arranged under the rack, and the walking transmission mechanism is driven by the driving device to drive the walking crawlers to run. A chain transmission mechanism and a work spindle are arranged in the front of the rack, and a trenching cutter device is arranged on the work spindle. The work spindle is driven by the chain transmission mechanism to drive a trenching cutter of the trenching cutter device to rotate for trenching work. The chain transmission mechanism is connected with the driving device, and the work spindle is connected with the hydraulic control device through a hydraulic telescopic rod. The work spindle drives the trenching cutter device to fall and rise under the action of the hydraulic telescopic rod, and therefore the automatic adjustment of trenching depth is realized. The hydraulic control device and the driving device are connected with the operation device. The crawler trencher realizes simple and efficient linear trenching and the automatic adjustment of trenching depth, and is suitable for trenching work of various terrains, such as a terrain with a steep slope, an uneven terrain, etc.

Owner:佰源(山东)机械制造有限公司 +1

Washing and drying device suitable for weaving

InactiveCN106048939AEnsure cleanlinessMake sure to drainLiquid/gas/vapor removalTextile treatment carriersManipulatorH shaped

The invention discloses a washing and drying device suitable for weaving, which comprises a frame, and a longitudinal guide rail, a cylinder and a controller which are arranged on the frame, and a transverse guide rail is connected to the cylinder; the transverse guide rail is vertically connected with two longitudinal guide rails so that an H-shaped structure is formed. A manipulator is connected to the transverse guide rail; the manipulator and the cylinder are connected with a controller; a fabric washing mechanism, a fabric filtering mechanism, and a fabric drying mechanism are successively arranged below the manipulator. The washing and drying device are simple in structure and convenient and quick to use. Through the washing and filtering, cleaning, filtering and drying of fabrics are ensured; the fabrics are easy to dry; dust permeating the interior of a drying box can be filtered and adsorbed; service lifetime of the drying box is prolonged; and situations that fabrics are polluted are reduced.

