Patents

Literature

105results about How to "Simple way of working" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for sending uplink data, base station, user equipment and communication network

ActiveCN103986566AAvoid shockImprove efficiencyTransmission path multiple useNetwork planningResource blockControl channel

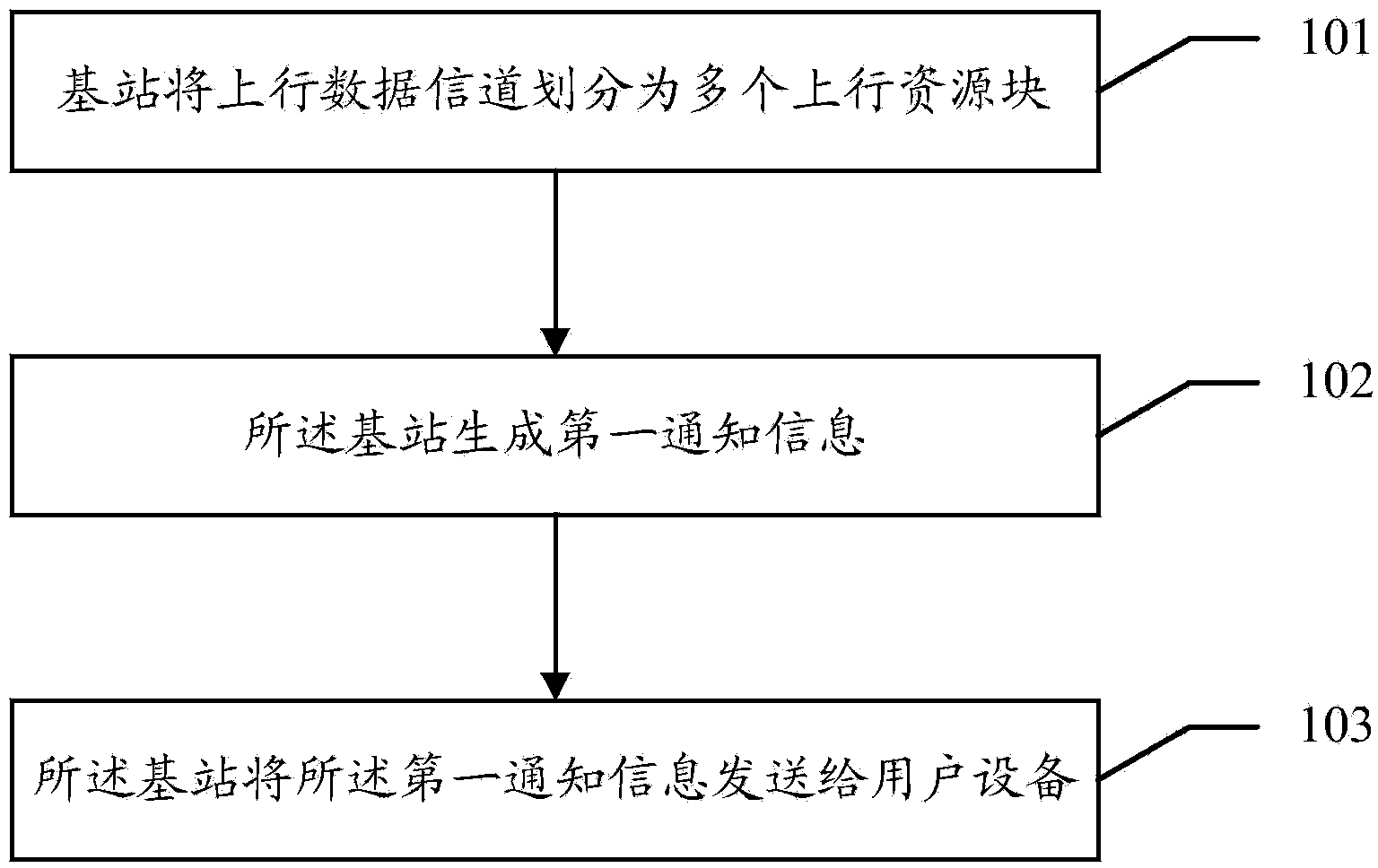

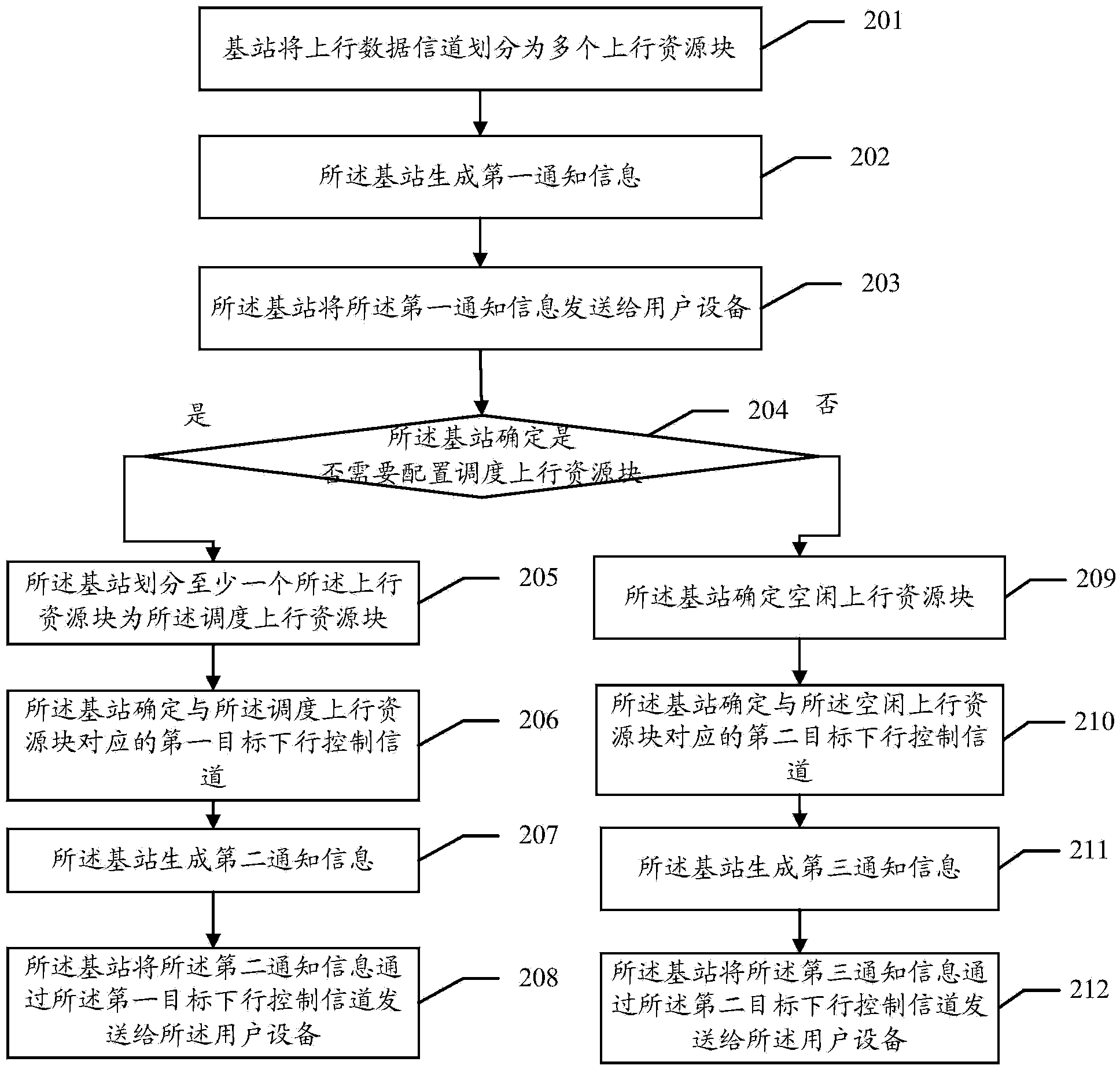

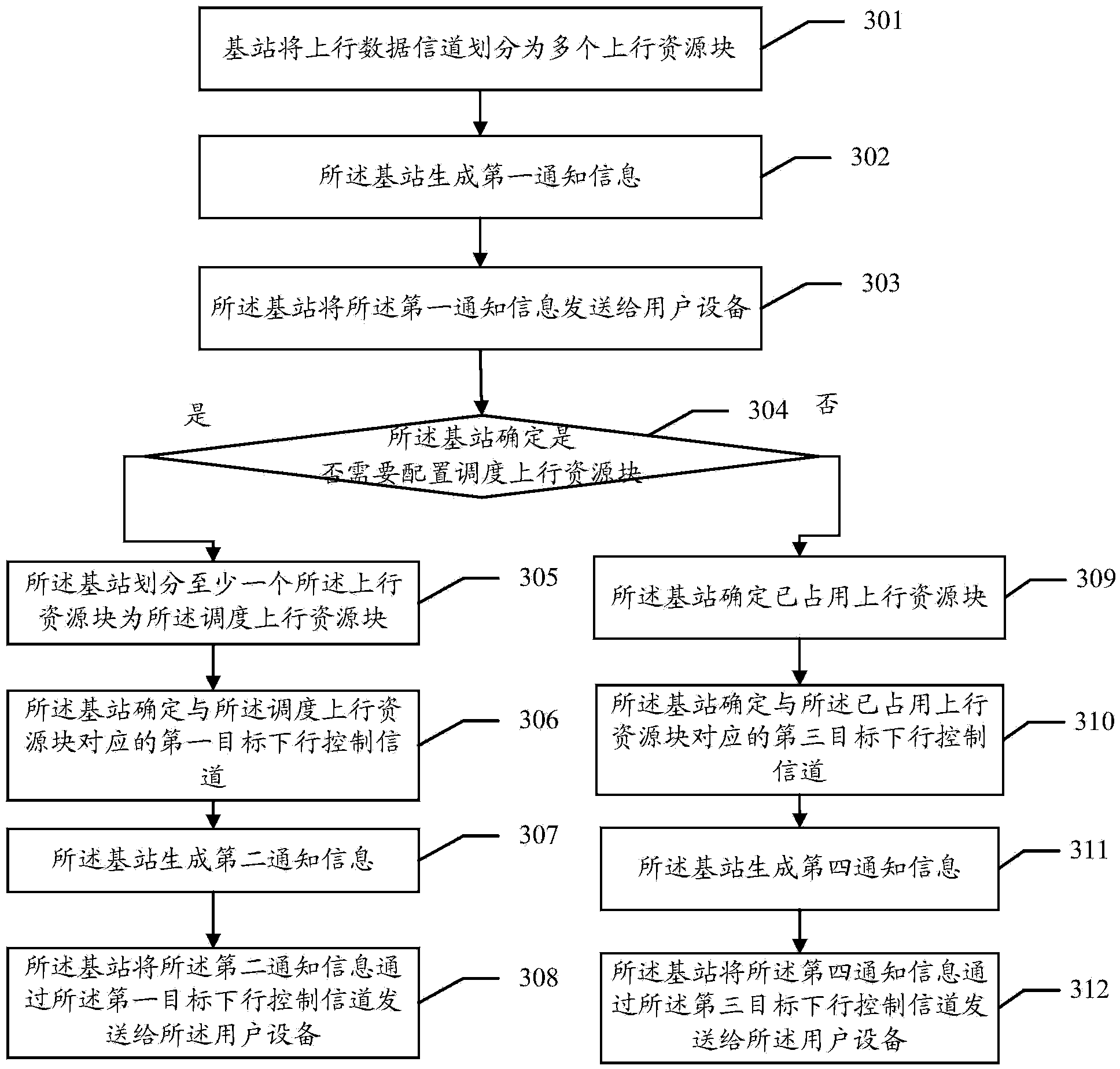

The embodiment of the invention discloses a method for sending uplink data, a base station, user equipment and a communication network. The method includes the steps that the base station is used for dividing an uplink data channel into a plurality of uplink resource blocks, and all the uplink resource blocks are in mutual orthogonality; the base station generates a first notification message which is used for indicating downlink control channels corresponding to all the uplink resource blocks and determined by the base station; the base station sends the first notification message to the user equipment so that the user equipment can monitor the downlink control channels so as to select a target uplink resource block used for sending uplink data, and the uplink data are sent through the target uplink resource block. In the embodiment, due to the fact that the uplink data channel is divided into the uplink resource blocks by the base station, the sending method can well support small data packages so that when network loads are light, high efficiency can be achieved.

