Natural luster finishing machine for warp-knitted ultrasoft sofa fabrics and production process thereof

A technology for ironing machines and sofas, which is applied in the direction of cleaning methods using tools, fabric surface trimming, cleaning methods and utensils, etc., can solve the problems of inconvenient cleaning process of ironing rollers, achieve wiping and thorough cleaning, and ensure cleaning. effect, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

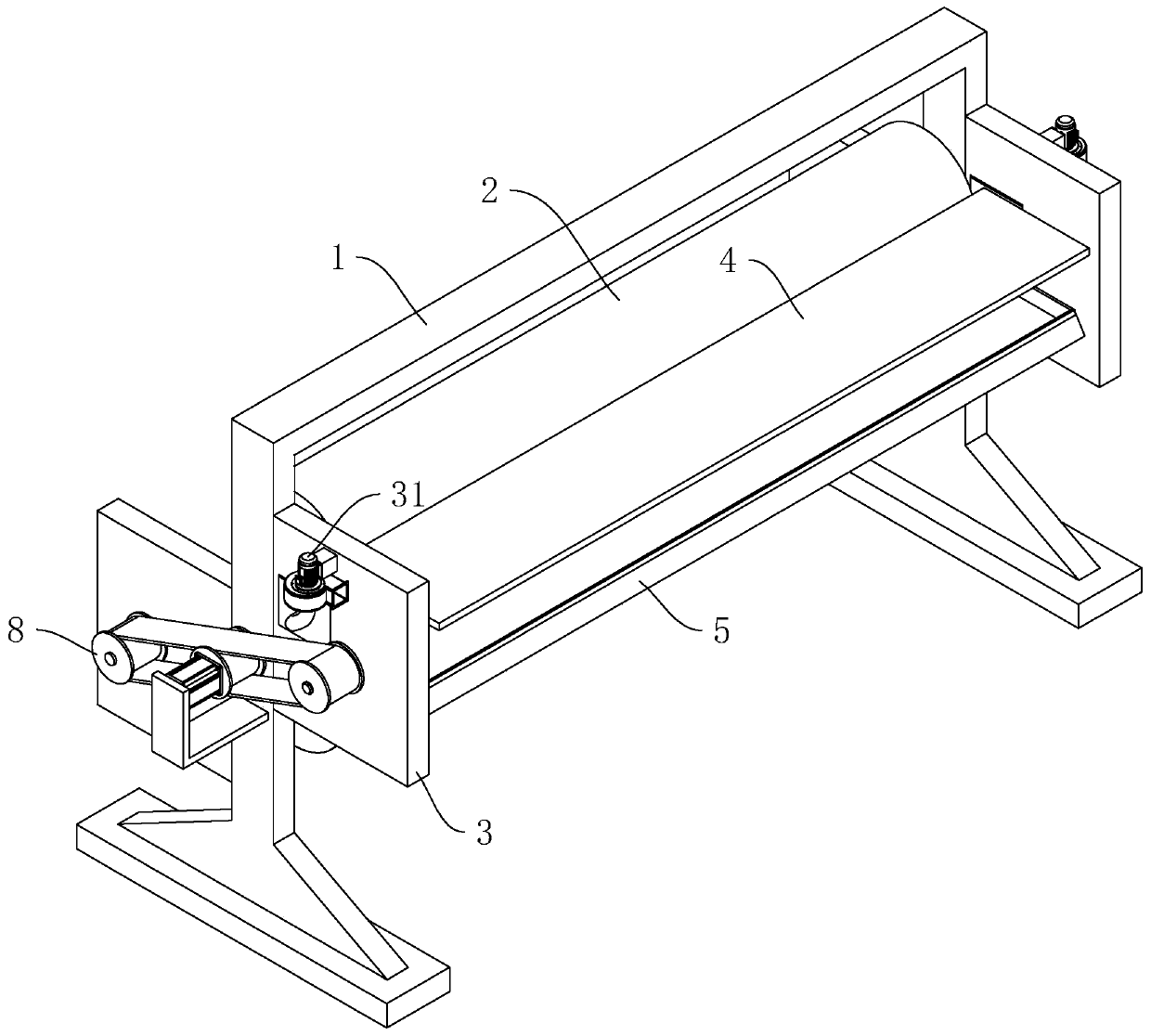

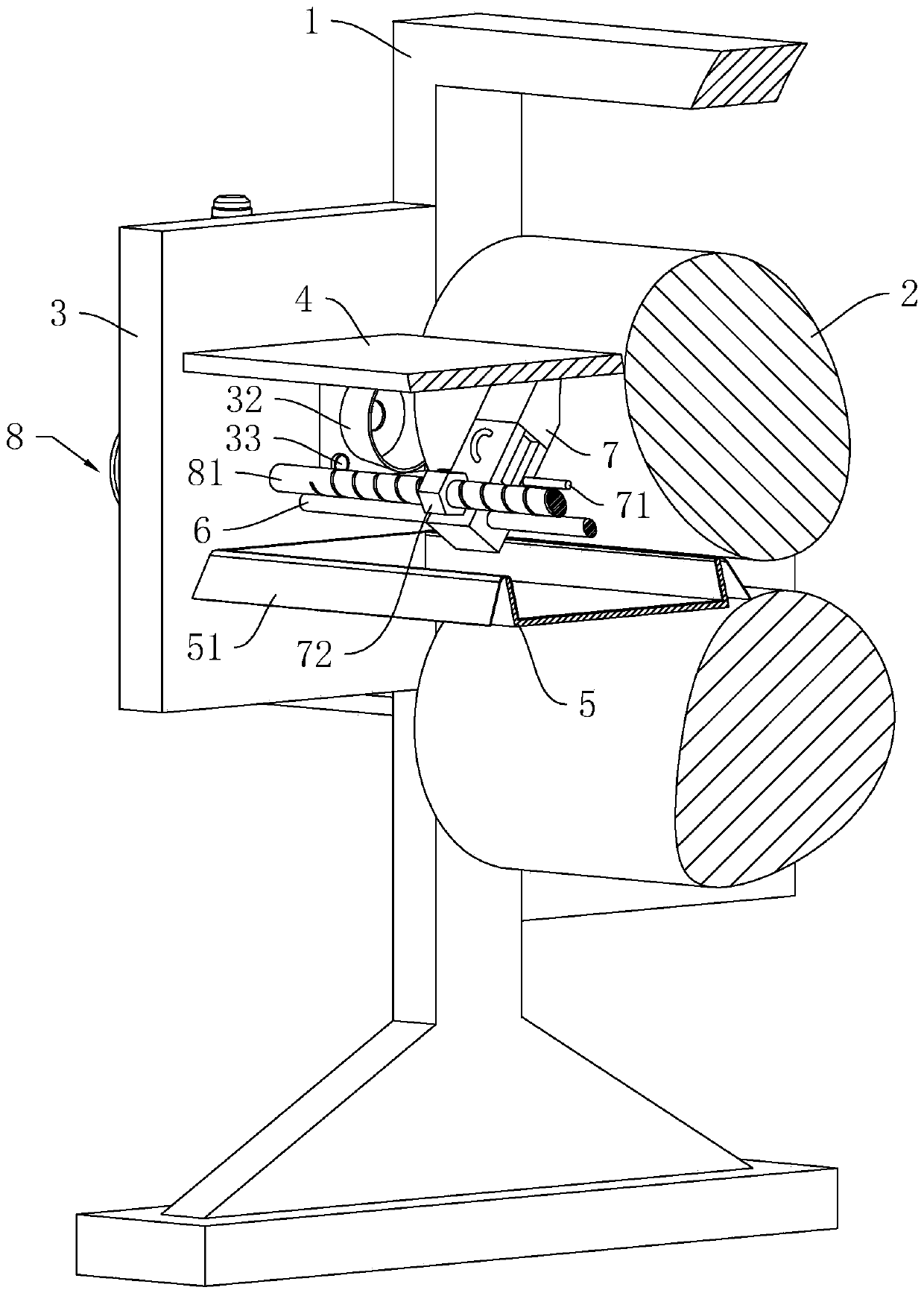

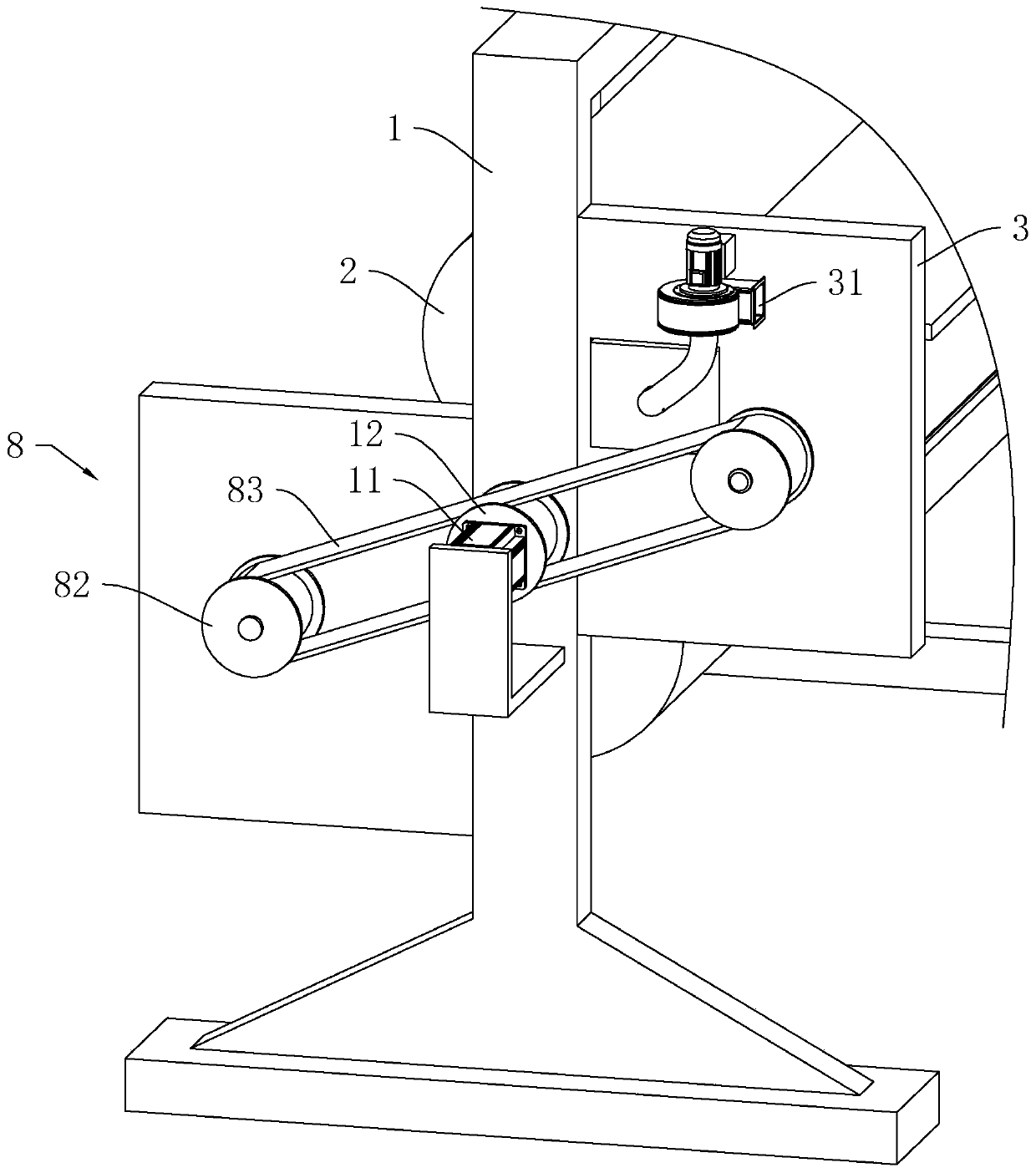

[0041] Embodiment 1: as figure 1 , figure 2 Shown, a kind of warp-knitted supersoft sofa fabric ironing machine comprises a frame 1, and a pair of ironing rollers 2 that are distributed up and down are rotatably connected in the frame 1.