Owner:SUZHOU KANGJIAN TEXTILE

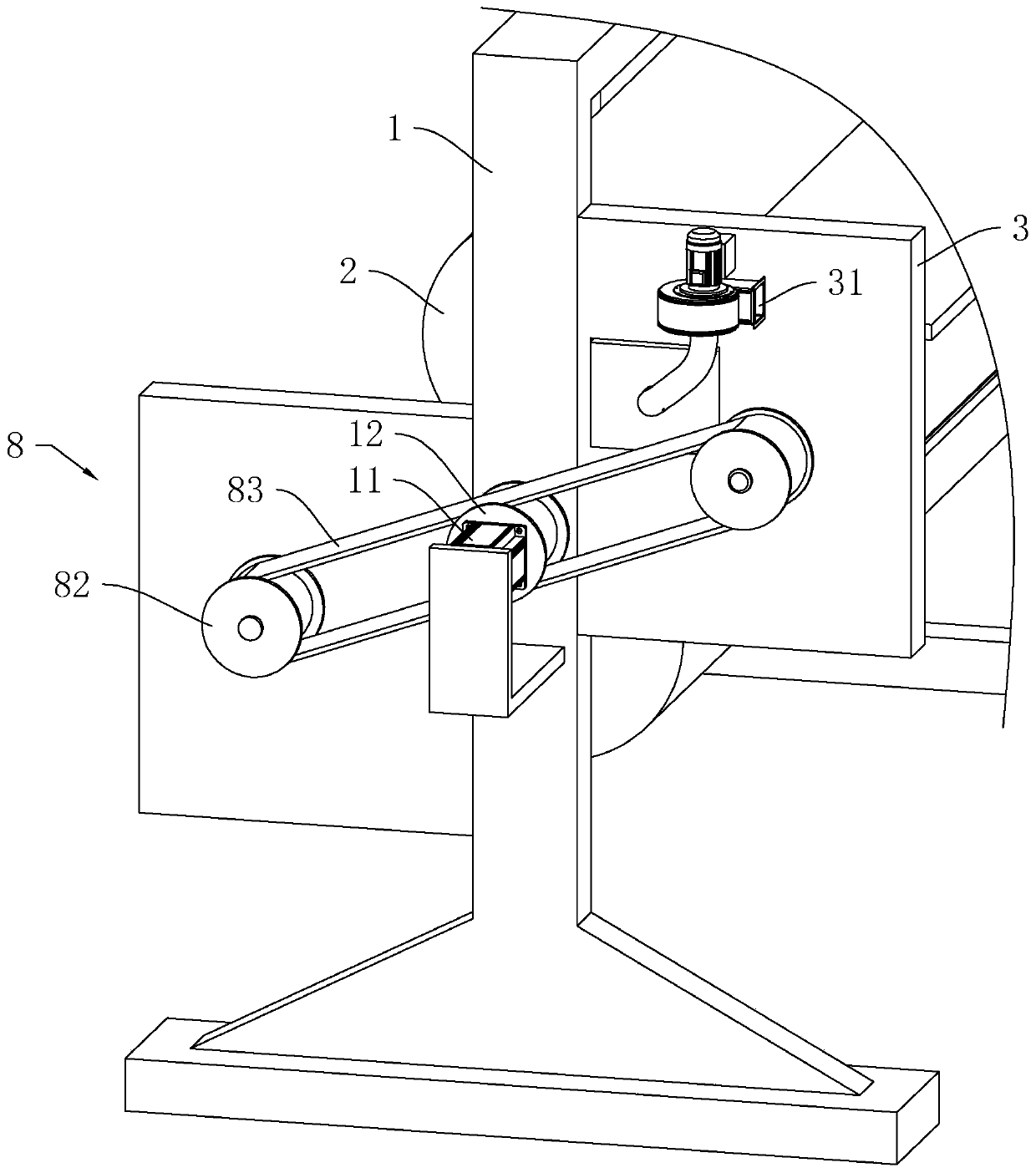

Synthetic wig forming device

ActiveCN110079953AImprove wig processing efficiencyEnsure cleanlinessTextile treatment containersWigsEngineeringForming processes

The invention discloses a synthetic wig forming device, and specifically relates to the field of processing of synthetic wig. The synthetic wig forming device comprises a middle enclosure, wherein a circulation conveying mechanism is arranged in the middle enclosure; a first wig carrying mechanism and a second wig carrying mechanism are fixedly arranged at the top of the circulation conveying mechanism; the circulation conveying mechanism comprises a transmission shaft; the transmission shaft penetrates through the middle enclosure; a positive and reverse motor is fixedly arranged on the sidesurface of the middle enclosure; the transmission shaft is in transmission connection with the positive and reverse motor; a rotating roller is connected to the outer side of the transmission shaft ina sleeving manner; a conveying belt is connected to the outer side of the rotating roller in a sleeving manner; each of the first wig carrying mechanism and the second wig carrying mechanism comprises a base; the bases are fixedly arranged at the top of the conveying belt. In a wig forming process, a wig can be dried without interruption, equipment does not need to be shut down. Therefore, compared with the prior art, the processing speed of the wig is not affected by halting, so that the processing speed of the wig is effectively improved.

Owner:ANHUI FORTUNE FASHION CULTURE

Height adjustable de-ironing separator used for building

InactiveCN107497597AImprove the effect of iron removalEnsure cleanlinessCleaningMagnetic separationEngineeringMechanical engineering

The invention discloses a height-adjustable iron remover for buildings, which includes a main casing, the main casing is a rectangular frame body, and adjustment blocks are fixed on the outer walls of the left and right side panels of the main casing, and the adjustment blocks are screwed to the corresponding In the vertical screw rod, the bottom end of the vertical screw rod is hinged on the lower base plate, the top end of the vertical screw rod is hinged on the bottom surface of the upper plate body, side vertical plates are fixed on the two lower base plates, and the top ends of the side vertical plates are fixed on On the upper plate body, a lifting motor is fixed on both sides of the top surface of the upper plate body, the output shaft of the lifting motor is a spline shaft, and the spline shaft is inserted and sleeved in the spline hole provided on the top of the vertical screw rod. The present invention can adjust the main casing up and down according to the height of the lower conveyor frame, so as to ensure that the conveyor belt is close to the building sundries conveyed on the lower conveyor frame, thereby improving the effect of iron removal, and the conveyor belt can be cleaned by the upper brush It is very convenient to carry out automatic cleaning to ensure its cleanliness, thereby ensuring the adsorption effect of the electromagnet block.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Wet area wall face wooden product mouldproof technology