Owner:SHANGHAI HUAWEI TECH CO LTD

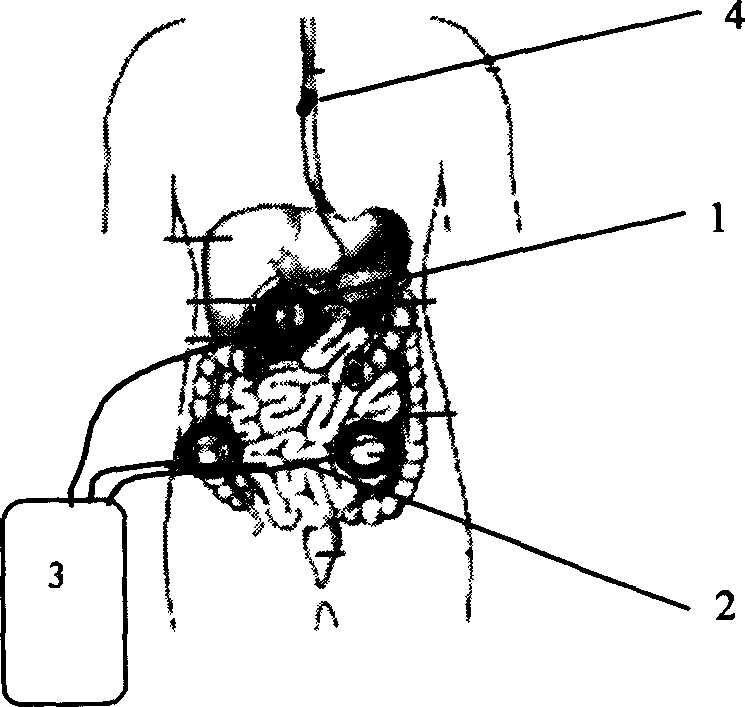

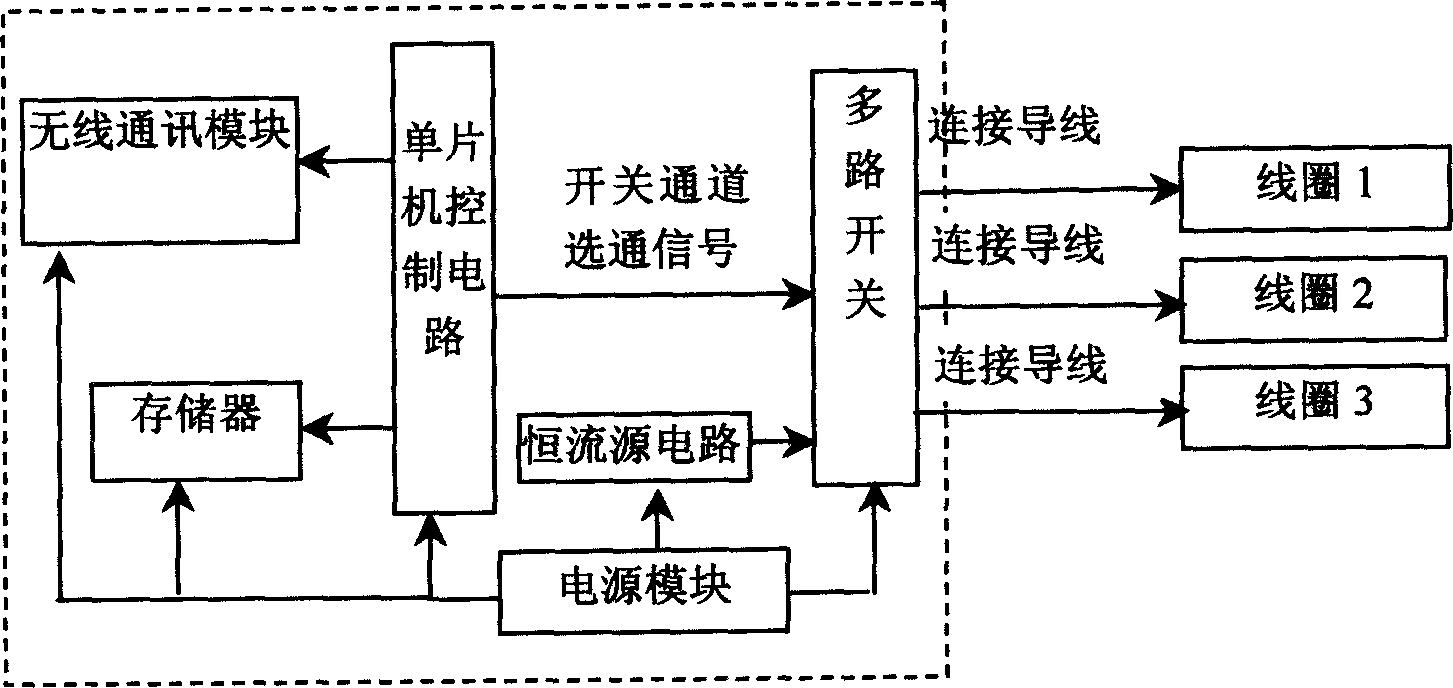

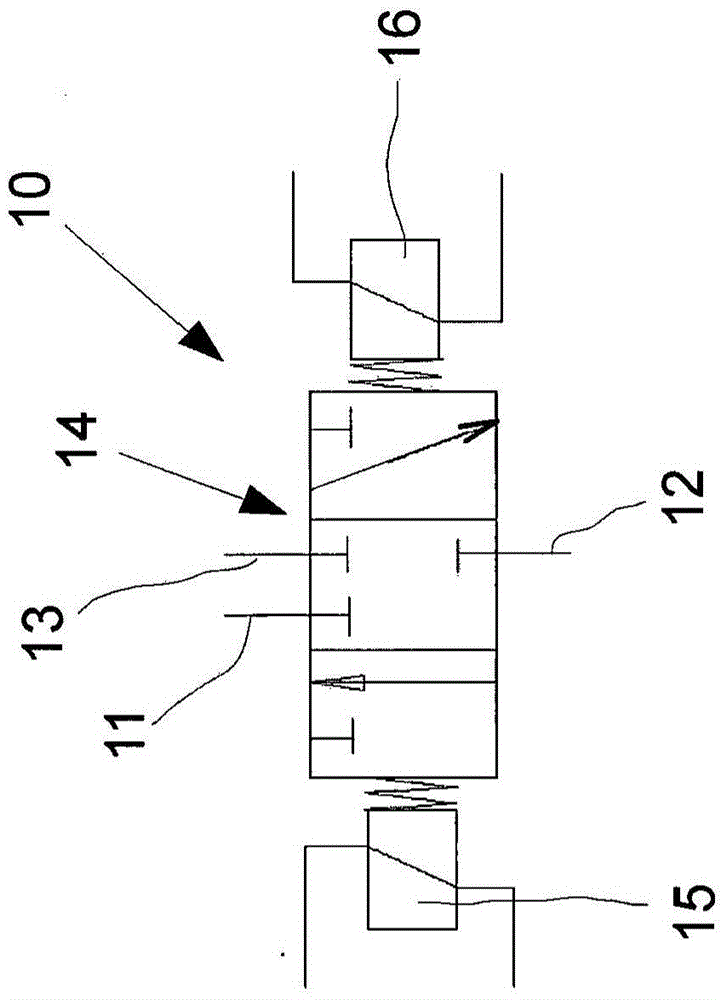

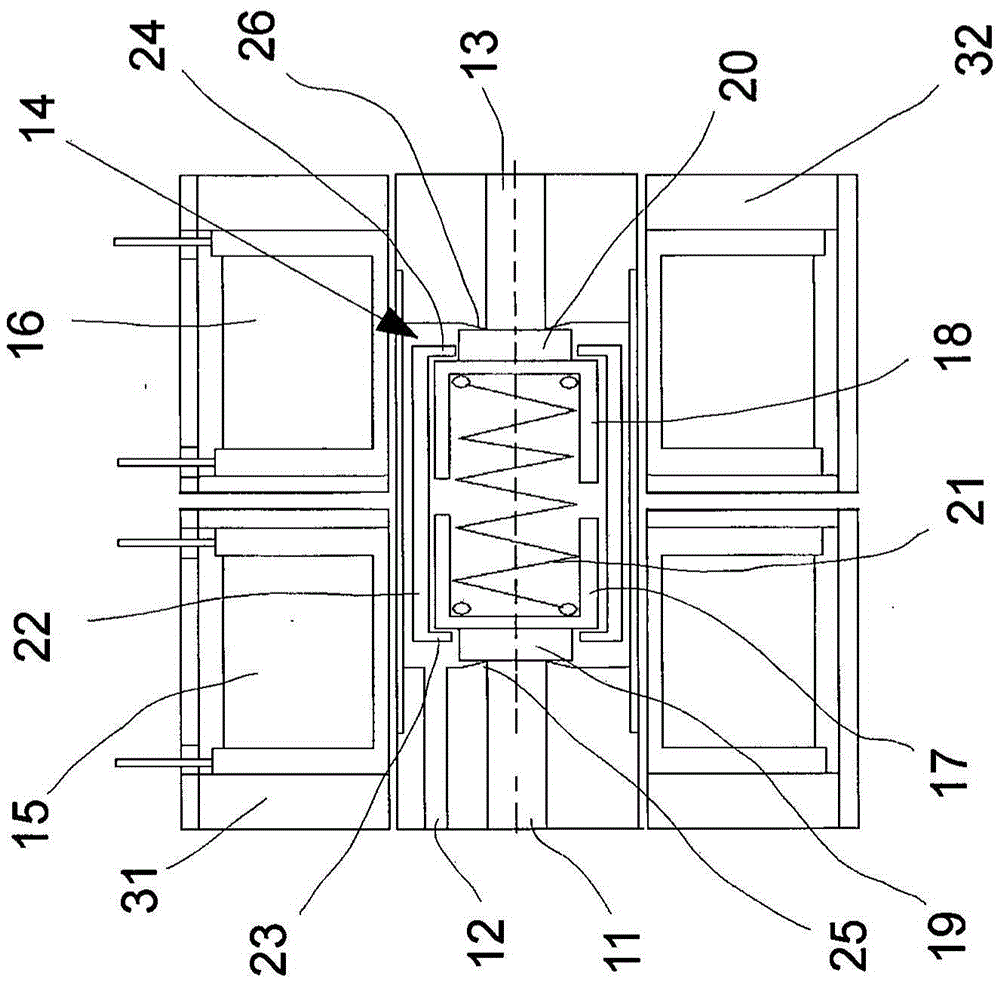

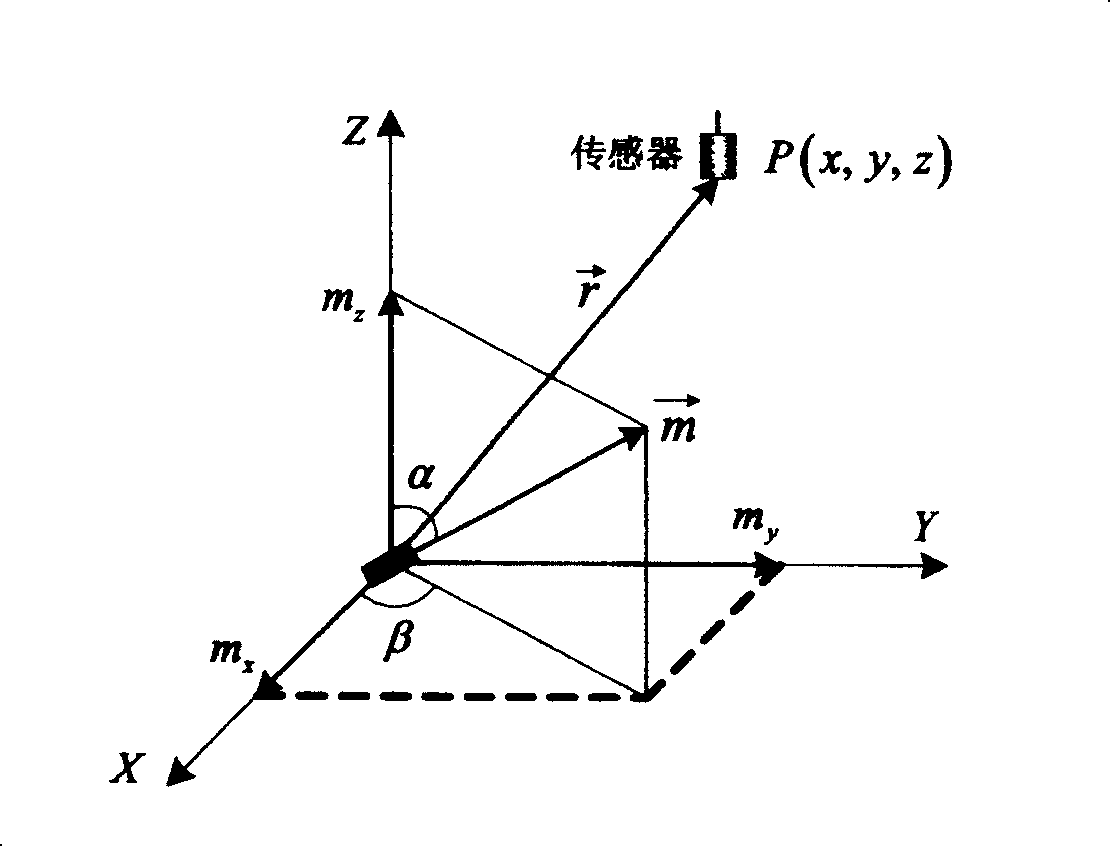

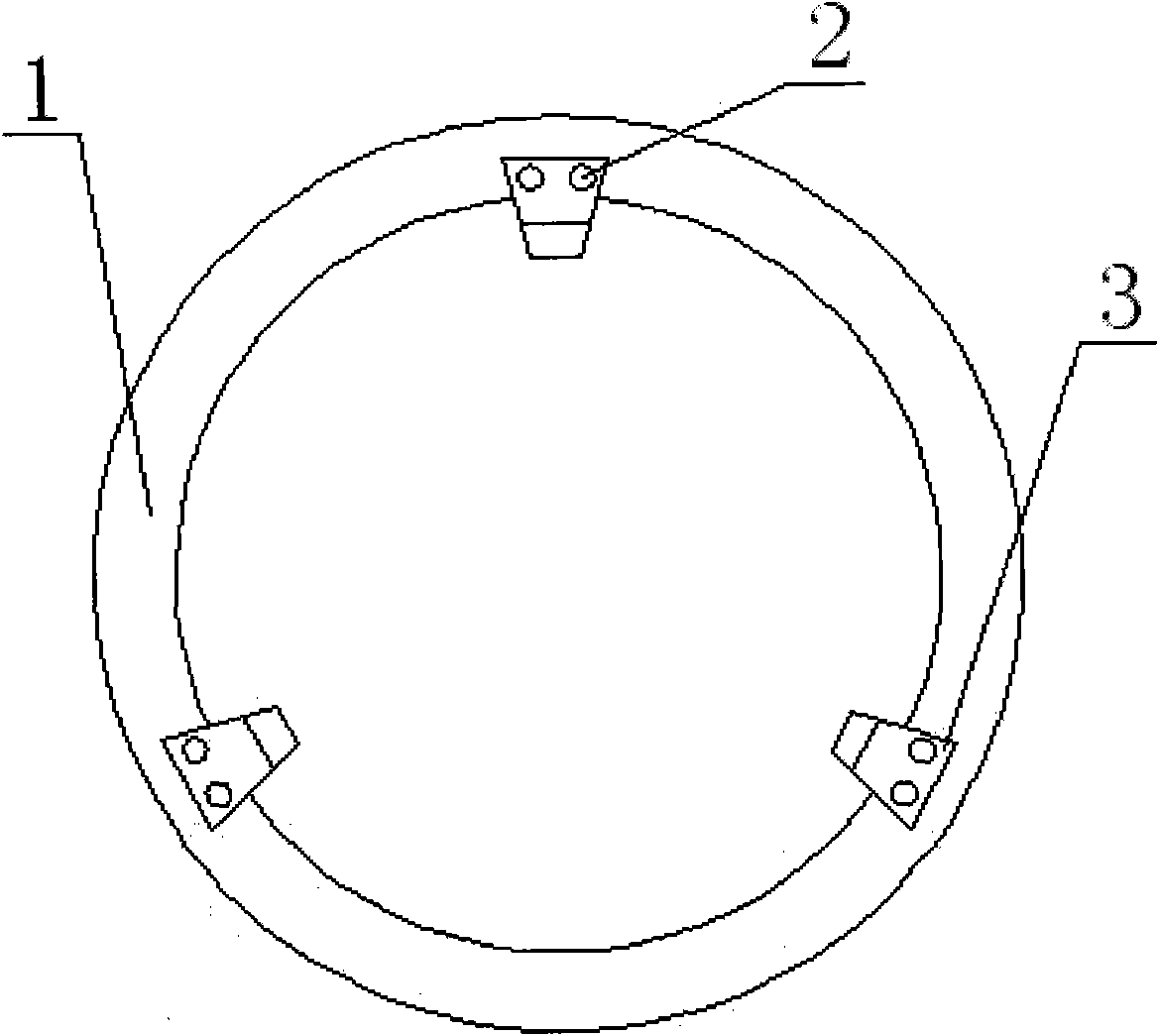

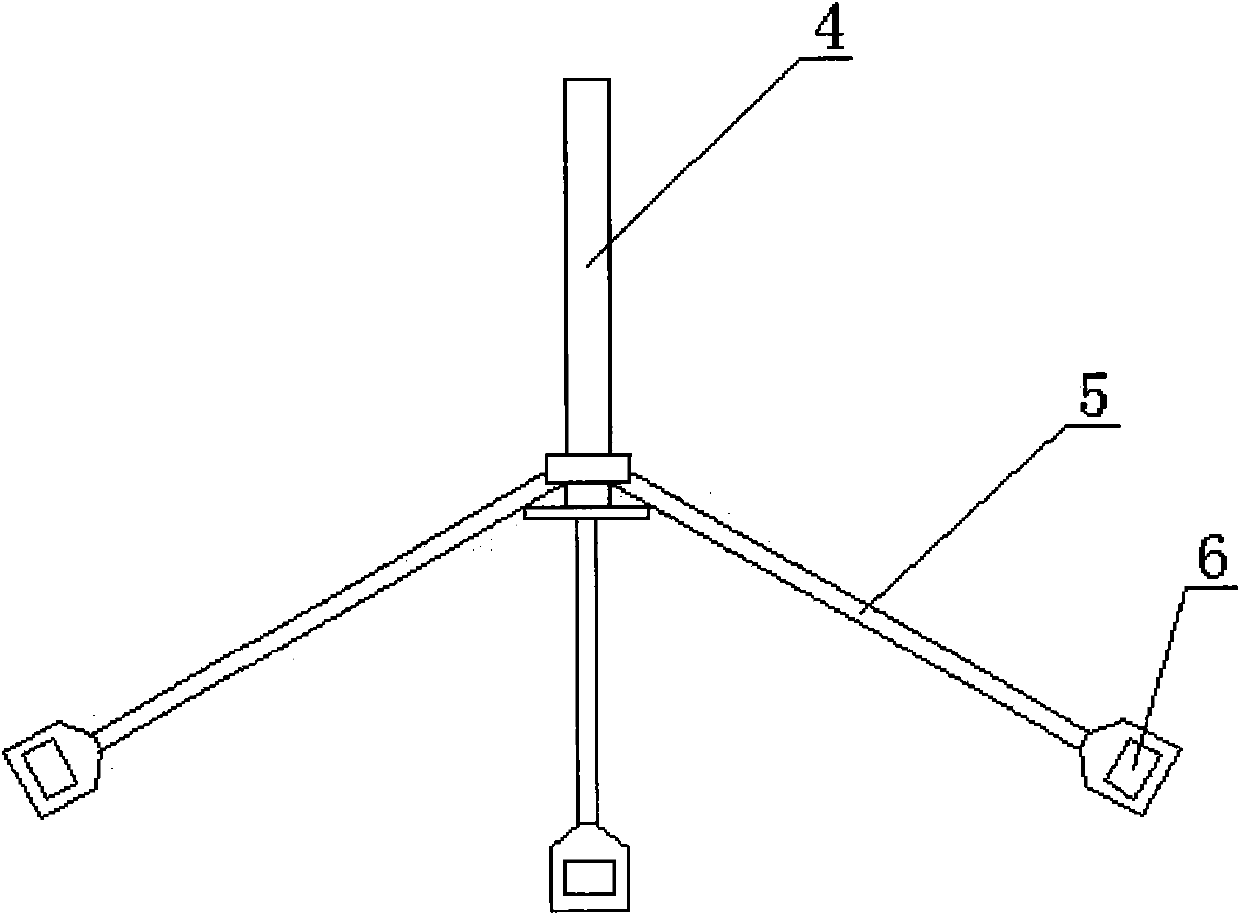

In vitro electro-magnetism excitation positioning system for remotely monitoring capsule swallowed in digestive tract

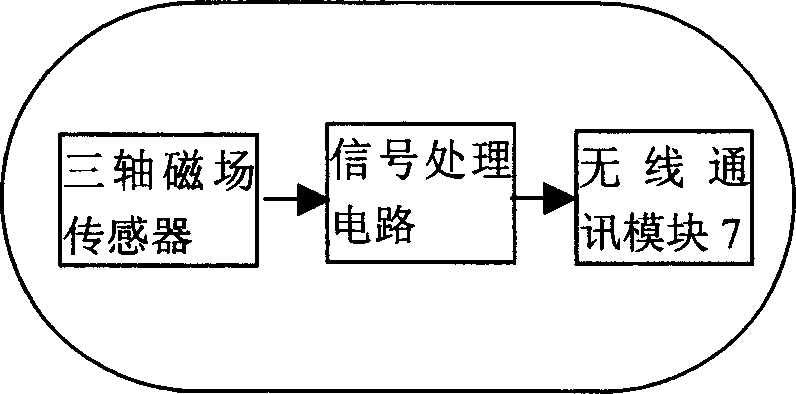

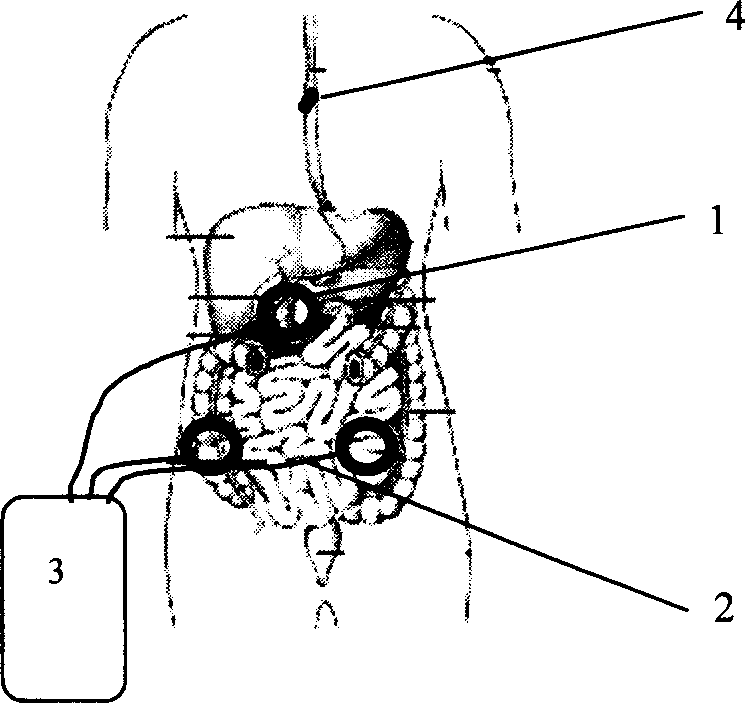

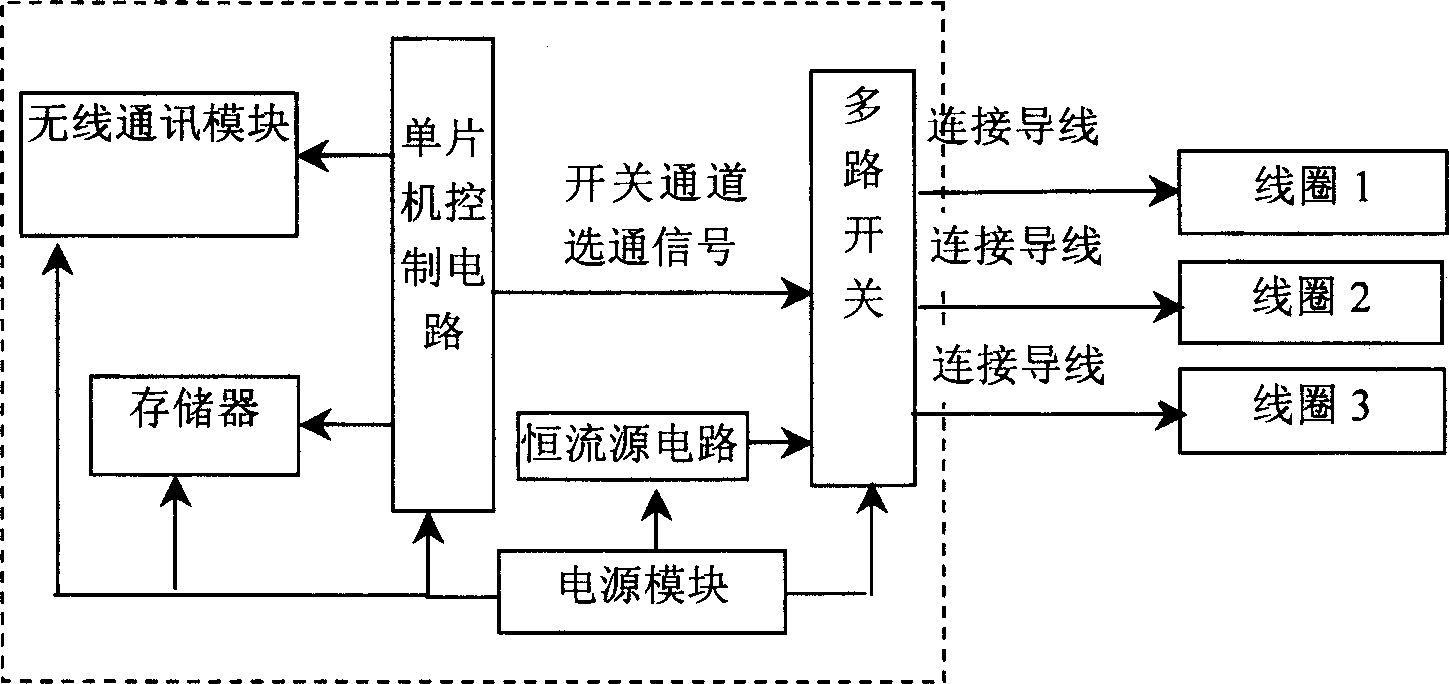

InactiveCN1620985AEasily damagedNo damageEndoscopesDiagnostic recording/measuringMicrocontrollerSignal processing circuits

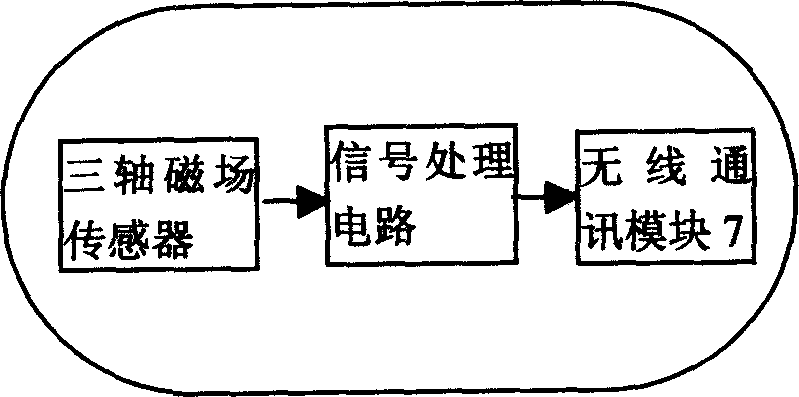

The digestive tract remote measuring capsule electromagnetically positioning system includes sealed capsule with three-axis magnetic field sensor, signal processing module and radio communication module; three extracorporeal ring static magnetic field exciting coils; and extracorporeal data record instrument comprising monochip computerized control circuit, constant-current source circuit, multiplex switch, radio communication module, memory and power source module. During system operation, the three coils are fixed onto the surface of body to produce magnetic field under the excitation of the current from the instrument successively, the intracorporeal capsule detects the magnetic fields and produces and emits digital signal, and the instrument receives, saves and processes the signal, so as to obtain the 3D locus of the capsule.

Owner:SHANGHAI JIAO TONG UNIV

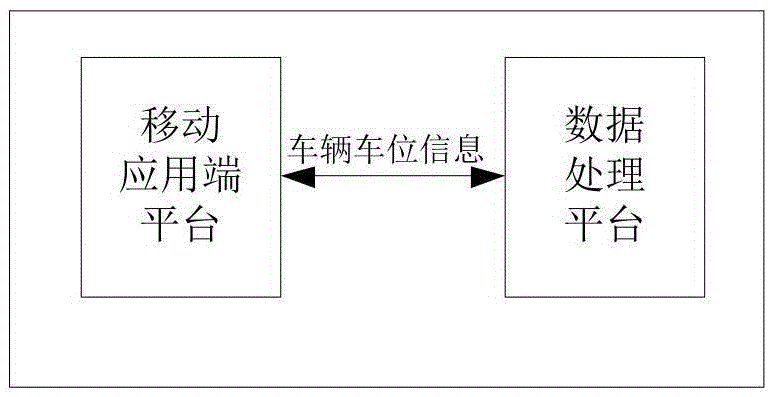

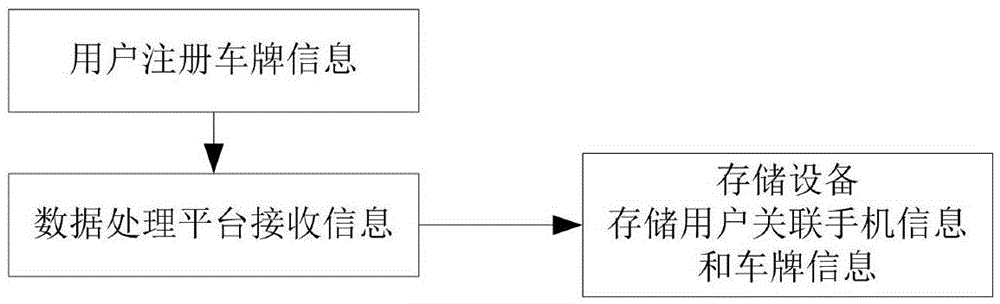

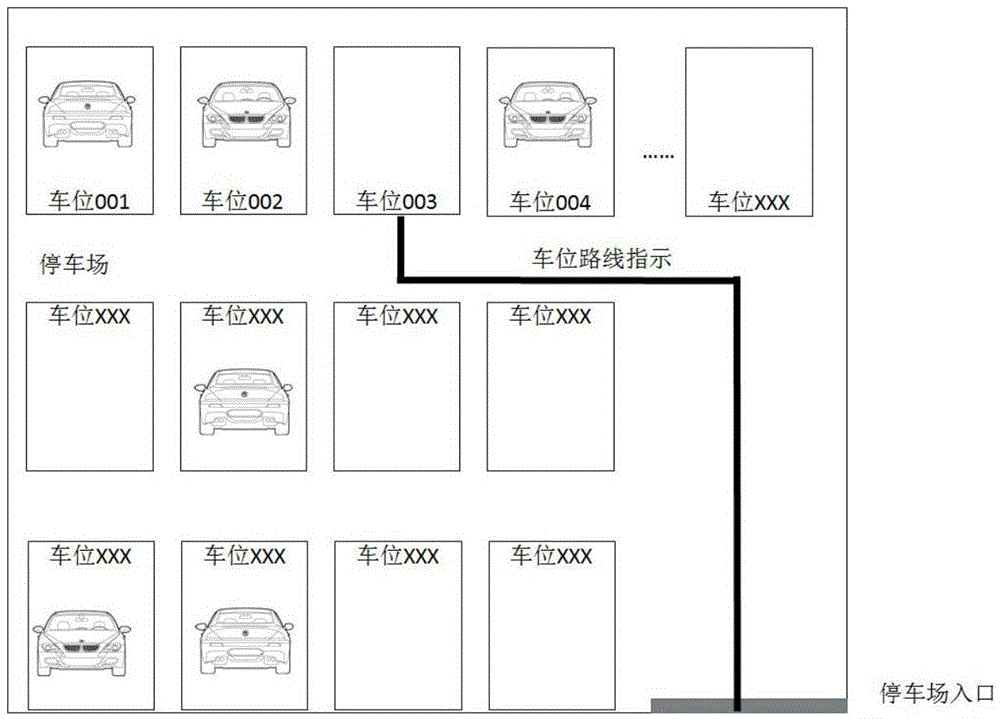

Intelligent garage management application system and method

ActiveCN105489054AEfficient Parking SolutionsConvenient Parking SolutionTicket-issuing apparatusIndication of parksing free spacesWireless dataMarine navigation

The invention relates to an intelligent garage management application system and method. The system comprises a mobile application platform and a data processing platform, and the mobile application platform is connected with the data processing platform via the wireless network. The mobile application platform sends a parking stall request instruction to the data processing platform, the data processing platform sends a parking stall sketch map including parking stall information to the mobile application platform, after parking, the mobile application platform sends parking install information, including identification of a parking stall of the intelligent garage, to the data processing platform, and the data processing platform processes the parking stall information and then records and stores the vehicle parking information. The method comprises a navigation management application method of the intelligent garage and an inverse vehicle searching management application method of the intelligent garage. The system and method have the advantages that via wireless data exchange, a high-efficiency convenient parking scheme is provided for users, the users are guided to park and find the vehicle via navigation, and the problem that parking and vehicle searching are difficult and tedious is solved.

Owner:INTELLIGENT INTER CONNECTION TECH CO LTD

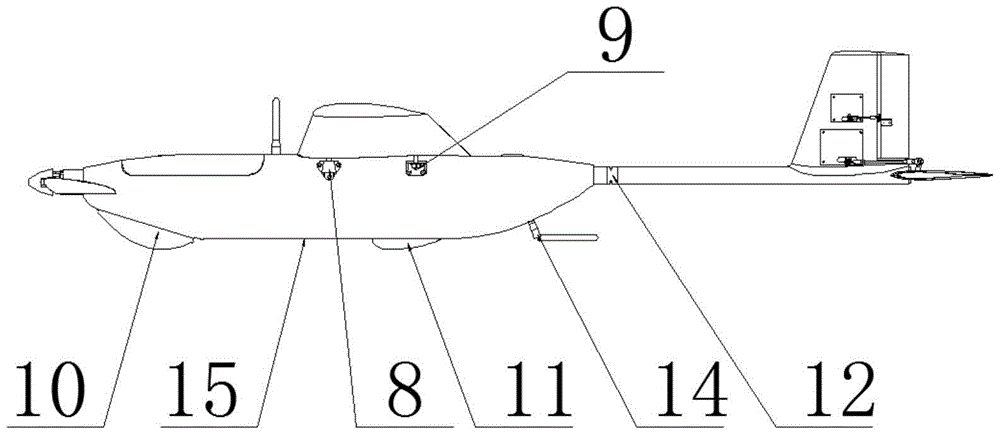

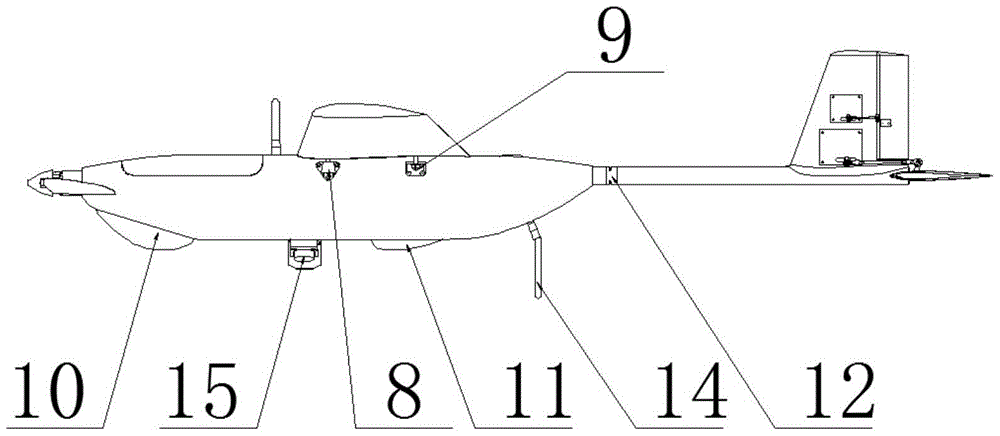

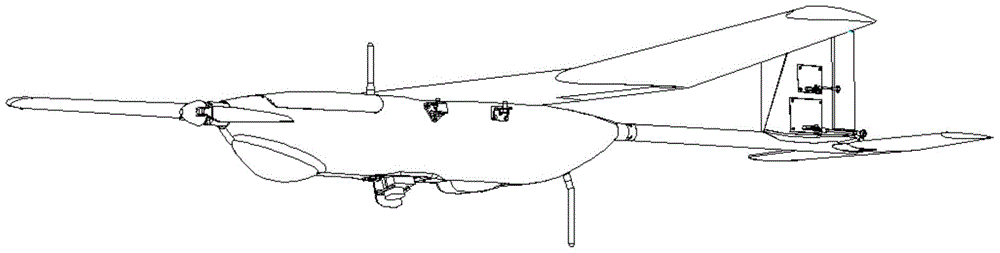

Small-sized light unmanned aerial vehicle structure with strike-resistant and impact dispersing and recycling functions

The invention provides a small-sized light unmanned aerial vehicle structure with strike-resistant and impact dispersing and recycling functions. The small-sized light unmanned aerial vehicle structure comprises a propeller, a fuselage, wings, a tail pipe, a horizontal tail and a vertical tail. The propeller is installed on the head of the fuselage. Rubbing blocks which are made of abrasion-proof materials are installed at the bottom of the fuselage. The rear end of the fuselage is connected with the tail pipe, and the axis of the tail pipe and the axis of the fuselage are located on the same straight line. The fuselage is detachably connected with the wings, the fuselage is detachably connected with the tail pipe, and the tail pipe is detachably connected with the horizontal tail. The unmanned aerial vehicle structure is simple, convenient to dismount and mount, easy to carry, short in preparation time of expansion operation, low in weight, capable of taking off in a hand throwing mode and being recycled after strike, and concise in working mode. Deep stall strike recovery can be achieved, and undamaged recovery can be realized by automatically loosening detachable parts.

Owner:NAT UNIV OF DEFENSE TECH

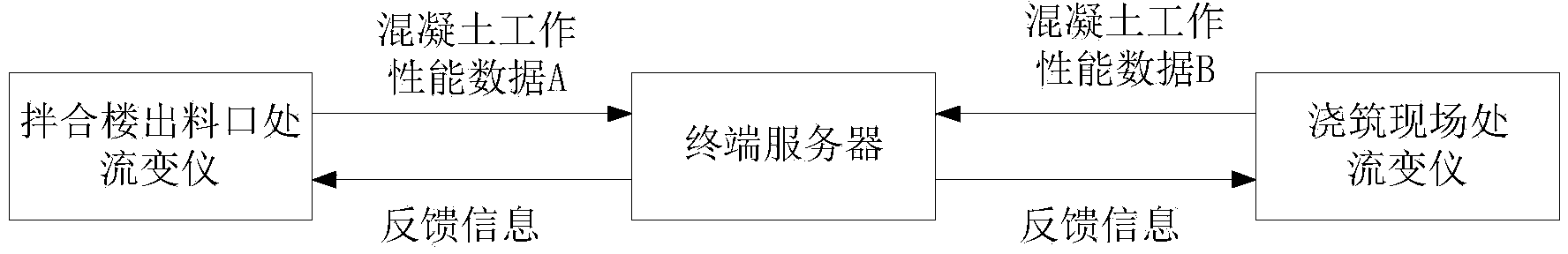

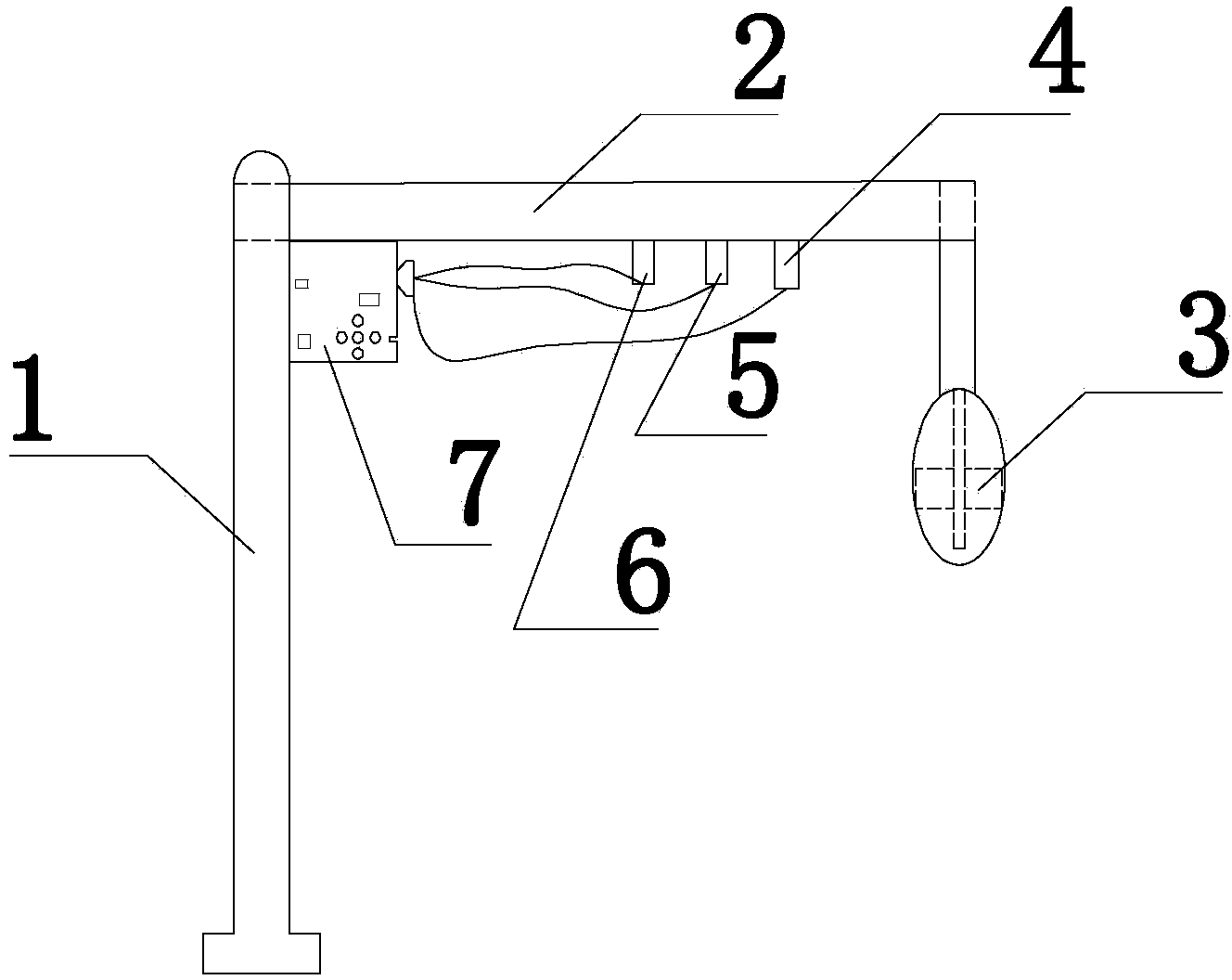

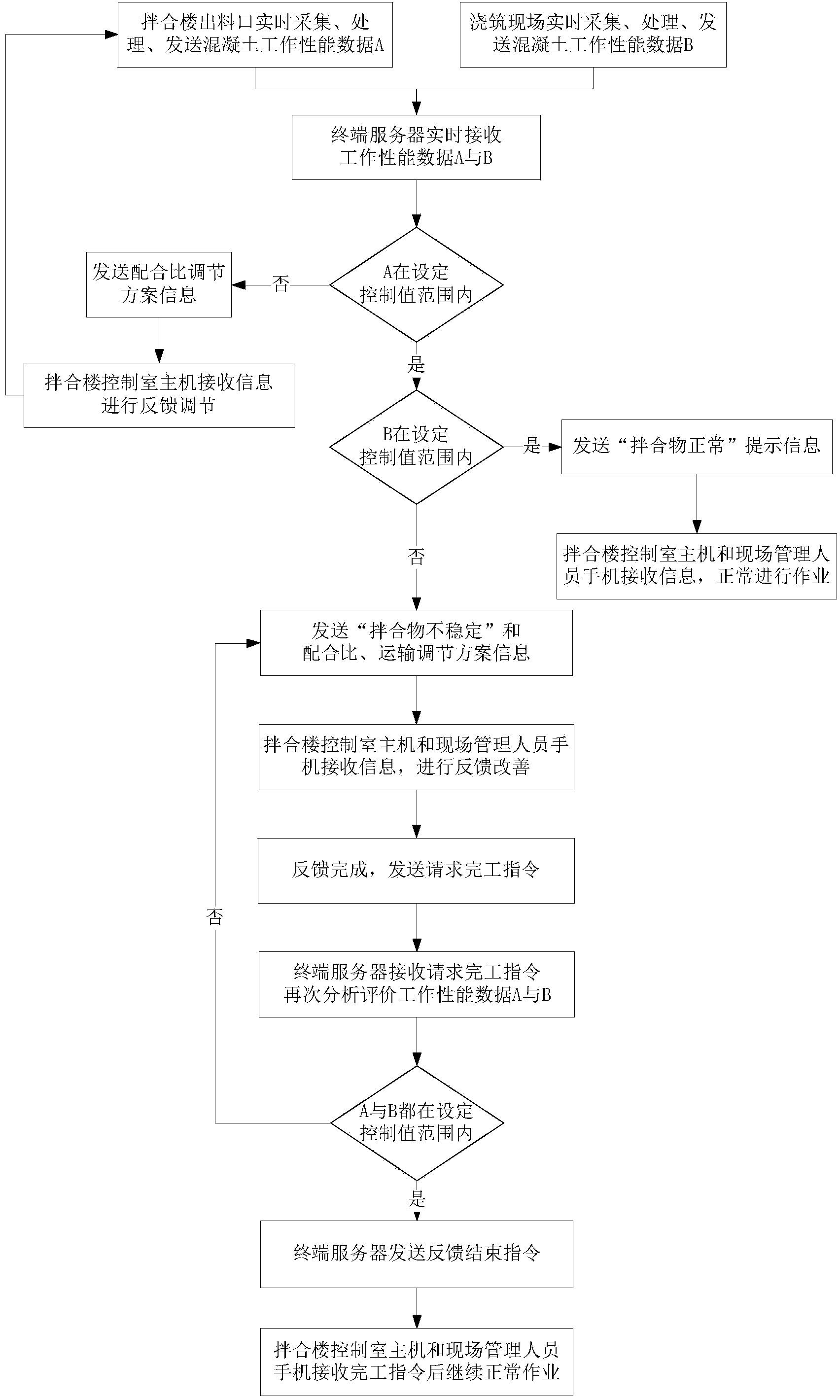

Online intelligent monitoring method for working performance of concrete at construction site

InactiveCN104345718AEnsure quality stabilityAvoid big differences in workabilityTotal factory controlProgramme total factory controlTerminal serverWork performance

The invention discloses an online intelligent monitoring method for working performance of concrete at a construction site. Through real-time collection and detection of an ageing change rule of rheological parameters of mixtures in the same mixing batch at a mixing floor discharge hole and the construction site, and the methods of analyzing, evaluating and feeding back by a terminal server, the working performance of the concrete in construction and transportation processes is monitored in real time. According to the online intelligent monitoring method, automatic intelligence of the detection process is achieved, overlarge deviation in difference of the working performance of the concrete at the construction site can be avoided, and the quality stability of the concrete mixture is ensured.

