Exhaust gas purification method and exhaust gas purification system for reciprocating internal combustion engine

A technology for exhaust gas purification and internal combustion engines, applied to internal combustion piston engines, combustion engines, exhaust gas treatment, etc., to achieve the effects of improving reduction, promoting reduction reactions, and inhibiting excessive characteristic deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

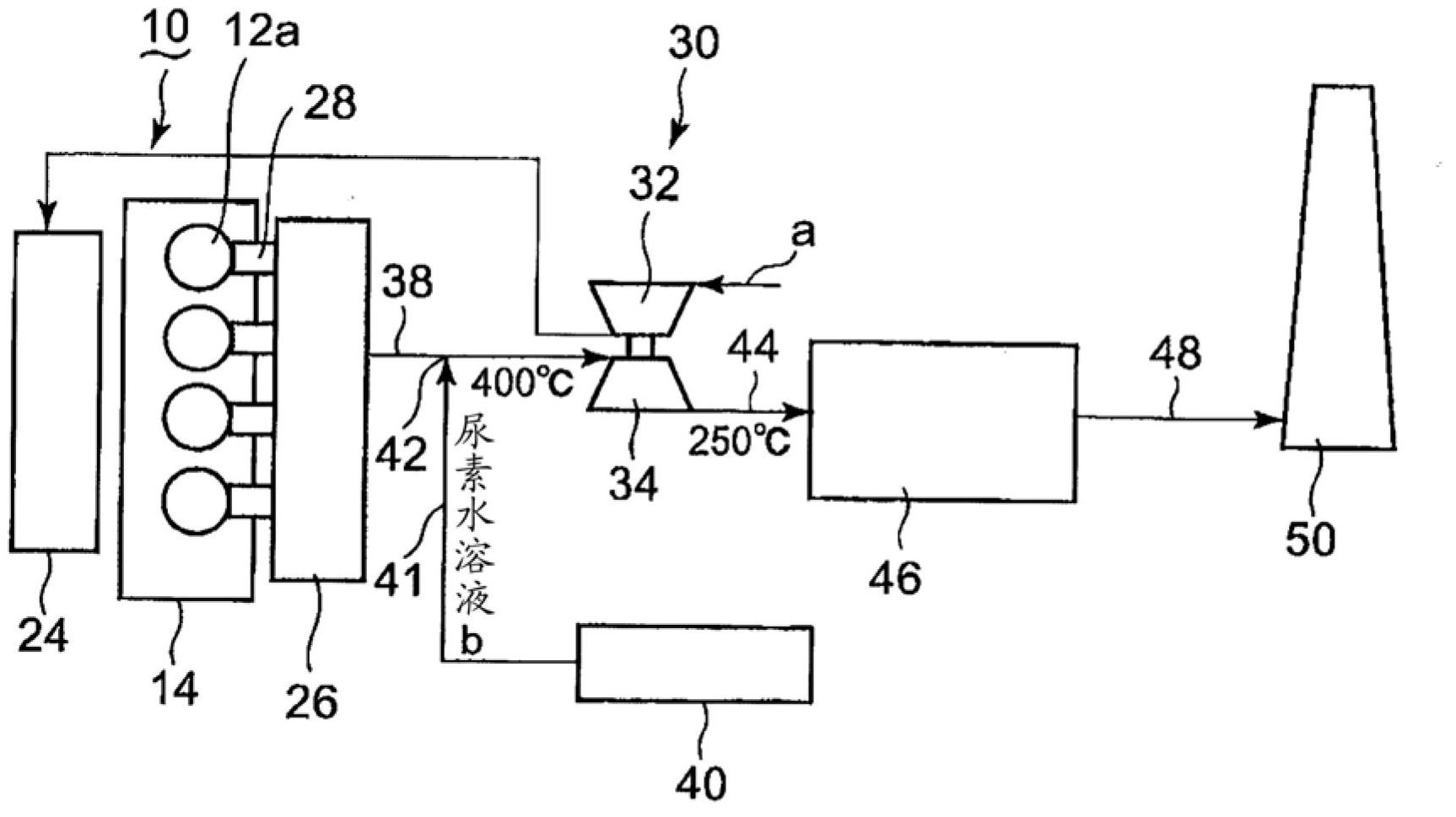

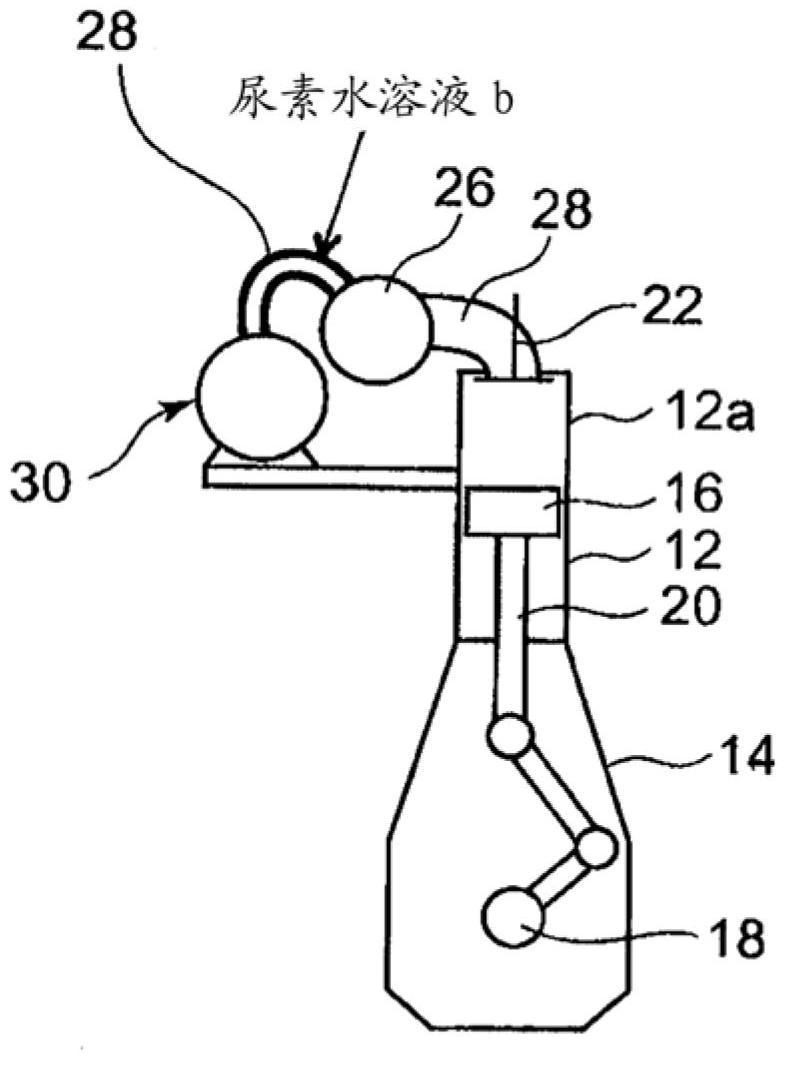

[0051] according to figure 1 and figure 2 The first embodiment of applying the method of the present invention and the system of the present invention to a two-stroke reciprocating marine diesel engine will be described. figure 1 and figure 2 Among them, a two-stroke reciprocating marine diesel engine 10 has a plurality of cylinders 12 , a ventilation chamber 24 and an exhaust manifold 26 . A crank chamber 14 is provided below the cylinder 12 , and a crankshaft 18 is provided in the crank chamber 14 . A piston 16 provided inside the cylinder 12 is connected to a crankshaft 18 via a piston rod 20 .

[0052] A cylinder head 12 a is provided on an upper portion of each cylinder 12 , and each cylinder head 12 a is connected to an exhaust manifold 26 via an exhaust branch pipe 28 . An exhaust valve 22 is provided at the outlet of the cylinder head 12a.

[0053] The compressed air a compressed by the compressor 32 of the supercharger 30 is supplied to the cylinder 12 via th...

Embodiment 2)