InactiveCN107938862AEnsure cleanlinessBeneficial to human healthBuilding insulationsEngineeringWood product

The invention relates to a decoration technology, in particular to a wet area wall face wooden product mouldproof technology. Mouldproof treatment is conducted on a wet area wall face back face and acabinet abutting against the back face, and the mouldproof technology comprises the following steps that 1, treatment is conducted on a base layer of a wall face, and an interface agent is brushed; 2,leveling treatment is conducted on the wall face; 3, a waterproof agent is brushed on the wall face, and a damp-proof layer is formed; 4, anti-corrosion treatment is conducted on a back plate, tightly abutting against the wall face, of the cabinet; 5, a damp-proof separation layer is arranged at the position where the back plate is in contact with the wall face when the cabinet is mounted; and 6,the cabinet is mounted. According to the wet area wall face wooden product mouldproof technology, three damp-proof layers are formed by brushing the damp-proof layer on the back face of the wet areawall face, conducting anti-corrosion treatment on the back plate of the cabinet and arranging the damp-proof separation layer at the position where the back plate of the cabinet is in contact with thewall face, dampness transmitted from the wet area wall face can be effectively blocked, dryness and cleanness of the cabinet are ensured, no mildew and bacteria is generated, a clean and sanitary environment in a non-wet area is ensured, physical health is facilitated, and wooden furniture is durable.