Owner:HOHAI UNIV +1

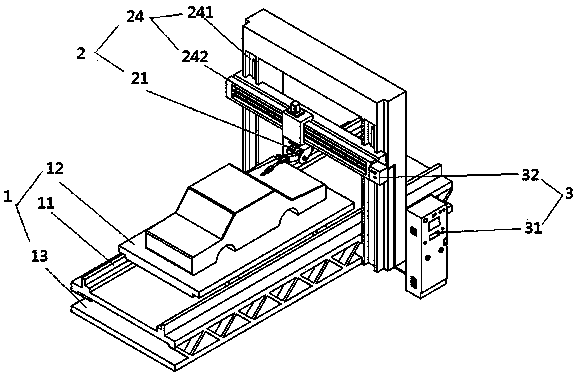

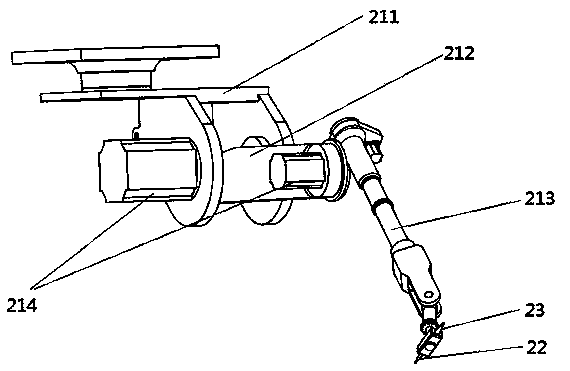

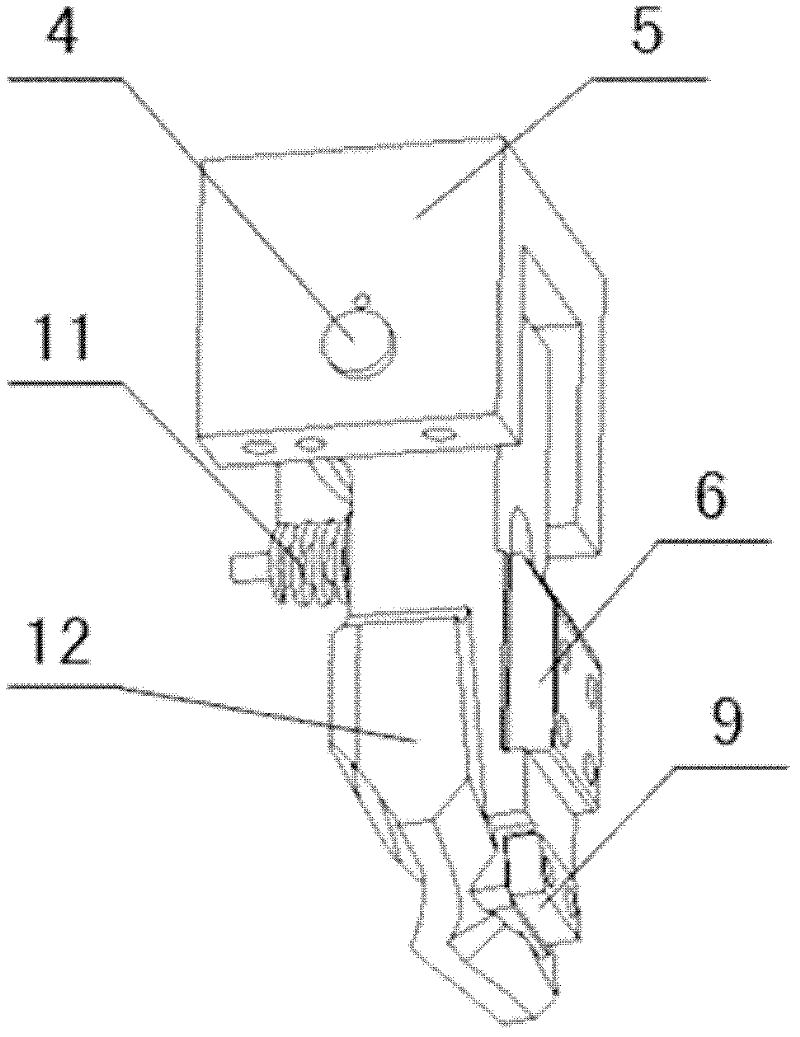

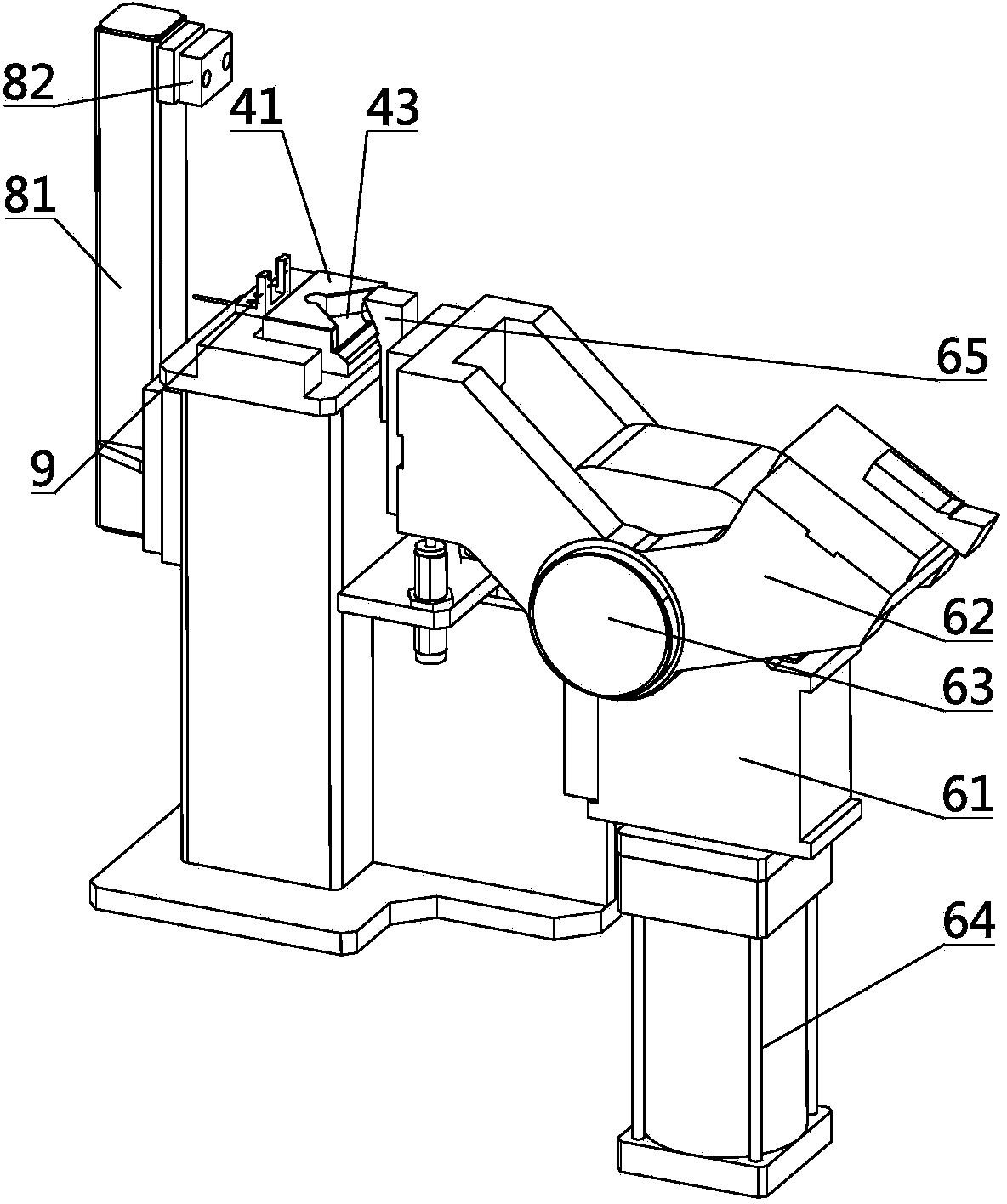

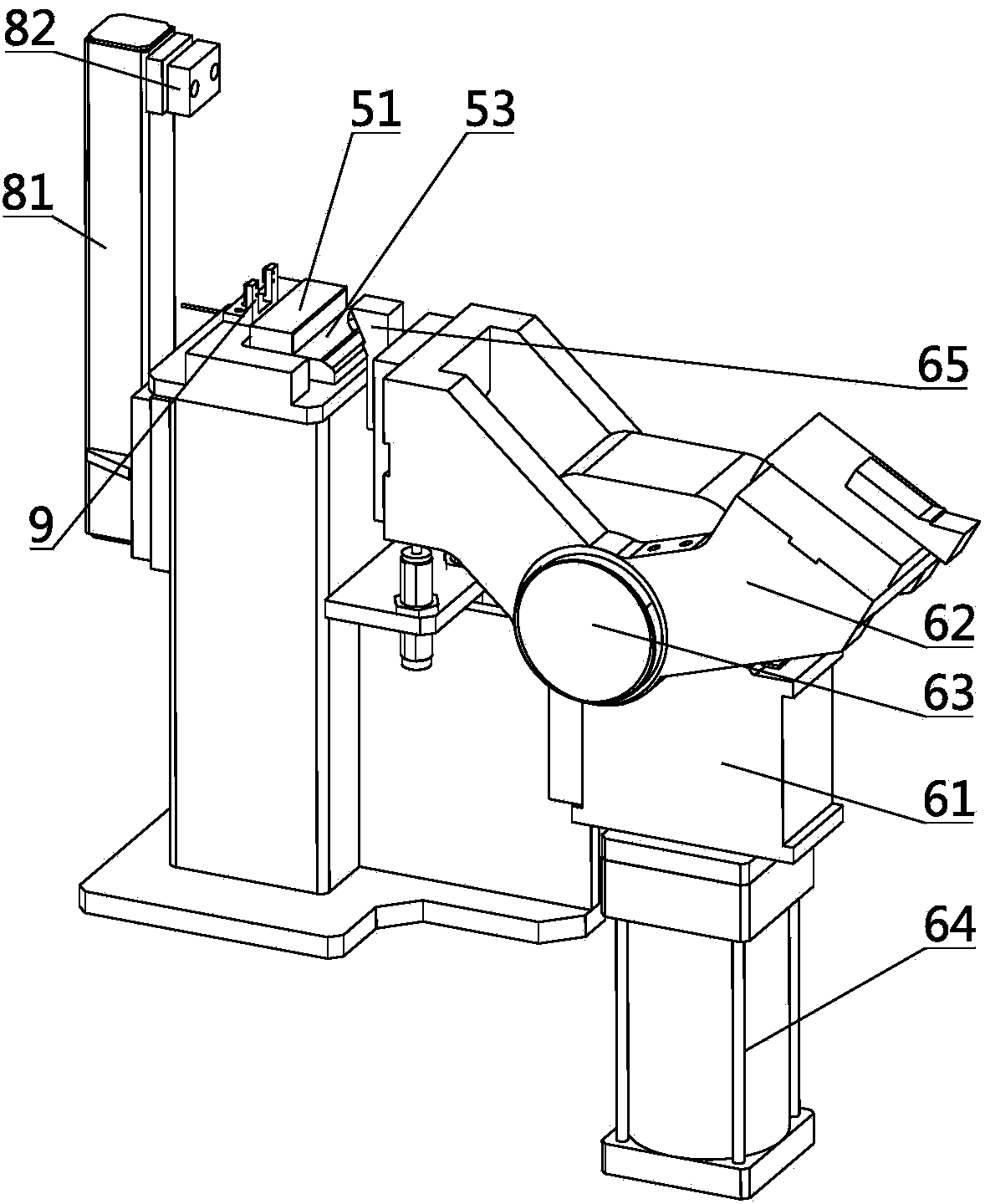

Undamaged disassembling device of windscreen of scraped car

ActiveCN104210573ASimple way of workingLow costVehicle dissasembly recoverySolid waste disposalSoftwareWindshield

The invention discloses an undamaged disassembling device of a windscreen of a scraped car. The undamaged disassembling device comprises a conveying part, a mechanical arm part and a control part, wherein the conveying part is used for conveying a to-be-disassembled car, the mechanical arm part is used for detecting the windscreen edge and cutting, the control part is used for controlling cutting parameters and a cutting path, the mechanical arm part comprises a mechanical arm, the tail end of the mechanical arm is provided with a windscreen edge detection sensor and a cutter, the windscreen edge detection sensor and the cutter are respectively and electrically connected with the control part, the windscreen edge detection sensor is used for detecting three-dimensional parameters of a plurality of feature points of the windscreen edge and sending the three-dimensional parameters to the control part, and the control part is used for determining the cutting path according to the three-dimensional parameters, sent from the windscreen edge detection sensor, of the feature points and controlling the cutter to cut according to the cutting path. According to the undamaged disassembling device disclosed by the invention, the calibrating on an outer starting position or an outer key position does not need to be carried out; complicated software processing is not needed; a human-computer interaction mode is adopted, and the production cost and the use cost are reduced.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

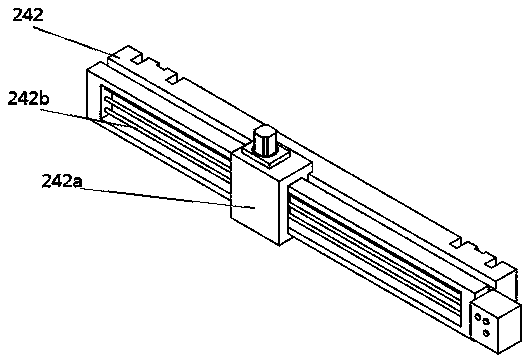

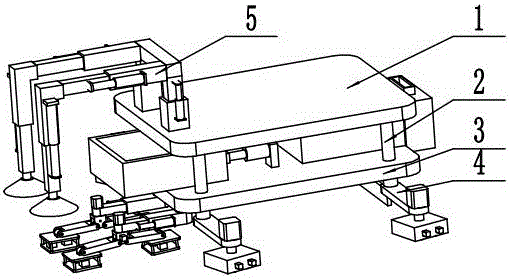

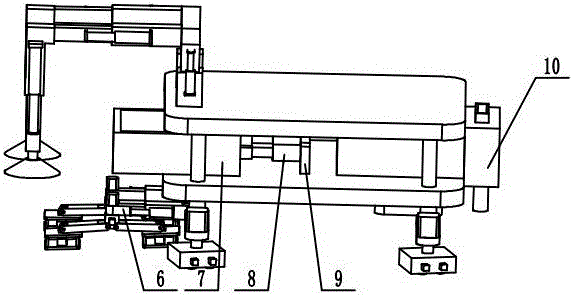

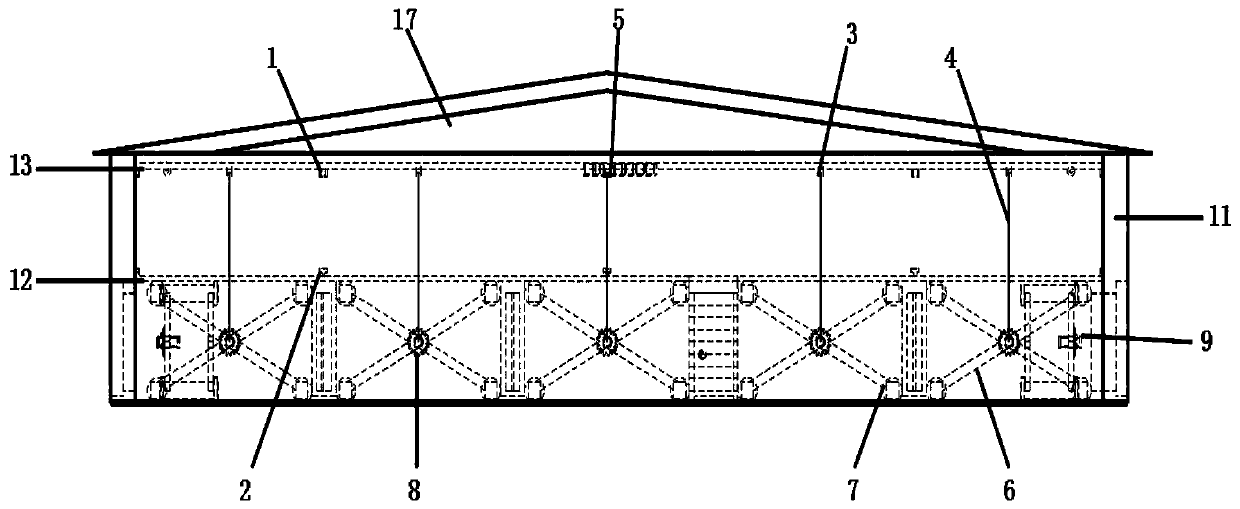

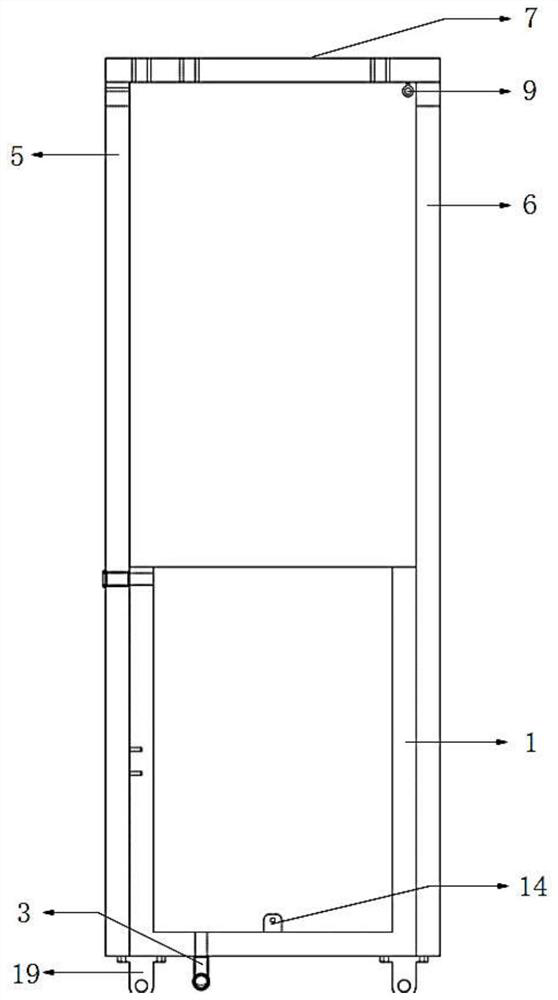

Ground tile laying robot

InactiveCN106760445AImprove work efficiencySimple way of workingBuilding constructionsEngineeringCeramic tiles

A ground tile laying robot comprises an upper plate, columns, a lower plate, four walking mechanisms, a laying mechanism, a compaction mechanism, ceramic tile frames, two first electrical cylinders, two electrical cylinder bases, a cement box, a rear rod, a first servo motor, a scraping plate, an upper end plate, second electrical cylinders and a lower end plate and is characterized in that four columns are arranged between the upper plate and the lower plate and are located at the positions of four corners respectively, the four walking mechanisms are installed at the positions of four corners of the lower surface of the lower plate, the two electrical cylinder bases are arranged at the position, close the back, of the cement box on the lower plate, the rear-end portions of the two first electrical cylinders are installed on the electrical cylinder bases respectively, and the front-end portions of the two first electrical cylinders are installed on connecting parts of the ceramic tile frames. The ground tile laying robot is provided with the ceramic tile frames, the working efficiency of the robot can be improved by pre-placing ceramic tiles, the ceramic tiles in the ceramic tile frames are automatically laid on the ground through united work of the laying mechanism and the compaction mechanism, and a working mode is simple and efficient.

Owner:台州大顺建设有限公司 +1

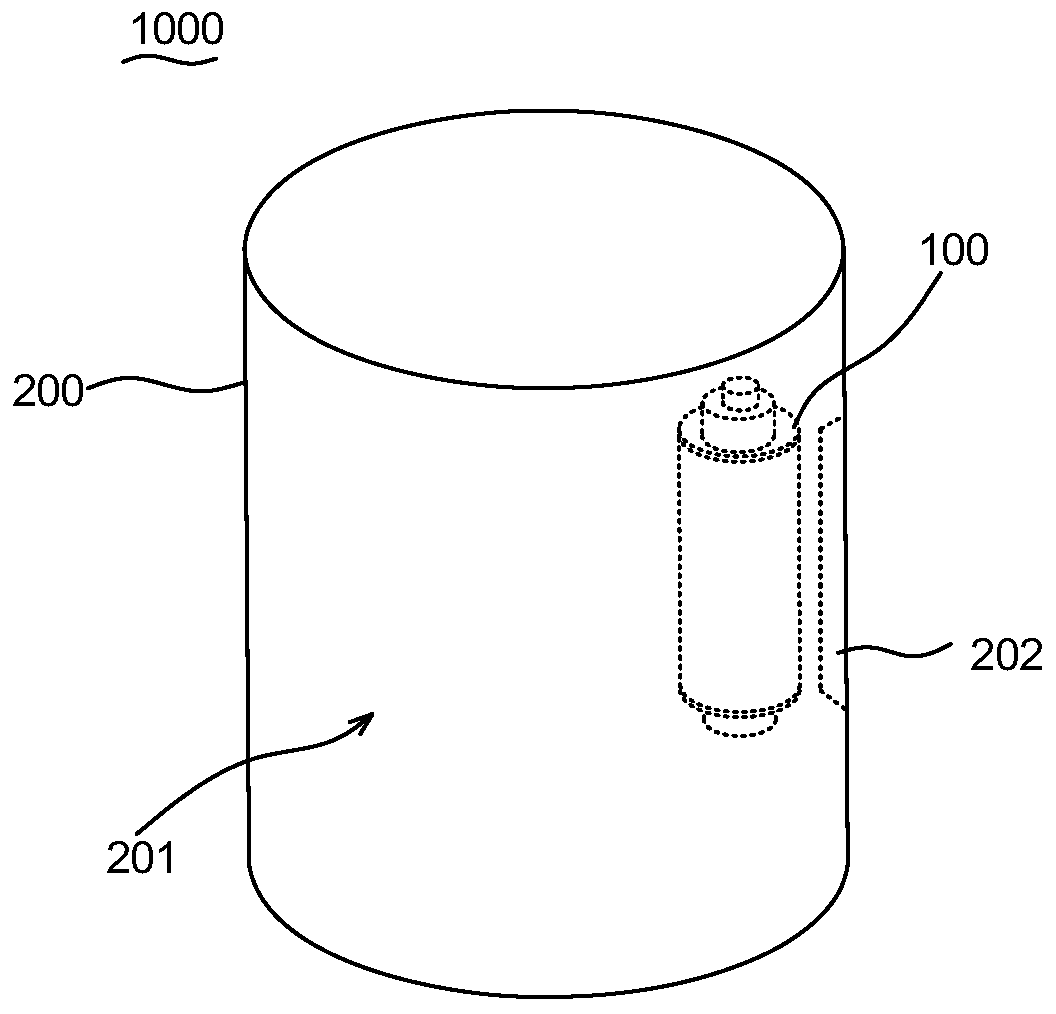

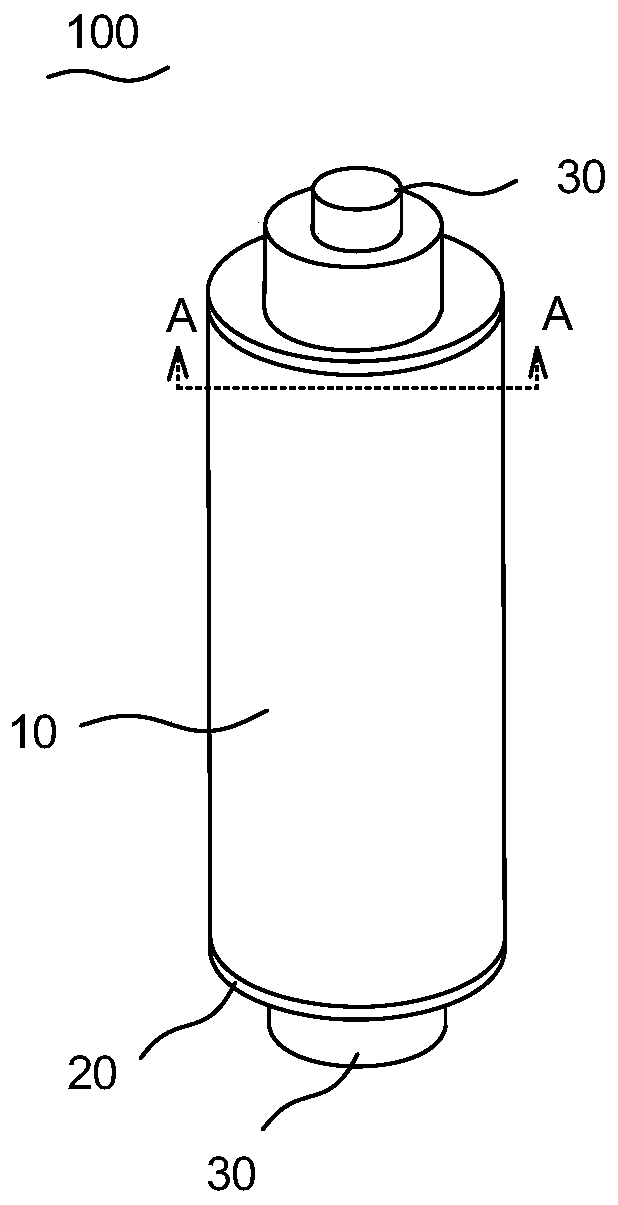

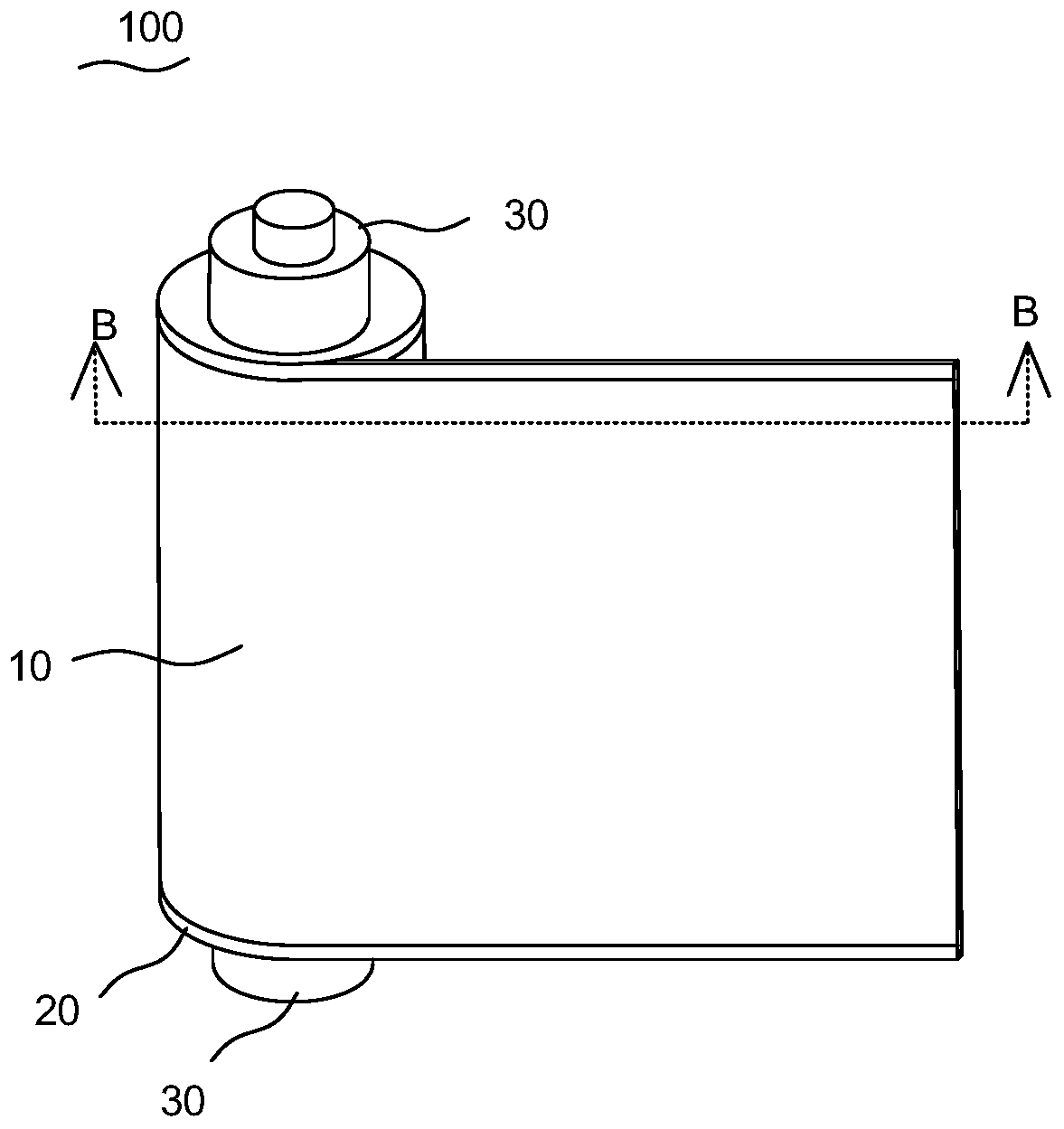

Flexible screen assembly and electronic device

ActiveCN110728912AIncrease the display areaImprove experienceIdentification meansComputer hardwareMechanical engineering

