Crawler trencher with adjustable trenching depth

A technology of crawler type and ditching machines, which is applied in the direction of earth movers/excavators, construction, etc., which can solve the problems that the ditching machine cannot be constructed, increases the labor intensity and operation cost of workers, and slows down the progress of ditching. Reduce the labor intensity of workers, the working method is simple and efficient, and the effect of ensuring the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

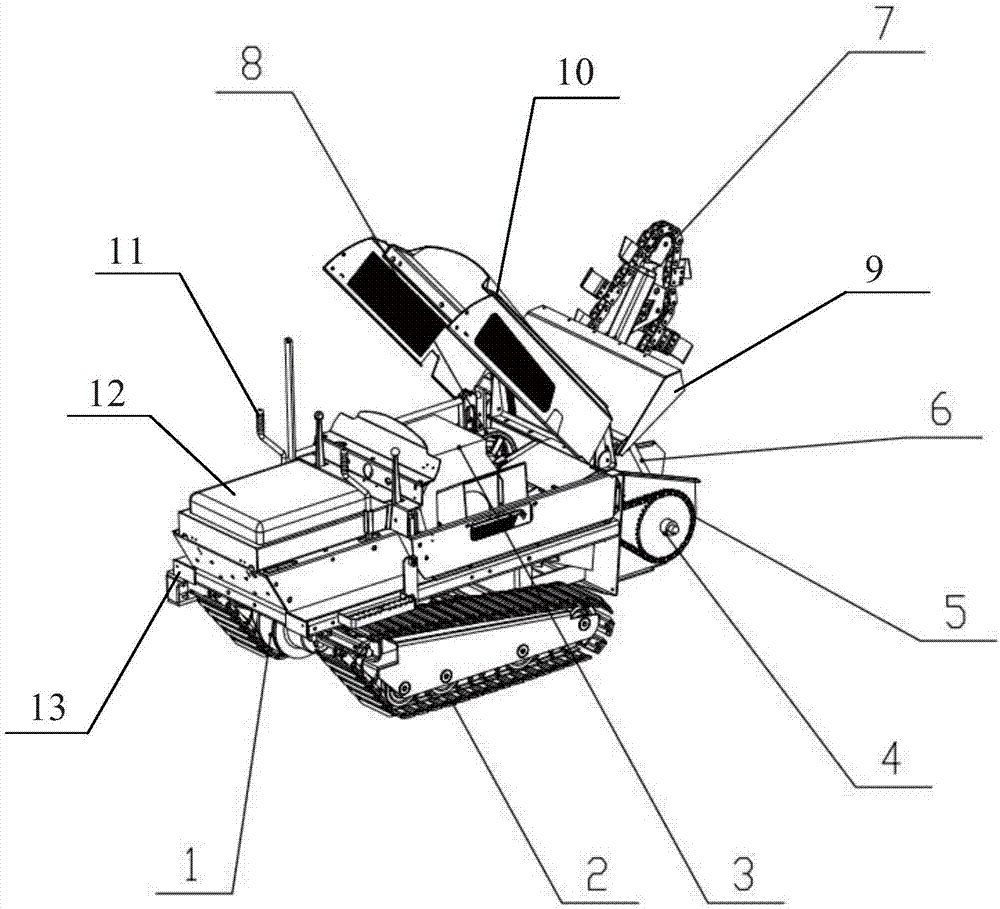

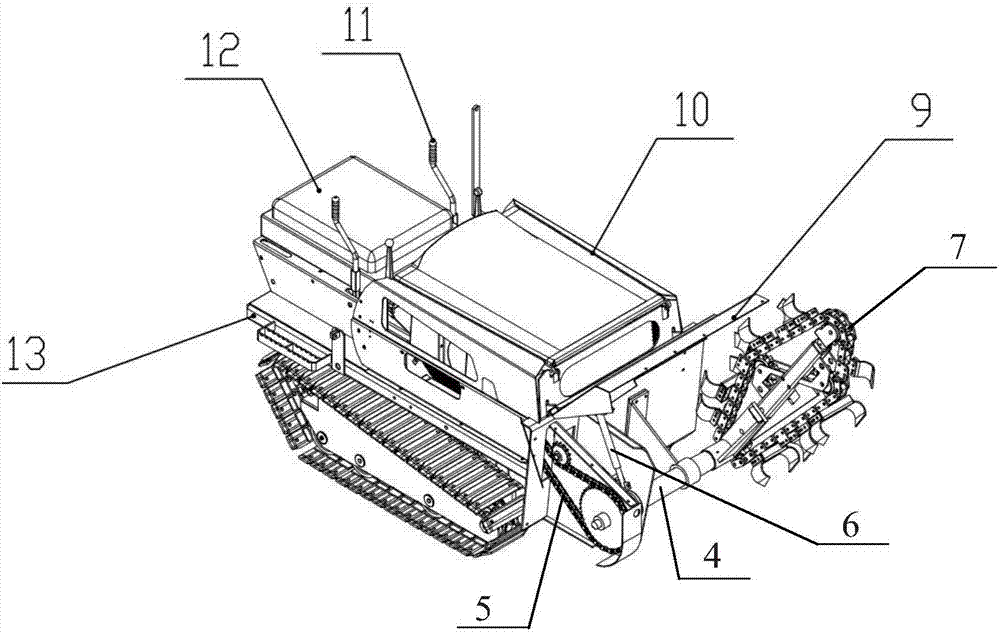

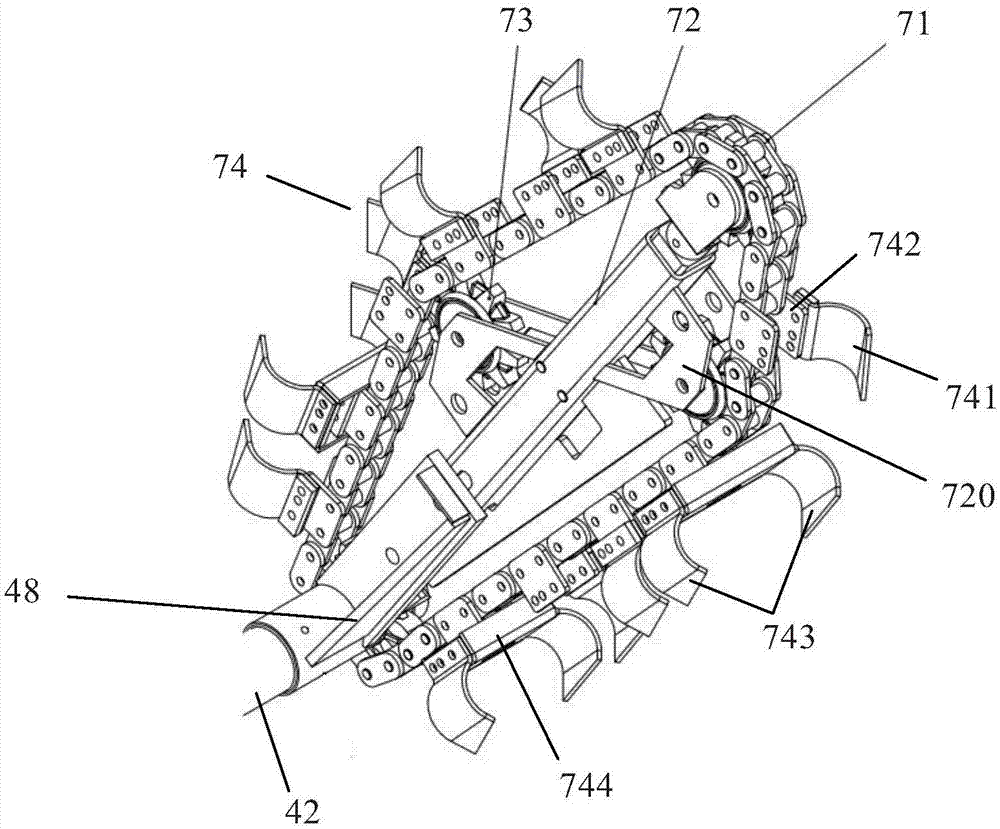

[0026] like Figure 1 to Figure 4 , the crawler type ditching machine with adjustable ditching depth of the present invention includes a frame 13, on which a driver's seat 12, a manipulation device 11, a hydraulic control device 3, and a drive device 8 are installed; Mechanism 1 and walking crawler belt 2, the walking transmission mechanism 1 drives the walking crawler belt 2 to run under the drive of the driving device 8; a chain transmission mechanism 5 and a working main shaft 4 are installed in front of the frame 13, and a ditching tool device 7 is installed on the working main shaft 4 The working main shaft 4 drives the ditching knife 74 on the ditching tool device 7 to rotate under the drive of the chain transmission mechanism 5 to carry out the ditching operation; the chain transmission mechanism 5 is connected with the driving device 8 and is controlled by the driving device 8; the working main shaft 4. The hydraulic telescopic rod 6 is connected to the hydraulic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com