Efficient textile machine dust removing plant

A technology of dust removal equipment and textile machines, which is applied in the direction of dust removal, cleaning methods and appliances, gas treatment, etc., which can solve problems such as low work efficiency, poor working environment, and dense dust, so as to reduce production costs, improve efficiency, and ensure cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

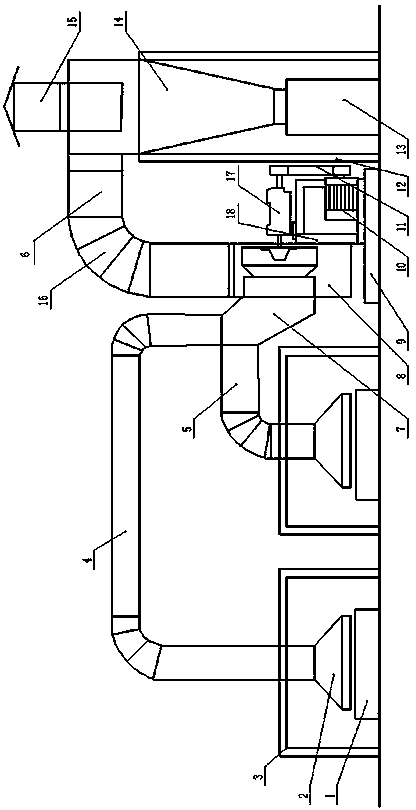

[0012] See figure 1 , A high-efficiency textile machine dust removal equipment, including a textile machine tool 1, a material air box body 8 and a fixed base 9; the textile machine tool 1 is provided with a dust suction port 2 which is not less than 0.75 mm thick Made of galvanized iron sheet, the suction port 2 is tapered, the upper part of the suction port 2 is fixed on the fixing frame 3, and the fixing frame 3 is erected above the textile machine tool 1. The textile machine tool 1 is equipped with two machines. The textile machine tool on the left 1 Connect the first pipe 4, the textile machine tool 1 on the right is connected to the second pipe 5. The first pipe 4 and the second pipe 5 are both connected to the bifurcation pipe 7, and the connection port at the left end of the bifurcation pipe 7 is intact and air-tight, The right end of the bif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com