The application provides a flexible screen assembly. The flexible screen assembly includes a flexible screen body, a support member, and a driving mechanism; the flexible screen body includes a display surface and a non-display surface opposite to each other; the support member is stacked and arranged on the non-display surface of the flexible screen body; and the driving mechanism is connected tothe support member to drive the support member to stretch and contract; wherein the support member is attached to the non-display surface of the flexible screen body to drive the flexible screen bodyto synchronously stretch and contract in the same direction when the support member stretches and contracts. According to the flexible screen assembly provided by the embodiment of the application, the driving mechanism drives the support member to move, thereby driving the flexible screen body to stretch and contract; therefore, the working mode is simple. The flexible screen body is contractedinside an electronic device by a rolling method, therefore, the space occupation is small; and when the flexible screen body is stretched, a larger deployment area can be provided, therefore, the userexperience is improved. In addition, the flexible screen is placed in a curled state without folding, which can extend the service life.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

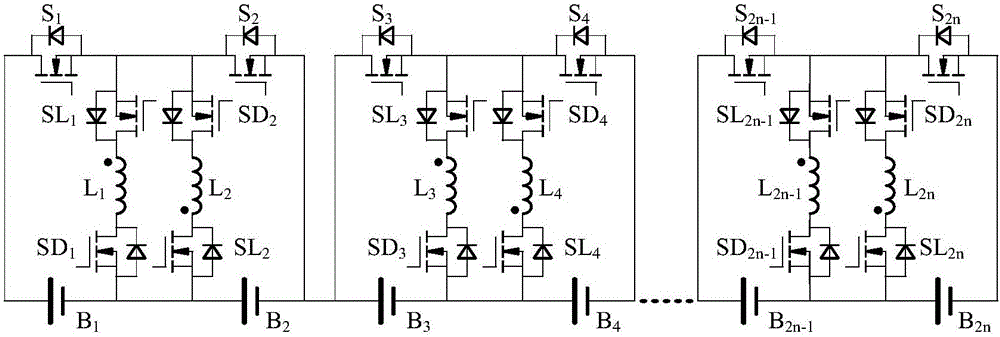

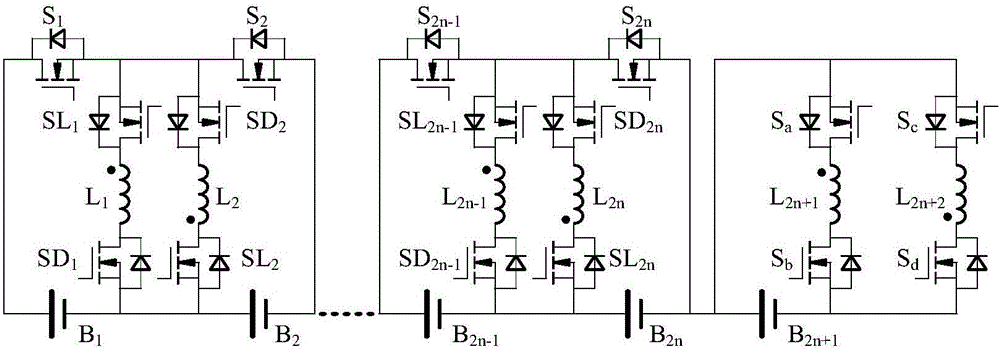

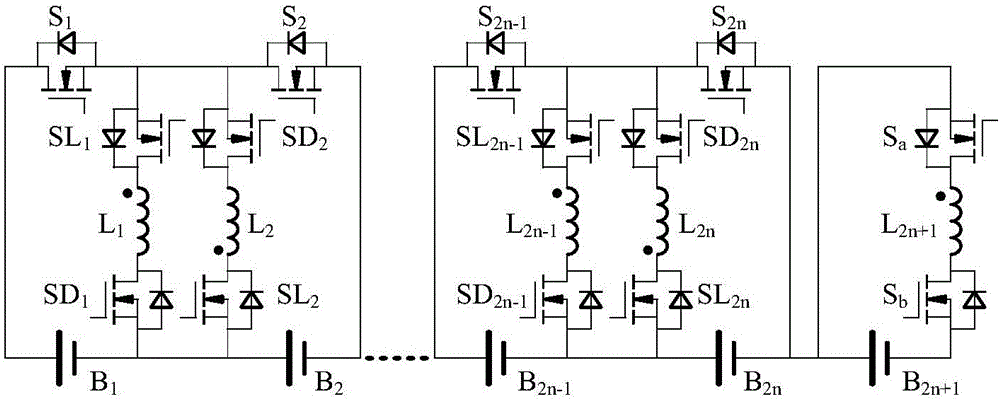

Series energy storage balance apparatus and method with point-to-point path

ActiveCN106532827AShort path for energy transferHigh speedCharge equalisation circuitElectric powerEnergy transferMOSFET

The invention relates to a series energy storage balance apparatus and method with a point-to-point path, and belongs to the power electronic technical field. When the number of series energy storage single units is 2n, 2n coupling inductors with the same number of turns and 6n MOSFET switching tubes are included; when the number of single units is 2n+1, 2n+2 coupling inductors and 6n+4 switching tubes are included; or 2n+1 coupling inductors and 6n+2 switching tubes also can be used. By controlling the on-off of the switching tubes, the single units with relatively high energy release energy to the coupling inductors, and then the energy in the coupling inductors is released to the single units with relatively low energy so as to realize direct balance among the single units. The apparatus has two working modes of Buck-Boost and flyback; and under the flyback working mode, energy transfer from one single unit to many other single units can be realized. By configuring the energy transfer path between any single units, direct balance between any single units is realized; and in addition, the series energy storage balance apparatus and method have the advantages of short energy transfer path, high balance speed, and relatively high efficiency.

Owner:HARBIN INST OF TECH

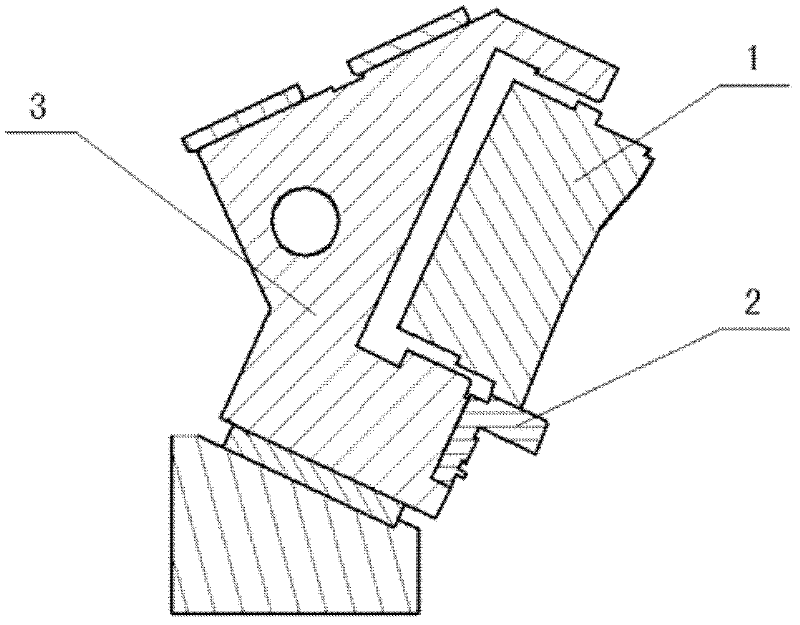

Side-forming small pressure core, stamping mould with same and stamping method

ActiveCN102527843AReduce manufacturing costSimple way of workingShaping toolsRotational axisEngineering

The invention discloses a side-forming small pressure core, a stamping mould with the same and a stamping method. The side-forming small pressure core comprises a rotary shaft, a mount, an inclined guide plate, a cushion and a rotary loose piece, the cross section of the mount is U-shaped, one end of the rotary loose piece is fixed in a U-shaped opening of the mount through the rotary shaft, the rotary loose piece rotates around the rotary shaft, the inclined guide plate is arranged on the side of the movable loose piece parallel to the rotary shaft, the cushion used for debugging in mounting is mounted on the rotary loose piece and located right below the inclined guide plate, and a main pressure core is provided with a return spring providing return force to the rotary loose piece. The side-forming small pressure core capable of rotating is simple in operation, and has lower requirements for unidirectional portions as compared with a self-made wedge mechanism with a pressure core and a reshaping tool block integrated, so that the self-made wedge mechanism with the pressure core and the reshaping tool block integrated is simplified, the space occupied by the small side core is quite small, and various components of the integral mould is more compact in arrangement.

Owner:FUZHEN TECH RES ANHUI

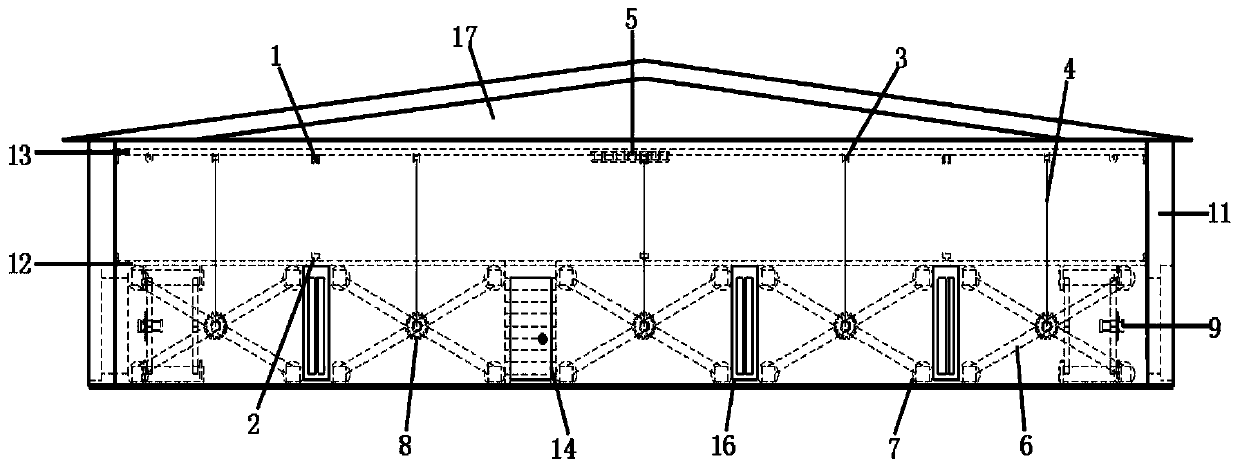

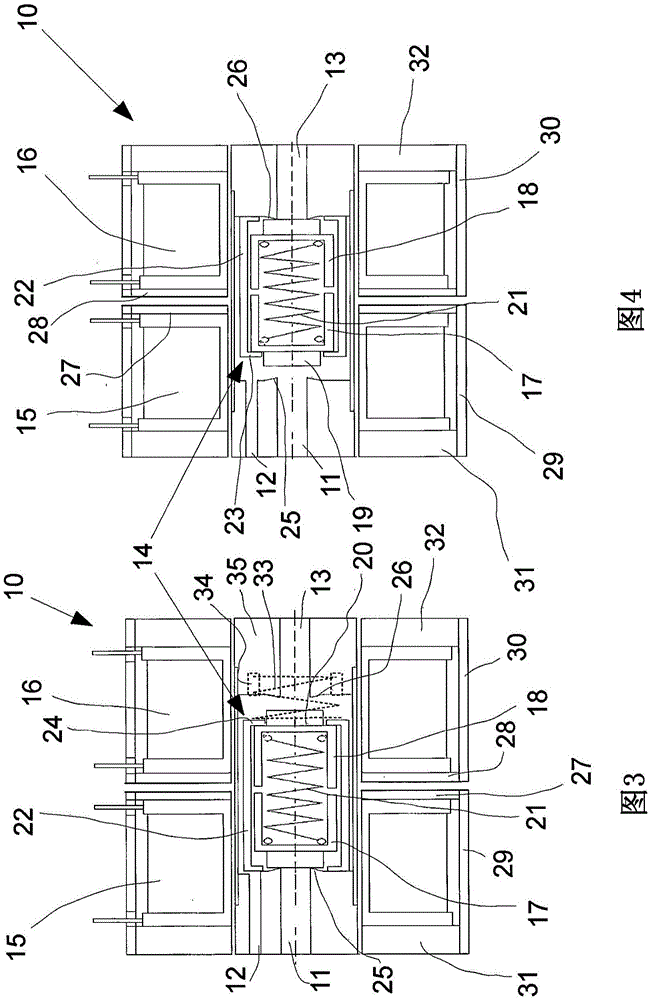

Storey height adjustable house structure with variable-position X-shaped steel supports

The invention discloses a storey height adjustable house structure with variable-position X-shaped steel supports. The storey height adjustable house structure comprises spring concave connecting pieces, convex connecting pieces, fixed pulleys, steel wire ropes, a motor, the X-shaped steel supports, variable-position pulleys, clamping gears, rotating shafts, metal clamping keys, outer walls, a first-layer floor, a second-layer floor, a door, stairs and windows. The motor rotates clockwise to lift the steel wire ropes through the pulleys to enable the rotating shafts to rotate, the rotating shafts are fixedly connected with the clamping gears, the metal clamping keys are connected with the rotating shafts through steel wires, the rotating shafts rotate to drive the metal clamping keys to contract, the clamping gears start to rotate, the variable-position pulleys start to roll on rails through rotation of the clamping gears, the X-shaped steel supports contract through movement of the variable-position pulleys, and therefore the first-layer floor ascends. The first-layer floor can descend slowly to recover the original state, a house is of a normal second-layer building structure, and the requirement of people for normal rest and life is met.

Owner:BEIJING UNIV OF TECH

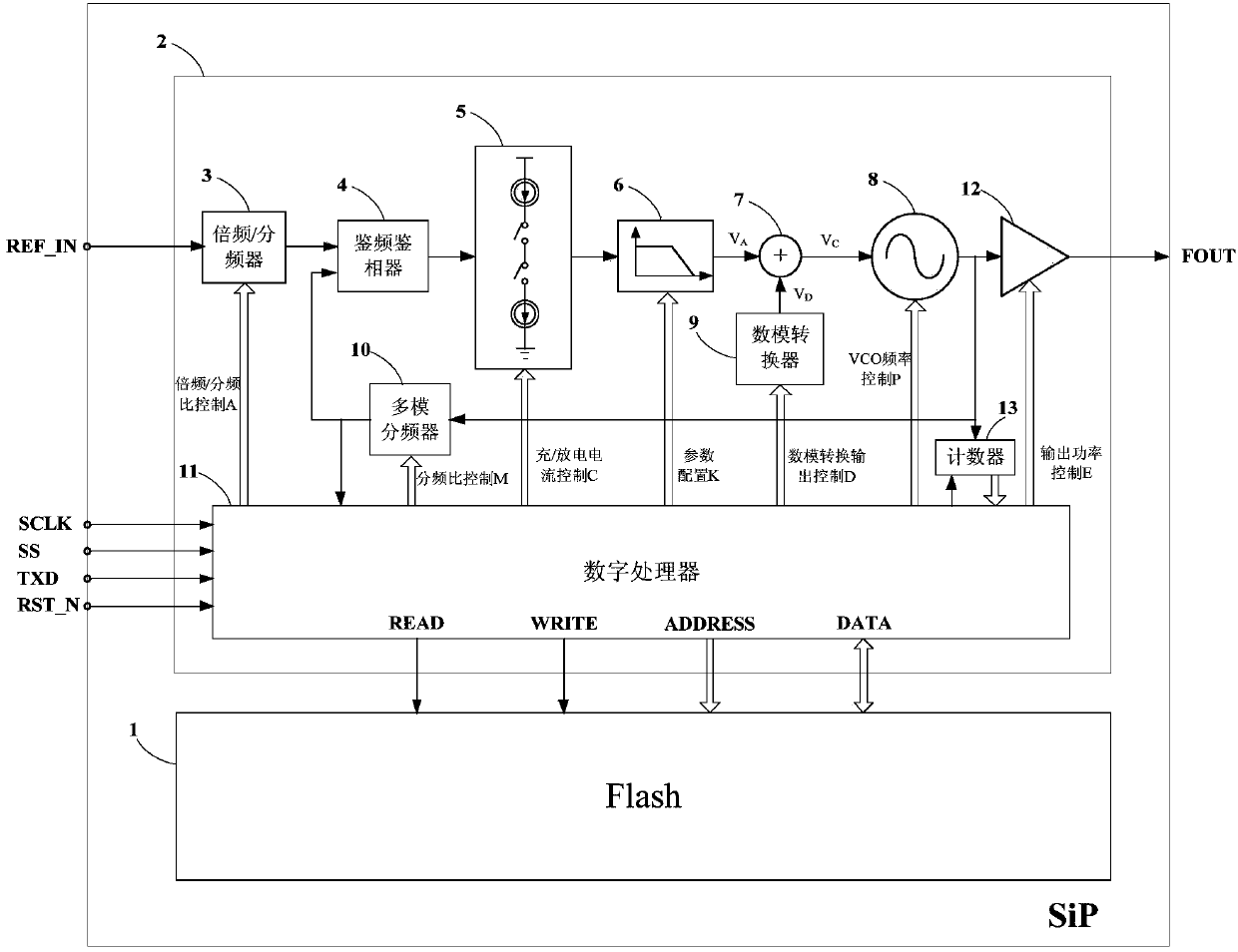

Rapid frequency switching microsystem based on integrated phase-locked loop chip

ActiveCN107947791ASimple configurationHighly integratedPulse automatic controlLoop filterDigital analog converter

The invention discloses a rapid frequency switching microsystem based on an integrated phase-locked loop chip. The rapid frequency switching microsystem comprises a Flash chip and an integrated phase-locked loop frequency synthesizer chip with a built-in VCO. The integrated phase-locked loop frequency synthesizer chip with the built-in VCO comprises a frequency multiplier / frequency divider, a phase frequency detector, a charge pump, a loop filter, a summing circuit, a broadband voltage-controlled oscillator, a digital to analog converter and a multimode frequency divider. The integrated phase-locked loop chip and the Flash chip form the rapid frequency switching microsystem based on the integrated phase-locked loop chip in a SiP mode. According to the microsystem, a high performance radiofrequency source signal is provided through utilization of the integrated phase-locked loop frequency synthesizer chip with the built-in VCO and a control signal stored in the Flash chip is read, so aphase-locked loop output frequency is rapidly switched. The microsystem provided by the invention is high in integration degree, the radio frequency source signal is output, a loop bandwidth is not influenced, and moreover, the locking time is greatly reduced.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

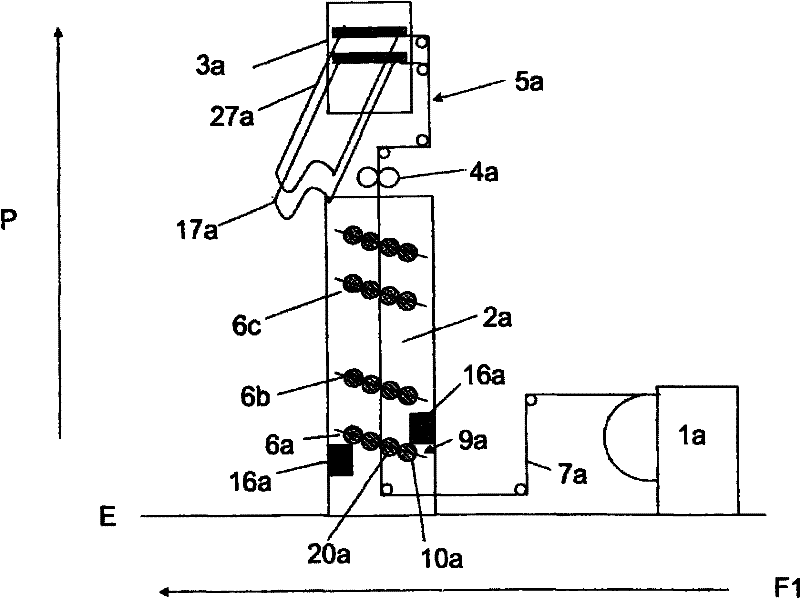

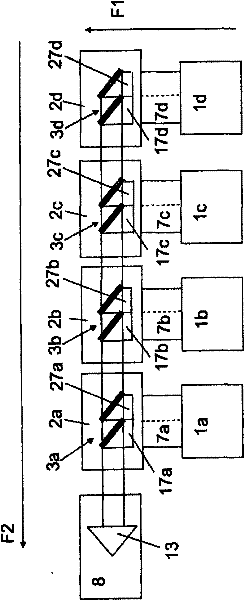

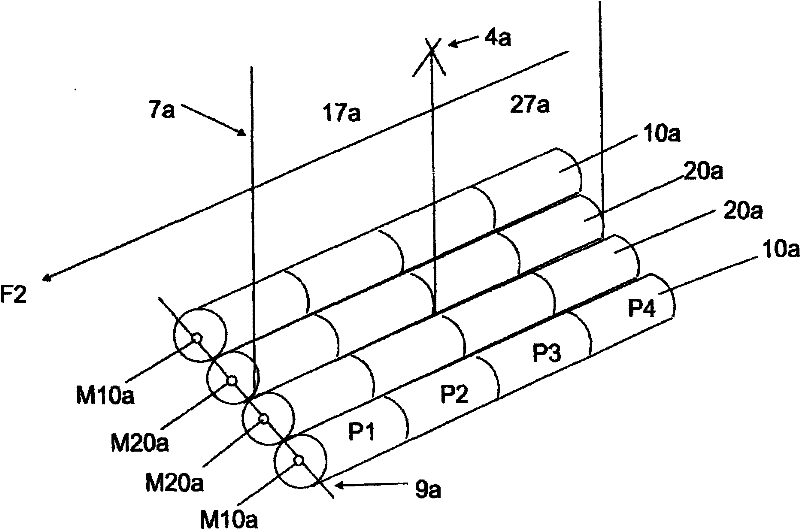

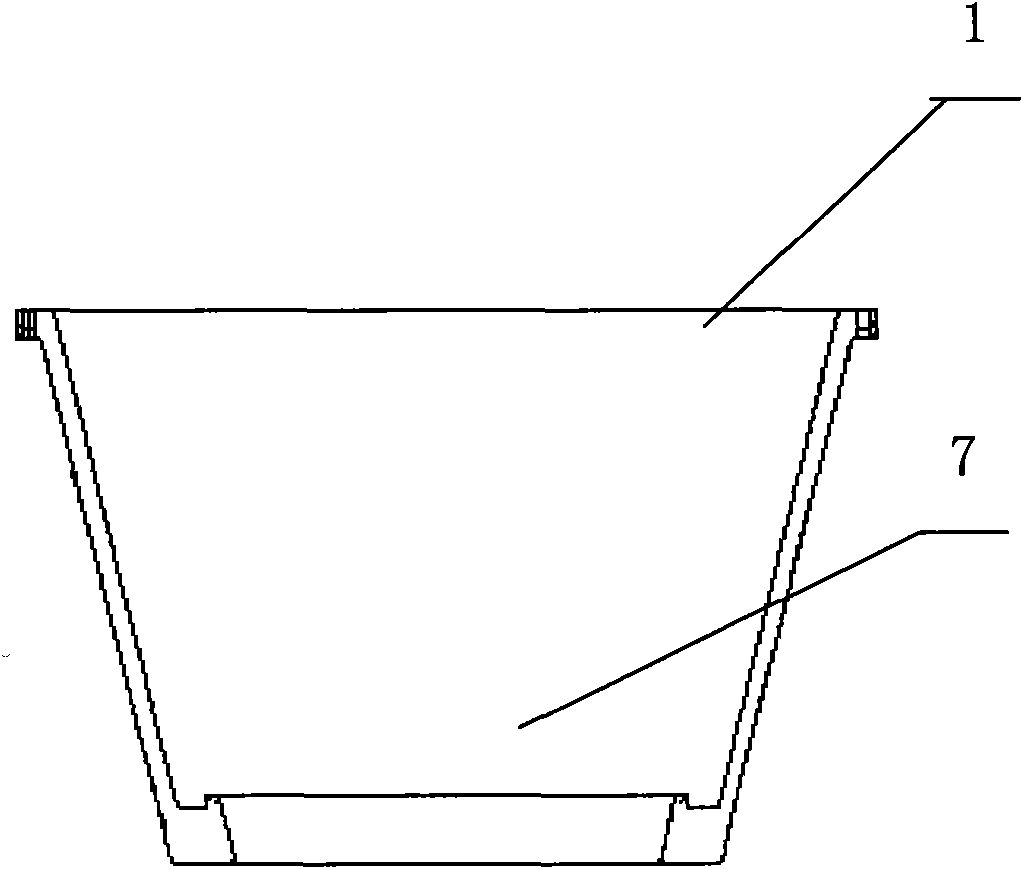

Rotating roller print assembly for sheets of multiple widths with fixed width folding apparatus

ActiveCN102161253ACompact structureReduce vibrationRotary lithographic machinesArticle deliveryPaper tapePrinting press

The invention discloses a rotating roller print assembly, comprising roller exchanging devices (1a,1b,1c,1d), a plurality of printing drums (2a,2b,2c,2d) with a plurality of printing devices (6a,6b,6c,6d), web turning devices (3a,3b,3c,3d) and at least one folding apparatus (8), wherein the web turning devices (3a,3b,3c,3d) turn paper webs (7a,7b,7c,7d) or partial paper webs (17a-17d, 27a-27d) around 90 degrees from the printing drums (2a,2b,2c,2d) to the folding apparatus. Preferably, the folding apparatus (8) is designed in the fixed width.