Owner:SHANGHAI JUTONG DECORATION GRP

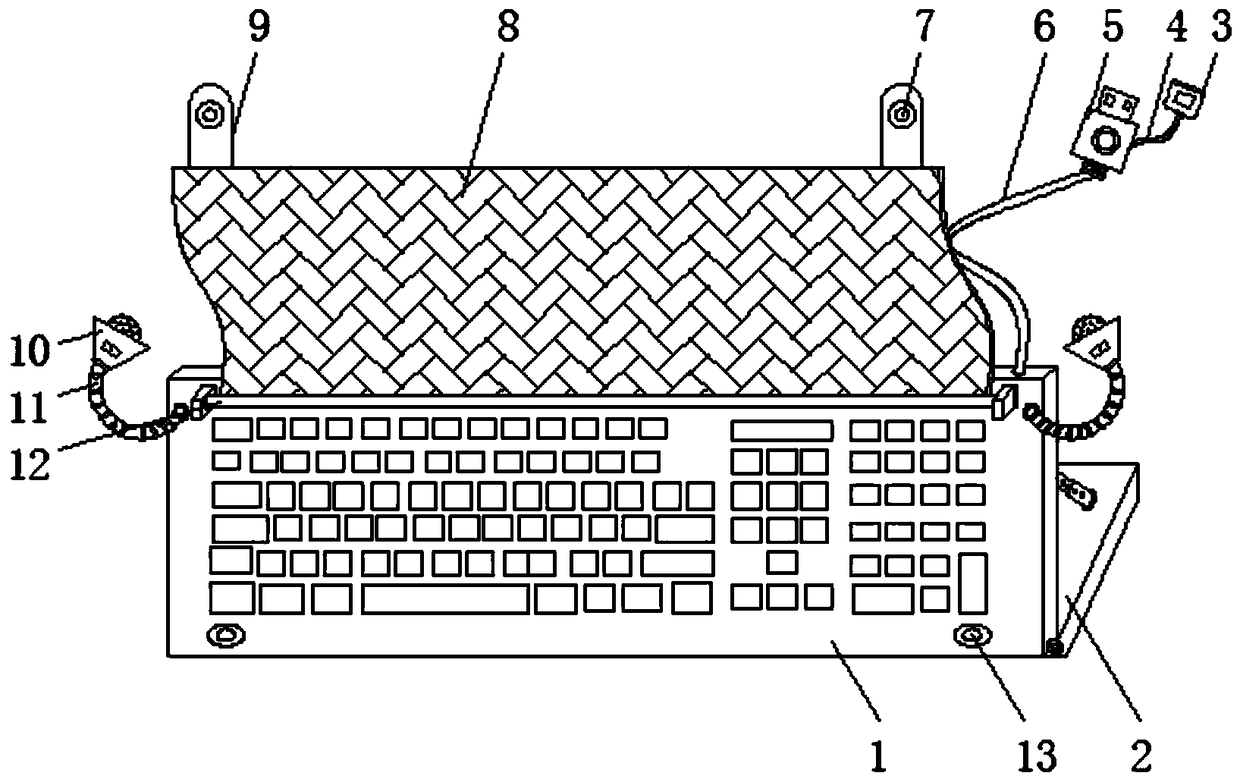

A computer keyboard with adjustable inclination angle

InactiveCN109460155AImprove convenienceEnsure cleanlinessInput/output for user-computer interactionEngineeringUSB

The invention discloses a computer keyboard with adjustable inclination angle, comprises a keyboard body and a fixed base, the keyboard body is arranged on a fixed base, A small drawer is pulled out from the inside of the fixed base, one end of the keyboard body is hinged with a fixed base through a rotary hinge, The bottom two sides of the other end of the keyboard body are connected with the fixed base through the telescopic adjusting rod, the upper surface rear end of the keyboard body is provided with a roller leather frame, the roller leather frame is wound with a dust-proof rubber leather, the keyboard body is connected with a keyboard wire, and the end of the keyboard wire is provided with a USB connector. The invention is convenient to raise the keyboard to an appropriate inclination angle, meets the different use requirements of people, improves the convenience of keyboard use, and the rubber skin wound on the rolling leather rack can cover the keyboard when not in use at ordinary times, so as to avoid dust and other sundries on the keyboard, thereby ensuring the cleanliness and sanitation of the keyboard.

Owner:合肥享淘科技有限公司

Environment-friendly garbage breaking device

InactiveCN110694733AConvenience to workEnsure cleanlinessGrain treatmentsElectric machineryWaste material

The invention discloses an environment-friendly garbage breaking device, and particularly relates to the technical field of environment-friendly equipment. The device comprises a box body, a breakingwheel is fixedly connected to one side of an inner cavity of the box body, a feeding pipe is fixedly connected to the position, corresponding to the breaking wheel, of the top of the box body, a firstmotor is fixedly connected to one end of the breaking wheel, bearings are embedded on the two sides of the inner cavity of the box body, rotating shafts are sleeved with the bearings, one ends of therotating shafts are fixedly connected with one ends of thread columns, and the other end of the rotating shaft on one side is fixedly connected with a second motor. Through the breaking wheel, a waste box, the thread column and a thread cap, compared with the prior art, the problems that a traditional breaking device does not facilitate taking and efficiency is affected are solved, a worker doesnot need to repeatedly take materials from the box body, work of a worker is facilitated, the breaking wheel and a partition board in the middle of the box body avoid splashing during garbage breaking, sanitation and tidiness of the outer environment of the box body are ensured, and use needs are met.