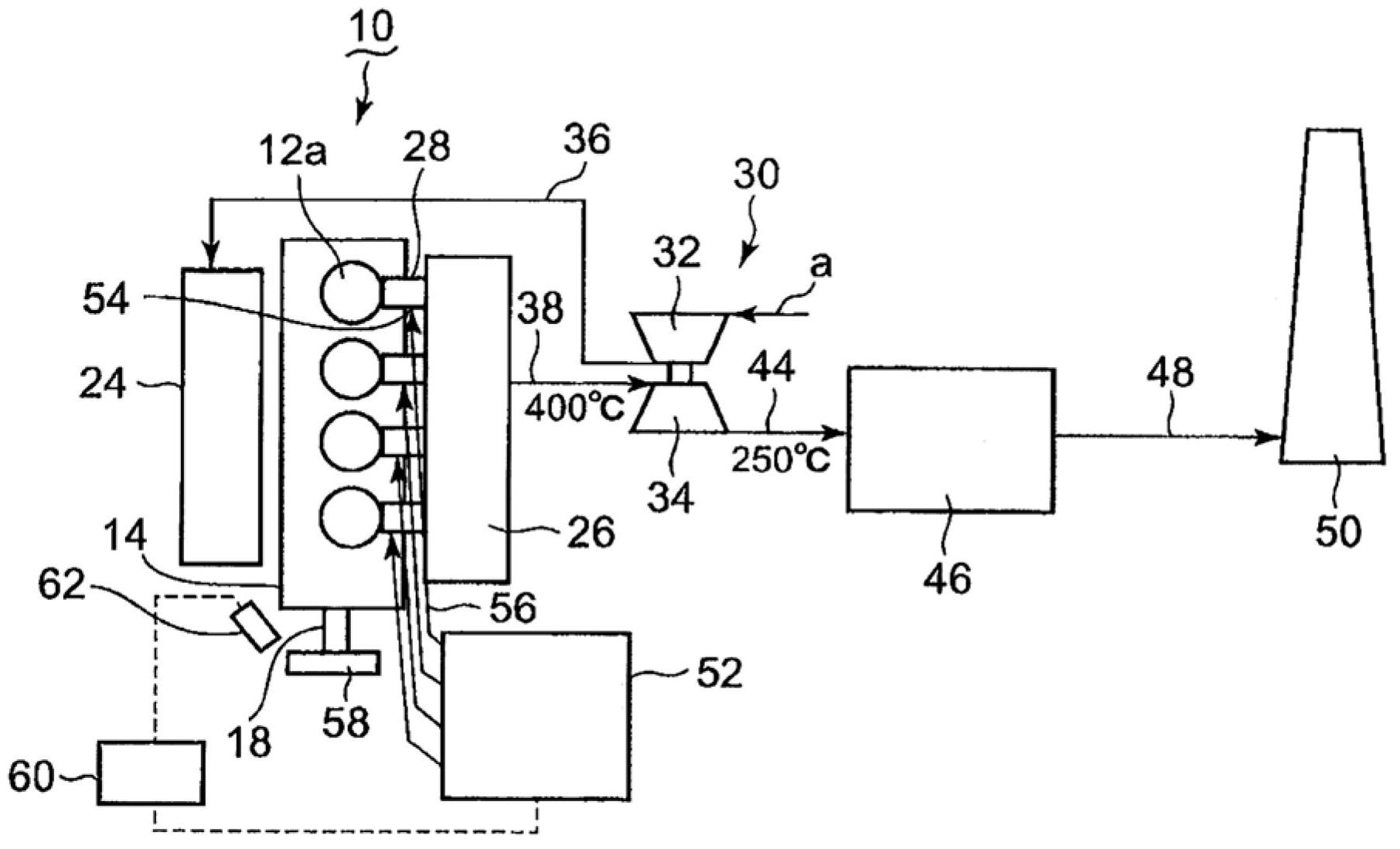

[0060] Next, pass image 3 The second embodiment of the method of the present invention and the system of the present invention will be described. image 3 Among them, a plurality of urea aqueous solution supply units 54 are provided in each of the plurality of exhaust branch pipes 28 . The urea aqueous solution b is supplied from the urea aqueous solution supply device 52 to each urea aqueous solution supply unit 54 via the piping 56 .

[0061] A stabilizer 58 is attached to the crankshaft 18 protruding to the outside of the crank chamber 14 . A crankshaft phase sensor 62 is provided near the crankshaft 18 , and the phase of the crankshaft 18 is detected by detecting a detection mark (not shown) attached to the stabilizer 58 by the crankshaft phase sensor 62 .

[0062] The phase detection signal of the crankshaft phase sensor 62 is sent to the controller 60, and the controller 60 sends a control signal to the urea aqueous solution supply device 52 according to the phase det...

Embodiment 3)

[0068] Next, pass Figure 4 and Figure 5 The third embodiment of the method of the present invention and the system of the present invention will be described. Figure 4The present embodiment is the same as the above-mentioned second embodiment in that the urea aqueous solution supply part 54 is provided in the exhaust branch pipe 28 . The difference from the second embodiment is that a rotation speed sensor 72 for detecting the rotation speed of the crankshaft 18 is provided instead of the crankshaft phase sensor 62 . Furthermore, an exhaust gas temperature sensor 74 for detecting the temperature of exhaust gas flowing through each exhaust branch pipe 28 is provided, and an ammonia concentration sensor 76 is installed in the exhaust gas path 48 downstream of the SCR catalytic converter 46 . Other structures are the same as the second embodiment.

[0069] In this embodiment, as the operating state quantity of the reciprocating marine diesel engine 10 in operation, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com