Owner:MANROLAND WEB SYST

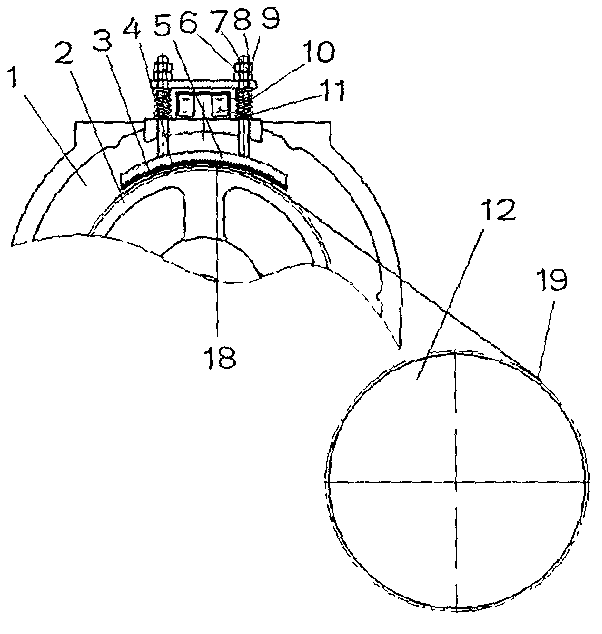

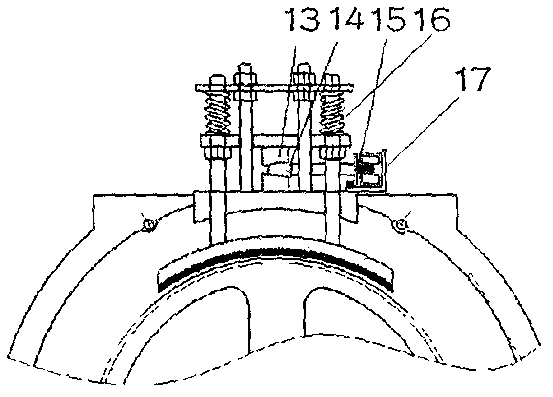

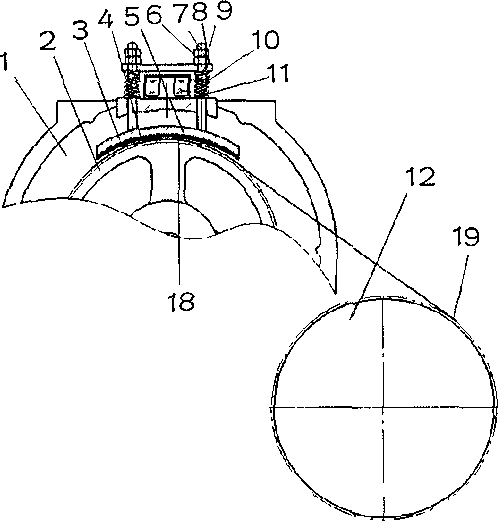

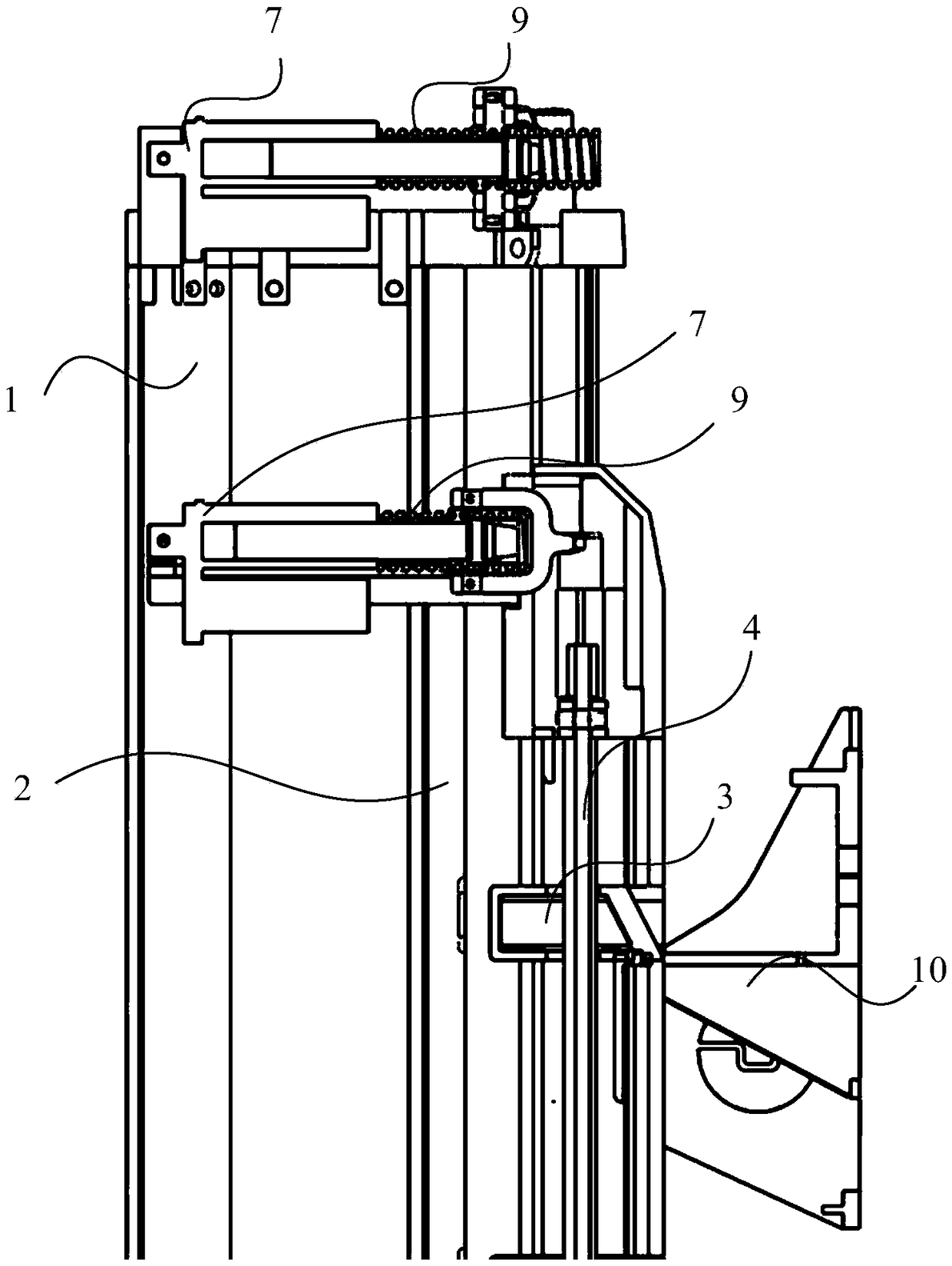

Elevator traction machine of steel wire rope antiskid device

InactiveCN102674118APlay a double protection functionAchieve brakingElevatorsBuilding liftsMetallic materialsEngineering

The invention relates to an elevator traction machine of a steel wire rope antiskid device. The elevator traction machine comprises a main body of the elevator traction machine, a traction sheave, a steel wire rope, a brake pad, a brake shoe, an upright column, a compressing plate, a regulating nut, an electromagnet and an electromagnetic coil. The elevator traction machine is characterized in that a danger emergency protective device is arranged on the traction machine; the danger emergency protective device comprises the brake pad, the brake shoe, the upright column, the compressing plate, a compression spring, the electromagnet and the electromagnetic coil; the brake pad can be made of a composite engineering material or metal material with high frictional factors; the electromagnetic coil can adopt a single-coil or multi-coil manner; the compressing plate can adjust the size of the frictional force through the upright column and the regulating nut when the device works; and the elevator traction machine can lead the working process of an elevator to be safer and reliable and has simple structure and good implementing effect.

Owner:郭自刚

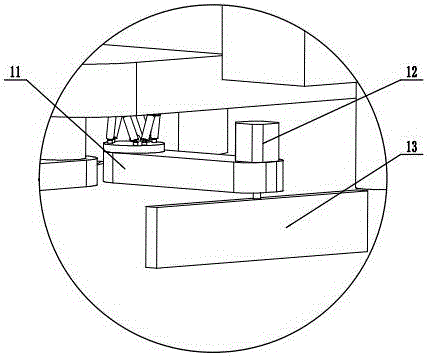

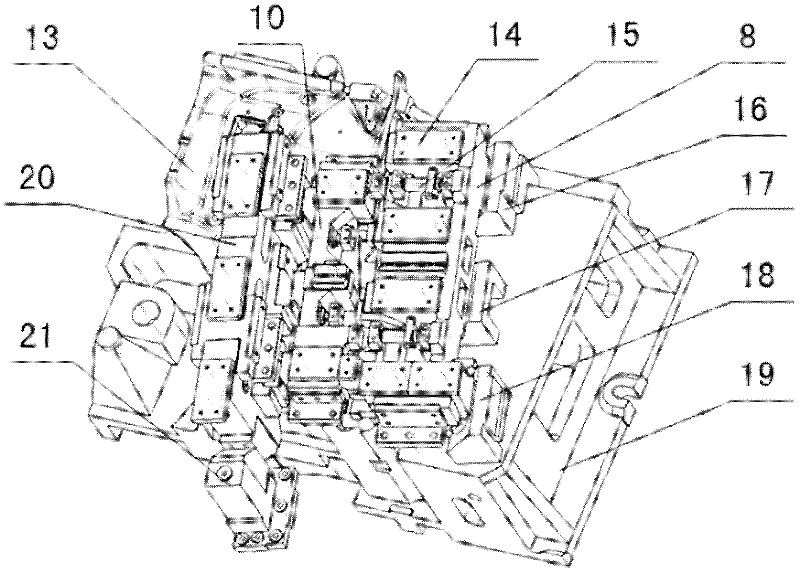

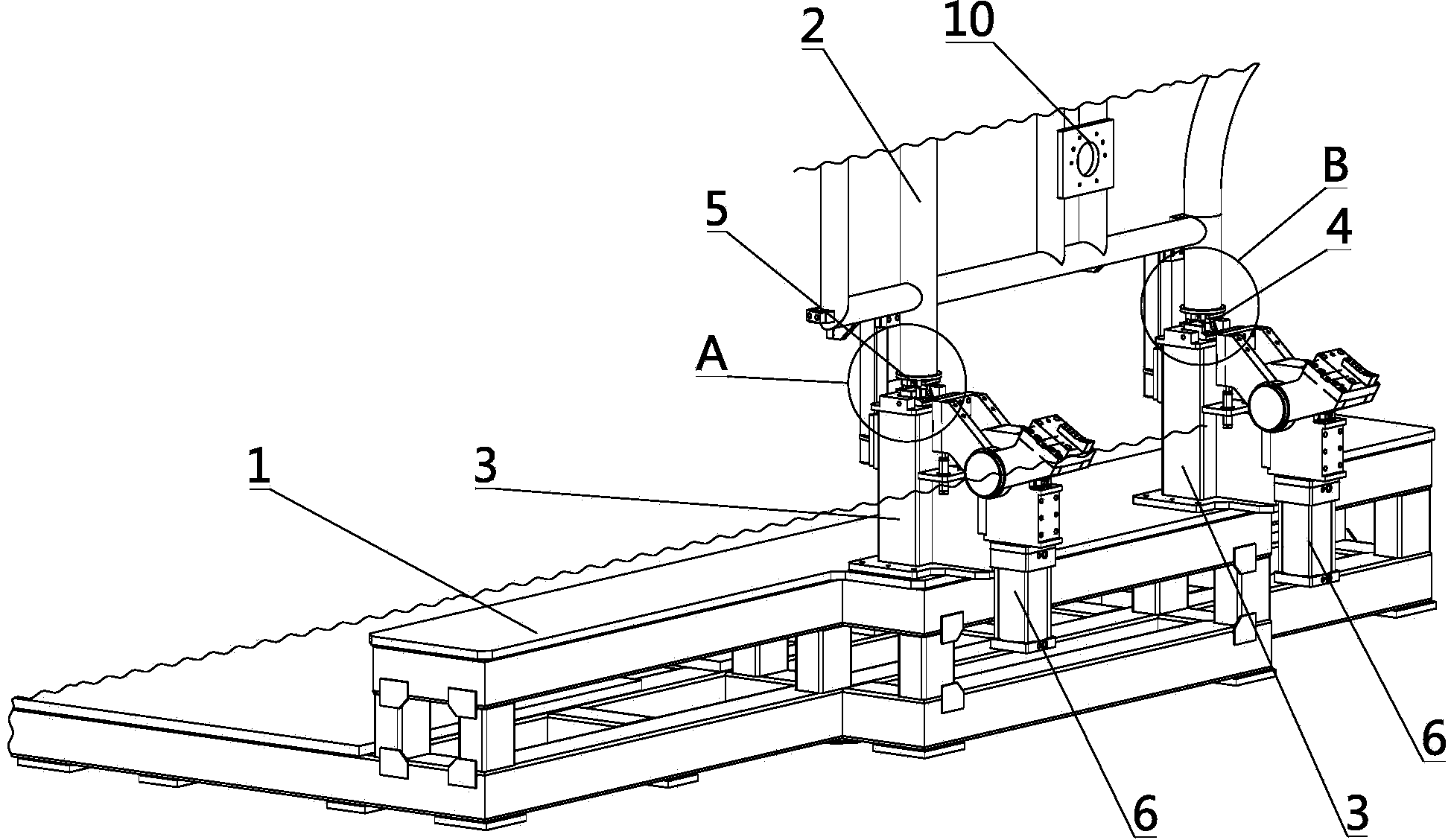

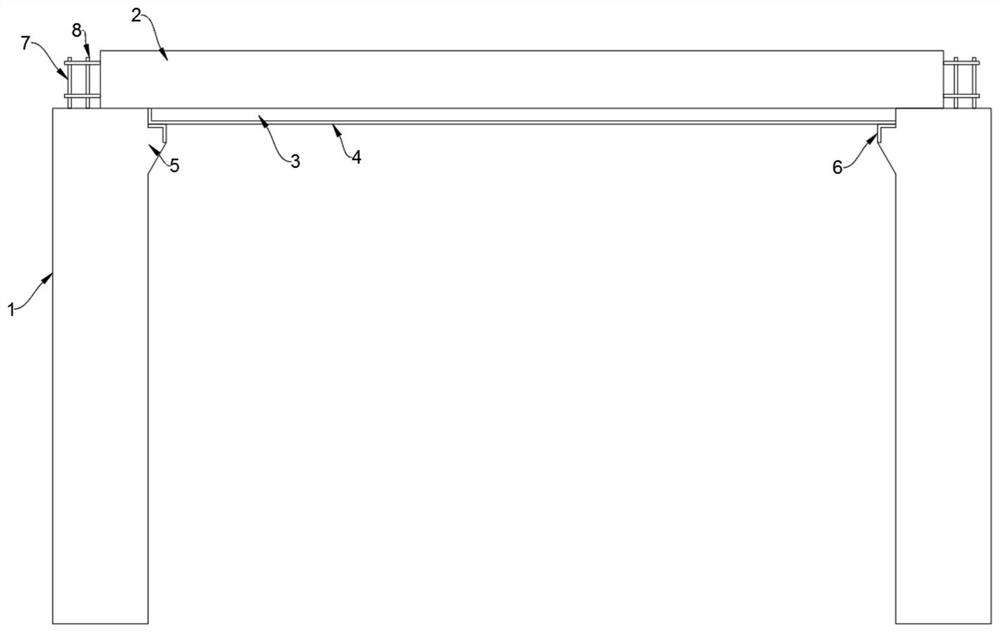

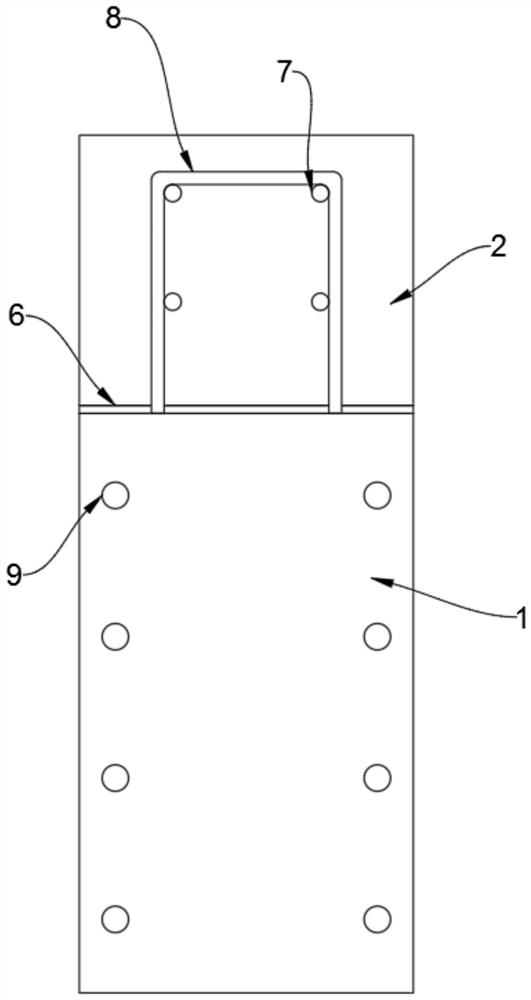

Rapid positioning and clamping system for flexible vehicle body welding line gripper clamp assembly

ActiveCN104384782AImprove positioning accuracyHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld line

The invention discloses a rapid positioning and clamping system for a flexible vehicle body welding line gripper clamp assembly. The rapid positioning and clamping system for the flexible vehicle body welding line gripper clamp assembly comprises the gripper clamp assembly and at least four upright posts, wherein the gripper clamp assembly comprises a frame; a gripper clamp is arranged on the frame; the at least four upright posts are mounted on a welding line platform and are used for carrying the frame; a three-direction positioning mechanism and a two-direction positioning mechanism are respectively arranged on the at least two upright posts which are positioned on the same side of the central line of the welding line platform; one compressing mechanism used for compressing the corresponding three-direction positioning mechanism and the corresponding two-direction positioning mechanism is arranged on the side wall of each upright post positioned on the outer side of the welding line platform. The rapid positioning and clamping system is simple in working mode, high in positioning accuracy, and firm and reliable in positioning, and can meet the production of various vehicle types; meanwhile, the positioning accuracy in the X,Y and Z directions is ensured; the rapid positioning and compressing between a positioned body and a positioning body are realized.

Owner:武汉东研智慧设计研究院有限公司

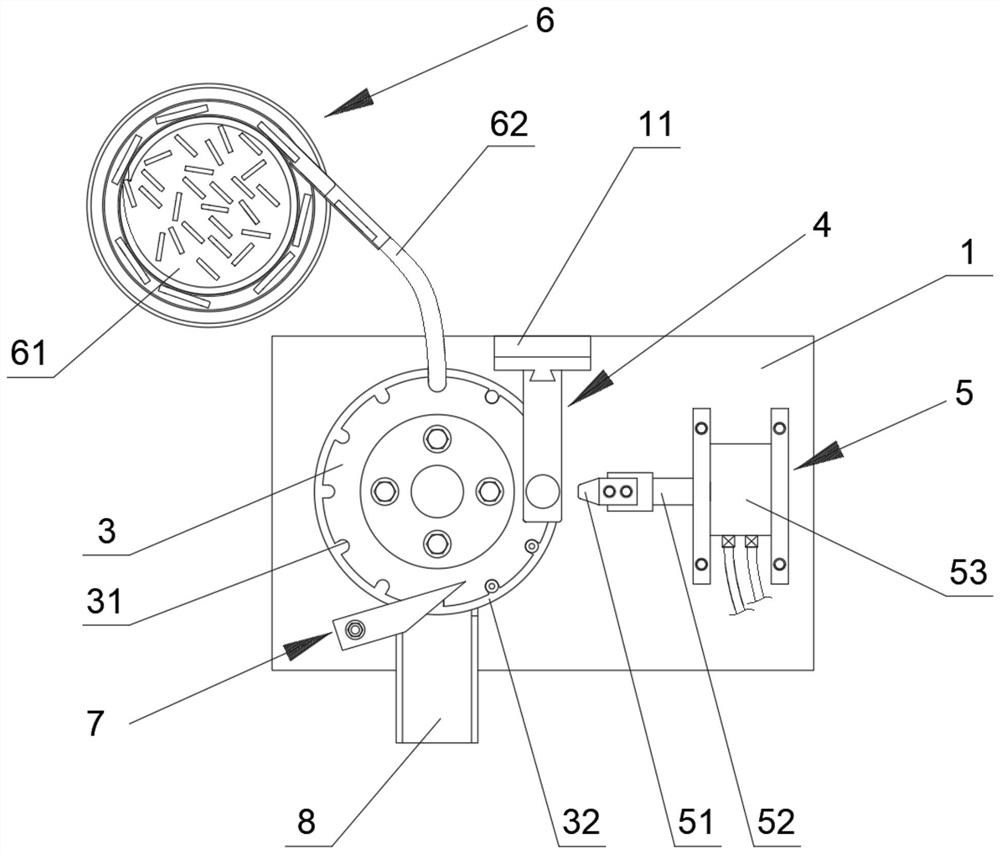

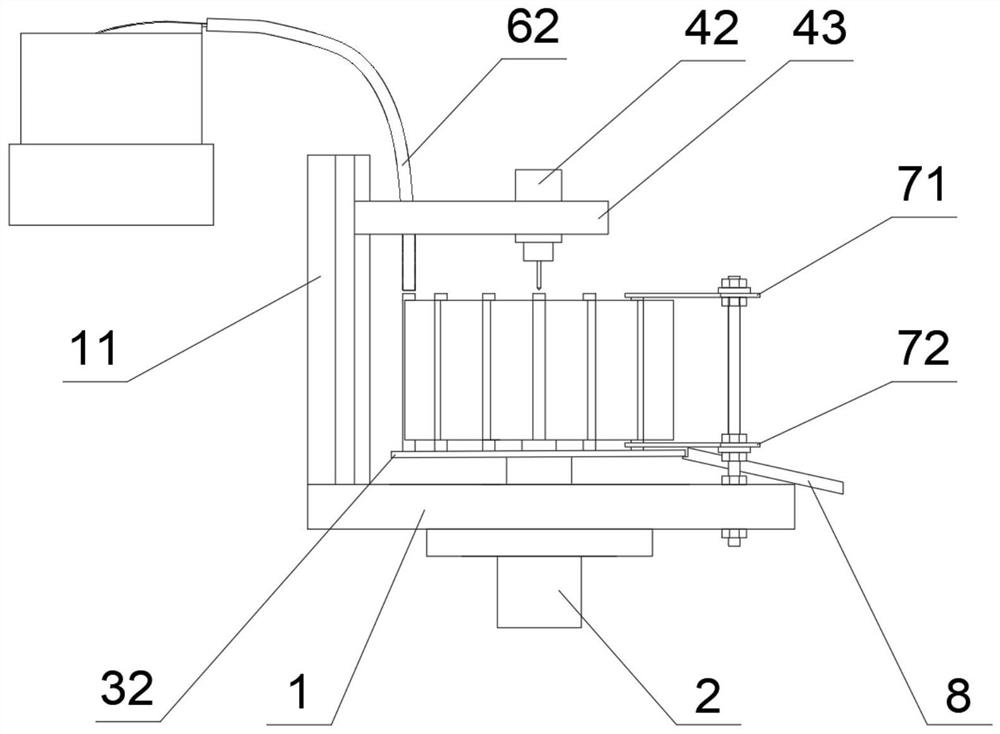

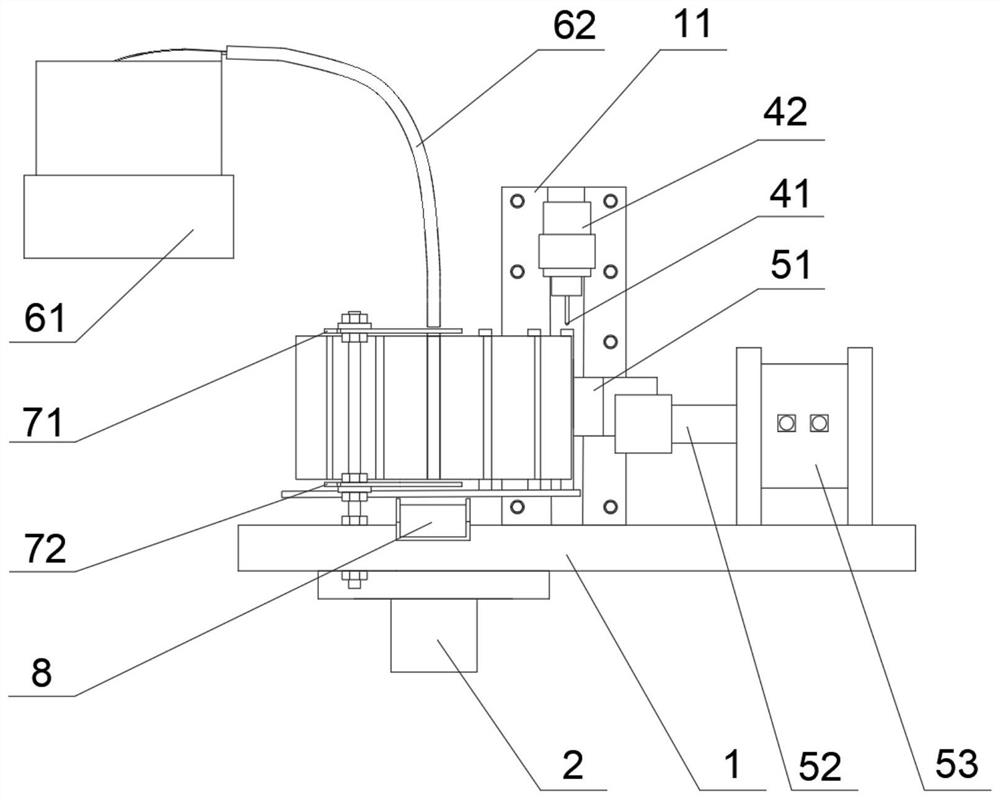

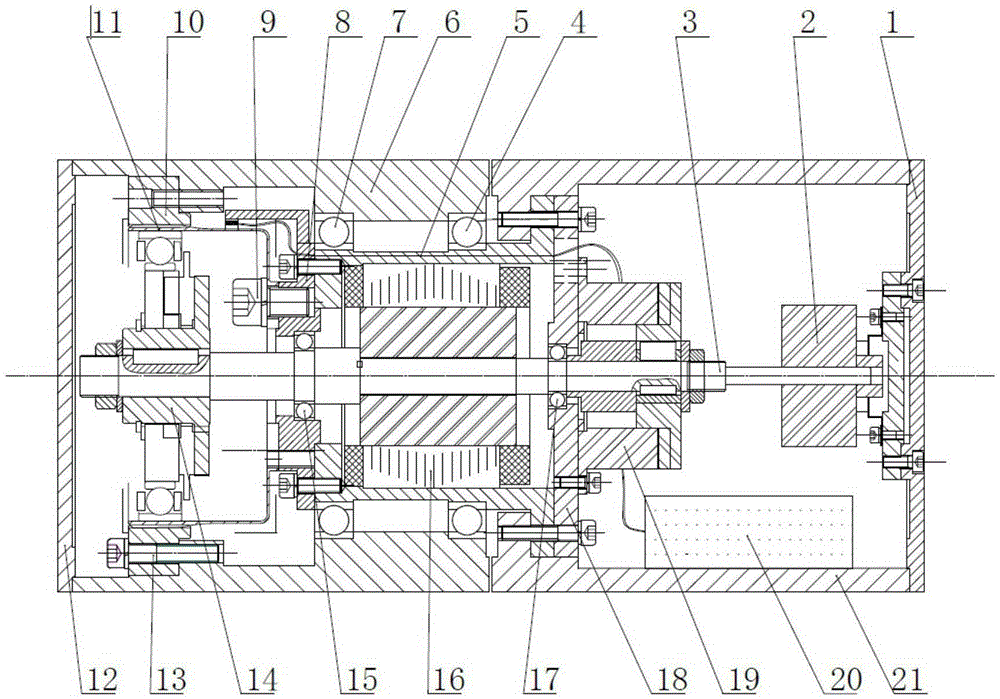

Axial vertical drilling machine

InactiveCN113084217ASave production spaceFacilitate automated productionMetal working apparatusBoring/drilling componentsElectric machineryDrilling machines

The invention relates to an axial vertical drilling machine which comprises a base, a machining rotary disc, a drilling mechanism and a fastening mechanism. The machining rotary disc is fixed onto the base and is controlled by a first motor to rotate; the drilling mechanism is arranged above the outer circumference of the machining rotary disc in the axial direction; the fastening mechanism is arranged on the radial outer side of the machining rotary disc; multiple axially-penetrating U-shaped opening clamping grooves are distributed in the outer circumference of the machining rotary disc in an array mode; U-shaped openings of the clamping grooves face the radial outer side of the machining rotary disc; the fastening mechanism is located on the radial outer side of the corresponding clamping groove below the drilling mechanism; and when the drilling mechanism drills a cylindrical hardware in the clamping groove, the fastening mechanism radially extrudes and fixes the cylindrical hardware. Compared with an original axial vertical drilling machine, according to the novel axial vertical drilling machine, a feeding station, a drilling station and a discharging station of the cylindrical hardware are integrated on the machining rotary disc, so that the production space is saved, and automatic production is facilitated; and the fastening mechanism ensures the stability of the cylindrical hardware during drilling, so that the service life of a drill bit is prolonged, and the coaxiality of drilled holes is improved.