Owner:邳州亚联环保科技有限公司

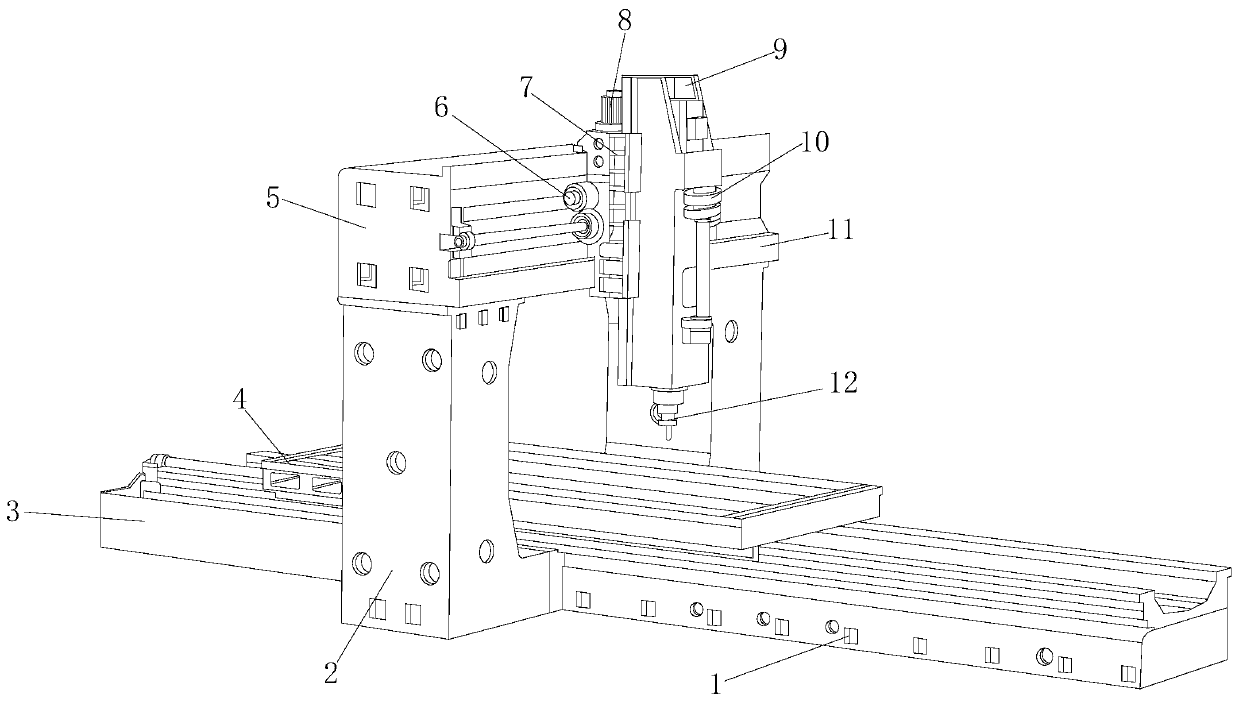

Gantry numerical control milling machine

ActiveCN111531215AImprove processing effectEnsure cleanlinessMilling equipment detailsPositioning apparatusElectric machineryMicro motor

The invention discloses a gantry numerical control milling machine. The gantry numerical control milling machine structurally comprises a sliding sleeve block, a supporting frame, a milling machine table, a fixing device, a movable groove, a sliding plate, a buckling block, a micro motor, a milling cutter head, an anti-collision cutter device, a sliding rail and a milling cutter. When the improvedgantry numerical control milling machine is used, the width of a limiting groove is adjusted through the cooperation of a protective spring and a traction rod, a to-be-machined workpiece is installedon a movable plate and fastened with the milling machine table through arc-shaped clamping blocks, so that the to-be-machined workpiece can be stably fixed to a machining position, air blowing treatment is conducted on gaps in the milling machine table through an air blowing head, and the cleanliness of the milling machine table is guaranteed. The milling cutter is installed in an anti-collisiontank, a lock catch and a clamping piece are matched to lock the milling cutter, a pull rod and a pull plate cooperates to pull the anti-collision tank, the milling cutter is pulled to a certain height, and the phenomenon that the milling cutter collides with the machined part is avoided. The milling cutter is protected using a buffer spring, the impact force generated when the pull rod pulls the milling cutter is reduced, and the production efficiency of the milling machine is improved.

