Side-forming small pressure core, stamping mould with same and stamping method

A technique for stamping dies and pressing cores, which is applied in the field of automobile panel moulds, can solve the problems involving many contents, unsightly surface drop, and affecting the smooth pick-up of parts, etc., and achieves simplified self-made wedge mechanism, reasonable and beautiful structure, and energy saving The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

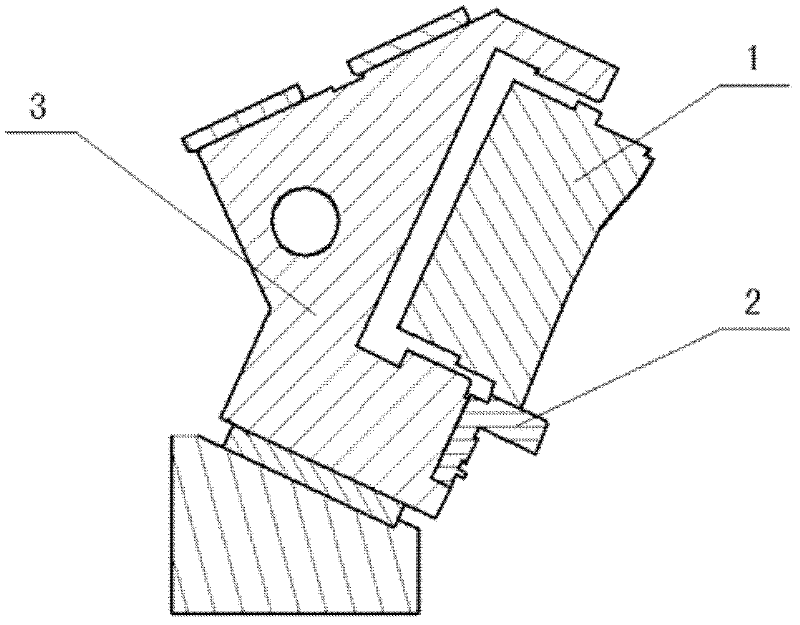

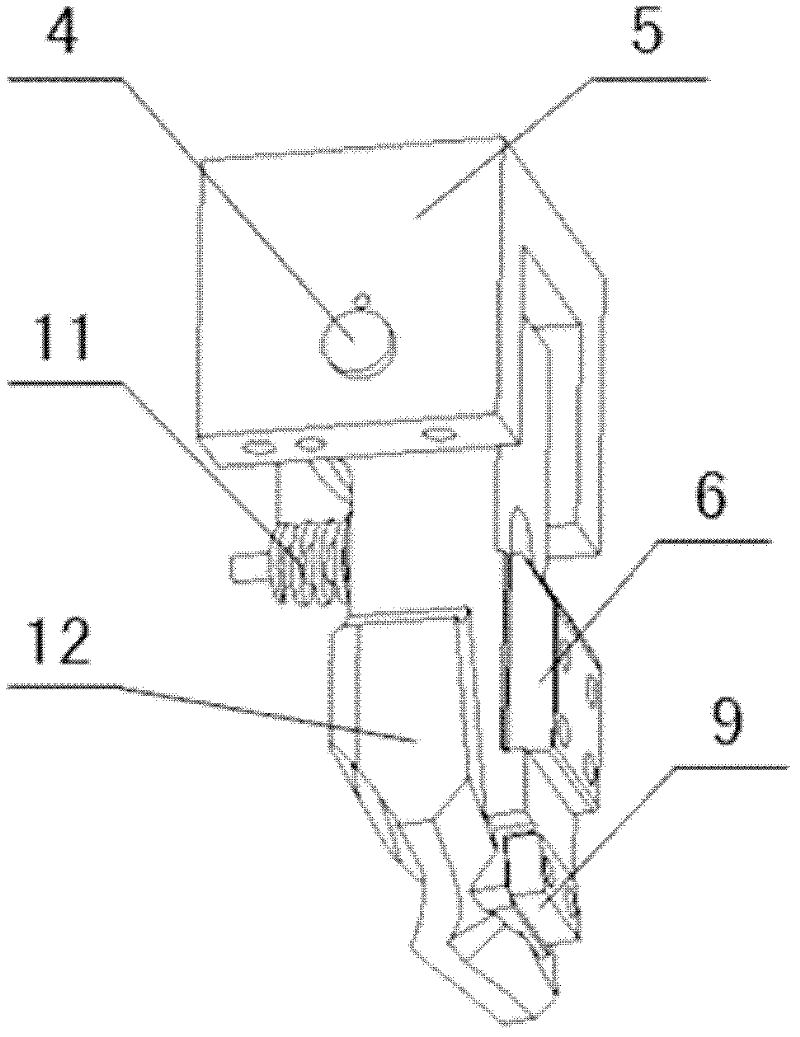

[0029] by figure 2 It can be seen from the structure shown that this kind of side forming small pressure core includes a rotating shaft 4, a mounting seat 5, an inclined guide plate 6, a cushion block 9, and a rotating block 12. The section of the mounting block 5 is U-shaped, and one end of the rotating block 12 passes The rotating shaft 4 is fixed in the U-shaped opening of the mounting seat 5, and the rotating block 12 rotates around the rotating shaft 4; the inclined guide plate 6 is arranged on the side of the rotating block 12 parallel to the rotating shaft 4, and is used as a cushion block for installation and debugging 9 is installed on the rotating block 12 and located directly below the inclined guide plate 6; the main pressure core 13 is also provided with a return spring 11 that provides the rotating block 12 with a return force.

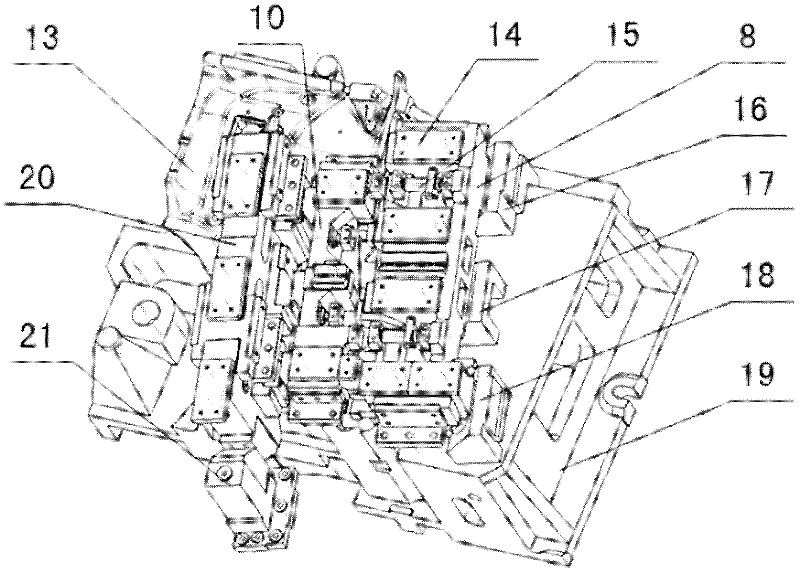

[0030] by Figure 3-Figure 7 It can be seen from the combination of the structure shown that this kind of stamping die with side forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com