Owner:福州玖铭金属制造有限公司

Valve arrangement

ActiveCN105579751AFunctionalCompact structureOperating means/releasing devices for valvesGearing controlTransmission brakeMagnetic valve

Owner:WABCO GMBH

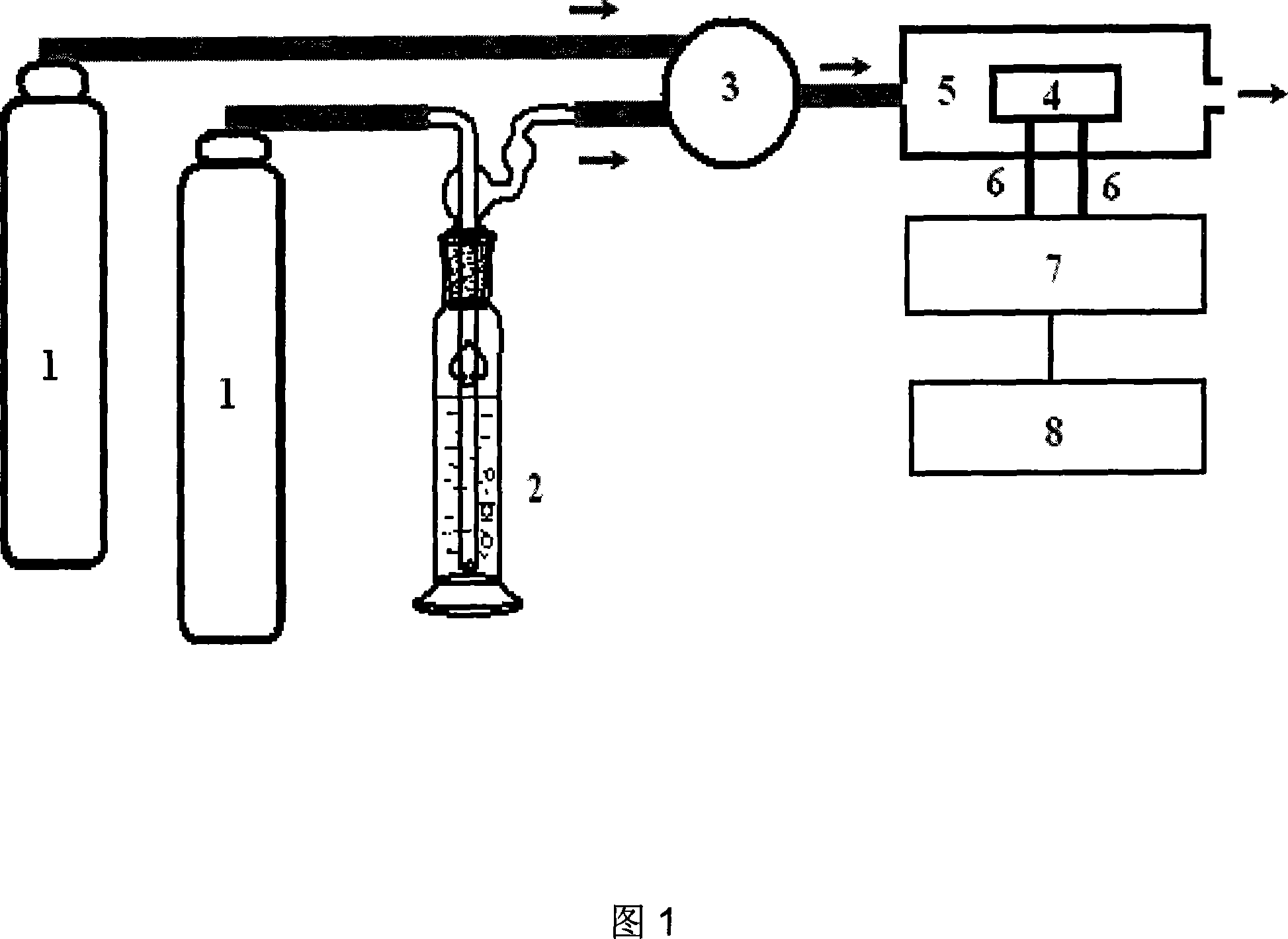

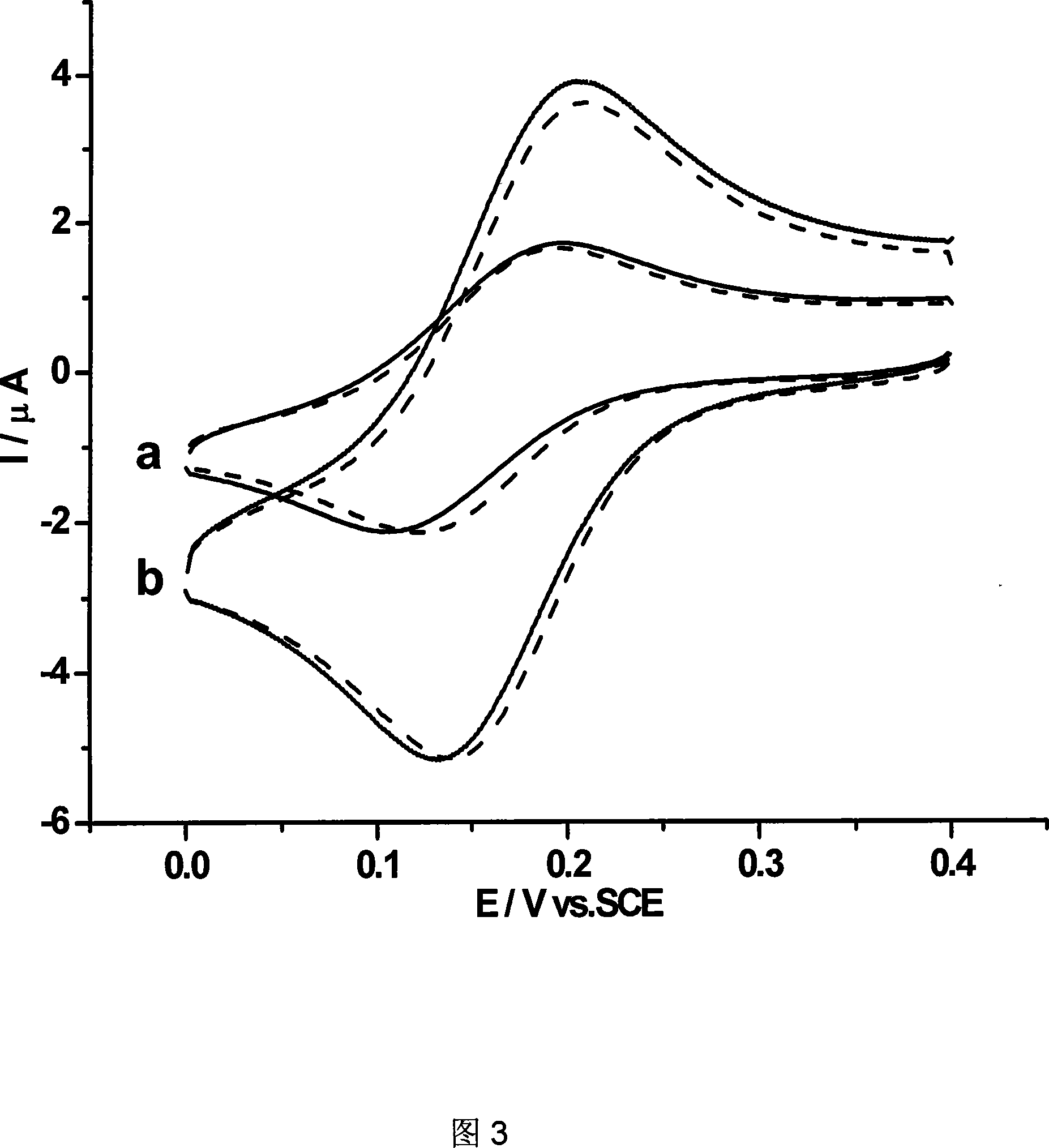

Ampere type humidity sensing device

InactiveCN101059475ALow costImprove anti-interference abilityMaterial electrochemical variablesEngineeringAlternating current

The invention relates to an ampere humidity sensor and a relative check method, based on room temperature ion liquid, which comprises a humidity sensitive element with room temperature ion liquid and electrochemical probe, a signal amplifier circuit, a check circuit, a reference circuit, a gas system, and a display control system, to use the charge current of the humidity sensitive element and the reaction current of the electrochemical probe to detect the humidity. The invention is characterized in that using the room temperature ion liquid as the sensitive part of humidity, using the change of reversal electrochemical property of oxidization reduction couple to detect the humidity of current type. The invention can overcome the defects of prior humidity sensor as bad exchangeable property, high cost, complex device, bad interference resistance, and small response signal linear range, caused by using alternative-current signal, to obtain the advantages as simple structure, low cost, stable property and high sensitivity.

Owner:SHANGHAI NORMAL UNIVERSITY

In vitro electro-magnetism excitation positioning system for remotely monitoring capsule swallowed in digestive tract

InactiveCN1287727CEasily damagedNo damageEndoscopesDiagnostic recording/measuringMicrocontrollerSignal processing circuits

The digestive tract remote measuring capsule electromagnetically positioning system includes sealed capsule with three-axis magnetic field sensor, signal processing module and radio communication module; three extracorporeal ring static magnetic field exciting coils; and extracorporeal data record instrument comprising monochip computerized control circuit, constant-current source circuit, multiplex switch, radio communication module, memory and power source module. During system operation, the three coils are fixed onto the surface of body to produce magnetic field under the excitation of the current from the instrument successively, the intracorporeal capsule detects the magnetic fields and produces and emits digital signal, and the instrument receives, saves and processes the signal, so as to obtain the 3D locus of the capsule.

Owner:SHANGHAI JIAO TONG UNIV

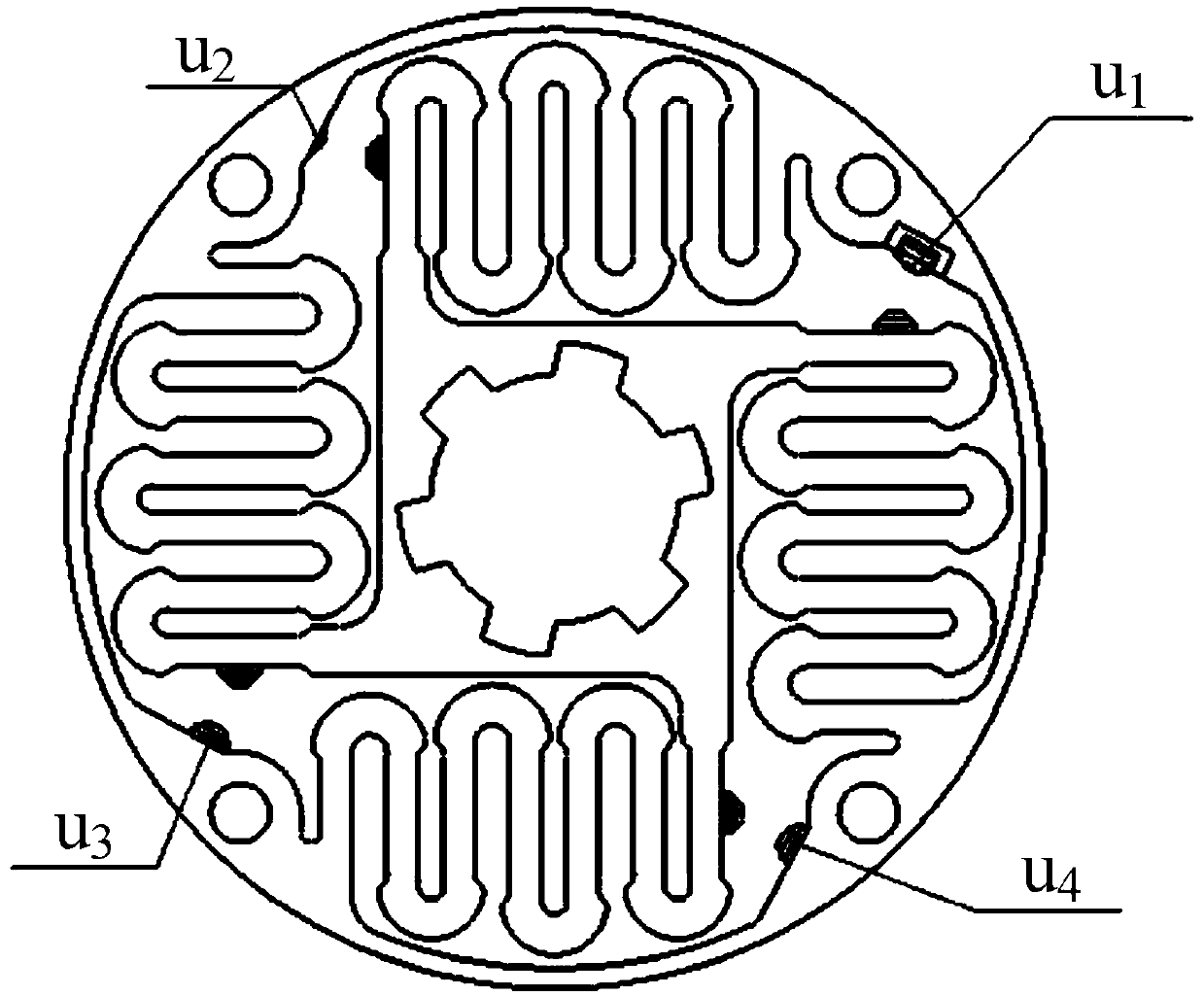

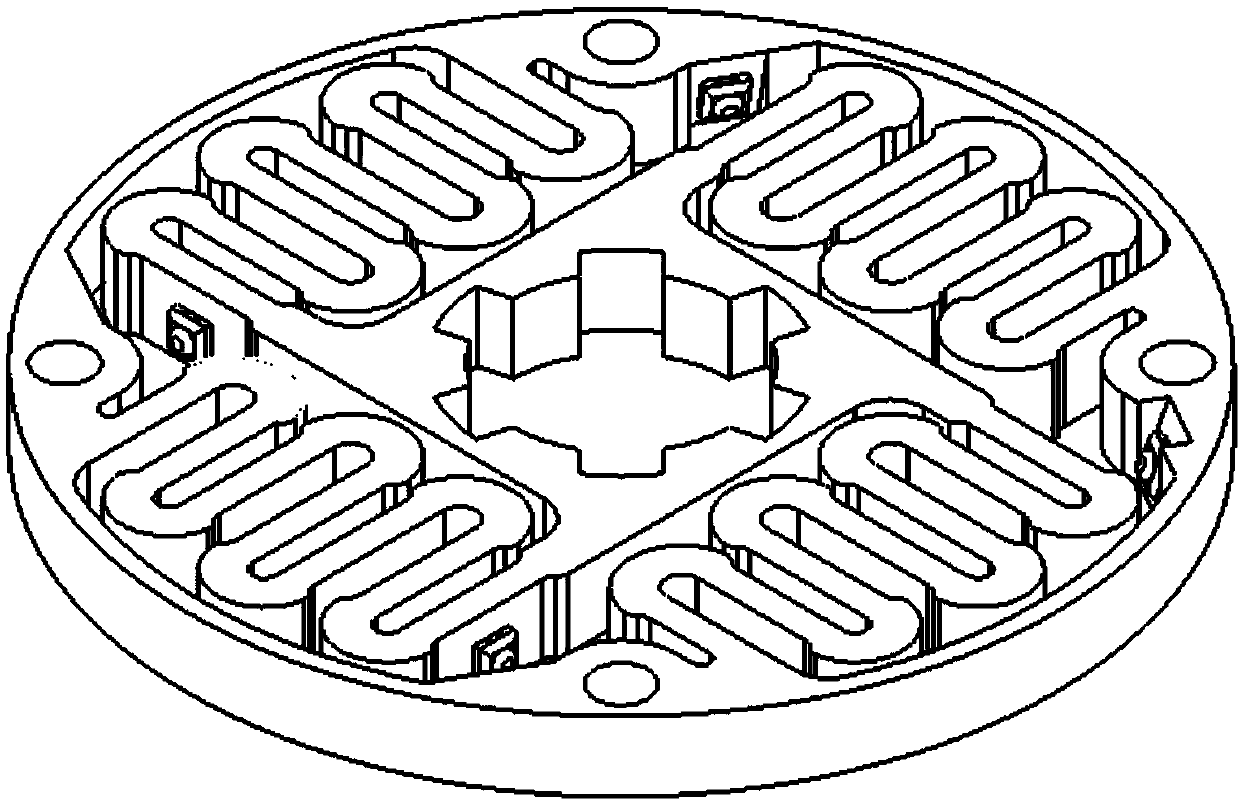

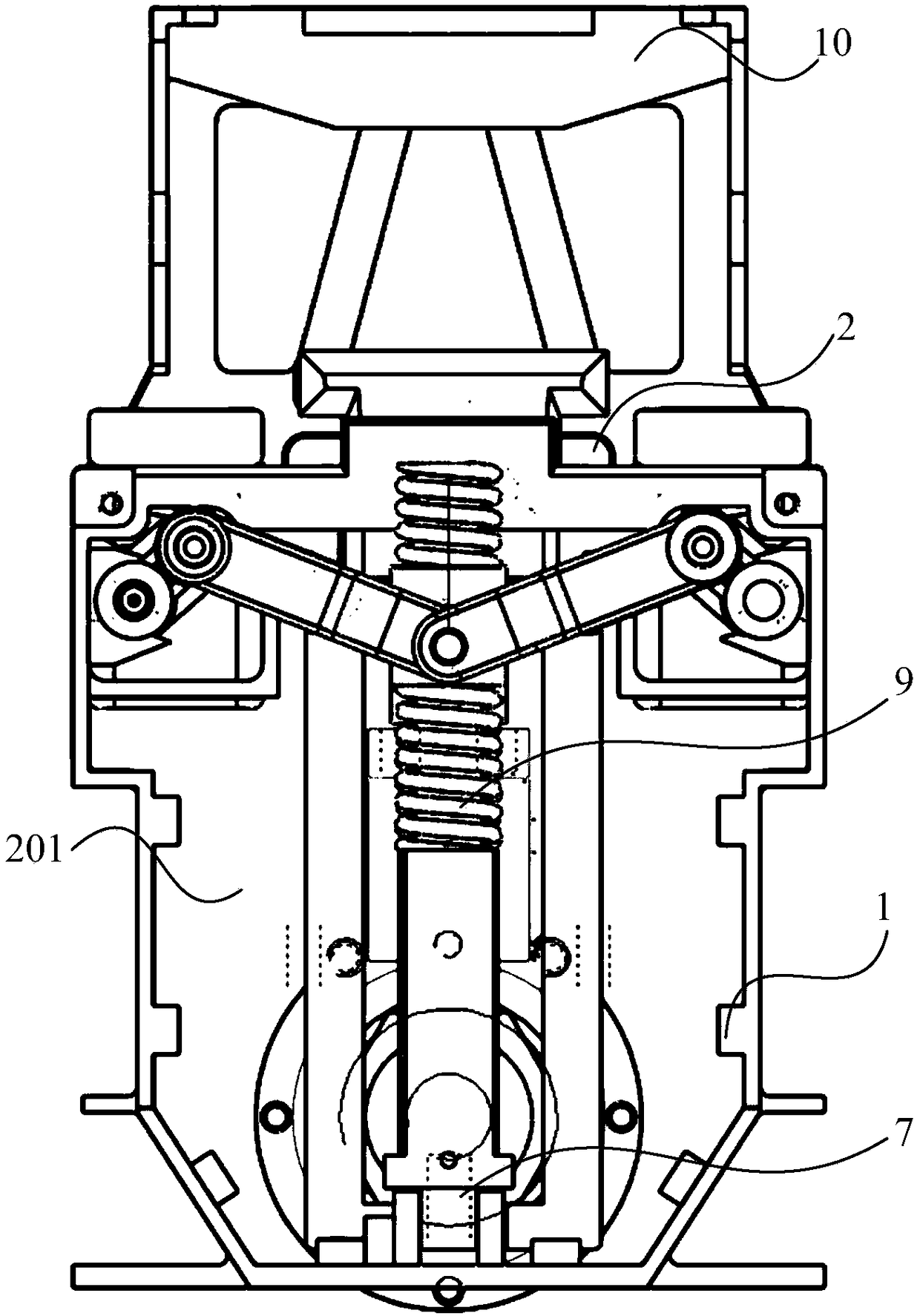

Robot joint torque sensor

InactiveCN108931328ADoes not increase joint flexibilitySimple way of workingWork measurementTorque measurementLeast squaresTorsion spring

The invention discloses a robot joint torque sensor. A traditional sensor is taken as an individual component and is arranged in a joint driving structure, which increases complexity and the cost of torque measurement. NPN silicon phototransistors and an infrared light emitting diode are fixed on a first planar torsion spring. A PCB signal processing circuit board carries out amplification and filtering processing on four voltage signals transmitted by the four NPN silicon phototransistors. Simulation voltages after filtering processing are converted into digital voltage signals. A least square method linear fitting algorithm is used to carry out linearity correction on the four digital voltage signals. And then, the four digital voltage signals after the linearity correction are calibrated and decoupled so that corresponding voltage values are converted into a torque value. In the invention, a hysteresis error and a temperature drift error are small, measurement precision is high, andsimultaneously, the influence of the torque sensor on joint flexibility is reduced.

Owner:HANGZHOU DIANZI UNIV

Connecting structure of precast concrete beam and cast-in-place column and construction method thereof

InactiveCN111764505AEasy to simplify the fixing methodReduce processBuilding constructionsArchitectural engineeringRebar

The invention discloses a connecting structure of a precast concrete beam and a cast-in-place column and a construction method thereof. The connecting structure of the precast concrete beam and the cast-in-place column comprises the cast-in-place columns, a column longitudinal reinforcement and the precast beam, wherein the column longitudinal reinforcement is arranged above the cast-in-place columns; the column longitudinal reinforcement extends into the cast-in-place columns to be fixedly connected with the cast-in-place columns; the precast beam is arranged above the cast-in-place columns;two cast-in-place columns are arranged; the two ends of the precast beam are correspondingly laminated to the two cast-in-place columns; ring buckle-shaped U-shaped reinforcements are arranged on thetwo sides of the precast beam; and the ring buckle-shaped U-shaped reinforcements extend into the precast beam to be fixedly connected with the precast beam. The problem that site assembling constructions of existing precast beam and cast-in-place column connecting structure and connecting mode are complicated during assembling connection of a prefabricated concrete structure is solved.

Owner:湖北省建工第二建设有限公司

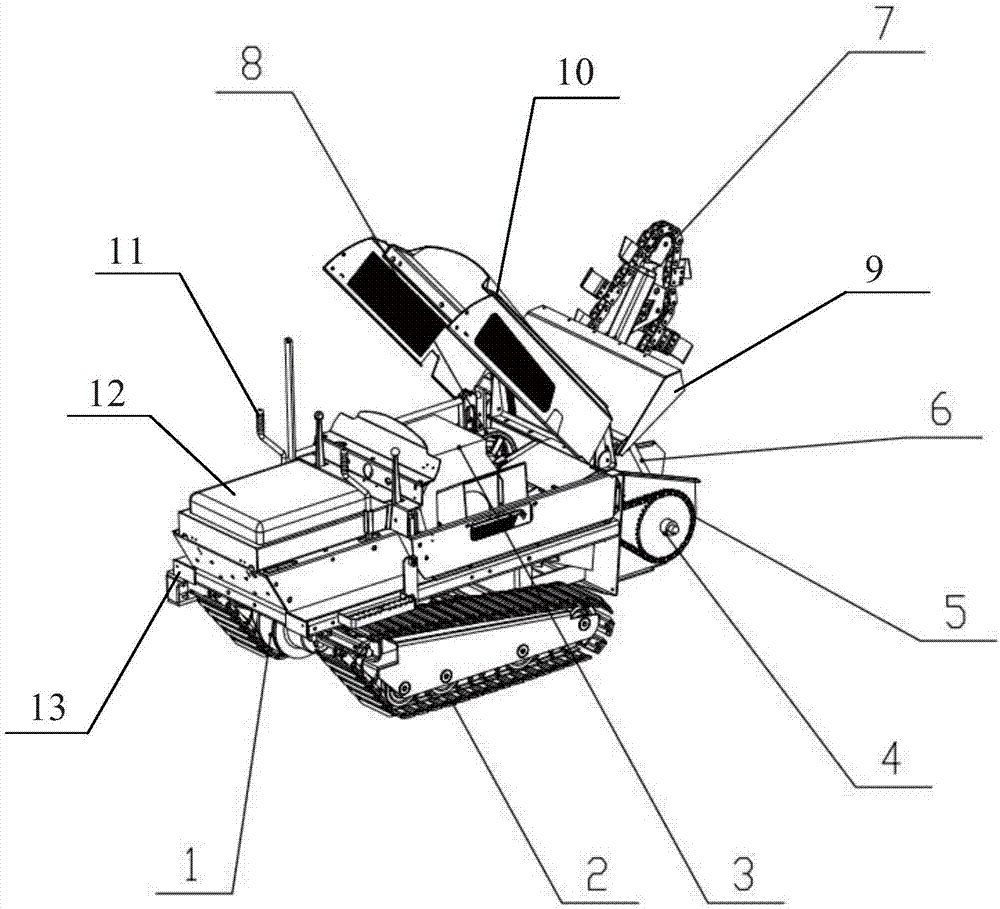

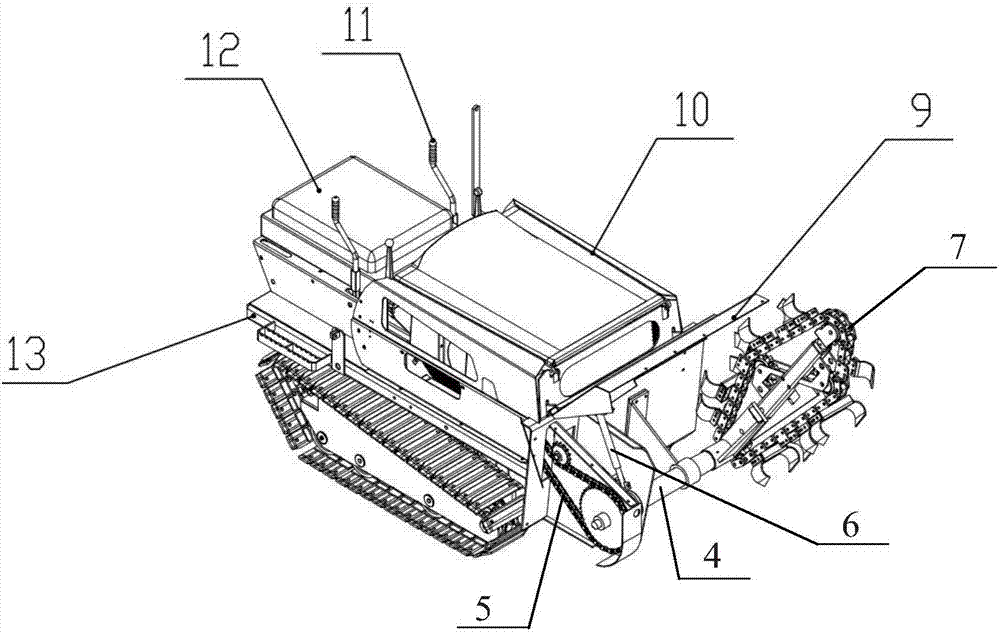

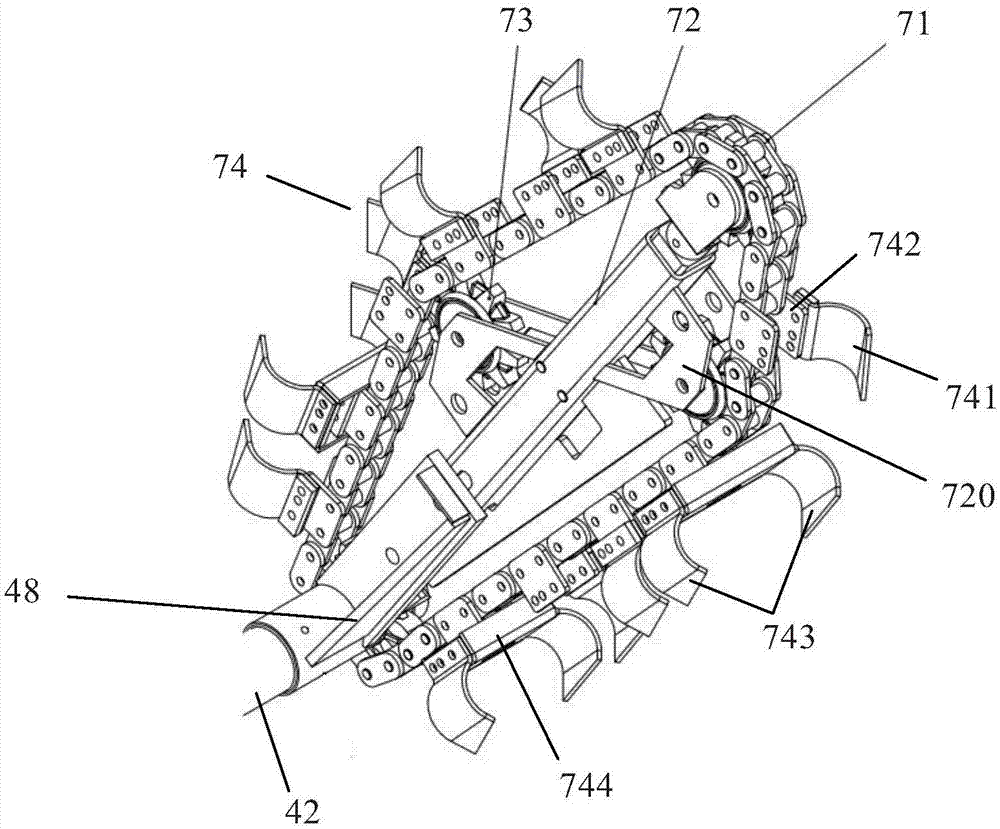

Crawler trencher with adjustable trenching depth

InactiveCN107326951AReasonable structural designCompact designSoil-shifting machines/dredgersTerrainEngineering

The invention discloses a crawler trencher with adjustable trenching depth. The crawler trencher comprises a rack, and a driver seat, an operation device, a hydraulic control device and a driving device are arranged on the rack. A walking transmission mechanism and walking crawlers are arranged under the rack, and the walking transmission mechanism is driven by the driving device to drive the walking crawlers to run. A chain transmission mechanism and a work spindle are arranged in the front of the rack, and a trenching cutter device is arranged on the work spindle. The work spindle is driven by the chain transmission mechanism to drive a trenching cutter of the trenching cutter device to rotate for trenching work. The chain transmission mechanism is connected with the driving device, and the work spindle is connected with the hydraulic control device through a hydraulic telescopic rod. The work spindle drives the trenching cutter device to fall and rise under the action of the hydraulic telescopic rod, and therefore the automatic adjustment of trenching depth is realized. The hydraulic control device and the driving device are connected with the operation device. The crawler trencher realizes simple and efficient linear trenching and the automatic adjustment of trenching depth, and is suitable for trenching work of various terrains, such as a terrain with a steep slope, an uneven terrain, etc.