[0042]When using the above-mentioned ironing machine, after the fabric crosses the outer wall of the upper end of the ironing roller 2 located above, the fabric is passed through the gap between a pair of ironing rollers 2, and finally the fabric is wound around the lower ironing roller. After the outer wall of the lower end of the ironing roller 2, the feeding of the fabric is realized. Then the relative rotation of the ironing roller 2 can be controlled to realize the continuous transmission and ironing operation of the fabric.

[0043] Such as figure 1 , figure 2 As shown, a pair of mounting seats 3 are provided on the front and rear sides of the frame 1 , and each pair of mounting seats 3 is distributed at both ends of the frame 1 ...

Embodiment 2

[0062] Embodiment 2: a kind of production technology of warp-knitted supersoft sofa fabric has applied above-mentioned ironing machine, comprises the steps:

[0063] S1, weaving, weaving the raw materials with a spray-painted weaving machine;

[0064] S2, fluffing, use the fluffing machine to evenly pull out a layer of fluff or long hair on the surface of the fabric, so that the fabric is thick and soft;

[0065] S3, ironing, using the ironing machine to process the fabric, so that the surface of the fabric is bulky, full of fluff, straight and bright;

[0066] S4, shearing, use a shearing machine to trim the fluff or long hairs of different lengths on the surface of the fabric, or cut the loops;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com