Embedded torque sensor and sensing device for joint module

A technology of torque sensor and joint module, applied in measurement devices, instruments, torque measurement and other directions, can solve the problems of inability to meet dynamic measurement requirements, inability to guarantee measurement accuracy, small size of the end face of the flexible wheel, etc., and achieve fast measurement speed and volume. Small, the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] The present invention has carried out measurement test, and test proves, this new built-in torque sensor can reach described actual effect.

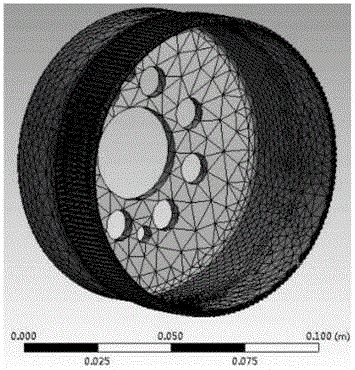

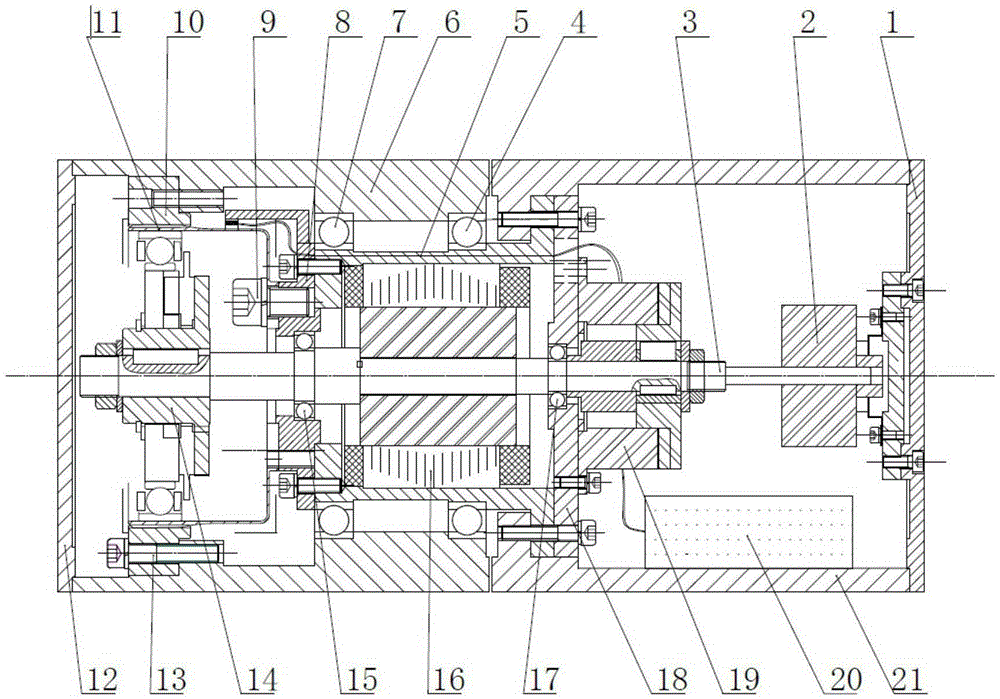

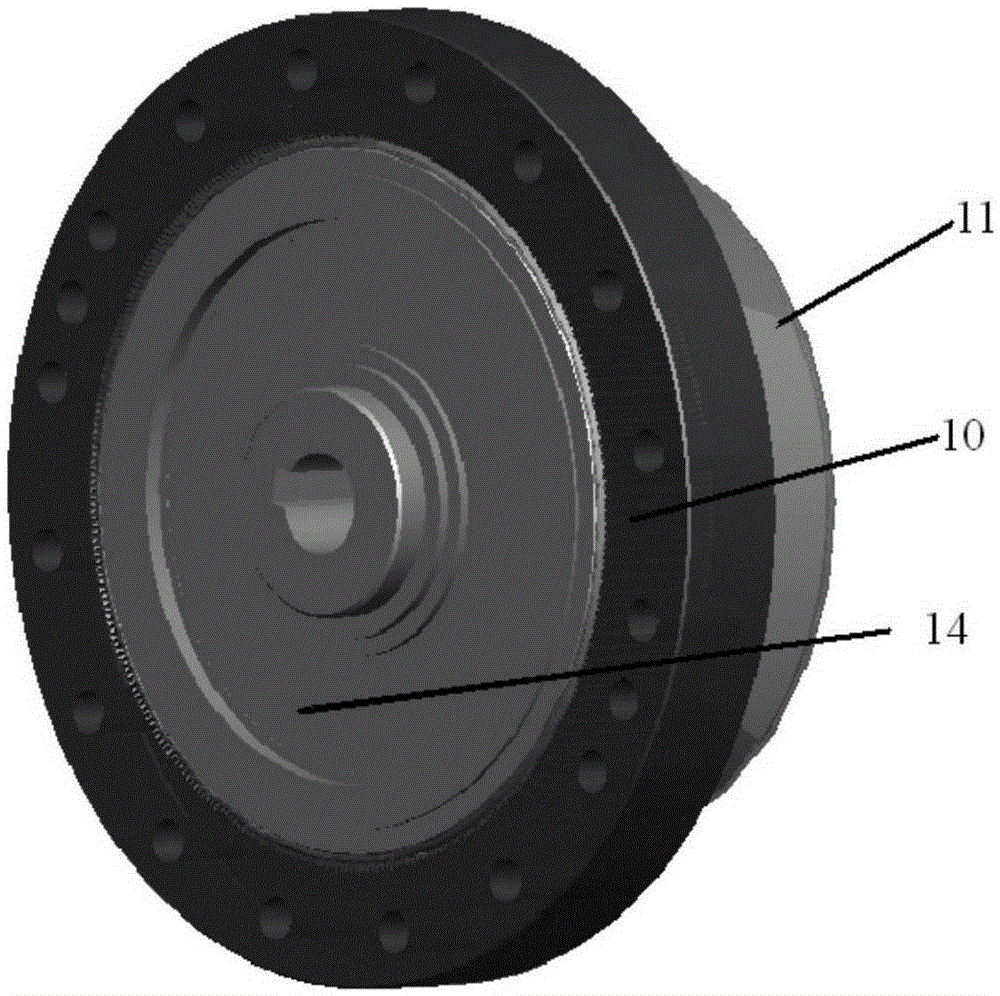

[0025] The measurement target of the embedded torque sensor of the present invention is a joint module, figure 1 It is a structural schematic diagram of the torque sensor embedded in the joint module of the present invention. The joint module is mainly composed of a static block and a moving block. The DC brushless motor 16 transmits the rotation to the wave generator 14 through the transmission bearing left 15 and the transmission bearing right 17. The wave generator 14 squeezes the flexible spline 11 to deform, and then the The output of the steel wheel 10 of the harmonic reducer; The photoelectric encoder 2, brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com