Owner:佰源(山东)机械制造有限公司 +1

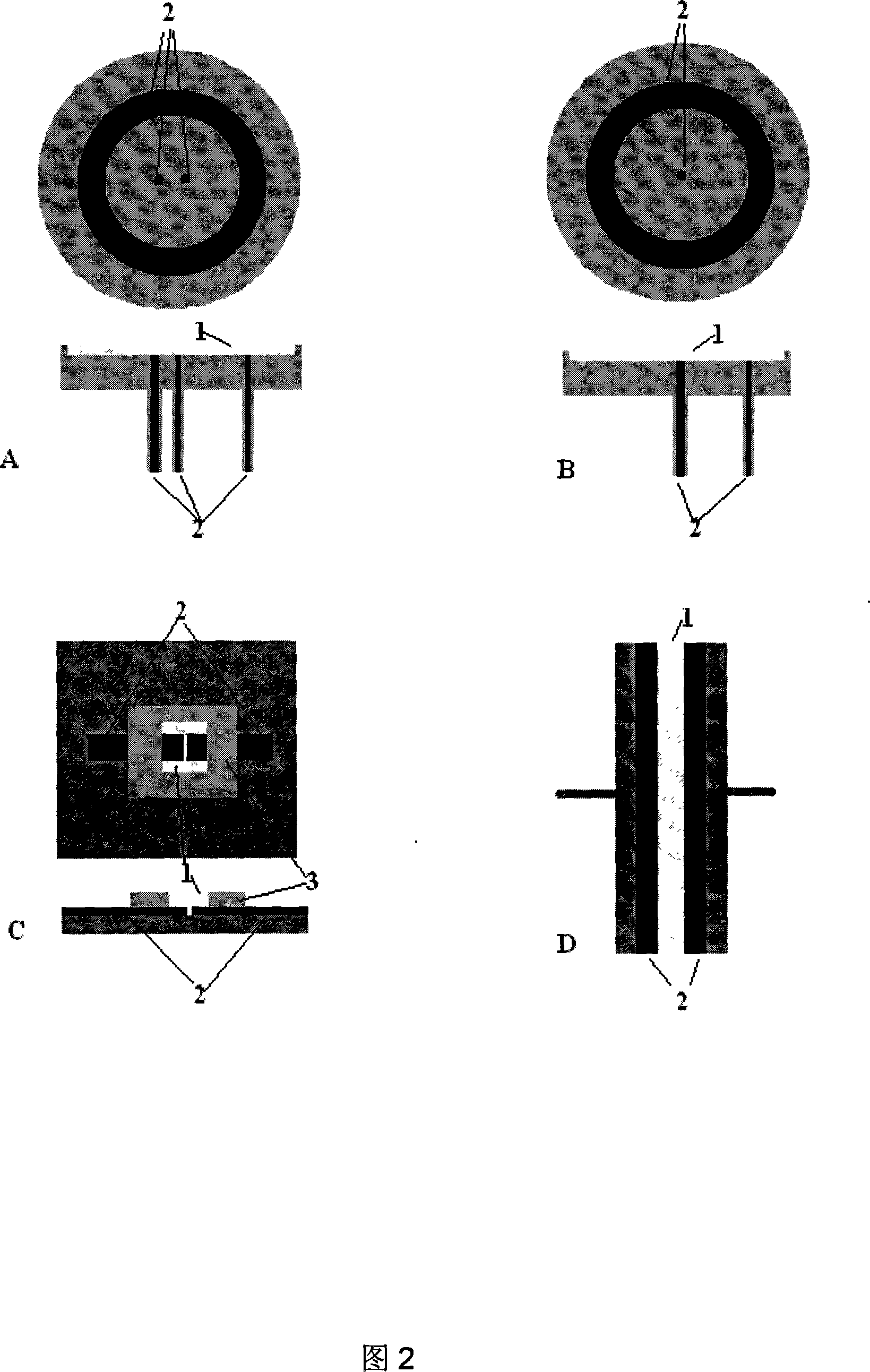

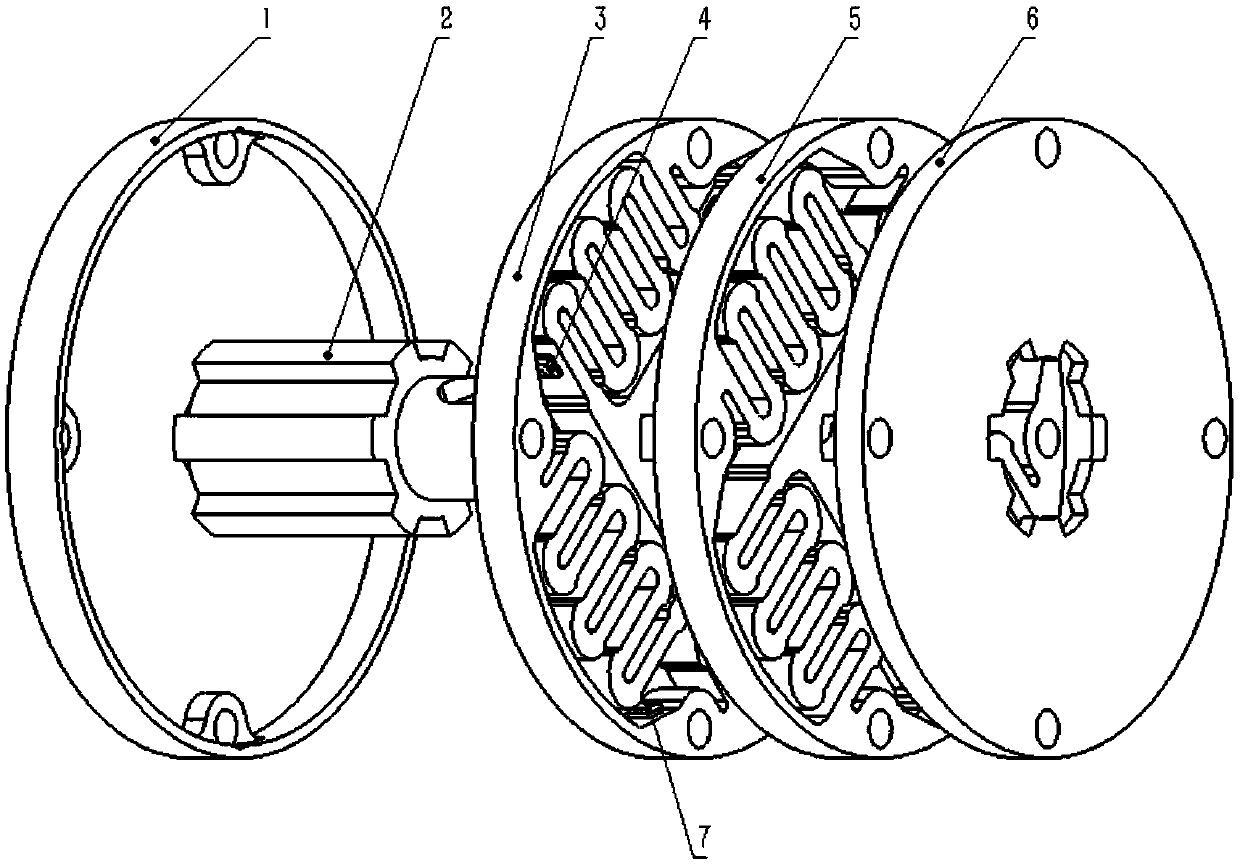

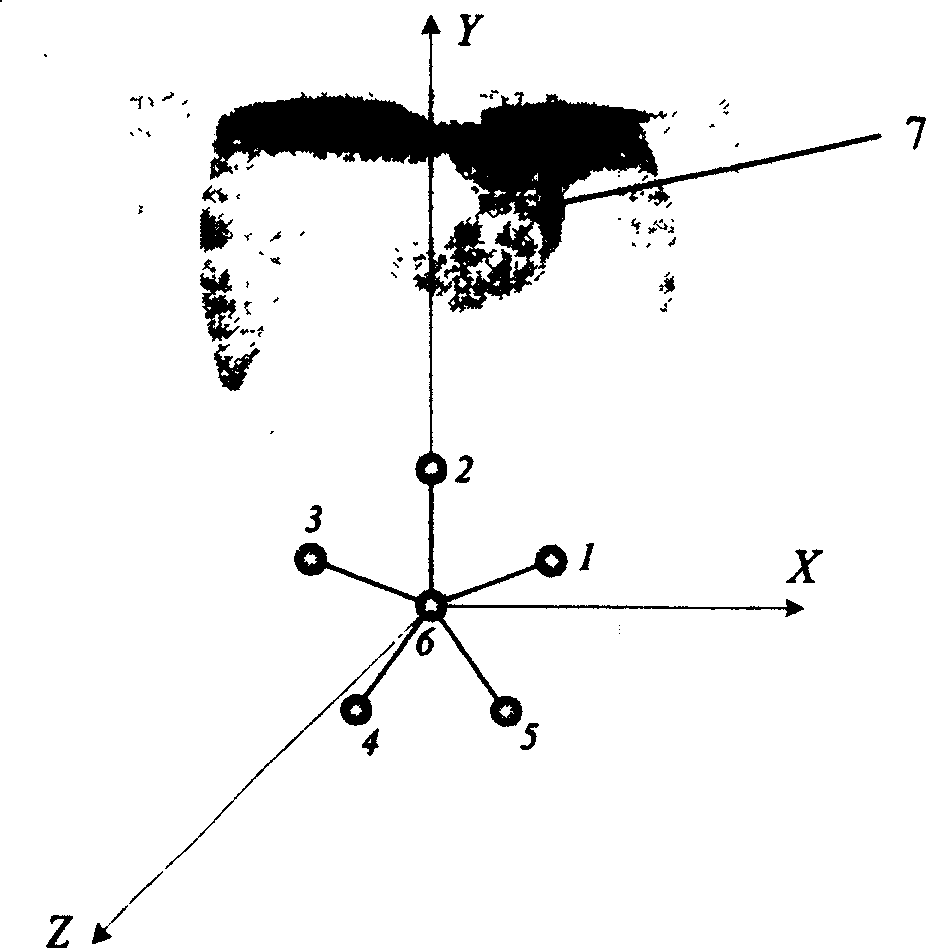

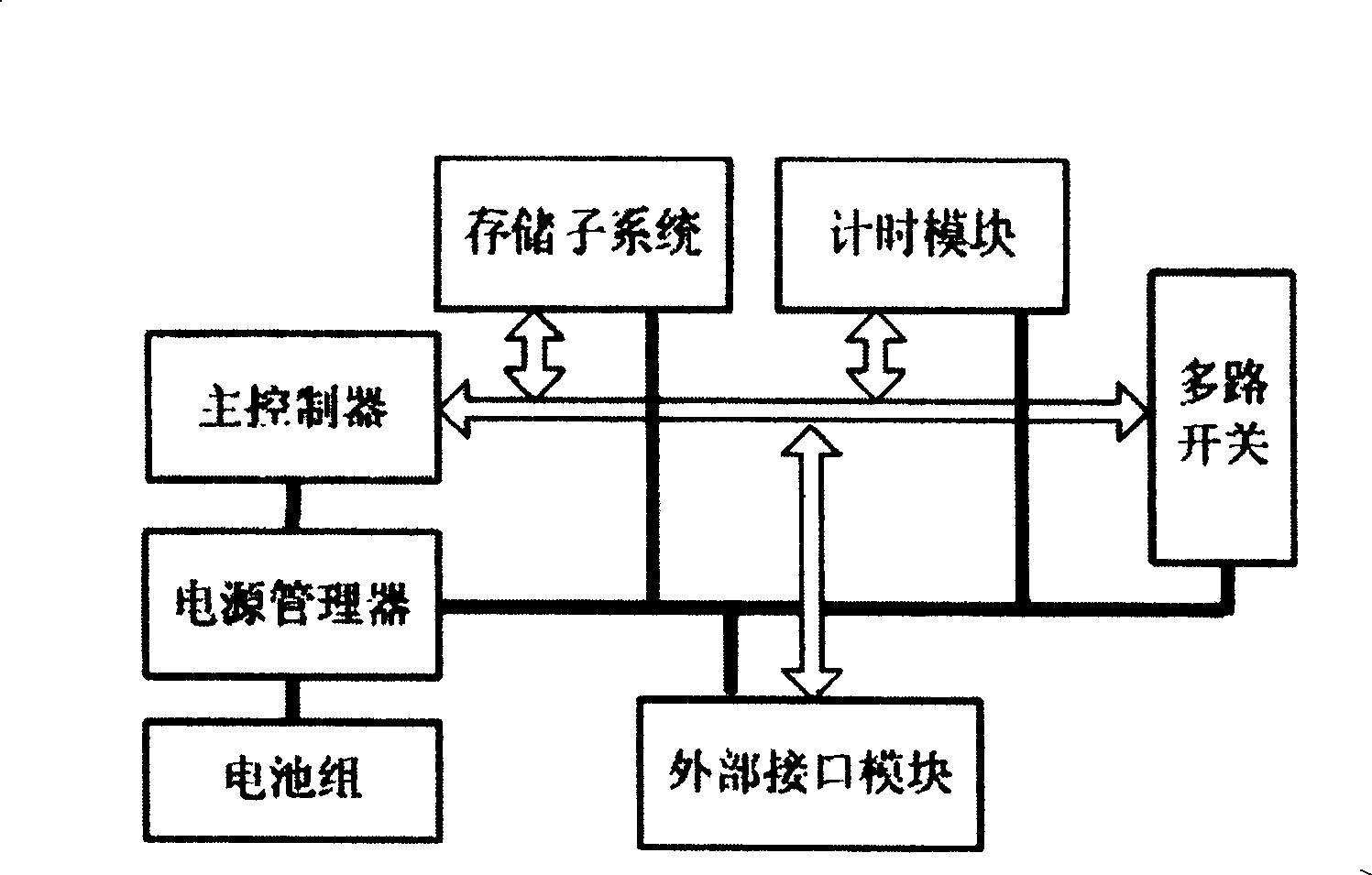

Swallowing type electronic remote detection continuous tracking and positioning system in capsule based on magnetic marker

InactiveCN100394888CNo damageReduce volumeDiagnostic recording/measuringSensorsMagnetic markerMultiway switching

The invention discloses a continual tracing location system based on ingestion type electronic remote sensing capsule of magnet marker, which comprises the following parts: capsule within magnetic marker, six magnet sensors and external location control device, wherein the external location control device is composed of multi-switch, main controller, power manager, battery group, storage subsystem and external interface mode; six magnet sensors are fixed on the body surface determination position, which connects the power manager and multi-switch; the location system adapts static magnetic field as criterion, which calculates three-dimensional trace through the corresponding function relationship of body magnet field distribution and maker position, which improves the measuring precision.

Owner:SAYES MEDICAL TECH

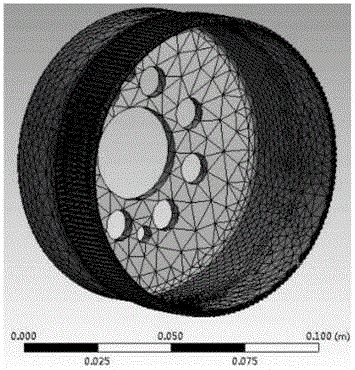

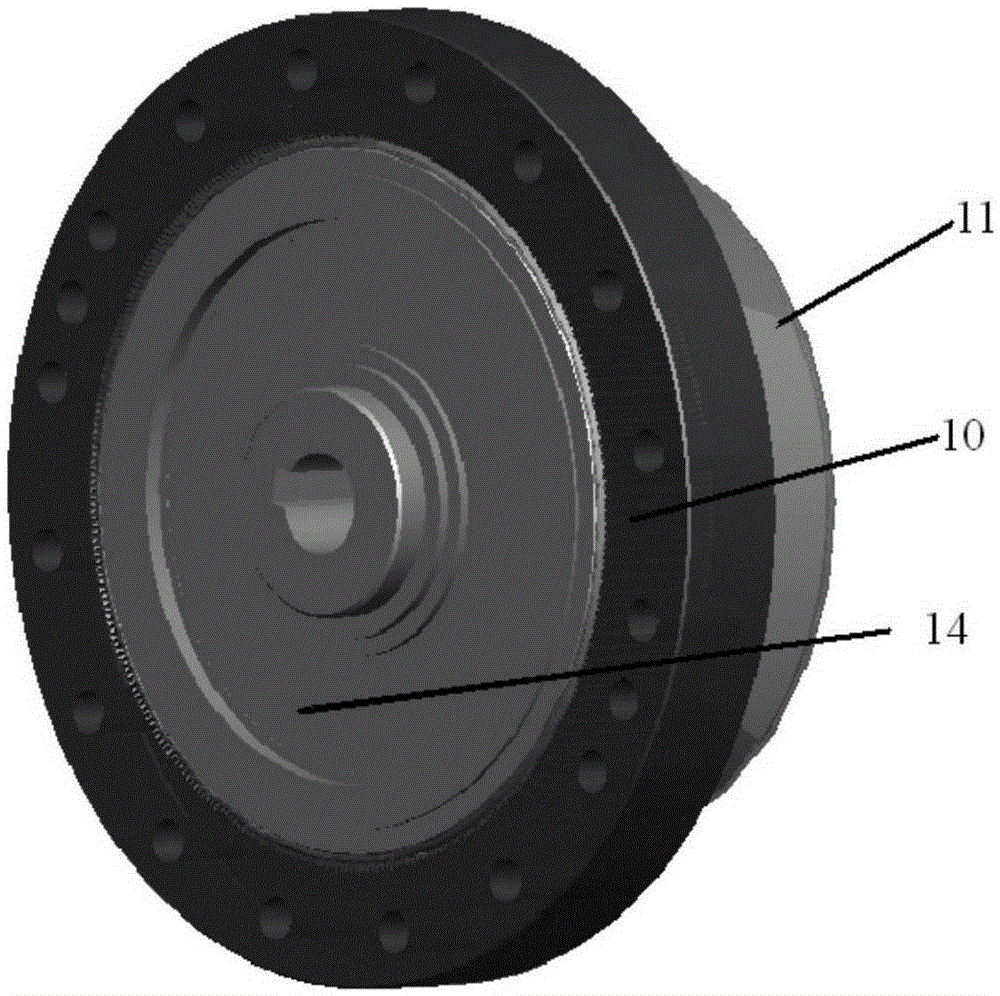

Embedded torque sensor and sensing device for joint module

ActiveCN106514720AHigh measurement accuracySimple way of workingWork measurementTorque measurementElastomerSignal processing circuits

The invention provides an embedded torque sensor for a joint module. The embedded torque sensor for the joint module comprises a sensor support flange, elastic bodies, strain gauges and a signal processing circuit, wherein one end of each elastic body adheres to the outer surface of the circumference of a flexible wheel while the other end of the elastic body adheres to a support; shear strain of a load moment born by a joint to the flexible wheel and extrusion deformation of a wave generator to the flexible wheel are transformed into elastic strain by self amplification, and then the elastic strain is transmitted to the strain gauges; the flexible wheel is extruded by the wave generator and then deforms into an ellipse; the strain gauges adhere to the elastic bodies to form a bridge circuit which is connected with the signal processing circuit; mechanical signals of the elastic strain are converted into voltage signals which are transmitted to the signal processing circuit; the signal processing circuit receives indicator signals when a photoelectric encoder in the joint module measures that a minor axis of the ellipse of the flexible wheel passes through the support; and a load voltage value which corresponds to the received voltage signals when the indicator signals are received is transformed into a load moment value. The invention further provides an embedded torque sensing device. The measurement precision of the load moment can be improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Method for increasing charging capacity of single crystal furnace

InactiveCN101768774AImprove production efficiency and outputDoes not affect product qualityBy pulling from meltEngineeringCrucible

The invention relates to a method for increasing the charging capacity of a single crystal furnace. The method includes the following steps: at the initial stage of adding silicon materials to the single crystal furnace, a furnace body upper cover of the single crystal furnace is opened, a clamping device is hooked by a lifting hook and is pulled upwards, a hook is pulled upwards by the clamping device, a flow guide cylinder is driven by the hook to ascend upwards, and the silicon materials are added again to a crucible; after the melting process of the silicon materials is finished, and the processing stage of downward moving of the flow guide cylinder is added at the clearance stage before the working procedure of crystal seeding; at the processing stage of the downward moving of the flow guide cylinder, the lifting hook moves downwards, the flow guide cylinder does not sink any longer after falling into the preset working position, but the clamping device continues to sink so as to cause the hook to separate from a pothook; after the clamping device separates from the hook, the lifting hook continues to pull the clamping device and move the clamping device to the outside of the single crystal furnace. The most obvious characteristic of the method in the invention is as follows: by adopting the simplest mode that the hook and the pothook work in a matching manner, the method can quickly finish the lifting of the flow guide cylinder, thereby greatly increasing the production efficiency.