Owner:漳州东刚精密机械有限公司

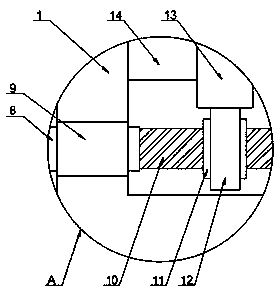

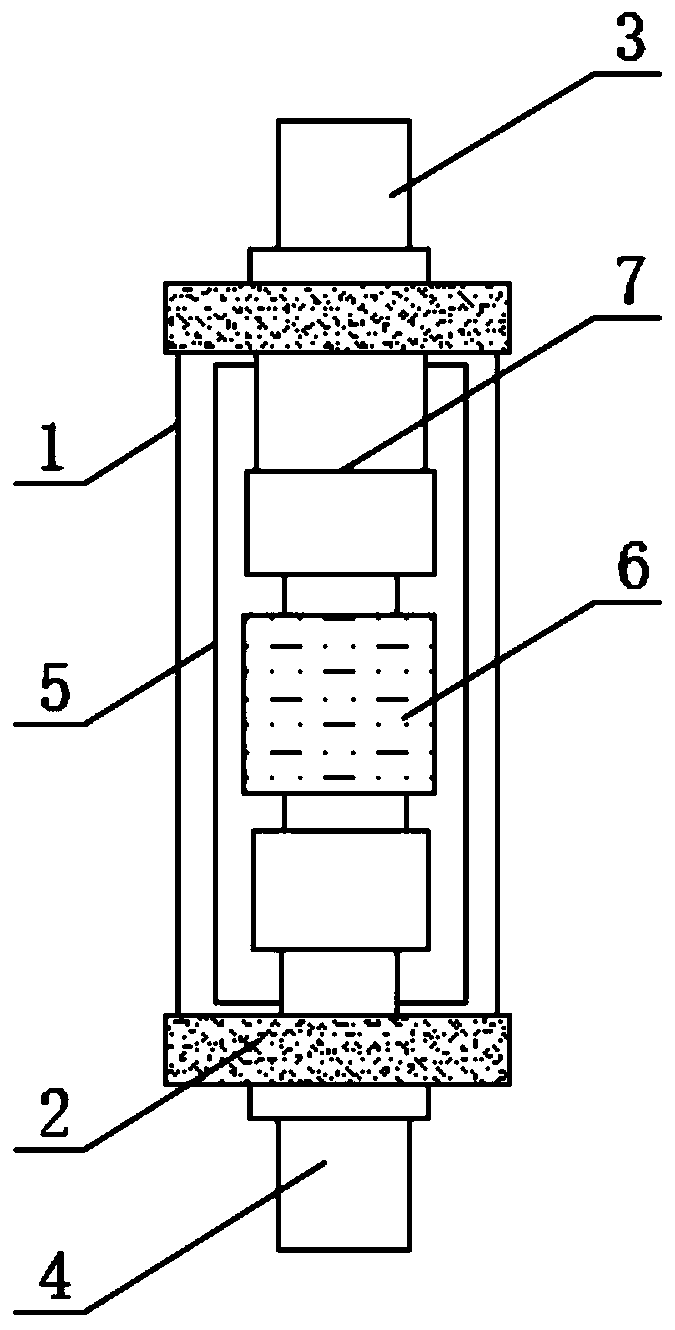

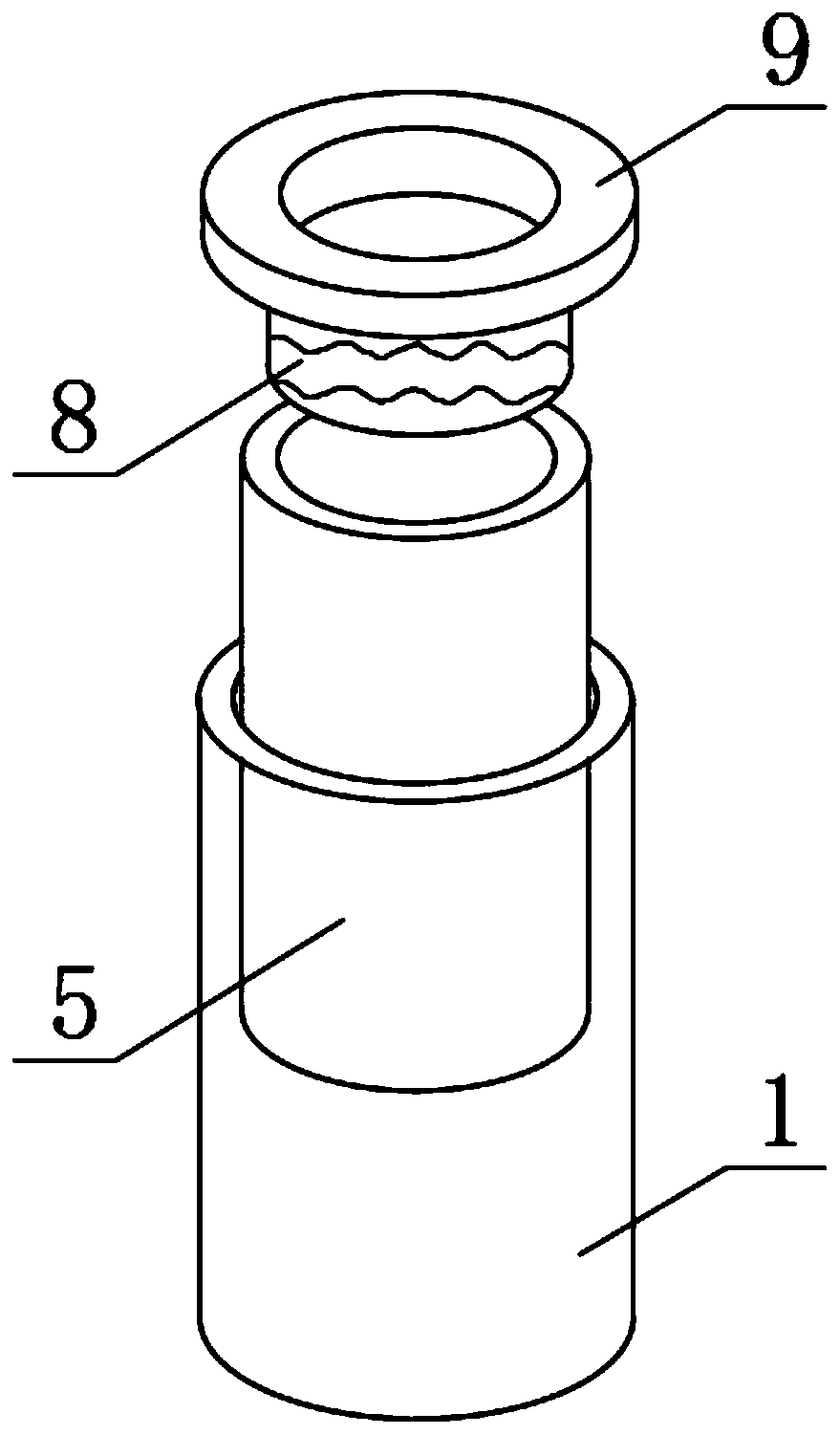

Multi-power extra-high-voltage vacuum arc extinguishing device

InactiveCN109979780ASimple structureEasy to operateHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh voltage

The invention discloses a multi-power extra-high-voltage vacuum arc extinguishing device. The device comprise a main body shell, mounting sleeve shells which are connected to the two ends of the outersurface of the main body shell in a sleeving mode, a movable conducting rod located on the outer surface of the upper end of the main body shell and a static conducting rod positioned on the outer surface of the bottom end of the main body shell; a shielding cylinder is arranged on the inner wall of the main body shell; a contact and a corrugated pipe are fixedly mounted in the main body shell; the corrugated pipe is located above the contact; a connecting sleeve is arranged above the shielding cylinder; a positioning ring is fixedly mounted on the outer surface of the upper end of the connecting sleeve; and a notch is formed in one side of the outer surface of the shielding cylinder. According to the multi-power extra-high-voltage vacuum arc extinguishing device, a user can convenientlytake out the shielding cylinder during use, so that the user can conveniently clean metal steam and liquid drops splashed on the shielding cylinder to keep the cleanness of the shielding cylinder; anda better application prospect is brought.

Owner:兴化市天东软件科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com