Owner:JINKO SOLAR CO LTD

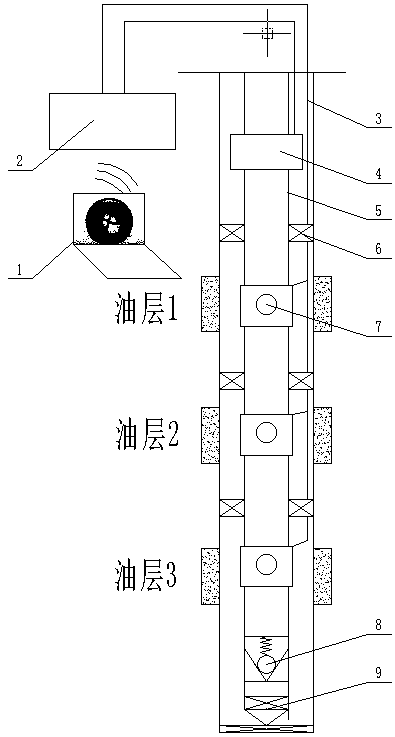

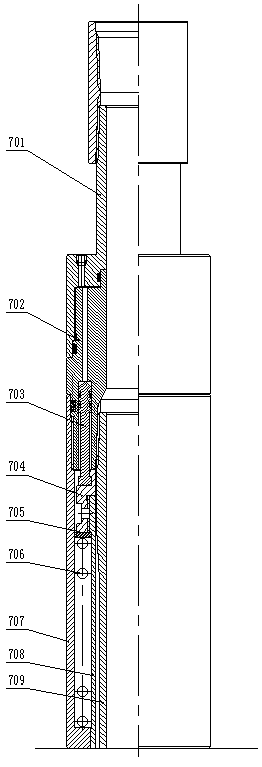

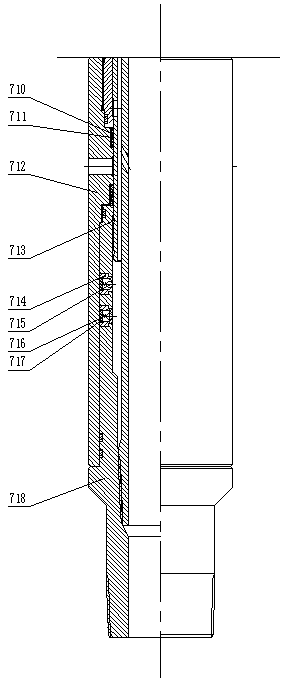

Time-sharing water injection tubular column and time-sharing water injection method

ActiveCN111173483ASimple way of workingReliable dataFluid removalControl systemEnvironmental engineering

The invention provides a time-sharing water injection tubular column and a time-sharing water injection method. The time-sharing water injection tubular column comprises an indoor control system, a wellhead control cabinet, a hydraulic control pipeline, an oil pipe, hydraulic control layered packers and hydraulic control water distribution devices, wherein the hydraulic control layered packers andthe hydraulic control water distribution devices are multiple; each hydraulic control layered packer sets the corresponding hydraulic control water distribution device in different oil layers, and the hydraulic control water distribution devices pressurize the ground in a stepped mode to achieve opening and closing of water distributors of the different oil layers; the wellhead control cabinet monitors and records the injection amount of the oil layers, remotely transmits the injection amount to the indoor control system and dynamically monitors the pressure of the hydraulic control pipelineat the same time so as to ensure that the pressure is within a reasonable range; and the indoor control system controls the wellhead control cabinet in a wired or wireless mode. According to the time-sharing water injection tubular column and the time-sharing water injection method, the corresponding water distribution device is started according to the ground pressing condition, a ground flow device meters the flow of an injection layer, and layered intermittent injection of a water injection well is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

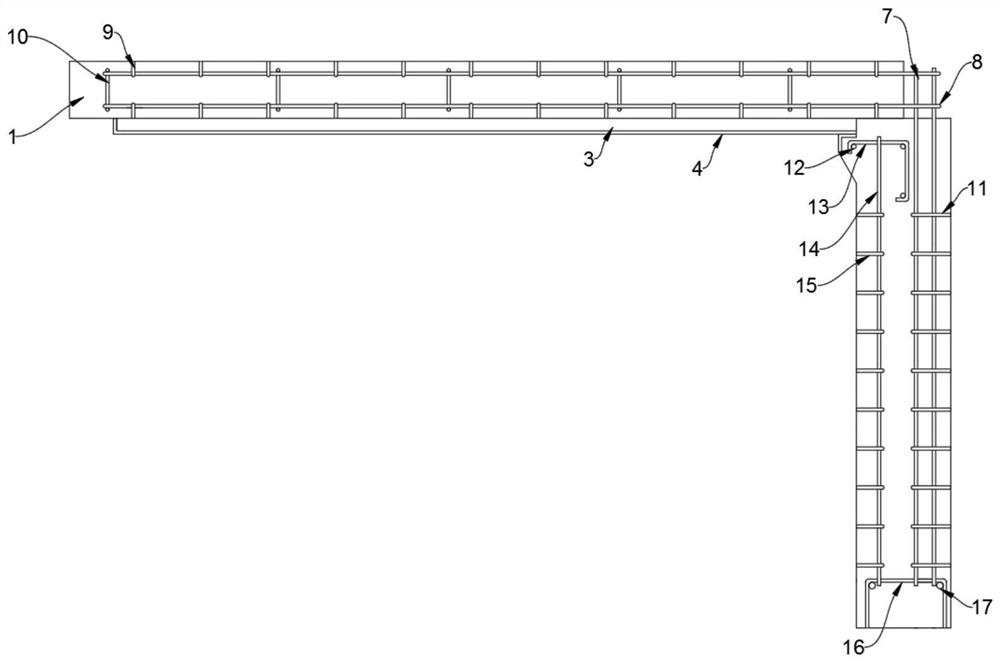

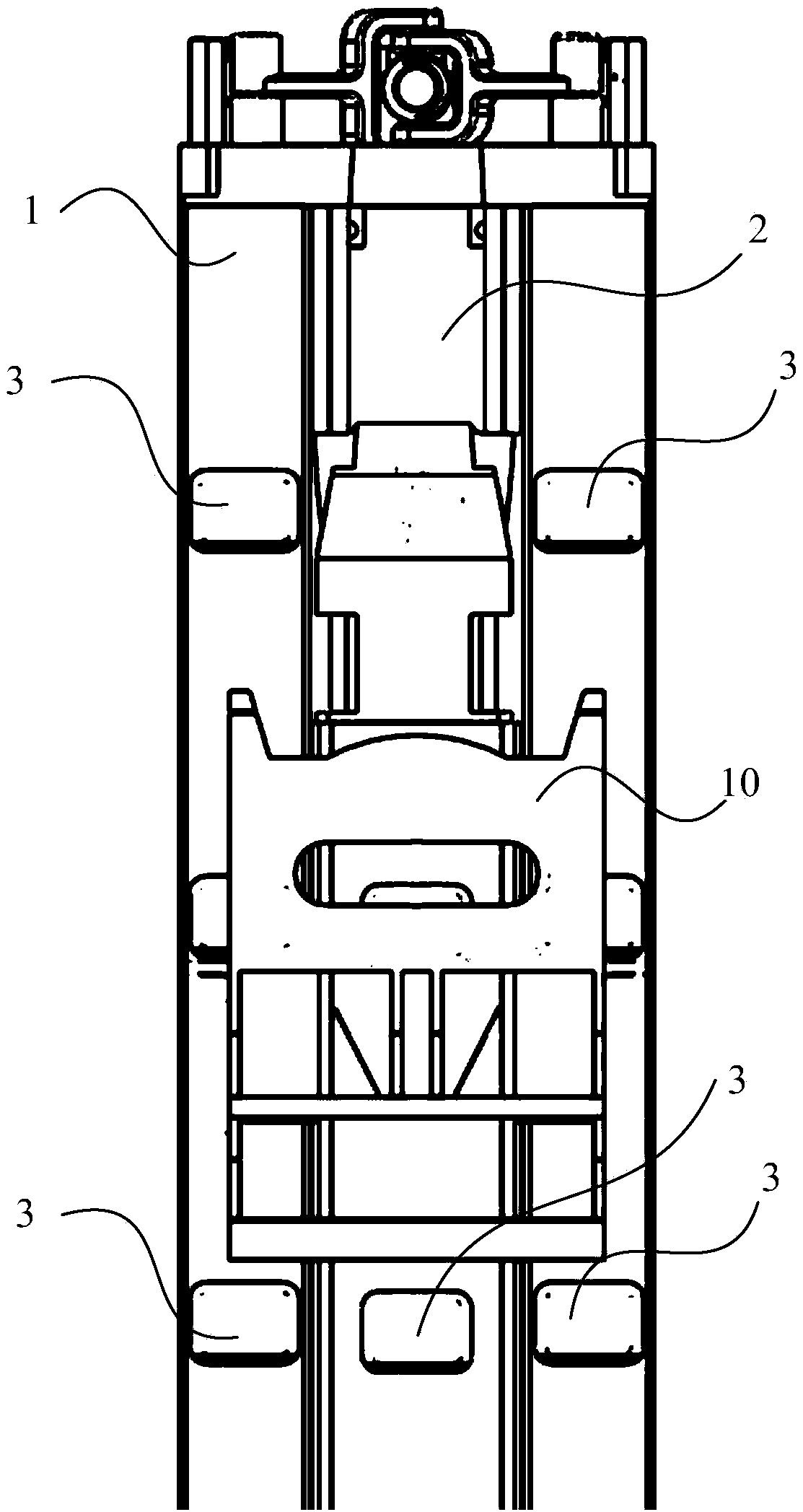

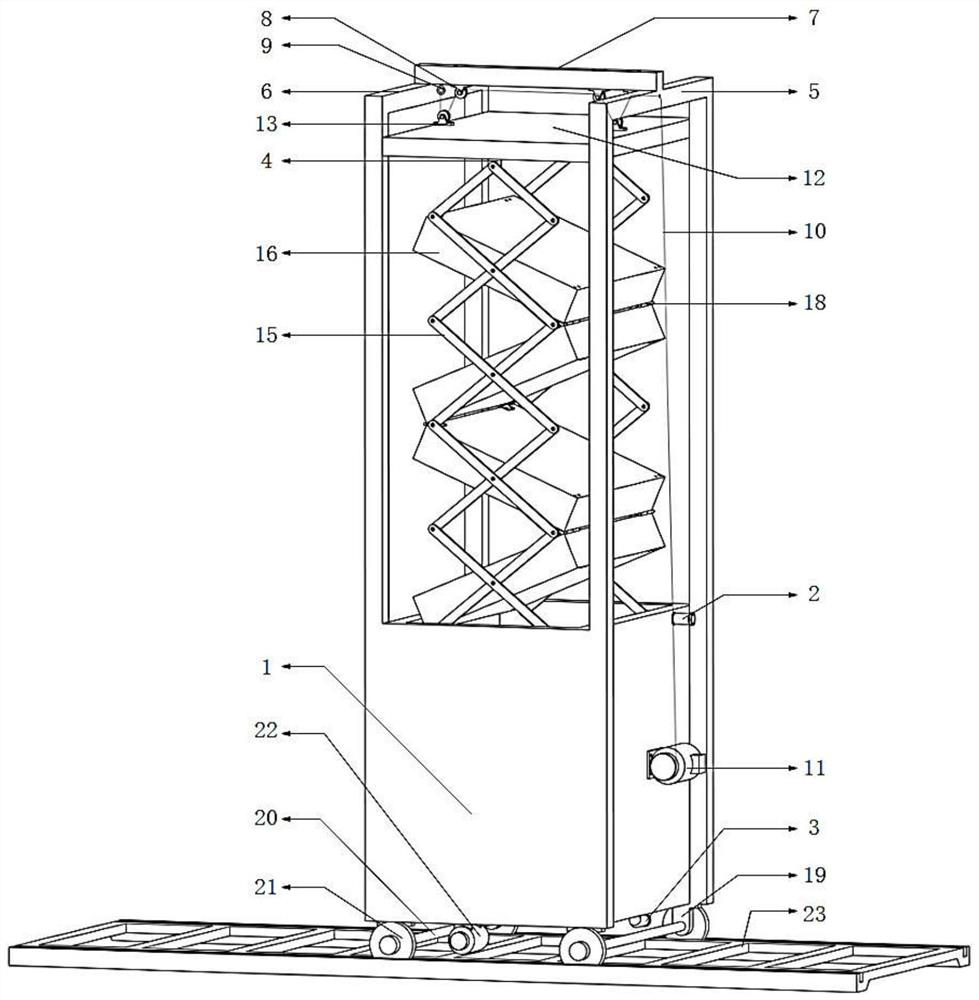

A slider-type telescopic claw floor climbing machine and a building climbing method thereof

The invention discloses a slider-type telescopic claw floor climbing machine and a building climbing method thereof. The slider-type telescopic claw climbing machine comprises an inner guide rail, anouter guide rail and a slider-type telescopic jaw mechanism, wherein the slider-type telescopic jaw mechanism comprises a slider-type telescopic jaw and a resetting part for keeping one end of the slider-type telescopic jaw to protrude out of the outer guide rail or the inner guide rail. The slider-type telescopic pawl mechanism is installed in a building climbing robot, wherein, that reset part of the slider-type telescopic pawl mechanism can keep the slider-type telescopic pawl in a state that the slider-type telescopic pawl protrudes out of an outer guide rail or an inner guide rail, thereby facilitating the internal and external rails of the building climbing machine to alternately climb on the building by means of an attachment wall seat installed on the building. The slider-type telescopic claw mechanism is firmly contacted with the wall mount on the building in the climbing process of the building climbing machine, does not need precise alignment like the existing mechanical claw, has simple and effective working mode, high working stability, simple and easy structure, convenient preparation and low preparation cost.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

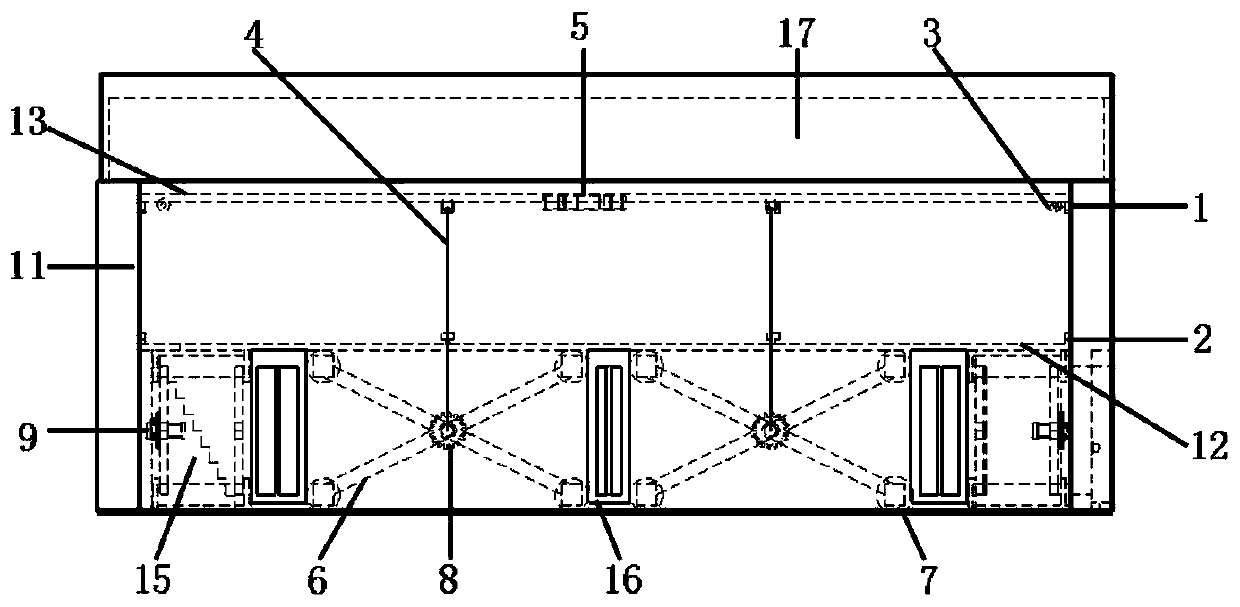

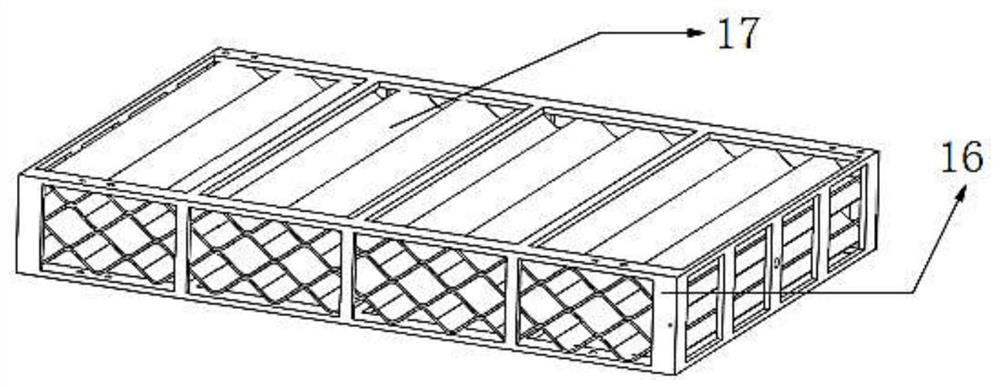

Mobile greenhouse CO2 gas fertilizer additional application device and CO2 gas fertilizer additional application method

ActiveCN112005756AEfficient captureRealize recyclingAgriculture gas emission reductionGreenhouse cultivationGreenhouseAgricultural engineering

The invention discloses a mobile greenhouse CO2 gas fertilizer additional application device and a CO2 gas fertilizer additional application method. The mobile greenhouse CO2 gas fertilizer additionalapplication device comprises a box body, a water inlet pipe, a water outlet pipe, a first lifting lug, a first support frame, a second support frame, a cross beam, a first pulley block, a lifting ring, a steel wire rope, a first motor, a box cover, a second pulley block, a second lifting lug, a hinge, an adsorbing material carrying frame, a wet-process regenerated CO2 adsorbing material, a hinge,a bearing seat, a wheel shaft, rollers, a second motor and concave guide rails. According to the mobile greenhouse CO2 gas fertilizer additional application device, the rollers and the guide rails atthe bottom do reciprocating linear motion so as to enter and exit the greenhouse, CO2 outside the greenhouse can be automatically captured and released into the greenhouse, the concentration of CO2 in the greenhouse is increased so as to promote photosynthesis of crops, the used wet-process regenerated CO2 adsorbing material is easy to recycle and regenerate, and efficient and continuous gas fertilizer additional application can be achieved.

Owner:NORTHWEST UNIV

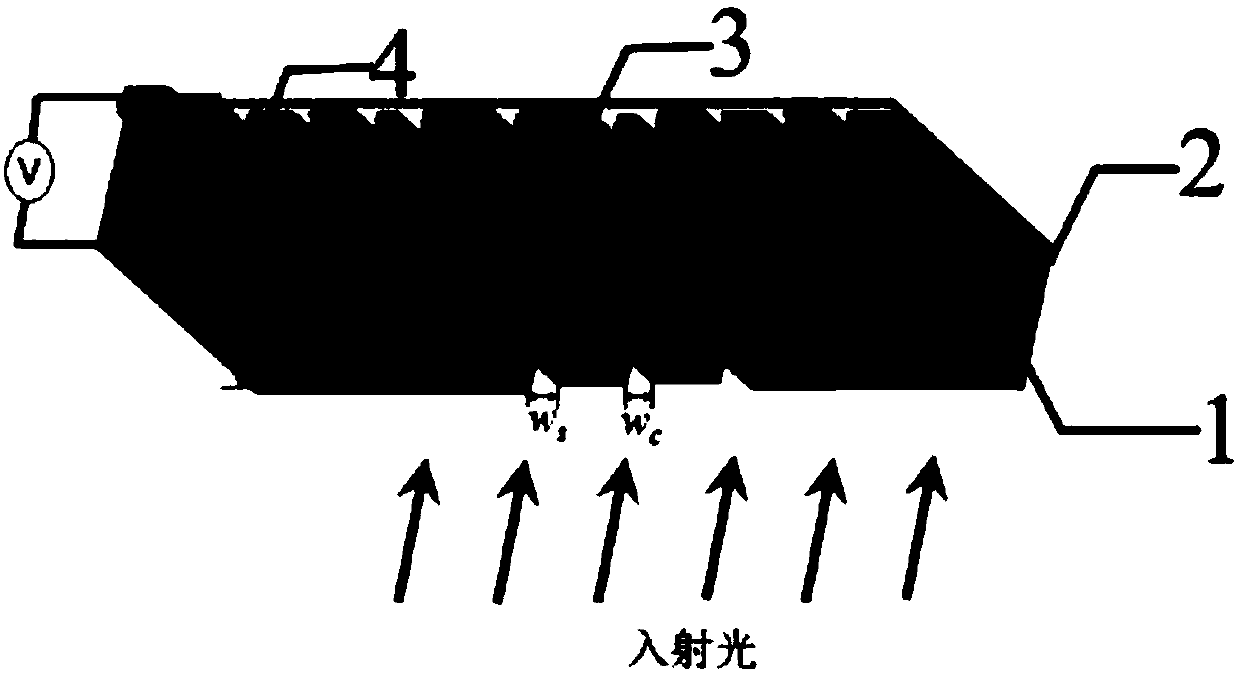

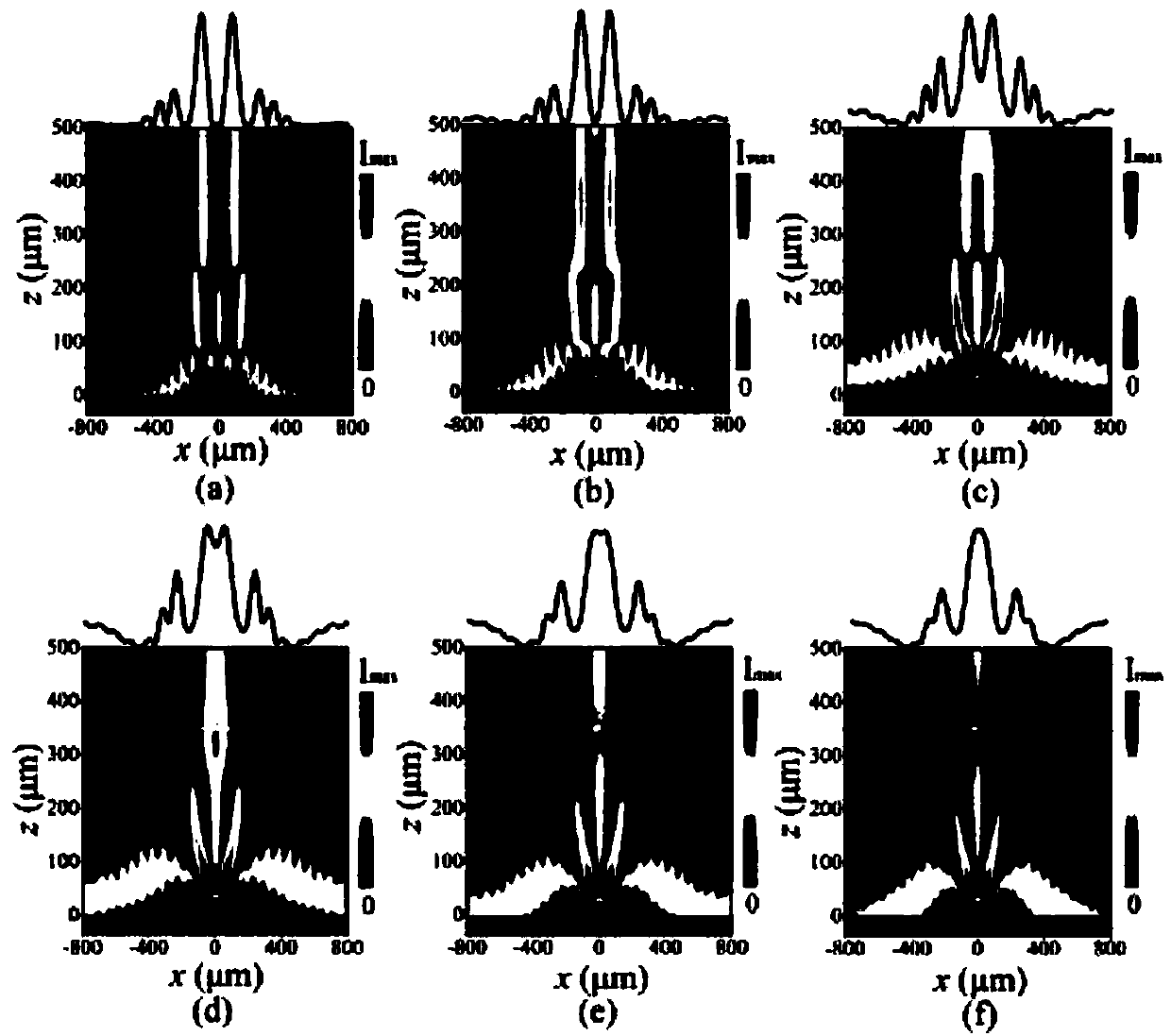

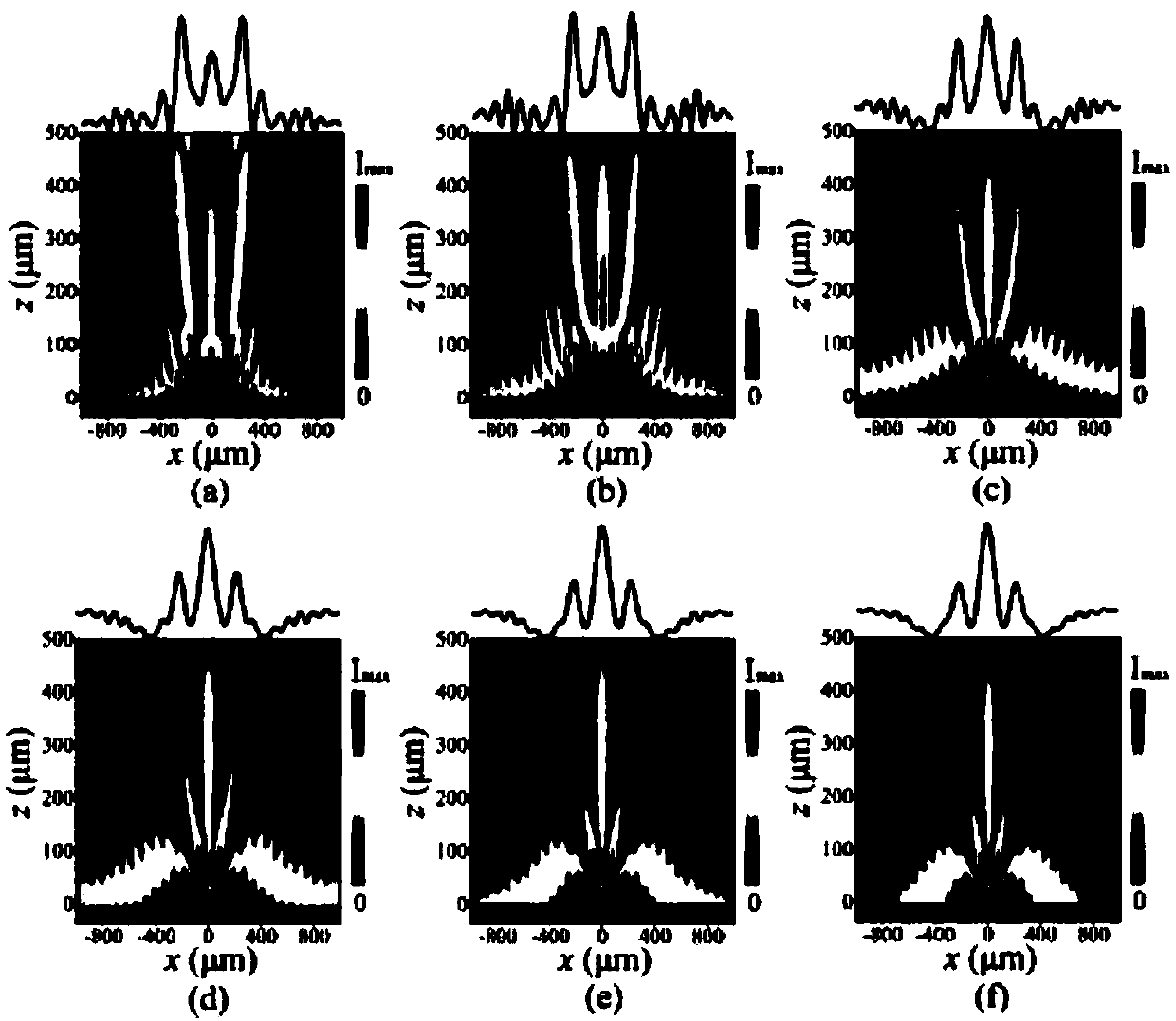

Tunable terahertz beam splitter

The invention discloses a tunable terahertz beam splitter comprising a copper-substrate transmission type grating 1, an aluminum-oxide insulating layer 2, a single-layer graphene sheet 3 and a metal electrode 4. The aluminum-oxide insulating layer 2 is plated on the emergent surface of the copper-substrate transmission type grating 1; the single-layer graphene sheet 3 covers the aluminum-oxide insulating layer 2; and the metal electrode 4 is plated on the single-layer graphene sheet 3. Two side seams and one central beam are formed in the copper-substrate transmission type grating 1; the central beam is arranged at the center of the copper-substrate transmission type grating 1; and the two side beams are arranged at the two sides of the central beam respectively and the distances between the two side beams and the central beam are 1. Grooves that are distributed uniformly at equal intervals with a cycle of lambda g are formed in the emergent surface of the copper-substrate transmissiontype grating 1. According to the tunable terahertz beam splitter disclosed by the invention, a novel technical means is provided for terahertz beam regulation in out-of-plane free space; and thus thebeam splitter has the great potential application value in fields of terahertz communication, imaging and sensing.

Owner:NANJING UNIV OF SCI & TECH

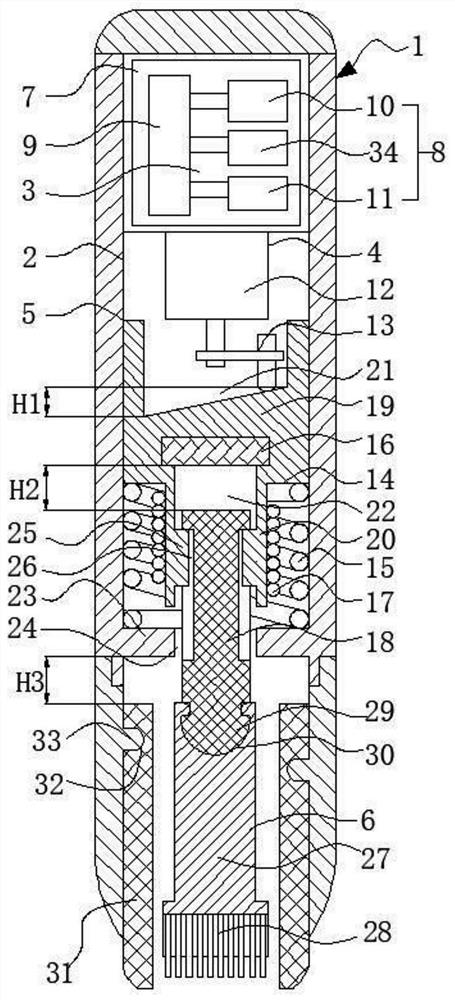

Intelligent microneedle puncture instrument, network system and control method

ActiveCN113975622AFlexible working styleReduce volumeMicroneedlesMedical devicesDrug deliveryPhysical therapy

The invention discloses an intelligent microneedle puncture instrument, a network system and a control method. The intelligent microneedle puncture instrument comprises a hollow cylindrical shell, a control mechanism, a driving mechanism, a flexible needle outlet adjusting mechanism and a microneedle suite, wherein the control mechanism, the driving mechanism and the flexible needle outlet adjusting mechanism are sequentially arranged in a hollow cavity of the shell from top to bottom, and the microneedle suite is detachably connected with the flexible needle outlet adjusting mechanism; and the microneedle array obtains needle withdrawing and puncturing depth ranges of 0-(H1 + H2) in the axial direction, makes contact with the skin of each area and punctures the skin, and transdermal drug delivery or physical therapy is carried out. The network system comprises an intelligent microneedle puncture instrument and an intelligent terminal, and the intelligent terminal is provided with a beauty / physiotherapy control applet or APP. The control method comprises the steps that the intelligent microneedle puncture instrument, an intelligent mobile phone and a remote server are connected, the APP calls the intelligent terminal, data of a user is obtained, the intelligent puncture instrument is controlled to work, and transdermal drug delivery or physiotherapy of the skin is carried out. The intelligent microneedle puncture instrument is easy to use, large in puncture depth adjusting range, good in effect and high in safety.

Owner:广州纳丽生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com